Impact-Resistant and Tough 3D Helicoidally Architected Polymer Composites Enabling Next-Generation Lightweight Silicon Photovoltaics Module Design and Technology

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Choice of Fiber Material

2.1.2. Choice of Matrix Material

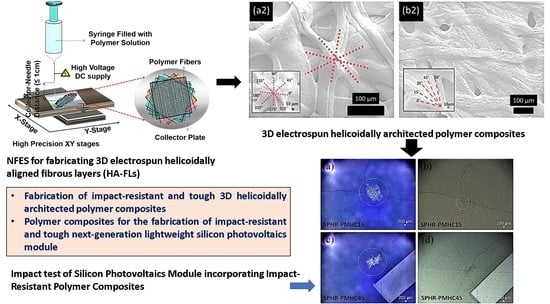

2.2. Electrospinning-Based Additive Manufacturing

2.3. Fabrication of Helicoidally-Aligned Synthetic Structural Composites (HA-SSCs)

2.4. Impact Testing

3. Results and Discussion

3.1. Physical Characteristics of the HA-SSCs

3.2. Impact Test of Photovoltaic (PV) Cells

3.3. Fracture of the Silicon Photovoltaic (PV) Cells

3.4. Enabling Next-Gen Lightweight Photovoltaic (PV) Module Technology

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Berger, K.; Cueli, A.B.; Boddaert, S.; Del Buono, M.; Delisle, V.; Fedorova, A.; Frontini, F.; Hendrick, P.; Inoue, S.; Ishii, H.; et al. International definitions of BIPV. In IEA 597 Photovoltaic Power Systems Programme; Report IEA-PVPS T15-04; IEA: Paris, France, 2018; Available online: https://iea-pvps.org/key-topics/international598definitions-of-bipv/ (accessed on 11 May 2021).

- Zhang, F.; Deng, H.; Margolis, R.; Su, J. Analysis of distributedgeneration photovoltaic deployment, installation time and cost, market barriers, and policies in China. Energy Policy 2015, 81, 43–55. [Google Scholar] [CrossRef] [Green Version]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Li, H.Y.; Perret-Aebi, L.E.; Ballif, C. Thermomechanical stability of lightweight glass-free photovoltaic modules based on a composite substrate. Sol. Energy Mater Sol. Cells 2018, 187, 82–90. [Google Scholar] [CrossRef]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Light and durable: Composite structures for building-integrated photovoltaic modules. Prog. Photovolt. Res. Appl. 2018, 26, 718–729. [Google Scholar] [CrossRef]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Ballif, C. Robust Glass-Free Lightweight Photovoltaic Modules with Improved Resistance to Mechanical Loads and Impact. IEEE J. Photovolt. 2019, 9, 245–251. [Google Scholar] [CrossRef]

- Ballif, C.; Perret-Aebi, L.E.; Lufkin, S.; Rey, E. Integrated thinking for photovoltaics in buildings. Nat. Energy 2018, 3, 438–442. [Google Scholar] [CrossRef]

- Kajisa, T.; Miyauchi, H.; Mizuhara, K.; Hayashi, K.; Tokimitsu, T.; Inoue, M.; Hara, K.; Masuda, A. Novel lighter weight crystalline silicon photovoltaic module using acrylic-film as a cover sheet. Jpn. J. Appl. Phys. 2014, 53, 092302. [Google Scholar] [CrossRef]

- Handara, V.; Illya, G.; Tippabhotla, S.K.; Shivakumar, R.; Budiman, A.S. Novel and Innovative Solar Photovoltaics Systems Design for Tropical and Near-Ocean Regions—An Overview and Research Directions. Proc. Eng. 2016, 139, 22. [Google Scholar] [CrossRef] [Green Version]

- Illya, G.; Handara, V.; Yujing, L.; Shivakumar, R.; Budiman, A.S. Backsheet Degradation under Salt Damp Heat Environments—Enabling Novel and Innovative Solar Photovoltaics Systems Design for Tropical Regions and Sea-Close Areas. Proc. Eng. 2016, 139, 7. [Google Scholar] [CrossRef] [Green Version]

- Illya, G.; Handara, V.; Siahandan, M.; Nathania, A.; Budiman, A.S. Mechanical Studies of Solar Photovoltaics (PV) Backsheets under Salt Damp Heat Environments. Proc. Eng. 2017, 215, 238–245. [Google Scholar] [CrossRef]

- Handara, V.; Radchenko, I.; Tippabhotla, S.K.; Narayanan, K.; Llya, G.; Kunz, M.; Tamura, N.; Budiman, A.S. Probing Stress and Fracture Mechanism in Encapsulated Thin Silicon Solar Cells by Synchrotron X-ray Microdiffraction. Sol. Energy Mater. Solar Cells 2017, 162, 30–40. [Google Scholar] [CrossRef] [Green Version]

- Dhere, N.G. Flexible packaging for PV modules. In Reliability of Photovoltaic Cells, Modules, Components, and Systems; International Society for Optics and Photonics: Bellingham, WA, USA, 2008; Volume 7048, p. 70480. [Google Scholar]

- Wright, A.; Lee, E.J. Impact Resistant Lightweight Photovoltaic Modules. U.S. Patent WO/2016/077402, 19 May 2016. [Google Scholar]

- Martins, A.C.; Chapuis, V.; Virtuani, A.; Perret-Aebi, L.E.; Ballif, C. Hail resistance of BIPV composite-based lightweight modules. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference Exhibition, Amsterdam, The Netherlands, 25–29 September 2017; pp. 2604–2608. [Google Scholar]

- Gaume, J.; Quesnel, F.; Guillerez, S.; LeQuang, N.; Williatte, S.; Goaer, G. Solight: A new lightweight PV module complying IEC standards. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- Boulanger, A.; Gaume, J.; Quesnel, F.; Ruols, P.; Rouby, F. Operasol: A light photovoltaic panel with integrated connectors. In Proceedings of the 33rd European Photovoltaic Solar Energy Conference Exhibition, Amsterdam, The Netherlands, 25–29 September 2017. [Google Scholar]

- Yang, W.; Chen, I.H.; Gludovatz, B.; Zimmermann, E.A.; Ritchie, R.O.; Meyers, M.A. Natural Flexible Dermal Armor. Adv. Mater. 2013, 25, 31–48. [Google Scholar] [CrossRef] [PubMed]

- Naleway, S.E.; Porter, M.M.; McKittrick, J.; Meyer, M.A. Structural Design Elements in Biological Materials: Application to Bioinspiration. Adv. Mater. 2015, 27, 5455–5476. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wegst, U.G.K.; Bai, H.; Saiz, E.; Tomsia, A.P.; Ritchie, R.O. Bioinspired Structural Materials. Nat. Mater. 2015, 14, 23–36. [Google Scholar] [CrossRef] [PubMed]

- Patek, S.N.; Caldwel, R.L. Extreme Impact and Cavitation Forces of a Biological Hammer: Strike Forces of the Peacock Mantis Shrimp Odontodactylus Scyllarus. J. Exp. Biol. 2005, 208, 3655–3664. [Google Scholar] [CrossRef] [Green Version]

- Cronin, T.W.; Marshall, N.J.; Quinn, C.A.; King, C.A. Ultraviolet Photoreception in Mantis Shrimp. Vis. Res. 1994, 34, 1443–1452. [Google Scholar] [CrossRef]

- Amini, S.; Tadayon, M.; Idapalapati, S.; Miserez, A. The Role of Quasi-Plasticity in the Extreme Contact Damage Tolerance of the Stomatopod Dactyl Club. Nat. Mater. 2015, 14, 943–950. [Google Scholar] [CrossRef] [PubMed]

- Fratzl, P.; Weinkamer, R. Nature’s Hierarchical Materials. Prog. Mater. Sci. 2007, 52, 1263–1334. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, K.; Sahay, R.; Baji, A.; Budiman, A.S. Impact-Resistant and Tough Helicoidally Aligned Ribbon Reinforced Composites with Tunable Mechanical Properties via Integrated Additive Manufacturing Methodologies. ACS Appl. Polym. Mater. 2020, 2, 3491–3504. [Google Scholar] [CrossRef]

- Sahay, R.; Agarwal, K.; Subramani, A.; Raghavan, N.; Budiman, A.S.; Baji, A. Helicoidally arranged polyacrylonitrile fiber-reinforced strong and impact-resistant thin polyvinyl alcohol film enabled by electrospinningbased additive manufacturing. Polymers 2020, 12, 2376. [Google Scholar] [CrossRef]

- Agarwal, K.; Zhou, Y.; Ali, H.P.A.; Radchenko, I.; Baji, A.; Budiman, A.S. Additive Manufacturing Enabled by Electrospinning for Tougher Bio-Inspired Materials. Adv. Mater. Sci. Eng. 2018, 2018, 8460751. [Google Scholar] [CrossRef] [Green Version]

- Agarwal, K.; Sahay, R.; Baji, A.; Budiman, A.S. Biomimetic Tough Helicoidally Structured Material Through Novel Electrospinning Based Additive Manufacturing. MRS Adv. 2019, 4, 2345–2354. [Google Scholar] [CrossRef]

- García-Payo, M.C.; Essalhi, M.; Khayet, M. Effects of PVDF-HFP concentration on membrane distillation performance and structural morphology of hollow fiber membranes. J. Membr. Sci. 2010, 347, 209–219. [Google Scholar] [CrossRef]

- Lalia, B.S.; Guillen-Burrieza, E.; Arafat, H.A.; Hashaikeh, R. Fabrication and characterization of polyvinylidenefluoride-co-hexafluoropropylene (PVDF-HFP) electrospun membranes for direct contact membrane distillation. J. Membr. Sci. 2013, 428, 104–115. [Google Scholar] [CrossRef]

- Stephan, A.M.; Nahm, K.S.; Kulandainathan, M.A. Poly (vinylidene fluoride-hexafluoropropylene)(PVdF-HFP) based composite electrolytes for lithium batteries. Eur. Polym. J. 2006, 42, 1728–1734. [Google Scholar] [CrossRef]

- Yang, L.; Zhao, Q.; Hou, Y. Flexible polyvinylidene fluoride based nanocomposites with high and stable piezoelectric performance over a wide temperature range utilizing the strong multi-interface effect. Compos. Sci. Technol. 2019, 174, 33–41. [Google Scholar] [CrossRef]

- Sahay, R.; Teo, C.J.; Chew, Y.T. New correlation formulae for the straight section of the electrospun jet from a polymer drop. J. Fluid Mech. 2013, 735, 150–175. [Google Scholar] [CrossRef]

- Zheng, J.Y.; Zhuang, M.F.; Yu, Z.J. The effect of surfactants on the diameter and morphology of electrospun ultrafine nanofiber. J. Nanomater. 2014, 2014, 8. [Google Scholar] [CrossRef]

- Chen, R.; Liu, J.; Yang, C. Transparent Impact-Resistant Composite Films with Bioinspired Hierarchical Structure. ACS Appl. Mater. Interfaces 2019, 11, 23616–23622. [Google Scholar] [CrossRef] [PubMed]

- Artabiei, S.N.A.; Sultan, M.T.H.; Jawaid, M.; Jayakrishna, K. Impact behaviour of hybrid composites for structural applications: A review. Compos. Part B Eng. 2018, 133, 112–121. [Google Scholar]

- Armstrong, R.W.; Walley, S.M. High strain rate properties of metals and alloys. Int. Mater. Rev. 2008, 53, 105–128. [Google Scholar] [CrossRef]

- Tabiei, A.; Nilakantan, G. Ballistic impact of dry woven fabric composites: A review. Appl. Mech. Rev. 2008, 61, 10801. [Google Scholar] [CrossRef]

- Song, W.J.R.; Tippabhotla, S.K.; Tay, A.A.O.; Budiman, A.S. Numerical Simulation of the Evolution of Stress in Solar Cells during the Entire Manufacturing Cycle of a Conventional Silicon Wafer-based Photovoltaic Laminate. IEEE J. Photovolt. 2018, 8, 210–217. [Google Scholar] [CrossRef]

- Budiman, A.S.; Illya, G.; Handara, V.; Caldwell, W.A.; Bonelli, C.; Kunz, M.; Tamura, N.; Verstraeten, D. Enabling Thin Silicon Technologies for Next Generation c-Si Solar PV Renewable Energy Systems using Synchrotron X-ray Microdiffraction as Stress and Crack Mechanism Probe. Sol. Energy Mater. Sol. Cells 2014, 130, 303–308. [Google Scholar] [CrossRef] [Green Version]

- Tippabhotla, S.K.; Radchenko, I.; Song, W.J.R.; Illya, G.; Handara, V.; Kunz, M.; Tamura, N.; Tay, A.A.O.; Budiman, A.S. From Cells to Laminate: Probing and Modeling Residual Stress Evolution in Thin Silicon Photovoltaic Modules using Synchrotron X-ray Micro-Diffraction Experiments and Finite Element Simulations. Prog. Photovolt. 2017, 25, 791–809. [Google Scholar] [CrossRef] [Green Version]

- Tippabhotla, S.K.; Song, W.J.R.; Tay, A.A.O.; Budiman, A.S. Effect of Encapsulants on the Thermomechanical Residual Stress in the Back-Contact Silicon Solar Cells of Photovoltaic Modules—A Constrained Local Curvature Model. Sol. Energy 2019, 182, 134–147. [Google Scholar] [CrossRef]

- Tian, T.; Morusupalli, R.; Shin, H.; Son, H.; Byun, K.; Joo, Y.; Caramto, R.; Smith, L.; Shen, Y.; Kunz, M.; et al. On the Mechanical Stresses of Cu Through-Silicon Via (TSV) Samples Fabricated by SK Hynix vs. SEMATECH—Enabling Robust and Reliable 3-D Interconnect/Integrated Circuit (IC) Technology. Proc. Eng. 2016, 139, 101–111. [Google Scholar] [CrossRef] [Green Version]

- Ali, I.; Tippabhotla, S.K.; Radchenko, I.; Al-Obeidi, A.; Stan, C.V.; Tamura, N.; Budiman, A.S. Probing Stress States in Silicon Nanowires during Electrochemical Lithiation using In Situ Synchrotron X-ray Microdiffraction. Front. Energy Res. 2018, 6, 19. [Google Scholar] [CrossRef]

- Tippabhotla, S.K.; Radchenko, I.; Stan, C.V.; Tamura, N.; Budiman, A.S. Stress Evolution in Silicon Nanowires during Electrochemical Lithiation Using In Situ Synchrotron X-ray Microdiffraction. J. Mater. Res. 2019, 34, 1622–1631. [Google Scholar] [CrossRef] [Green Version]

- Budiman, A.S.; Shin, H.-A.-S.; Kim, B.-J.; Hwang, S.-H.; Son, H.-Y.; Suh, M.-S.; Chung, Q.-H.; Byun, K.-Y.; Tamura, N.; Kunz, M.; et al. Measurements of Stresses in Cu and Si around Through-Silicon Via by Synchrotron X-Ray Microdiffraction for 3-Dimensional Integrated Circuits. Microelectron. Rel. 2012, 52, 530–533. [Google Scholar] [CrossRef]

- Budiman, A.S.; Illya, G.; Anbazhagan, S.; Tippabhotla, S.K.; Song, W.J.R.; Sahay, R.; Tay, A.A.O. Enabling lightweight PC-PC Photovoltaics Module Technology—Enhancing Integration of Silicon Solar Cells into Aesthetic Design for Greener Building and Urban Structures. Sol. Energy 2021, 227, 38–45. [Google Scholar]

- Kim, I.; Kim, T.; Lee, S.; Matei, B. Extremely Foldable and Highly Transparent Nanofiber-Based Electrodes for Liquid Crystal Smart Devices. Sci. Rep. 2018, 8, 11517. [Google Scholar] [CrossRef] [PubMed]

- Matei, E.; Busuioc, C.; Evanghelidis, A.; Zgura, I.; Enculescu, M.; Beregoi, M.; Enculescu, I. Hierarchical Functionalization of Electrospun Fibers by Electrodeposition of Zinc Oxide Nanostructures. Appl. Surf. Sci. 2018, 458, 555–563. [Google Scholar] [CrossRef]

- Wu, M.; Wu, Y.; Liu, Z.; Liu, H. Optically Transparent Poly(methyl methacrylate) Composite Films Reinforced with Electrospun Polyacrylonitrile Nanofibers. J. Compos. Mater. 2012, 46, 2731–2738. [Google Scholar] [CrossRef]

- Ali, H.P.A.; Radchenko, I.; Li, N.; Budiman, A.S. The Roles of Interfaces and Other Microstructural Features in Cu/Nb Nanolayers as Revealed by In Situ Beam Bending Experiments Inside a Scanning Electron Microscope (SEM). Mater. Sci. Eng. A 2018, 738, 253–263. [Google Scholar]

| Samples | Height at Which the Silicon Cell Breaks (cm) | Specific Gravitational Potential Energy (10–2 Jcm3/g) |

|---|---|---|

| Silicon solar cell | 25 ± 5 | - |

| EVA on Si cell | 50 ± 4 | 7.3 ± 0.5 |

| HA-SSC15 on Si cell | 69 ± 2 | 9.4 ± 0.2 |

| HA-SSC45 on Si cell | 82 ± 4 | 11.2 ± 0.2 |

| Bare Si Cell | Si Cell + EVA | Si + HA-SSC15 | Si + HA-SSC45 | |

|---|---|---|---|---|

| Mean (cm) | 25.39 | 48.97 | 70.05 | 82.06 |

| Standard Deviation (cm) | 3.19 | 2.71 | 2.19 | 2.29 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Budiman, A.S.; Sahay, R.; Agarwal, K.; Illya, G.; Widjaja, R.G.; Baji, A.; Raghavan, N. Impact-Resistant and Tough 3D Helicoidally Architected Polymer Composites Enabling Next-Generation Lightweight Silicon Photovoltaics Module Design and Technology. Polymers 2021, 13, 3315. https://doi.org/10.3390/polym13193315

Budiman AS, Sahay R, Agarwal K, Illya G, Widjaja RG, Baji A, Raghavan N. Impact-Resistant and Tough 3D Helicoidally Architected Polymer Composites Enabling Next-Generation Lightweight Silicon Photovoltaics Module Design and Technology. Polymers. 2021; 13(19):3315. https://doi.org/10.3390/polym13193315

Chicago/Turabian StyleBudiman, Arief Suriadi, Rahul Sahay, Komal Agarwal, Gregoria Illya, Ryo Geoffrey Widjaja, Avinash Baji, and Nagarajan Raghavan. 2021. "Impact-Resistant and Tough 3D Helicoidally Architected Polymer Composites Enabling Next-Generation Lightweight Silicon Photovoltaics Module Design and Technology" Polymers 13, no. 19: 3315. https://doi.org/10.3390/polym13193315

APA StyleBudiman, A. S., Sahay, R., Agarwal, K., Illya, G., Widjaja, R. G., Baji, A., & Raghavan, N. (2021). Impact-Resistant and Tough 3D Helicoidally Architected Polymer Composites Enabling Next-Generation Lightweight Silicon Photovoltaics Module Design and Technology. Polymers, 13(19), 3315. https://doi.org/10.3390/polym13193315