Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Chemical, Physical and Morphological Analysis of GCC and PCC

2.3. Composite Preparation and Test Specimen Obtaining

2.4. Evaluation of the Mechanical Properties

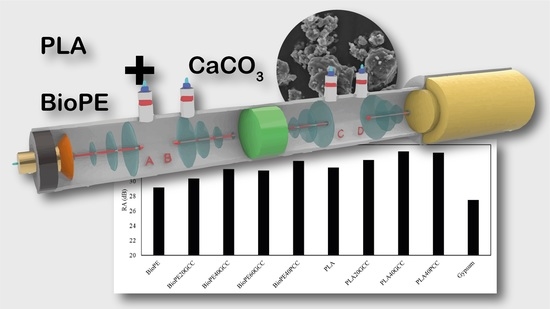

2.5. Acoustic Characterization

2.6. Color Analysis of the Composites

3. Results and Discussion

3.1. Characterization of GCC and PCC

3.2. Physical Characterization of the Composites

3.3. Mechanical Characterization of the Composites

3.4. Acoustic Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- La Rosa, A.D.; Recca, G.; Summerscales, J.; Latteri, A.; Cozzo, G.; Cicala, G. Bio-based versus traditional polymer composites. A life cycle assessment perspective. J. Clean. Prod. 2014, 74, 135–144. [Google Scholar] [CrossRef]

- Oliver-Ortega, H.; Granda, L.A.A.; Espinach, F.X.X.; Delgado-Aguilar, M.; Duran, J.; Mutjé, P. Stiffness of bio-based polyamide 11 reinforced with softwood stone ground-wood fibres as an alternative to polypropylene-glass fibre composites. Eur. Polym. J. 2016, 84, 481–489. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-polyethylene reinforced with thermomechanical pulp fibers: Mechanical and micromechanical characterization and its application in 3D-printing by fused deposition modelling. Compos. Part B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Walker, S.; Rothman, R. Life cycle assessment of bio-based and fossil-based plastic: A review. J. Clean. Prod. 2020, 261, 121158. [Google Scholar] [CrossRef]

- Yu, L.; Dean, K.; Li, L. Polymer blends and composites from renewable resources. Prog. Polym. Sci. 2006, 31, 576–602. [Google Scholar] [CrossRef]

- Fortelny, I.; Ujcic, A.; Fambri, L.; Slouf, M. Phase Structure, Compatibility, and Toughness of PLA/PCL Blends: A Review. Front. Mater. 2019, 6, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Delgado-Aguilar, M.; Puig, R.; Sazdovski, I.; Fullana-i-Palmer, P. Polylactic Acid/Polycaprolactone Blends : On the Path to Circular Economy, Substituting Single-Use Commodity Plastic Products. Materials 2020, 13, 2655. [Google Scholar] [CrossRef] [PubMed]

- Dorgan, J.R.; Janzen, J.; Clayton, M.P. Melt rheology of variable L-content poly(lactic acid). J. Rheol. 2005, 49, 607. [Google Scholar] [CrossRef]

- Lim, L.T.; Auras, R.; Rubino, M. Processing technologies for poly(lactic acid). Prog. Polym. Sci. 2008, 33, 820–852. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [Green Version]

- Lagarón, J.M. Polylactic acid (PLA) nanocomposites for food packaging applications. In Multifunctional and Nanoreinforced Polymers for Food Packaging; Woodhead Publishing: Sawston, UK, 2011; pp. 485–497. [Google Scholar]

- Ostafinska, A.; Fortelny, I.; Nevoralova, M.; Hodan, J.; Kredatusova, J.; Slouf, M. Synergistic effects in mechanical properties of PLA/PCL blends with optimized composition, processing, and morphology. RSC Adv. 2015, 5, 98971–98982. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A. Mechanical performance of biocomposites based on PLA and PHBV reinforced with natural fibres—A comparative study to PP. Compos. Sci. Technol. 2010, 70, 1687–1696. [Google Scholar] [CrossRef] [Green Version]

- Dammak, M.; Fourati, Y.; Tarrés, Q.; Delgado-Aguilar, M.; Mutjé, P.; Boufi, S. Blends of PBAT with plasticized starch for packaging applications: Mechanical properties, rheological behaviour and biodegradability. Ind. Crop. Prod. 2020, 144, 112061. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.; Moldes, D.; Echtermeyer, A.; Chinga-Carrasco, G. 3D Printable Filaments Made of Biobased Polyethylene Biocomposites. Polymers 2018, 10, 314. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Serra-Parareda, F.; Tarrés, Q.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Vilaseca, F. Biobased composites from biobased-polyethylene and barley thermomechanical fibers: Micromechanics of composites. Materials 2019, 12, 4182. [Google Scholar] [CrossRef] [Green Version]

- Kwon, S.; Kim, K.J.; Kim, H.; Kundu, P.P.; Kim, T.J.; Lee, Y.K.; Lee, B.H.; Choe, S. Tensile property and interfacial dewetting in the calcite filled HDPE, LDPE, and LLDPE composites. Polymer 2002, 43, 6901–6909. [Google Scholar] [CrossRef]

- De Oliveira, A.G.; Fernandes Moreno, J.; De Sousa, A.M.F.; Alves Escócio, V.; de Oliveira Cavalcanti Guimarães, M.J.; da Silva, A.L.N. Composites based on high-density polyethylene, polylactide and calcium carbonate: Effect of calcium carbonate nanoparticles as co-compatibilizers. Polym. Bull. 2020, 77, 2889–2904. [Google Scholar] [CrossRef]

- Atikler, U.; Basalp, D.; Tihminliog, F. Mechanical and Morphological Properties of Recycled High-Density Polyethylene, Filled with Calcium Carbonate and Fly Ash. J. Appl. Polym. Sci. 2006, 102, 4460–4467. [Google Scholar] [CrossRef] [Green Version]

- Oliver-Ortega, H.; Julian, F.; Espinach, F.X.; Tarrés, Q.; Ardanuy, M.; Mutjé, P. Research on the use of lignocellulosic fibers reinforced bio-polyamide 11 with composites for automotive parts: Car door handle case study. J. Clean. Prod. 2019, 226, 64–73. [Google Scholar] [CrossRef]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, biodegradable polymers and biocomposites: An overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Owuamanam, S.; Cree, D. Progress of Bio-Calcium Carbonate Waste Eggshell and Seashell Fillers in Polymer Composites: A Review. J. Compos. Sci. 2020, 4, 70. [Google Scholar] [CrossRef]

- Srivabut, C.; Ratanawilai, T.; Hiziroglu, S. Effect of nanoclay, talcum, and calcium carbonate as filler on properties of composites manufactured from recycled polypropylene and rubberwood fiber. Constr. Build. Mater. 2018, 162, 450–458. [Google Scholar] [CrossRef]

- Çoban, O.; Bora, M.Ö.; Kutluk, T. Comparative Study of Volcanic Particle and Calcium Carbonate Filler Materials in HDPE for Thermal and Mechanical Properties. Polym. Compos. 2018, 39, E1900–E1907. [Google Scholar] [CrossRef]

- Li, P.; Kim, B.-J.; Wang, Q.; Wu, Q. Experimental and numerical analysis of the sound insulation property of wood plastic composites (WPCs) filled with precipitated CaCO3. Holzforschung 2013, 63, 301–306. [Google Scholar] [CrossRef]

- Reixach, R.; Del Rey, R.; Alba, J.; Arbat, G.; Espinach, F.X.; Mutjé, P. Acoustic properties of agroforestry waste orange pruning fibers reinforced polypropylene composites as an alternative to laminated gypsum boards. Constr. Build. Mater. 2015, 77, 124–129. [Google Scholar] [CrossRef] [Green Version]

- Naghmouchi, I.; Espinach, F.X.; Del Rey, R.; Alba, J.; Bouff, S.; Mutje, P. Comparison of the soundproofing characteristics of olive stone filled polypropylene, gypsum boards and wood fiber reinforced polypropylene. Cell. Chem. Technol. 2016, 50, 411–415. [Google Scholar]

- Choe, H.; Heon Lee, J.; Hyeun Kim, J. Polyurethane composite foams including CaCO3 fillers for enhanced sound absorption and compression properties. Compos. Sci. Technol. 2020, 194, 108153. [Google Scholar] [CrossRef]

- Dissanayake, D.G.K.; Weerasinghe, D.U.; Thebuwanage, L.M.; Bandara, U.A.A. An environmentally friendly sound insulation material from post—Industrial textile waste and natural rubber. J. Build. Eng. 2021, 33, 101606. [Google Scholar] [CrossRef]

- Gustavsson, M.; Karawacki, E.; Gustafsson, S.E. Thermal conductivity, thermal diffusivity, and specific heat of thin samples from transient measurements with hot disk sensors. Rev. Sci. Instrum. 1994, 65, 3856. [Google Scholar] [CrossRef]

- Stansfeld, S.A.; Matheson, M.P. Noise pollution: Non-auditory effects on health. Br. Med. Bull. 2003, 68, 243–257. [Google Scholar] [CrossRef] [PubMed]

- Fuks, K.; Moebus, S.; Hertel, S.; Viehmann, A.; Nonnemacher, M.; Dragano, N.; Möhlenkamp, S.; Jakobs, H.; Kessler, C.; Erbel, R.; et al. Long-Term Urban Particulate Air Pollution, Traffic Noise, and Arterial Blood Pressure. Environ. Health Perspect. 2011, 119, 1706–1711. [Google Scholar] [CrossRef] [Green Version]

- Tzivian, L.; Winkler, A.; Dlugaj, M.; Schikowski, T.; Vossoughi, M.; Fuks, K.; Weinmayr, G.; Hoffmann, B. Effect of long-term outdoor air pollution and noise on cognitive and psychological functions in adults. Int. J. Hyg. Environ. Health 2015, 218, 1–11. [Google Scholar] [CrossRef]

- Hongisto, V.; Oliva, D.; Keränen, J. Subjective and objective rating of airbone sound insulation-living sounds. Acta Acust. United Acust. 2014, 100, 848–863. [Google Scholar] [CrossRef]

- Caballol, D.; Raposo, Á.P. Analysis of the measurement of transmission loss in rigid building materials with a standing wave tube. Constr. Build. Mater. 2018, 182, 242–248. [Google Scholar] [CrossRef]

- Aiken, T.A.; McPolin, D.; Russell, M.; Madden, M.; Bagnall, L. Physical and mechanical performance of magnesium-based construction boards: A comparative study. Constr. Build. Mater. 2021, 270, 121397. [Google Scholar] [CrossRef]

- Gao, L.; Wang, Z.; Xie, J.; Wang, Z.; Li, H. Study on the sound absorption coefficient model for porous asphalt pavements based on a CT scanning technique. Constr. Build. Mater. 2020, 230, 117019. [Google Scholar] [CrossRef]

- Yoon, J.; Kim, H.; Koh, T.; Pyo, S. Microstructural characteristics of sound absorbable porous cement-based materials by incorporating natural fibers and aluminum powder. Constr. Build. Mater. 2020, 243, 118167. [Google Scholar] [CrossRef]

- Wang, L.; Zhang, F.S. Characterization of a novel sound absorption material derived from waste agricultural film. Constr. Build. Mater. 2017, 157, 237–243. [Google Scholar] [CrossRef]

- Zhang, B.; Poon, C.S. Sound insulation properties of rubberized lightweight aggregate concrete. J. Clean. Prod. 2018, 172, 3176–3185. [Google Scholar] [CrossRef]

- Novak, R.A. Sound insulation of lightweight double walls. Appl. Acoust. 1992, 37, 281–303. [Google Scholar] [CrossRef]

- Yang, X.; Tang, X.; Ma, L.; Sun, Y. Sound Insulation Performance of Structural Wood Wall Integrated with Wood Plastic Composite. J. Bioresour. Bioprod. 2019, 4, 111–118. [Google Scholar] [CrossRef]

- Dansk Standard. DS 490:2007 Sound Classification of Dwellings; Danmarks Standardiseringsorganisation: København, Denmark, 2007. [Google Scholar]

- Echeverria, C.A.; Pahlevani, F.; Handoko, W.; Jiang, C.; Doolan, C.; Sahajwalla, V. Engineered hybrid fibre reinforced composites for sound absorption building applications. Resour. Conserv. Recycl. 2019, 143, 1–14. [Google Scholar] [CrossRef]

- Bhingare, N.H.; Prakash, S.; Jatti, V.S. A review on natural and waste material composite as acoustic material. Polym. Test. 2019, 80, 106142. [Google Scholar] [CrossRef]

- Tarrés, Q.; Vilaseca, F.; Herrera-Franco, P.J.; Espinach, F.X.; Delgado-Aguilar, M.; Mutjé, P. Interface and micromechanical characterization of tensile strength of bio-based composites from polypropylene and henequen strands. Ind. Crop. Prod. 2019, 132. [Google Scholar] [CrossRef]

- Hassan, T.; Jamshaid, H.; Mishra, R.; Khan, M.Q.; Petru, M.; Novak, J.; Choteborsky, R.; Hromasova, M. Acoustic, Mechanical and Thermal Properties of Green Composites Reinforced with Natural Fibers Waste. Polymers 2020, 12, 654. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.Z.; Jiang, X.H. Soundproofing effect of polypropylene/inorganic particle composites. Compos. Part B Eng. 2012, 43, 1995–1998. [Google Scholar] [CrossRef]

- Liang, J.-Z. Prediction of sound transmission losses for polymer/inorganic particle composites. Polym. Compos. 2014, 36, 2059–2065. [Google Scholar] [CrossRef]

- Bouzit, S.; Laasri, S.; Taha, M.; Laghzizil, A.; Hajjaji, A.; Merli, F.; Buratti, C. Characterization of Natural Gypsum Materials and Their Composites for Building Applications. Appl. Sci. 2019, 9, 2443. [Google Scholar] [CrossRef] [Green Version]

- Flaten, E.M.; Seiersten, M.; Andreassen, J.-P. Polymorphism and morphology of calcium carbonate precipitated in mixed solvents of ethylene glycol and water. J. Cryst. Growth 2009, 311, 3533–3538. [Google Scholar] [CrossRef]

- Zlem Cizer, Ö.; Rodriguez-Navarro, C.; Ruiz-Agudo, E.; Elsen, J.; Van Gemert, D.; Gemert, V.; Van Balen, K.; Balen, V. Phase and morphology evolution of calcium carbonate precipitated by carbonation of hydrated lime. J. Mater. Sci. 2012, 47, 6151–6165. [Google Scholar] [CrossRef] [Green Version]

- López, J.P.; Mendez, J.A.; Espinach, F.X.; Julian, F.; Mutjé, P.; Vilaseca, F. Tensile strength characteristics of polypropylene composites reinforced with stone groundwood fibres from softwood. Bioresources 2012, 7, 3188–3200. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Coltelli, M.B.; Lazzeri, A. Rigid filler toughening in PLA-Calcium Carbonate composites: Effect of particle surface treatment and matrix plasticization. Eur. Polym. J. 2019, 113, 78–88. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Espinach, F.X.; Mutjé, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. Mater. Des. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Anastas, P.; Warner, J. Green Chemistry: Theory and Practice; Oxford University Press: Oxford, UK, 1998. [Google Scholar]

- Espinach, F.X.X.; Julian, F.; Verdaguer, N.; Torres, L.; Pelach, M.A.A.; Vilaseca, F.; Mutje, P. Analysis of tensile and flexural modulus in hemp strands/polypropylene composites. Compos. Part B Eng. 2013, 47, 339–343. [Google Scholar] [CrossRef]

- López, J.P.; Mutjé, P.; Angels Pèlach, M.; El Mansouri, N.E.; Boufi, S.; Vilaseca, F. Analysis of the tensile modulus of polypropylene composites reinforced with stone groundwood fibers. BioResources 2012, 7, 1310–1323. [Google Scholar] [CrossRef]

- Tarrés, Q.; Oliver-Ortega, H.; Alcalà, M.; Espinach, X.X.; Mutjé, P.; Delgado-Aguilar, M. Research on the strengthening advantages on using cellulose nanofibers as polyvinyl alcohol reinforcement. Polymers 2020, 12, 974. [Google Scholar] [CrossRef] [Green Version]

- Thomason, J.L. The Influence of Fibre Properties on the Properties of Glass-Fibre-Reinforced Polyamide 6,6. J. Compos. Mater. 2000, 34, 158–172. [Google Scholar] [CrossRef]

- Biswas, J.; Kim, H.; Lee, H.; Choe, S. Air-Hole Properties of Calcite-Filled Polypropylene Copolymer Films. J. Appl. Polym. Sci. 2008, 109, 1420–1430. [Google Scholar] [CrossRef]

- Etelaaho, P.; Haveri, S.; Jarvela, P. Comparison of the Morphology and Mechanical Properties of Unmodified and Surface-Modified Nanosized Calcium Carbonate in a Polypropylene Matrix. Polym. Compos. 2011, 32, 8. [Google Scholar] [CrossRef]

- Padevet, P.; Tesárek, P.; Plachý, T. Evolution of mechanical properties of gypsum in time. Int. J. Mech. 2011, 5, 1–9. [Google Scholar]

- Rahmanian, I. Thermal and Mechanical Properties of Gypsum Boards and Their Influences on Fire Resistance of Gypsum Board Based Systems; University of Manchester: Manchester, UK, 2011. [Google Scholar]

- Espinach, F.X.; Mendez, J.A.; Granda, L.A.; Pelach, M.A.; Delgado-Aguilar, M.; Mutje, P. Bleached kraft softwood fibers reinforced polylactic acid composites, tensile and flexural strengths. In Natural Fiber-Reinforced Biodegradable and Bioresorbable Polymer Composites; Woodhead Publishing: Sawston, UK, 2017. [Google Scholar]

- Espigulé, E.; Vilaseca, F.; Puigvert, X.; Mutjé, P. Biocomposites from Starch-based Biopolymer and Rape Fibers. Part II: Stiffening, Flex-ural and Impact Strength, and Product Development. Curr. Org. Chem. 2013, 17, 1641–1646. [Google Scholar] [CrossRef]

- ASTM E90—09. Standard Test Method for Laboratory Measurement of Airborne Sound Transmission Loss of Building Partitions and Elements; ASTM International: Pensilvania, PA, USA, 2016. [Google Scholar]

- ISO 10140-2:2021. Acoustics—Laboratory Measurement of Sound Insulation of Building Elements—Part 2: Measurement of Airborne Sound Insulation; International Organization for Standardization: Ginebra, Switzerland, 2021. [Google Scholar]

- Brekke, A. Calculation methods for the transmission loss of single, double and triple partitions. Appl. Acoust. 1981, 14, 225–240. [Google Scholar] [CrossRef]

- Davy, J.L. The improvement of a simple theoretical model for the prediction of the sound insulation of double leaf walls. J. Acoust. Soc. Am. 2010, 127, 841–849. [Google Scholar] [CrossRef] [Green Version]

- Vinokur, R.Y. Transmission loss of triple partitions at low frequencies. Appl. Acoust. 1990, 29, 15–24. [Google Scholar] [CrossRef]

- Alba, J.; Ramis, J. Modelling of impervious layers from measurements of the sound reduction index. Appl. Acoust. 2003, 64, 385–400. [Google Scholar] [CrossRef]

- Vigran, T. Predicting the sound reduction index of finite size specimen by a simplified spatial windowing technique. J. Sound Vib. 2009, 325, 507–512. [Google Scholar] [CrossRef]

| Specimen | Density (kg/m3) |

|---|---|

| PLA | 1165 |

| PLA20GCC | 1316 |

| PLA40GCC | 1526 |

| PLA40PCC | 1477 |

| BioPE | 846 |

| BioPE20GCC | 979 |

| BioPE40GCC | 1137 |

| BioPE60GCC | 1293 |

| BioPE40PCC | 1117 |

| PLA | PLA20GCC | PLA40GCC | PLA40PCC | |

|---|---|---|---|---|

| H: 69 | H: 90 | H: 96 | H: 82 | |

| S: 15 | S: 10 | S: 8 | S: 9 | |

| L: 75 | L: 76 | L: 75 | L: 77 | |

| BioPE | BioPE20GCC | BioPE40GCC | BioPE60GCC | BioPE40PCC |

| H: 190 | H: 88 | H: 90 | H: 96 | H: 69 |

| S: 16 | S: 9 | S: 9 | S: 8 | S: 10 |

| L: 78 | L: 72 | L: 73 | L: 74 | L: 73 |

| σt (MPa) | εtM (%) | εt (%) | Et (GPa) | |

|---|---|---|---|---|

| PLA | 62.58 ± 0.83 e | 3.284 ± 0.073 b | 4.224 ± 0.033 b | 3.821 ± 0.110 e |

| PLA20GCC | 45.48 ± 0.99 d | 1.871 ± 0.106 a | 1.893 ± 0.127 a | 5.042 ± 0.070 f |

| BioPE | 18.05 ± 0.159 b | 12.180 ± 525 e | >100mm e | 1.060 ± 0.028 a |

| BioPE20GCC | 16.07 ± 0.16 a | 7.595 ± 0.406 d | 23.430 ± 1.409 f | 1.265 ± 0.058 b |

| BioPE40GCC | 17.55 ± 0.51 b | 6.174 ± 0.211 c | 10.830 ± 0.204 d | 1.530 ± 0.006 c |

| BioPE40PCC | 17.97 ± 0.26 b,c | 6.510 ± 0.430 c | 8.434 ± 1.195 c | 1.499 ± 0.083 c |

| BioPE60GCC | 19.15 ± 0.15 c | 6.214 ± 0.181 c | 6.474 ± 0.211 c | 1.785 ± 0.038 d |

| σf (MPa) | D (mm) | εf (%) | Ef (GPa) | |

|---|---|---|---|---|

| PLA | 114.10 ± 1.21 f | 6.975 ± 0.073 c | 4.69 ± 0.05 c | 3.987 ± 0.0153 d |

| PLA20GCC | 68.13 ± 1.18 e | 4.167 ± 0.106 b | 2.80 ± 0.07 b | 3.848 ± 0.0048 d |

| PLA40GCC | 20.41 ± 0.74 a | 0.646 ± 0.093 a | 0.43 ± 0.06 a | 4.843 ± 0.0063 e |

| BioPE | 21.25 ± 0.34 a | 9.790 ± 0.054 f | 6.58 ± 0.04 f | 0.839 ± 0.0025 a |

| BioPE20GCC | 23.84 ± 0.49 b | 8.938 ± 0.031 e | 6.01 ± 0.02 e | 0.965 ± 0.0020 a,b |

| BioPE40GCC | 27.60 ± 0.27 c | 8.996 ± 0.091 e | 6.05 ± 0.06 e | 1.257 ± 0.0002 b,c |

| BioPE40PCC | 28.33 ± 0.37 c,d | 8.692 ± 0.045 d | 5.84 ± 0.03 d | 1.341 ± 0.0014 b,c |

| BioPE60GCC | 30.52 ± 0.60 d | 8.912 ± 0.040 d,e | 5.99 ± 0.03 d,e | 1.633 ± 0.0123 c |

| Charpy Unnotched (kJ/m2) | Charpy Notched (kJ/m2) | Izod (J/m) | |

|---|---|---|---|

| PLA | 24.46 ± 1.10 d | 2.90 ± 0.16 b | 34.51 ± 0.86 b,c |

| PLA20GCC | 16.48 ± 0.76 c | 2.64 ± 0.21 b | 27.99 ± 1.12 b |

| PLA40GCC | 2.73 ± 0.85 b | <0.5J a | 2.44 ± 1.99 a |

| BioPE | >5.5J a | 6.66 ± 0.73 f | 52.67 ± 2.72 e |

| BioPE20GCC | >5.5J a | 5.94 ± 0.08 e | 49.38 ± 5.58 e |

| BioPE40GCC | 43.65 ± 0.78 f | 3.63 ± 0.06 c | 40.40 ± 3.86 c,d |

| BioPE40PCC | 35.76 ± 1.13 e | 3.67 ± 0.08 c | 38.01 ± 3.06 c,d |

| BioPE60GCC | 49.61 ± 2.24 g | 5.17 ± 0.23 d | 45.96 ± 8.28 d,e |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Serra-Parareda, F.; Alba, J.; Tarrés, Q.; Espinach, F.X.; Mutjé, P.; Delgado-Aguilar, M. Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications. Polymers 2021, 13, 3323. https://doi.org/10.3390/polym13193323

Serra-Parareda F, Alba J, Tarrés Q, Espinach FX, Mutjé P, Delgado-Aguilar M. Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications. Polymers. 2021; 13(19):3323. https://doi.org/10.3390/polym13193323

Chicago/Turabian StyleSerra-Parareda, Ferran, Jesús Alba, Quim Tarrés, Francesc X. Espinach, Pere Mutjé, and Marc Delgado-Aguilar. 2021. "Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications" Polymers 13, no. 19: 3323. https://doi.org/10.3390/polym13193323

APA StyleSerra-Parareda, F., Alba, J., Tarrés, Q., Espinach, F. X., Mutjé, P., & Delgado-Aguilar, M. (2021). Characterization of CaCO3 Filled Poly(lactic) Acid and Bio Polyethylene Materials for Building Applications. Polymers, 13(19), 3323. https://doi.org/10.3390/polym13193323