Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management

Abstract

:1. Introduction

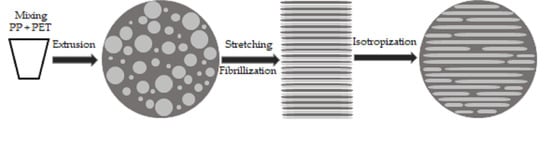

- Melt blend two thermodynamically immiscible polymers whose melting temperatures differ by at least 30 °K; then

- Stretch the extruded blend at a temperature above the glass transition temperature of both polymers to orient the polymer phases (fibrillization); then

- Isotropize the polymer matrix by an annealing process where the annealing temperature is above the matrix material’s melting temperature.

- Proper dispersion of the reinforcing fibrils is achieved as the fibrils are developed once the melt blend leaves the extruder, overcoming the problem that existed in fiber composites.

- As the fibril diameter is decreased and reaches a micro-scale, the critical length needed to create a fiber pullout is decreased, which reduces the fiber pullout problem.

- MFCs have a lower density compared to fiber-reinforced composites, which results in weight reduction.

- The MFC process is more environmentally friendly compared to fiber composites.

- The MFC process is fully recyclable.

2. Materials and Methods

2.1. Materials

2.2. Rheology

2.3. Blending and Filament Processing

2.3.1. Blending of MFC

2.3.2. Filament Stretching and Processing

- The speed of the filament before entering the stretching chamber (6.5–12.5 cm/s in 3 steps)

- The temperature of the stretching chamber (90, 105, 120 °C)

- The melt temperature via extruder barrel heating (258, 269 °C)

2.4. Thermal Characterization

Differential Scanning Calorimetry (DSC)

3. Results

3.1. Rheological Properties

3.2. Thermal Properties

3.3. Morphology

3.4. Optimization of Filament Stretching

3.5. Isotropization

3.6. Filament Optimization

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Directive 2000/53/EC of the European Parliament and of the Council. 2000. Available online: http://eurlex.europa.eu/LexUriServ/LexUriServ.do?uri=CONSLEG:2000L0053:20050701:EN:PDF (accessed on 7 January 2005).

- Narula, C.K.; Allison, J.E.; Bauer, D.R.; Gandhi, H.S. Gandhi: Materials Chemistry Issues Related to Advanced Materials Applications in the Automotive Industry. Chem. Mater. 1996, 8, 984–1003. [Google Scholar] [CrossRef]

- Mazda Develops Automatic Bumper Recycling Process 2009. Available online: http://green.autoblog.com/2009/03/23/mazda-develops-automatic-bumper-recycling-process (accessed on 23 March 2009).

- Evstatiev, M.; Fakirov, S. Microfibrillar Reinforcement of Polymer Blends. Polymer 1992, 33, 877–880. [Google Scholar] [CrossRef]

- Fakirov, S.; Bhattacharyya, D.; Shields, R.J. Nanofibril reinforced composites from polymer blends. Colloids Surf. A Physicochem. Eng. Asp. 2008, 313–314, 2–8. [Google Scholar] [CrossRef]

- Evstatiev, M.; Fakirov, S.; Krasteva, B.; Friedrich, K.; Covas, J.; Cunha, A. Recycling of poly(ethylene terephthalate) as polymer-polymer composites. Polym. Eng. Sci. 2002, 42, 826–835. [Google Scholar] [CrossRef]

- Friedrich, K.; Evstatiev, M.; Fakirov, S.; Evstatiev, O.; Ishii, M.; Harrass, M. Microfibrillar reinforced composites from PET/PP blends: Processing, morphology and mechanical properties. Compos. Sci. Technol. 2005, 65, 107–116. [Google Scholar] [CrossRef]

- Shahnooshia, M.; Javadia, A.; Nazockdasta, H.; Altstadtb, V. Development of in situ nanofibrillar poly (lactic acid)/poly (butyleneterephthalate) composites: Non-isothermal crystallization and crystal morphology. Eur. Polym. J. 2002, 125, 109489. [Google Scholar] [CrossRef]

- Mishra, R.K.; Verma, K.; Chaudhary, R.G.; Lambat, T.; Joseph, K. An efficient fabrication of polypropylene hybrid nanocomposites using carbon nanotubes and PET fibrils. Mater. Today Proc. 2020, 29, 794–800. [Google Scholar] [CrossRef]

- Mi, D.; Wang, Y.; Kuzmanovic, M.; Delva, L.; Jiang, Y.; Cardon, L.; Zhang, J.; Ragaert, K. Effects of Phase Morphology on Mechanical Properties: Oriented/Unoriented PP Crystal Combination with Spherical/Microfibrillar PET Phase. Polymers 2019, 11, 248. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kuzmanović, M.; Delva, L.; Cardon, L.; Ragaert, K. Relationship between the Processing, Structure, and Properties of Microfibrillar Composites. Adv. Mater. 2020, 32, 2003938. [Google Scholar] [CrossRef] [PubMed]

- Kuzmanović, M.; Delva, L.; Mi, D.; Martins, C.I.; Cardon, L.; Ragaert, K. Development of Crystalline Morphology and Its Relationship with Mechanical Properties of PP/PET Microfibrillar Composites Containing POE and POE-g-MA. Polymers 2018, 10, 291. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Evstatiev, M.; Simeonova, S.; Pai, J.; Friedrich, K. Preparation and Characterization of MFC Structured Biodegradable Polymer Materials from Poly(L-lactide)/Poly(butylene adipate-co-terephatalate) Blends with Improved Mechanical and Barrier Properties. J. Mater. Sci. 2013, 48, 6312–6331. [Google Scholar] [CrossRef]

- Gupta, V.B.; Sett, S.K.; Venkataraman, A. Flow-drawing of poly(ethylene terephthalate). Polym. Eng. Sci. 1990, 30, 1252–1257. [Google Scholar] [CrossRef]

- Clark, E.S.; Scott, L.S. Superdrawn crystalline polymers: A new class of high-strength fiber. Polym. Eng. Sci. 1974, 14, 682–686. [Google Scholar] [CrossRef]

- Fakirov, S.; Battacharyya, D.; Lin, R.J.T.; Fuchs, C.; Friedrich, K. Contribution of coalescence to microfibril formation in polymer blends during cold drawing. J. Macromol. Sci. 2007, 46 Pt B, 183–194. [Google Scholar] [CrossRef]

- Friedrich, K.; Ueda, E.; Kamo, H.; Evstatiev, M.; Fakirov, S. Direct Electron Microscopic Observation of Transcrystalline Layers in Microfibrillar Reinforced Polymer-Polymer Composites. J. Mater. Sci. 2002, 37, 4299–4306. [Google Scholar] [CrossRef]

| Polymer Type | Polymer Grade | Manufacturer | Density (g/cm3) | Tm, proc. Temp. (°C) | MFR (dg/min) | Intrinsic Viscosity (dl/g) |

|---|---|---|---|---|---|---|

| PET | BC111 | Sabic | 0.838 | 246–256 | - | 0.74–0.78 |

| PP | 500P | Sabic | 0.905 | 200–225 | 3 | - |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Almajid, A.; Walter, R.; Kroos, T.; Junaidi, H.; Gurka, M.; Abdelrazek Khalil, K. Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management. Polymers 2021, 13, 233. https://doi.org/10.3390/polym13020233

Almajid A, Walter R, Kroos T, Junaidi H, Gurka M, Abdelrazek Khalil K. Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management. Polymers. 2021; 13(2):233. https://doi.org/10.3390/polym13020233

Chicago/Turabian StyleAlmajid, Abdulhakim, Rolf Walter, Tim Kroos, Harry Junaidi, Martin Gurka, and Khalil Abdelrazek Khalil. 2021. "Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management" Polymers 13, no. 2: 233. https://doi.org/10.3390/polym13020233

APA StyleAlmajid, A., Walter, R., Kroos, T., Junaidi, H., Gurka, M., & Abdelrazek Khalil, K. (2021). Development of Polypropylene/Polyethylene Terephthalate Microfibrillar Composites Filament to Support Waste Management. Polymers, 13(2), 233. https://doi.org/10.3390/polym13020233