3.1. Synthesis and Characterization of WPUD

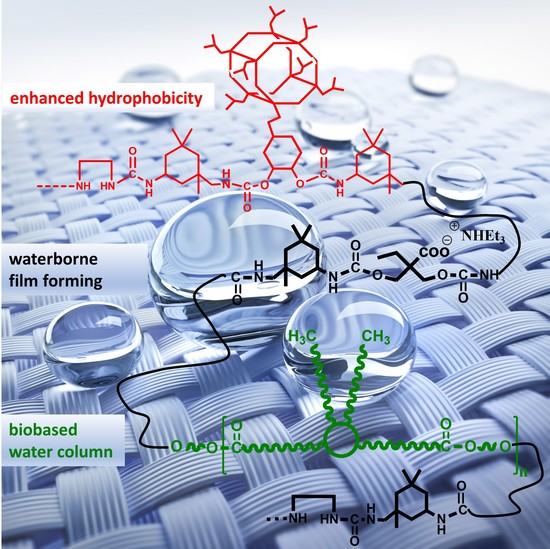

A series of WPUD were synthesized using the prepolymer method, as reported in the experimental section. Once the prepolymer was obtained, the neutralization of the carboxyl groups with triethylamine and subsequent phase inversion in water was carried out. Finally, chain extension via EDA was performed, followed by acetone removal by rotary evaporation and standardization to 35% solid content. The scheme of the synthesis strategy of the WPUD can be seen in

Figure 4.

WPUD were first characterized by FTIR. The infrared spectra of all synthesized polymers showed the complete conversion of isocyanate groups judging by the absence of the characteristic free isocyanate band at 2275 cm

−1. By comparing the spectrum of the starting polyol Priplast 3238 with those of the synthesized polyurethane-ureas, the appearance of new bands that are indicative of the formation of urethane/urea bonds could be clearly confirmed (

Figure 5). The broad band of NH asymmetrical and symmetrical stretching vibration at 3351 cm

−1 indicated the great extent of NH established hydrogen bonds with carbonyl groups from urethane, urea, ester, and ionic carboxylate from internal emulsifier DMBA [

11]. The region of 1500–1600 cm

−1 showed NH-CO stretching and NH bending bands of the urethane group at 1548 cm

−1. The region between 1740 and 1600 cm

−1 showed characteristic C=O stretching bands from DMBA carboxylate, urethane, and urea carbonyl groups at approximately the 1661–1700 cm

−1 region, partially overlapped with the ester band from the polyester polyol at 1739 cm

−1. COC(O) stretching bands and NH out-of-plane bending bands from urethane functional groups at 1242 cm

−1 and 775 cm

−1, respectively, were clearly observed. On the other hand, the pure POSS-OH showed strong bands at 1108, 743, and 480 cm

−1 that corresponded to the Si-O-Si asymmetric stretching, symmetric stretching, and bending mode, respectively. The pure POSS-OH also showed a band at 1039 cm

−1 that, according to [

9], can be attributed to Si-isobutyl. 3238-3PDO, 3238-1, 3238-2, 32387PDO showed all the aforementioned characteristic polyurethane-urea bands while 3238-3POSS and 3238-7POSS showed the same bands plus the characteristic silsesquioxane peaks.

All of the synthesized WPUD were dried on Teflon plates to obtain the corresponding films. All of the obtained films were transparent (except the ones containing POSS that were not completely clear) and homogenous and were used for NMR, mechanical, thermal, and swelling characterization.

Figure 6 shows the appearance of the synthesized WPUD as well as the appearance of casted film from two of the polyurethane-urea dispersions (3238-7POSS and 3238-7PDO).

1H NMR spectra of all polymer films were recorded, thus confirming chemical structure.

Figure 7 and

Figure 8 depict the

1H NMR spectra of 3238-3PDO and starting Priplast 3238 polyol and 3238-3POSS and starting POSS-OH, respectively, with peak assignments.

1H NMR spectra provided structural information regarding Priplast 3238 polyol, pure POSS-OH, and WPUD films. The main peaks of Priplast 3238 were in good agreement with those reported by Bueno-Ferrer’s work [

12], showing a CH

2C(O)O signal at 2.30 ppm and peaks from CH

2OC(O) and CH

2 in the β position of the ester group at 4.15 and 1.61, respectively (

Figure 7).

The CH

2 peaks from the methylene in the α, β, and γ position with respect to free hydroxyl groups (COO-C

γH

2-C

βH

2-C

αH

2-OH) appeared at 3.69, 1.96, and 4.23 ppm, respectively. In the WPUD, the full conversion of hydroxyl groups to form polyurethane segments was confirmed by downfield shifting of the α and β peaks in the polymer spectra (

Figure 7).

Commercially available IPDI consists of an isomer mixture of approximately 75:25 in favor of the cis-isomer, leading to different reaction mixtures [

13] and resulting in complex

1H-NMR spectra. For a better interpretation of the

1H-NMR spectra of the synthesized polyurethane-ureas, they were compared with the ones of model compounds reported in our previous work [

14] (IPDI:DMBA, IPDI:PDO, IPDI:EDA, IPDI:EtOH) that were obtained by reacting IPDI with the corresponding building blocks in a molar ratio of 2:1. This made it possible to more precisely assign some of the main signals of the polyurethane-ureas under study.

Urethane moieties gave the following weak signals:

IPDI CH2 in α-position to -NHC(O) group (a’), 3.24 ppm and 2.88 ppm corresponding to the trans-isomer (25% abundance) and cis-isomer (75% abundance), respectively.

IPDI CH in α-position to -NHC(O) group (g’), 3.73 ppm.

The incorporation of internal emulsifier (DMBA) into the polymer backbone could be assessed by the following signals: DMBA CH2 in α-position to OC(O) group (D1), 4.26 ppm; DMBA methylene group (D2) attached to methyl, 1.31 ppm; DMBA methyl group (D3), 0.86 ppm.

Triethylammonium salt could be assessed by the peaks at 3.02 (T1) and 1.37 (T2) ppm that correspond to CH2 and CH3, respectively, of the ethyl group.

Figure 8 depicts the

1H NMR spectra of sample 3238-3POSS and pure POSS-OH with peak assignments. Hydrogens 6, 6′ and 7, 7′ from the cyclohexyl ring were diastereotopic and therefore appeared at different chemical shifts. In pure POSS-OH, the signals from the methine hydrogens directly bonded to the hydroxyl groups appeared in the form of complex multiplets at 3.58 and 3.44 ppm. In all the WPUD containing POSS-OH as a building block, the full conversion of hydroxyl groups from POSS-OH to form polyurethane segments was confirmed by downfield shifting of the -CH-O- signals from the cyclohexyl ring in the polymer spectra (

Figure 8).

The thermal properties of the developed WPUD were analyzed by DSC and TGA. The non-isothermal DSC thermograms for all of the WPUD films as well as Priplast 3238 were registered. DSC curves of the synthesized WPUD performed at a heating rate of 10 °C min

−1 are shown in

Figure 9 and thermal transition temperatures for all of the WPUD are summarized in

Table 4.

Two

Tg values were detected for all of the synthesized WPUD,

Tg1 and

Tg2, which corresponded to soft segment and hard segment phases, respectively. The

Tg1 of the soft segment phase was close to the value observed for Priplast 3238 polyester polyol. This is an indication that there was a phase segregation between hard polyurethane-urea segments and polyester soft segments. All of the WPUD showed

Tg2 values between 70 and 90 °C, corresponding to the softening of hard segments. Melting temperatures and small enthalpies associated with the melting of crystallized hard segments were also detected in the range of 144–170 °C and data collected from these thermograms are shown in

Table 4.

The thermal stability of the synthesized WPUD films was studied via TGA under N

2 and air atmospheres and the curves of experiments 3238-3POSS and 3238-3PDO are shown in

Figure 10. The degradation temperatures under the N

2 atmosphere corresponding to a weight loss of 10% and the temperatures of the maximum degradation rate for each degradation stage are collected in

Table 4 for all of the WPUD. All of the (co)polymers had sufficient thermal stability to withstand, without degradation, the temperature conditions that are required during coating procedures.

As can be observed in

Figure 10 and

Table 4, under N

2 conditions thermal degradation occurred in three stages, with similar temperatures of maximum degradation rate for all the synthesized WPUD. The first step occurred in the temperature range of 242–263 °C and could be attributed to the volatilization of triethylamine, which was in the form of carboxylate salt. Stage 2 took place in the temperature range of 307–332 °C and corresponded to the degradation of urethane and urea bonds [

8,

14]. Finally, Stage 3, between 416 and 432 °C, was related to the degradation of segments of Priplast 3238 polyol as far as the TGA curve of this pure polyol showed a single degradation step under an N

2 atmosphere at a maximum degradation rate of 414 °C. Thermal degradation profiles under N

2 and air atmospheres were quite similar except for the fact that a fourth degradation step around 550 °C could be detected under oxidative conditions due to the complete decomposition to CO

2. It is also worth noting that polymers containing POSS-OH in their structure left a residual weight that corresponded with silicon dioxide (

Figure 10).

Stress–strain tensile experiments were carried out to evaluate the mechanical properties of the synthesized WPUD films.

Figure 11 and

Figure 12 display the stress–strain curves from the experimental designs that included POSS-OH and PDO in the tertiary mixture, respectively, and

Table 5 displays the main mechanical properties of films.

The ratio of Priplast 3238, DMBA, and PDO or POSS-OH in the polyol ternary mixture determined the polyol composition in each synthesized polymer and, therefore, the hard segment content. There was a reasonably good match between the Young modulus and hard segment content. In general, higher hard segment content showed a higher Young modulus. However, experiment 3238-3PDO (38.8 wt.% HS) led to a slightly higher Young modulus than experiment 3238-1 (40.6 wt.% HS), which could be explained by the greater influence of PDO on the polymer rigidity caused by stronger hydrogen bonding interactions between urethane groups as compared to DMBA. Experiment 3238-3POSS (47.0 wt.% HS) led to a lower Young modulus than experiment 3238-1 (40.6 wt.% HS) due to the bulkiness of the heptaisobutyl POSS groups and the consequent reduction of hydrogen bonding interactions. The concordance between stress at 100% strain (σ

100%) and hard segment content was even better, as can be seen in the surface plots in

Figure 13. The strain at break was also very well correlated to the amount of Priplast 3238 (the polyol that provides flexibility); the higher the ratio of Priplast with respect to PDO or POSS-OH and DMBA, the higher the strain at break (see the contour plots in

Figure 14).

Water swelling of the films after 48 h at 25 °C was assessed on all of the WPUD films.

Figure 15 shows the water swelling values. The swelling values of the films after 48 h were consistent with the increased content of hydrophilic chain extender (DMBA), in agreement with the behavior that was reported by Xu et al. for waterborne polyurethane emulsions using dimethylol propionic acid (DMPA) as an internal emulsifier [

15]. Contour plots from the ternary mixture experimental designs clearly confirm the relationship between DMBA content and water swelling in

Figure 16.

Dispersion stability, particle size, and particle size distribution of WPUD were also investigated.

Figure S1 (Supplementary Material) shows the particle size distribution (PSD) curves of all developed aqueous polymeric dispersions analyzed by DLS. Particle size distribution curves are unimodal for all WPUD.

Table 6 summarizes average particle size of all of the WPUD, PdI values, and Z-potential. Low particle size values ranging from 57 to 66 nm were observed for the dispersions with the lowest molar% of Priplast 3238, namely, 3238-1, 3238-3PDO, and 3238-3POSS. This is consistent with the fact that Priplast 3238 is a highly hydrophobic polyol of high Mw. Logically, the WPUD with the highest particle size was 3238-2 (203 nm) because it had the highest Priplast 3238 content. The dispersions with intermediate content in Priplast 3238 (3238-7PDO and 3238-7POSS) displayed intermediate particle size values. It is also worth mentioning that those WPUD with the same composition but having POSS-OH instead of PDO, for instance 3238-7POSS vs. 3238-7PDO, showed higher particle size, probably because POSS-OH provides more hydrophobicity than PDO and has a higher molecular weight. The polydispersity indexes (PdI) were below 0.2, which indicated that products had satisfactory stability and good dispersibility. The smaller the value of PdI, the better the homogeneity of the dispersion [

16].

The stability of the dispersions was assessed by measuring the Z-potential of each WPUD. The Z-potential values are shown in

Table 6. For all of the 3238 series, the Z-potential presented values ranging from −58 to −22 mV, indicating that the nanodroplets were negatively charged at the surface due to the presence of carboxylate groups. Most of the Z-potential absolute values were higher than 30 mV and were generally considered to represent stable emulsions [

17,

18]. However, 3238-1 and 3238-3PDO showed Z-potential absolute values below 30 mV. Despite this fact, the appearance of all of the WPUD emulsions stored at 4 °C and 40 °C for 6 months was good and there were no visual signs of instability such as phase separation, gelling, sedimentation, or creaming.

Finally, accelerated sedimentation tests of WPUD emulsions were also carried out. The analysis of the tested emulsions performed at 4 °C and 40 °C and relative centrifugal force of 2000×

g is shown in

Figures S2 and S3 (Supplementary Material). The first scanning profile obtained is indicated in red at the bottom, and the last in green at the top. Only a small clarification was observed at the meniscus area and small sedimentations were observed at the bottom with time, whereas the light transmission of the samples remained constant with time, indicating a good stability of the emulsions. The greater the change in light transmittance during the acceleration of the emulsion, the worse the stability [

14].

3.2. Characterization of Textiles Coated with WPUD

In order to validate the applicability and properties of the polymeric dispersions, all of the synthesized WPUD were formulated in the form of printing pastes and subsequently face-coated on 100% polyester fabrics referenced as UPRON. Knife coating was the method chosen to carry out the coatings, as it is a widely employed method in the textile sector to produce accurate and reproducible coatings, being easily scalable to standard industrial textile machinery. In this way, this work has the purpose of performing the validation of the WPUD in application conditions that are very similar to those that are commonly used at an industrial level.

Smooth glass slides were also coated with all of the above-mentioned printing pastes, and WCA and OCA were measured to establish a comparison between the glass smooth coating substrate and the inherently rough textile substrate (UPRON).

Table 7 lists the values of WCA and OCA measured on glass slides and UPRON fabrics coated with WPUD printing pastes.

As could be observed, WCAs of coated UPRON fabrics were between 108 and 135° for the synthesized WPUD, which means low water wettability, but not superhydrophobicity (>150°). The incorporation of POSS-OH in the polymer increased significantly the WCA of the coated fabrics. It is important to point out that the WCAs of coated glass slides were much lower than the WCAs of WPUD coated fabrics. Thus, the inherent roughness of the textile substrate contributed to achieving high values of WCA [

19]. The OCA values of the coated surfaces were low. However, it is worth noting that in the case of coated fabrics the oil droplets, while not maintaining their spherical shape, did not penetrate the coating either. This is an indication that the coatings exerted a remarkable barrier effect against olive oil.

The determination of resistance to water penetration measured by hydrostatic pressure tests (also known as water column), stiffness, air permeability, and water vapor resistance were performed on UPRON fabrics face-coated with the printing pastes (

Table 8). Printing paste made from experiment 3238-2 showed the highest water column value of all the experiments, which is consistent with the mechanical properties of this sample, having the highest ε

b of all the samples. It is also worth noting that incorporation of POSS-OH in the polymer structure did not significantly alter water column properties with respect to polyurethane-ureas obtained without using POSS-OH as a co-polyol. Water column values higher than 30 cm were achieved by all of the coated fabrics, thus being in the same range as fossil-based coatings reported in our previous work [

14].

Air permeability dramatically decreased and stiffness increased in all of the coated fabrics compared to untreated fabrics. This is logical when considering that we applied a polymer layer to one of the faces of the fabric. Reduced air permeability can be a positive feature when it comes to outdoor sportwear with wind-stopper functionality.

The standard ISO 11092 uses the sweating guarded hotplate method (skin model method), to simulate the heat and moisture transfer process close to the human skin and to test the thermal resistance and water vapor resistance of textiles under steady-state conditions to evaluate the comfort of textiles. The lower the water vapor resistance (R

et), the higher the breathability. In this work, R

et was assessed for all of the coated fabrics on the coated face (“face”) and on the uncoated face (“back”) with no significant differences between “face” and “back”. However, it should be noted that the greater the soft segment content, the greater the water vapor resistance, as can be clearly seen in contour plots from

Figure 17. Although the R

et values obtained for all of the coatings were quite high (>150 m

2 Pa W

−1) and denoted low perspiration breathability and therefore low comfort, we can conclude that coating breathability decreased for those polymers with higher amounts of Priplast 3238. On the other hand, for a given mol.% of Priplast 3238 and DMBA, R

et decreased when we replaced PDO for POSS-OH (Ret 3238-3PDO > Ret 3238-3POSS, Ret 3238-7PDO > Ret 3238-7POSS). This observation made us think that the incorporation of bulky heptaisobutyl POSS as a pendant side group in the polymer chain prevented close packing of adjacent chains, thus favoring water molecule diffusion.

Figure 18 shows the SEM micrographs of uncoated and coated UPRON fabrics with the printing pastes made from experiments 3238-3PDO and 3238-3POSS. The presence of the coating in the fiber’s surface could be seen for coated samples. The coatings were not distributed in a completely homogeneous way. The roughness of the surfaces seemed to increase with the presence of the POSS-OH.

The presence of the element Si in the surface could be clearly observed in the fabrics coated with WPUD containing heptaisobutyl POSS functional groups, as can be observed in the EDS spectra (

Figure 19).

Finally, it is important to underline that all WPUD led to stable coating pastes with good runnability properties with the Werner Mathis coating machine. Therefore, it is to be expected that the WPUD would lead to good results in later stages of industrial scaling.