Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Printers

2.2. Coefficient of Thermal Expansion Studies

2.3. FLIR Camera and Test Setup

2.4. Dimensional Accuracy Prints and Moisture Content

2.5. Metrology

2.6. Microscopy

3. Results and Discussion

3.1. Coefficient of Thermal Expansion

3.2. Effects of CTE during Printing

3.3. Role of Moisture in Dimensional Stability

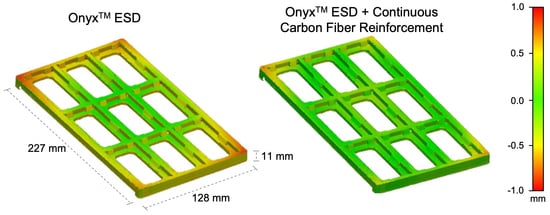

3.4. Mitigation of Dimensional Change with Continuous Fiber Reinforcement

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wohlers, T. Wohlers Report 2021. In Wohlers Associates; Wohlers Associates Inc.: Fort Collins, CO, USA, 2021. [Google Scholar]

- Krajangsawasdi, N.; Blok, L.G.; Hamerton, I.; Longana, M.L.; Woods, B.K.S.; Ivanov, D.S. Fused Deposition Modelling of Fibre Reinforced Polymer Composites: A Parametric Review. J. Compos. Sci. 2021, 5, 29. [Google Scholar] [CrossRef]

- Sanei, S.; Popescu, D. 3D-Printed Carbon Fiber Reinforced Polymer Composites: A Systematic Review. J. Compos. Sci. 2020, 4, 98. [Google Scholar] [CrossRef]

- Popescu, D.; Zapciu, A.; Amza, C.; Baciu, F.; Marinescu, R. FDM process parameters influence over the mechanical properties of polymer specimens: A review. Polym. Test. 2018, 69, 157–166. [Google Scholar] [CrossRef]

- Ding, S.; Zou, B.; Wang, P.; Ding, H. Effects of nozzle temperature and building orientation on mechanical properties and microstructure of PEEK and PEI printed by 3D-FDM. Polym. Test. 2019, 78, 105948. [Google Scholar] [CrossRef]

- Attolico, M.A.; Casavola, C.; Cazzato, A.; Moramarco, V.; Renna, G. Effect of extrusion temperature on fused filament fabrication parts orthotropic behaviour. Rapid Prototyp. J. 2019, 26, 639–647. [Google Scholar] [CrossRef]

- Rajpurohit, S.R.; Dave, H.K. Effect of process parameters on tensile strength of FDM printed PLA part. Rapid Prototyp. J. 2018, 24, 1317–1324. [Google Scholar] [CrossRef]

- Ćwikła, G.; Grabowik, C.W.; Kalinowski, K.; Paprocka, I.; Ociepka, P. The influence of printing parameters on selected mechanical properties of FDM/FFF 3D-printed parts. IOP Conf. Series Mater. Sci. Eng. 2017, 227, 012033. [Google Scholar] [CrossRef]

- Akhoundi, B.; Behravesh, A.H. Effect of Filling Pattern on the Tensile and Flexural Mechanical Properties of FDM 3D Printed Products. Exp. Mech. 2019, 59, 883–897. [Google Scholar] [CrossRef]

- Terekhina, S.; Skornyakov, I.; Tarasova, T.; Egorov, S. Effects of the Infill Density on the Mechanical Properties of Nylon Specimens Made by Filament Fused Fabrication. Technologies 2019, 7, 57. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Faust, J.; Roy-Mayhew, J.D. Drivers of mechanical performance variance in 3D -printed fused filament fabrication parts: An Onyx FR case study. Polym. Compos. 2021, 42, 4786–4794. [Google Scholar] [CrossRef]

- Oberg, E.; Jones, F.; Horton, H.; Ryffel, H. Machinery’s Handbook, 29th ed.; Industrial Press Inc.: New York, NY, USA, 2012; p. 662. [Google Scholar]

- Redwood, B. Dimensional Accuracy of 3D Printed Parts. Available online: https://www.hubs.com/knowledge-base/dimensional-accuracy-3d-printed-parts/ (accessed on 9 September 2021).

- Msallem, B.; Sharma, N.; Cao, S.; Halbeisen, F.; Zeilhofer, H.-F.; Thieringer, F.M. Evaluation of the Dimensional Accuracy of 3D-Printed Anatomical Mandibular Models Using FFF, SLA, SLS, MJ, and BJ Printing Technology. J. Clin. Med. 2020, 9, 817. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdullah, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. Part B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Reuvers, N.; Huinink, H.; Adan, O. Plasticization lags behind water migration in nylon-6: An NMR imaging and relaxation study. Polymer 2015, 63, 127–133. [Google Scholar] [CrossRef]

- Valentin, D.; Paray, F.; Guetta, B. The hygrothermal behaviour of glass fibre reinforced Pa66 composites: A study of the effect of water absorption on their mechanical properties. J. Mater. Sci. 1987, 22, 46–56. [Google Scholar] [CrossRef]

- Kikuchi, B.C.; Bussamra, F.L.D.S.; Donadon, M.V.; Ferreira, R.T.L.; Sales, R.D.C.M. Moisture effect on the mechanical properties of additively manufactured continuous carbon fiber-reinforced Nylon-based thermoplastic. Polym. Compos. 2020, 41, 5227–5245. [Google Scholar] [CrossRef]

- Ding, Q.; Li, X.; Zhang, D.; Zhao, G.; Sun, Z. Anisotropy of poly(lactic acid)/carbon fiber composites prepared by fused deposition modeling. J. Appl. Polym. Sci. 2019, 137, 48786. [Google Scholar] [CrossRef]

- Bharvirkar, M.; Nquyen, P.; Pistor, C. Thermo-mechanical analysis of parts fabricated via fused deposition modeling (FDM). In Proceedings of the 1999 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 9 August 1999. [Google Scholar]

- Baker, A.M.; McCoy, J.; Majumdar, B.S.; Rumley-Ouellette, B.J.; Wahry, J.; Marchi, A.N.; Bernardin, J.D.; Spernjak, D. Testing and Simulation of Thermal and Mechanical Properties of Additively Manufactured Parts Using Fused Deposition Modelling (FDM). 2018. Available online: https://www.osti.gov/servlets/purl/1463519 (accessed on 9 September 2021).

- Stratasys. FDM Nylon 12 Material Data Sheet. Available online: https://www.stratasys.com/materials/search/fdm-nylon-12 (accessed on 9 September 2021).

- Stratasys. FDM Nylon 12CF Material Data Sheet. Available online: https://www.stratasys.com/materials/search/fdm-nylon-12cf (accessed on 9 September 2021).

- Pradere, C.; Sauder, C. Transverse and longitudinal coefficient of thermal expansion of carbon fibers at high temperatures (300–2500K). Carbon 2008, 46, 1874–1884. [Google Scholar] [CrossRef]

- Kulkarni, R.; Ochoa, O. Transverse and Longitudinal CTE Measurements of Carbon Fibers and their Impact on Interfacial Residual Stresses in Composites. J. Compos. Mater. 2005, 40, 733–754. [Google Scholar] [CrossRef]

- Alsoufin, M.S.; Elsayed, A.E. Warping Deformation of Desktop 3D Printed Parts Manufactured by Open Source Fused Deposition Modeling (FDM) System. Int. J. Mech. Mechatron. Eng. 2017, 17, 7–16. [Google Scholar]

- Butt, J.; Bhaskar, R. Investigating the Effects of Annealing on the Mechanical Properties of FFF-Printed Thermoplastics. J. Manuf. Mater. Process. 2020, 4, 38. [Google Scholar] [CrossRef]

| Temperature Range [°C] | Coefficient of Thermal Expansion [10−5 1/°C] |

|---|---|

| 25–40 | 4.2 |

| 40–60 | 3.1 |

| 60–75 | 4.6 |

| 75–100 | 4.0 |

| 100–120 | 2.8 |

| 120–150 | 3.5 |

| 25–150 (overall) | 3.6 |

| Material | Coefficient of Thermal Expansion [10−5 1/°C] | |||

|---|---|---|---|---|

| XY | ZX | |||

| 0° (Flow) | 45°/−45° | 90° (x-Flow) | 0° | |

| Onyx | 2.2 | 3.6 | 9.5 | 24.8 |

| Onyx FR | 2.4 | 3.0 | 8.4 | 17.2 |

| Onyx ESD | 4.6 | 8.2 | 9.6 | 18.5 |

| Nylon White | 17.5 | 13.2 | 11.4 | 16.1 |

| Fill Angle | Coefficient of Thermal Expansion [10−5 1/°C] | |

|---|---|---|

| Onyx, Infill Only | Onyx, Infill + Shell | |

| 0° | 2.3 | 2.2 |

| 45°/−45° | 3.6 | 4.5 |

| 90° | 9.5 | 6.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Faust, J.L.; Kelly, P.G.; Jones, B.D.; Roy-Mayhew, J.D. Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts. Polymers 2021, 13, 3637. https://doi.org/10.3390/polym13213637

Faust JL, Kelly PG, Jones BD, Roy-Mayhew JD. Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts. Polymers. 2021; 13(21):3637. https://doi.org/10.3390/polym13213637

Chicago/Turabian StyleFaust, Jessica L., Peter G. Kelly, Bruce D. Jones, and Joseph D. Roy-Mayhew. 2021. "Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts" Polymers 13, no. 21: 3637. https://doi.org/10.3390/polym13213637

APA StyleFaust, J. L., Kelly, P. G., Jones, B. D., & Roy-Mayhew, J. D. (2021). Effects of Coefficient of Thermal Expansion and Moisture Absorption on the Dimensional Accuracy of Carbon-Reinforced 3D Printed Parts. Polymers, 13(21), 3637. https://doi.org/10.3390/polym13213637