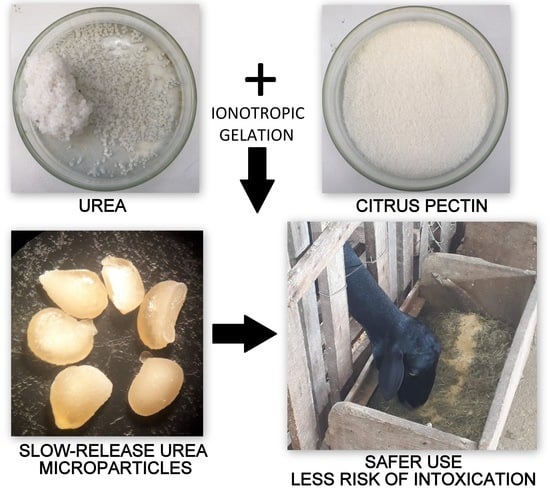

Polymeric Microparticles of Calcium Pectinate Containing Urea for Slow Release in Ruminant Diet

Abstract

:1. Introduction

2. Materials and Methods

2.1. Obtaining and Characterization of Microencapsulated Systems

2.2. Ethical Considerations, Animals, Diets and General Procedures

2.3. Degradation Kinetics and Ruminal and Blood Serum Parameters

2.4. Blood Metabolites

2.5. Statistical Analysis

3. Results

3.1. Characterization of Microencapsulated Systems

3.2. Degradation Kinetics and Ruminal and Blood Serum Parameters

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geron, L.J.V.; Garcia, J.; de Aguiar, S.C.; da Costa, F.G.; da Silva, A.P.; Sousa Neto, E.L.; de Carvalho, J.T.H.; Roberto, L.S.; Coelho, K.S.M.; Santos, I.S. Effect of slow release urea in sheep feed on nitrogen balance. Semina Ciencias Agr. 2018, 39, 683–696. [Google Scholar] [CrossRef] [Green Version]

- Calomeni, G.D.; Gardinal, R.; Ventureli, B.C.; de Freitas, J.E., Jr.; Vendramini, T.H.A.; Takiya, C.S.; de Souza, H.N.; Rennó, F.P. Effects of polymer-coated slow-realese urea on performance, ruminal fermentation, and blood, metabolites in dairy cows. Rev. Bras. Zootec. 2015, 44, 327–334. [Google Scholar] [CrossRef] [Green Version]

- Van Soest, P.J. Nutritional Ecology of the Ruminant; Cornell University: Ithaca, NY, USA, 1994. [Google Scholar]

- Patra, A.K. Rumen Microbiology: From Evolution to Revolution; Puniya, A.K., Singh, R., Kamra, D.N., Eds.; Springer: Basingstoke, Reino Unido, 2015; pp. 329–341. [Google Scholar]

- Patra, A.K.; Aschenbach, J.R. Ureases in the gastrointestinal tracts of ruminant and monogastric animals and their implication in urea-N/ammonia metabolism: A review. J. Adv. Res. 2018, 13, 39–50. [Google Scholar] [CrossRef]

- De Medeiros, T.T.B.; Silva, A.M.D.A.; Da Silva, A.L.; Bezerra, L.R.; Agostini, D.L.D.S.; De Oliveira, D.L.V.; Mazzetto, S.E.; Kotzebue, L.R.V.; Oliveira, J.R.; Souto, G.S.B.; et al. Carnauba wax as a wall material for urea microencapsulation. J. Sci. Food Agric. 2019, 99, 1078–1087. [Google Scholar] [CrossRef]

- Campos, A.C.; Silva, A.L.; Silva, A.M.; Filho, J.M.A.; Costa, T.; Filho, J.M.P.; Oliveira, J.P.; Bezerra, L.R. Dietary replacement of soybean meal with lipid matrix-encapsulated urea does not modify milk production and composition in dairy goats. Anim. Feed. Sci. Technol. 2020, 274, 114763. [Google Scholar] [CrossRef]

- Souza, V.L.; Almeida, R.; Silva, D.F.F.; Piekarski, P.R.B.; Jesus, C.P.; Pereira, M.N. Effects of partial replacement of soybean meal by protected urea on milk yield and composition. Arq. Bras. Med. Vet. Zoot. 2010, 62, 1415–1422. [Google Scholar] [CrossRef] [Green Version]

- Carvalho, A.D.B.; da Silva, A.; Netto, A.; de Medeiros, T.; Filho, J.A.; Agostini, D.D.S.; de Oliveira, D.; Mazzetto, S.; Kotzebue, L.; Oliveira, J.; et al. Effect of slow-release urea microencapsulated in beeswax and its inclusion in ruminant diets. Small Rumin. Res. 2019, 179, 56–63. [Google Scholar] [CrossRef]

- de Carvalho Neto, J.P.; Bezerra, L.R.; da Silva, A.L.; de Moura, J.F.P.; Pereira Filho, J.M.; da Silva Filho, E.C.; Guedes, A.F.; Araújo, M.J.; Edvan, R.L.; Oliveira, R.L. Methionine microencapsulated with a carnauba (Copernicia prunifera) wax matrix for protection from degradation in the rumen. Livest. Sci. 2019, 228, 53–60. [Google Scholar] [CrossRef]

- Mohnen, D. Pectin structure and biosynthesis. Curr. Opin. Plant. Biol. 2008, 11, 266–277. [Google Scholar] [CrossRef]

- Zema, D.A.; Calabrò, P.S.; Folino, A.; Tamburino, V.; Zappia, G.; Zimbone, S.M. Valorisation of citrus processing waste: A review. Waste Manag. 2018, 80, 252–273. [Google Scholar] [CrossRef] [PubMed]

- Huang, J.; Liao, J.; Qi, J.; Jiang, W.; Yang, X. Structural and physicochemical properties of pectin-rich dietary fiber prepared from citrus peel. Food Hydrocoll. 2021, 110, 106140. [Google Scholar] [CrossRef]

- Morris, G.A.; Ralet, M.C.; Bonnin, E.; Thibault, J.F.; Harding, S.E. Physical characterisation of the rhamnogalacturonan and homogalacturonan fractions of sugar beet (Beta vulgaris) pectin. Carbohydr. Polym. 2010, 82, 1161–1167. [Google Scholar] [CrossRef] [Green Version]

- Shtriker , M.G.; Hahn, M.; Taieb, E.; Nyska, A.; Moallem, U.; Tirosh, O.; Madar, Z. Fenugreek galactomannan and citrus pectin improve several parameters associated with glucose metabolism and modulate gut microbiota in mice. Nutrition 2018, 46, 134–142. [Google Scholar] [CrossRef]

- Ben-Ghedalia, D.; Yosef, E.; Miron, J.; Est, Y. The effects of starch- and pectin-rich diets on quantitative aspects of digestion in sheep. Anim. Feed Sci. Technol. 1989, 24, 289–298. [Google Scholar] [CrossRef]

- Alves, E.M.; Magalhães, D.R.; Freitas, M.A.; Santos, E.D.J.D.; Pereira, M.L.A.; Pedreira, M.D.S. Nitrogen metabolism and microbial synthesis in sheep fed diets containing slow release urea to replace the conventional urea. Acta Sci. Anim. Sci. 2014, 36, 55–62. [Google Scholar] [CrossRef] [Green Version]

- Alves, F.J.L.; Ferreira, M.A.; Urbano, S.A.; Andrade, R.P.X.; Silva, A.E.M.; Siqueira, M.C.B.; Oliveira, J.P.F.; Silva, J.L. Performance of lambs fed alternative protein sources to soybean meal. Rev. Bras. Zootec. 2016, 45, 145–150. [Google Scholar] [CrossRef] [Green Version]

- Nedovica, V.; Kalusevica, A.; Manojlovicb, V.; Levica, S.; Bugarskib, B. An overview of encapsulation technologies for food applications. Proc. Food Sci. 2010, 1, 1806–1815. [Google Scholar] [CrossRef] [Green Version]

- AOAC. Official Methods of Analysis of AOAC, 12th ed.; AOAC International: Gaithersburg, MD, USA, 1990. [Google Scholar]

- Brazil. Resolução Normativa No. 39, de 20 de Junho de 2018. Ministério da Ciência, Tecnologia, Inovações e Comunicações. Dispõe Sobre Restrições ao Uso de Animais em Procedimentos Classificados com Grau de Invasividade 3 e 4, em Complemento à Diretriz Brasileira Para o Cuidado e a Utilização de Animais em Atividades de Ensino ou de Pesquisa Científica-DBCA. Available online: http://www.mctic.gov.br/mctic/opencms/institucional/concea/arquivos/ (accessed on August 2021).

- NRC. Nutrient Requirements of Small Ruminants: Sheep, Goats, Cervids and New World Camelids, 3rd ed.; The National Academies Press: Washington, DC, USA, 2007. [Google Scholar]

- Van Soest, P.J.; Robertson, J.B.; Lewis, B.A. Methods for dietary fiber, neutral detergent fiber, and nonstarch polyssacharides in relation to animal nutrition. J. Dairy Sci. 1991, 74, 3583–3597. [Google Scholar] [CrossRef]

- Senger, C.C.D.; Kozloski, G.V.; Snachez, L.M.B.; Mesquita, F.R.; Alves, T.P.; Castagnino, D.S. Evalution of autoclave procedures for fibre analysis in forage and concetrate feedstuffs. Anim. Feed Sci. Technol. 2008, 146, 169–174. [Google Scholar] [CrossRef]

- Hall, M.B. Neutral Detergent-Soluble Carbohydrates. Nutritional Relevance and Analysis: A Laborary Manual; University of Florida: Gainesville, FL, USA, 2000. [Google Scholar]

- Ørskov, E.R.; McDonald, T. The estimation of protein degradability in the rumen from incubation measurements weighted according to rate passage. J. Agric. Sci. 1979, 92, 499–503. [Google Scholar] [CrossRef] [Green Version]

- SAS. SAS Systems for Windows; Version 9.1; SAS Institute Inc.: Cary, NC, USA, 2003. [Google Scholar]

- Noh, J.; Kim, J.; Kim, J.S.; Chung, Y.S.; Chang, S.T.; Park, J. Microencapsulation by pectin for multi-components carriers bearing both hydrophobic and hydrophilic active agents. Carbohydr. Polym. 2018, 182, 172–179. [Google Scholar] [CrossRef] [PubMed]

- Williams, A.G.; Coleman, G.S. The Rumen Protozoa; Springer: New York, NY, USA, 1992. [Google Scholar]

- Newbold, C.J.; De La Fuente, G.; Belanche, A.; Ramos-Morales, E.; McEwan, N. The Role of Ciliate Protozoa in the Rumen. Front. Microbiol. 2015, 6, 1313. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ng, F.; Kittelmann, S.; Patchett, M.L.; Attwood, G.T.; Janssen, P.H.; Rakonjac, J.; Gagic, D. An adhesin from hydrogenutilizing rumen methanogen Methanobrevibacter ruminantium M1 binds a broad range of hydrogen-producing microorganisms. Environ. Microbiol. 2016, 18, 3010–3021. [Google Scholar] [CrossRef] [PubMed]

- Alcaide, E.M.; Martín-García, A.I.; Aguilera, J.F. A comparative study of nutrient digestibility, kinetics of degradation and passage and rumen fermentation pattern in goats and sheep offered good quality diets. Livest. Prod. Sci. 2000, 64, 215–223. [Google Scholar] [CrossRef]

- Patra, A.K.; Saxena, J. The effect and mode of action of saponins on the microbial populations and fermentation in the rumen and ruminant production. Nutr. Res. Rev. 2009, 22, 204–219. [Google Scholar] [CrossRef] [PubMed]

- Bezerra, L.R.; Oliveira, W.D.C.; Silva, T.P.D.; Torreao, J.N.C.; Marques, C.A.T.; Araujo, M.J.; Oliveira, R.L. Comparative hematological analysis of Morada Nova and Santa Inês ewes in all reproductive stages. Pesq. Vet. Bras. 2017, 37, 408–414. [Google Scholar] [CrossRef] [Green Version]

- Kaneko, J.J.; Harvey, J.W.; Bruss, M.L. Clinical Biochemistry of Domestic Animals, 6th ed.; Academic: San Diego, CA, USA, 2008. [Google Scholar]

- Ziguer, E.A.; Roll, V.F.B.; Bermudes, R.F.; Montagner, P.; Pfeiter, L.F.M.; Pino, F.A.B.D.; Corrêa, M.N.; Dionello, N.J.L. Performance and metabolic pattern of feedlot lambs using soyabean hulls associated to different non-protein nitrogen sources. Rev. Bras. Zootec. 2012, 41, 449–456. [Google Scholar] [CrossRef] [Green Version]

- Netto, A.J.; Silva, A.M.D.A.; Bezerra, L.R.; Carvalho, A.D.B.; Agostini, D.L.D.S.; de Oliveira, D.L.V.; Mazzetto, S.E.; Kotzebue, L.R.V.; Oliveira, J.R.; Oliveira, R.L.; et al. Lipid microspheres containing urea for slow release of nonprotein N in ruminant diets. Anim. Prod. Sci. 2021, acepted. [Google Scholar]

- Kozloski, G.V. Bioquímica dos Ruminantes, 3rd ed.; Editora UFSM: Santa Maria, Brazil, 2011. [Google Scholar]

| Item | Ingredients | |||||||

|---|---|---|---|---|---|---|---|---|

| Chemical Composition (g/kg DM) | Tifton-85 Hay | Soybean Meal | Ground Corn | MPec1 | MPec2 | MPec3 | MPec 3 | Urea |

| Dry matter (g/kg as fed) | 872 | 907 | 889 | 990 | 990 | 990 | 990 | - |

| Ash | 60.3 | 70.1 | 15.1 | - | - | - | - | - |

| Crude protein | 54.1 | 489 | 93.9 | 740 | 796 | 875 | 77.3 | 2800 |

| Ether extract | 10.8 | 54.9 | 30.1 | 24.3 | 24.3 | 24.3 | 24.3 | - |

| Neutral detergent fiber | 728 | 198 | 158 | 219 | 219 | 219 | 219 | - |

| Acid detergent fiber | 371 | 95.2 | 43.0 | - | - | - | - | - |

| Nonfibrous carbohydrate | 138 | 487 | 751 | 59.5 | 59.5 | 59.5 | 59.5 | - |

| Experimental diets | ||||||||

| Ingredient proportion (g/kg DM) | Urea | MPec1 | MPec2 | MPec3 | MPec | |||

| Tifton-85 hay | 600 | 600 | 600 | 600 | 600 | |||

| Soybean meal | 60.0 | 80.0 | 80.0 | 80.0 | 90.0 | |||

| Ground corn | 325 | 305 | 305 | 305 | 295 | |||

| Encapsulation material 1 | 5.00 | 5.00 | 5.00 | 5.00 | 5.00 | |||

| Mineral mixture 2 | 10.0 | 10.0 | 10.0 | 10.0 | 10.0 | |||

| Chemical composition (g/kg DM) | ||||||||

| Dry matter (g/kg as fed) | 881 | 882 | 882 | 882 | 882 | |||

| Ash | 55.2 | 56.3 | 56.3 | 56.3 | 5.68 | |||

| Crude protein | 106 | 104 | 104 | 105 | 105 | |||

| Ether extract | 19.6 | 2.02 | 2.02 | 2.02 | 2.04 | |||

| Neutral detergent fiber | 500 | 501 | 501 | 501 | 502 | |||

| Acid detergent fiber | 243 | 244 | 244 | 244 | 244 | |||

| Nonfibrous carbohydrate | 356 | 354 | 354 | 354 | 351 | |||

| Variables (%) | Microencapsulated Urea | p-Value 1 | ||

|---|---|---|---|---|

| MPec1 | Mpec2 | Mpec3 | ||

| Microencapsulation yield | 92.2 a ± 0.02 | 93.3 b ± 0.03 | 97.1 c ± 0.04 | <0.01 |

| Microencapsulation efficiency | 262 a ± 1.17 | 218 b ± 1.12 | 264 a ± 1.16 | <0.01 |

| Nitrogen (N) total | 11.2 a ± 0.08 | 12.8 b ± 0.09 | 14.0 c ± 0.10 | <0.01 |

| Crude protein | 70.1 c ± 0.88 | 80.2 b ± 1.06 | 87.5 a ± 0.79 | <0.01 |

| Theoretical urea content | 10.0 c ± 0.0 | 20.0 b ± 0.0 | 30.0 a ± 0.0 | <0.01 |

| Actual urea content | 25.2 b ± 0.48 | 28.4 a ± 0.32 | 31.1 a ± 0.30 | <0.01 |

| Variables | Microencapsulated Urea | p-Value | |||

|---|---|---|---|---|---|

| MPec1 | MPec2 | MPec3 | MPec | ||

| Dry matter (DM) | |||||

| a 1 (%) | 14.5 b ± 3.42 | 16.5 b ± 1.49 | 21.1 c ± 6.58 | 11.9 a ± 3.61 | <0.01 |

| b 2 (%) | 66.2 ab ± 12.00 | 68.2 ab ± 1.55 | 63.5 b ± 12.26 | 70.1 a ± 6.14 | <0.01 |

| U 3 (%) | 19.2 a ± 5.88 | 15.3 b ± 3.04 | 15.4 b ± 5.90 | 18.0 a ± 8.02 | <0.01 |

| c 4 (%h−1) | 4.48 a ± 2.37 | 0.35 c ± 0.25 | 0.66 c ± 0.25 | 2.67 b ± 0.89 | <0.01 |

| ED 5 (%) | 36.4 ± 11.25 | 19.2 ± 3.74 | 25.9 ± 5.86 | 29.1 ± 8.02 | 0.34 |

| Crude Protein (CP) | |||||

| a 1 (%) | 63.1 b ± 18.02 | 56.3 b ± 7.92 | 12.7 c ± 4.10 | 97.3 a ± 0.05 | <0.01 |

| b 2 (%) | 33.6 b ± 10.95 | 40.6 b ± 8.92 | 79.5 a ± 10.58 | 2.10 c ± 0.33 | <0.01 |

| U 3 (%) | 3.33 ab ± 1.04 | 3.15 ab ± 1.12 | 7.81 a ± 6.11 | 0.56 b ± 0.27 | <0.01 |

| c 4 (%h−1) | 7.17 b ± 3.93 | 3.57 c ± 0.69 | 9.08 a ± 1.80 | 9.30 a ± 4.87 | <0.01 |

| ED 5 (%) | 80.1 b ± 3.66 | 68.5 c ± 6.63 | 54.7 d ± 0.74 | 98.2 a ± 0.58 | <0.01 |

| Metabolites | Microencapsulated Urea | Free | p-Value | |||

|---|---|---|---|---|---|---|

| MPec1 | MPec2 | MPec3 | Urea | MPec | ||

| Albumin (g/dL) | 2.78 a ± 0.11 | 2.69 a ± 0.20 | 2.21 b ± 0.35 | 2.36 b ± 0.24 | 2.23 b ± 0.32 | 0.03 |

| Total protein (g/dL) | 6.53 a ± 0.27 | 6.35 a ± 0.45 | 5.23 b ± 0.78 | 5.54 b ± 0.61 | 5.32 b ± 0.81 | <0.01 |

| BUN 3 (mg/dL) | 52.7 b ± 6.49 | 53.7 b ± 8.17 | 58.0 a ± 9.13 | 52.4 b ± 11.26 | 37.8 c ± 6.28 | <0.01 |

| Creatinine (mg/dL) | 0.64 a ± 0.09 | 0.64 a ± 0.14 | 0.53 b ± 0.14 | 0.50 b ± 0.10 | 0.47 b ± 0.10 | 0.028 |

| Cholesterol (mg/dL) | 29.0 a ± 5.87 | 29.4 a ± 8.81 | 22.8 b ± 6.09 | 24.5 b ± 5.11 | 22.6 b ± 3.62 | <0.01 |

| Triglycerides (mg/dL) | 14.9 ± 6.40 | 16.1 ± 3.78 | 14.2 ± 4.63 | 13.4 ± 4.85 | 15.1 ± 5.43 | 0.64 |

| Calcium (mmol/L) | 2.68 ± 0.39 | 2.72 ± 0.46 | 2.93 ± 0.22 | 2.76 ± 0.31 | 2.64 ± 0.35 | 0.53 |

| Chlorine (mmol/L) | 110 ± 6.19 | 110 ± 5.12 | 112 ± 3.25 | 115 ± 17.26 | 109 ± 16.92 | 0.55 |

| Potassium (mmol/L) | 5.58 ± 2.57 | 8.64 ± 6.41 | 10.3 ± 3.15 | 4.97 ± 2.45 | 4.67 ± 0.99 | 0.48 |

| Sodium (mmol/L) | 141 ± 9.72 | 136 ± 9.38 | 132 ± 3.18 | 144 ± 21.68 | 136 ± 21.50 | 0.23 |

| AST 4 (U/L) | 59.2 ab ± 13.31 | 53.7 ab ± 10.40 | 41.6 b ± 10.66 | 65.9 a ± 11.52 | 57.1 ab ± 10.69 | <0.01 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melo, M.; da Silva, A.; Silva Filho, E.; Oliveira, R.; Silva Junior, J.; Oliveira, J.P.; Vaz, A.; Moura, J.; Pereira Filho, J.; Bezerra, L. Polymeric Microparticles of Calcium Pectinate Containing Urea for Slow Release in Ruminant Diet. Polymers 2021, 13, 3776. https://doi.org/10.3390/polym13213776

Melo M, da Silva A, Silva Filho E, Oliveira R, Silva Junior J, Oliveira JP, Vaz A, Moura J, Pereira Filho J, Bezerra L. Polymeric Microparticles of Calcium Pectinate Containing Urea for Slow Release in Ruminant Diet. Polymers. 2021; 13(21):3776. https://doi.org/10.3390/polym13213776

Chicago/Turabian StyleMelo, Myrla, André da Silva, Edson Silva Filho, Ronaldo Oliveira, Jarbas Silva Junior, Juliana Paula Oliveira, Antônio Vaz, José Moura, José Pereira Filho, and Leilson Bezerra. 2021. "Polymeric Microparticles of Calcium Pectinate Containing Urea for Slow Release in Ruminant Diet" Polymers 13, no. 21: 3776. https://doi.org/10.3390/polym13213776

APA StyleMelo, M., da Silva, A., Silva Filho, E., Oliveira, R., Silva Junior, J., Oliveira, J. P., Vaz, A., Moura, J., Pereira Filho, J., & Bezerra, L. (2021). Polymeric Microparticles of Calcium Pectinate Containing Urea for Slow Release in Ruminant Diet. Polymers, 13(21), 3776. https://doi.org/10.3390/polym13213776