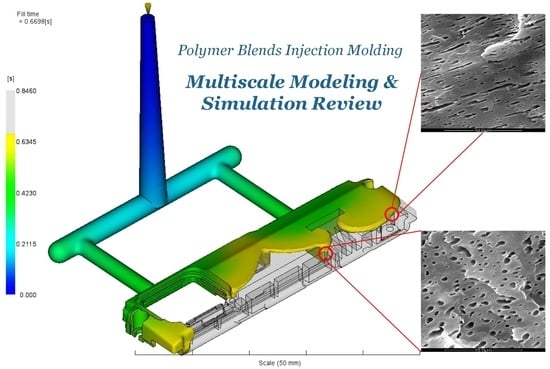

Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review

Abstract

:1. Introduction

2. Framework of Multiscale Modeling

3. Mesoscopic Modeling of Droplet Morphology Evolution

3.1. Ellipsoid Droplet Models

3.1.1. Basic Quantities

3.1.2. Deformation

3.1.3. Breakup

- (1)

- k* < 0.1, droplets do not deform;

- (2)

- 0.1 < k* < 1, droplets deform, but do not break up;

- (3)

- 1 < k* < 4, droplets deform and split into two major sub-droplets;

- (4)

- k* > 4, droplets form fibers with the affine deformation of the medium.

3.1.4. Coalescence

3.1.5. Size Distribution

3.2. Phase Field Models

3.3. Lattice Boltzmann Method

4. Macroscopic Mold-Filling Flow Simulation

5. Scale-Bridging Strategies

5.1. Parameter-Based Methods

5.2. Particle-Based Methods

6. Outlook and Summary

- Polymer melts are mostly viscoelastic fluids. Although the generalized Newtonian fluid model has been able to accurately simulate the filling flow process in most cases, for some products with high requirements on mechanical properties, optical properties, or geometric accuracy, the residual stress caused by viscoelasticity during the filling and packing process is often not negligible. Therefore, how to establish a stable and efficient method for solving the viscoelastic flow solution for the actual product forming process is also an important topic worth studying.

- The energy equation of the filling flow process is significantly convection-dominant, and the boundedness of the discrete scheme of the convection term in the equation has an important impact on the accuracy and stability of the whole filling flow simulation. Therefore, it is necessary to study the discrete scheme of the convection diffusion equation with high accuracy under an unstructured grid to satisfy the boundedness.

- In the simulation of the mold-filling flow process, the solution of the algebraic equation system occupies most of the computational time, among which the solution of the velocity-pressure coupled algebraic equation system takes the most time. Therefore, for the research and development of efficient solution methods for the velocity-pressure-coupled algebraic equation system, shortening the process is also an important part of the next work.

- When the fraction of the blends exceeds a certain range (greater than about 40%), the dispersed phase no longer exists in the form of isolated droplets, and the simulation algorithm based on the ellipsoidal assumption becomes invalid and other morphology models could be considered, such as the interfacial tensor model.

- Most current models of droplet morphology evolution are limited to Newtonian fluids due to the non-uniformity and strong nonlinearity of the viscoelastic constitutive equations. However, the elasticity of the polymer melt has a significant effect on the evolution of droplet morphology, so the role of component elasticity on phase morphology should be considered, for example, by introducing empirical parameters into the models.

- The evolution equation of droplet size distribution is an important way to parameterize the microstructure of the blend. However, the current evolution models are still based on the ellipsoidal droplet assumption, which cannot characterize the complex morphology of the dispersed phase, so there is a need to establish the evolution equations of the dispersed phase distribution based on the tensor form or the component concentration form in the future.

- Compared with traditional Eulerian methods, such as the finite volume method and the finite element method, the SPH method, based on the Lagrangian description, has the natural advantage of automatically recording polymer history in simulating polymer melt flow; however, poor numerical stability, high computational cost, and difficulty in boundary handling confine its further application in simulating polymer processing, which needs to be addressed in the future.

- The rheological constitutive relationship of polymers is the key to realizing the coupling between macroscopic and mesoscopic scales; however, it is not easy to establish the constitutive relationship of polymer blends in traditional equation form. It is a promising alternative to use the current data-driven modeling method based on deep learning to propose the constitutive relationship of polymer blends.

- Since the size of the dispersed phase droplets in the blend is very small and their number is very large, simulating the morphological evolution of the entire dispersed phase during the mold-filling flow is still unaffordable under current computing power, so it is necessary to investigate the use of parallel computing and GPU accelerometers to increase the efficiency of the simulation and the use of multidimensional fractal theory for the parametric description of dispersed phase morphology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ηm | polymer viscosity of matrix |

| ηd | polymer viscosity of droplet |

| γ | shear rate |

| Γ | interfacial tension |

| R | droplet radius |

| D0 | droplet diameter |

| Ca | capillary number |

| Cacrit | critical capillary number |

| p | viscosity radio |

| G | ellipsoid droplet tensor |

| L | velocity gradient tensor |

| Df | droplet deformability |

| L | major axis of droplet |

| B | minor axis of droplet |

| W | width of droplet |

| θ | orientation angle of droplet |

| τr | surface-tension relaxation time |

| eij | deformation rate tensor |

| wij | vorticity tensor |

| f1 | MM model parameter |

| f2 | MM model parameter |

| k* | simplified capillary number |

| d | diameter of the split sub-droplet |

| d* | critical diameter of fiber breakup |

| tb | time required for droplet breakup |

| Nd | total number of droplets of volume V |

| Xm | main wave number |

| pcoll | collision probability |

| tloc | local residence time |

| pexp | liquid film discharge probability |

| hc | critical thickness of the liquid film for breakup |

| Deq | diameter at equilibrium |

| diameter at zero component | |

| R* | radii of droplets after coalescence |

| nk | number of droplets of volume kV1 |

| C(i, j) | coalescence coagulation kernel |

| F(i) | overall breakup frequency |

| nf(i) | number of fragments formed at breakup of a droplet of volume iV1 |

| ω(i, j) | probability that a fragment formed by the breakup of a droplet of volume jV1 will have volume iV1 |

| ηαp | apparent viscosity of the blend |

| EDK | volume energy |

| R0 | droplet radius for ϕ = 0 |

| tB* | dimensionless breakup time |

| Rc | critical value for breakup |

| R* | ratio of R and Rc |

| D | diffusion coefficient |

| μ | chemical potential |

| c | concentration of the fluid |

| ξ | thermal noise |

| fσ,α(x,t) | particle probability distribution function |

| eα | discrete particle velocity |

| G(|eα|) | interaction function of pseudo-potential lattice Boltzmann method |

| interaction constant | |

| w(|eα|2) | weight function of LBM |

| ρ | density |

| u | velocity |

| P | pressure |

| T | temperature |

| cp | specific heat |

| λ | heat conductivity |

| η | viscosity |

| A | area tensor |

| dim | dimension |

| vσ | kinematic viscosity of component σ |

| ρσ | density of component σ |

| τσ | relaxation time of component σ |

| jσ | momentum flux of component σ |

References

- Zhou, H. Computer Modeling for Injection Molding: Simulation, Optimization, and Control; Wiley: Hoboken, NJ, USA, 2013. [Google Scholar] [CrossRef]

- Tucker, C.L., III; Moldenaers, P. Microstructural evolution in polymer blends. Ann. Rev. Fluid Mech. 2002, 34, 177–210. [Google Scholar] [CrossRef]

- Ren, M.K.; Gu, J.F.; Li, Z.; Ruan, S.L.; Shen, C.Y. Simulation of polymer melt injection molding filling Flow based on an improved SPH method with modified low-dissipation riemann solver. In Macromol. Theory Simulations; Wiley Online Library: Hoboken, NJ, USA, 2021. [Google Scholar] [CrossRef]

- Ying, J.; Xie, X.; Peng, S.; Zhou, H.; Li, D. Morphology and rheology of PP/POE blends in high shear stress field. J. Thermoplast. Compos. Mater. 2018, 31, 1263–1280. [Google Scholar] [CrossRef]

- Deng, L.; Fan, S.; Zhang, Y.; Huang, Z.G.; Jiang, S.F.; Li, J.Q.; Zhou, H.M. A novel multiscale methodology for simulating droplet morphology evolution during injection molding of polymer blends. Polymers 2021, 13, 133. [Google Scholar] [CrossRef]

- Iza, M.; Bousmina, M. Nonlinear rheology of immiscible polymer blends: Step strain experiments. J. Rheol. 2000, 44, 1363–1384. [Google Scholar] [CrossRef]

- Taylor, G.I. The viscosity of a fluid containing small drops of another fluid. Proc. R. Soc. Lond. Ser. A 1932, 138, 41–48. [Google Scholar]

- Doi, M.; Ohta, T. Dynamics and rheology of complex interfaces. I. J. Chem. Phys. 1991, 95, 1242–1248. [Google Scholar] [CrossRef]

- Maffettone, P.L.; Minale, M. Equation of change for ellipsoidal drops in viscous flow. J. Non-Newton. Fluid Mech. 1998, 78, 227–241. [Google Scholar] [CrossRef]

- Jackson, N.E.; Tucker, C.L. A model for large deformation of an ellipsoidal droplet with interfacial tension. J. Rheol. 2003, 47, 659–682. [Google Scholar] [CrossRef]

- Eshelby, J.D. The Determination of the elastic field of an ellipsoidal inclusion, and related problems. Proc. R. Soc. Math. Phys. Eng. Sci. 1957, 241, 376–396. [Google Scholar] [CrossRef]

- Khakhar, D.V.; Ottino, J.M. Deformation and breakup of slender drops in linear flows. J. Fluid Mech. 1986, 166, 265–285. [Google Scholar] [CrossRef]

- Yu, W.; Bousmina, M. Ellipsoidal model for droplet deformation in emulsions. J. Rheol. 2003, 47, 1011–1039. [Google Scholar] [CrossRef]

- Janssen, J.M.H. Dynamics of liquid-liquid mixing. Polym. Eng. Sci. 1995, 35, 1766–1780. [Google Scholar] [CrossRef] [Green Version]

- Cox, R. The deformation of a drop in a general time-dependent fluid flow. J. Fluid Mech. 1969, 37, 601–623. [Google Scholar] [CrossRef]

- Delaby, I.; Ernst, B.; Froelich, D.; Muller, R. Droplet deformation in immiscible polymer blends during transient uniaxial elongational flow. Polym. Eng. Sci. 1996, 36, 1627–1635. [Google Scholar] [CrossRef]

- Elemans, P. Modelling of Processing of Incompatible Polymer Blends. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 1989. [Google Scholar]

- Huneault, Z.; Shi, H.; Utracki, L.A. Development of polymer blend morphology during compounding in a twin-screw extruder. Part IV: A new computational model with coalescence. Polym. Eng. Sci. 1995, 35, 115–127. [Google Scholar] [CrossRef]

- Debruijn, R.A. Deformation and Breakup of Drops in Simple Shear Flows. Ph.D. Thesis, Technische Universiteit Eindhoven, Eindhoven, The Netherlands, 1991. [Google Scholar]

- Grace, H.P. Dispersion phenomena in high viscosity immiscible fluid systems and application of static mixers as dispersion devices in such systems. Chem. Eng. Commun. 1982, 14, 225–277. [Google Scholar] [CrossRef]

- Rayleigh, L. On the instability of jets. Proc. Lond. Math. Soc. 1878, 1, 4–13. [Google Scholar] [CrossRef] [Green Version]

- Loor, A.D.; Cassagnau, P.; Michel, A.; Vergnes, B. Morphological changes of a polymer blend into a twin-screw extruder. Int. Polym. Process. J. Polym. Process. Soc. 1994, 9, 211–218. [Google Scholar] [CrossRef]

- Forteln, I. Theoretical aspects of phase morphology development. In Micro- and Nanostructured Multiphase Polymer Blend Systems; CRC Press: Boca Raton, FL, USA, 2005. [Google Scholar]

- Tokita, N. Analysis of morphology formation in elastomer blends. Rubber Chem. Technol. 1977, 50, 292–300. [Google Scholar] [CrossRef]

- Fortelný, I.; Jůza, J. Prediction of average droplet size in flowing immiscible polymer blends. J. Appl. Polym. Sci. 2017, 134, 45250. [Google Scholar] [CrossRef]

- Cristini, V.; Guido, S.; Alfani, A.; Blawzdziewicz, J.; Loewenberg, M. Drop breakup and fragment size distribution in shear flow. J. Rheol. 2003, 47, 1283–1298. [Google Scholar] [CrossRef] [Green Version]

- Fortelný, I.; Dimzoski, B.; Michálková, D.; Mikešová, J.; Kaprálková, L. Dependence of the average size of particles formed during steady mixing on their concentration in immiscible polymer blends. J. Macromol. Sci. Part B 2013, 52, 662–673. [Google Scholar] [CrossRef]

- Fortelný, I.; Ostafińska, A.; Michálková, D.; Jůza, J.; Mikešová, J.; Šlouf, M. Phase structure evolution during mixing and processing of poly(lactic acid)/polycaprolactone (PLA/PCL) blends. Polym. Bull. 2015, 72, 2931–2947. [Google Scholar] [CrossRef]

- Patlazhan, S.A.; Lindt, J.T. Kinetics of structure development in liquid-liquid dispersions under simple shear flow—Theory. J. Rheol. 1996, 40, 1095–1113. [Google Scholar] [CrossRef]

- Janssen, J. Emulsions: The dynamics of liquid-liquid mixing. In Materials Science and Technology; Wiley: Hoboken, NJ, USA, 2006. [Google Scholar]

- Delamare, L.; Vergnes, B. Computation of the morphological changes of a polymer blend along a twin-screw extruder. Polym. Eng. Sci. 1996, 36, 1685–1693. [Google Scholar] [CrossRef]

- Potente, H.; Bastian, M. Calculating morphology development of polymer blends in extruders on the basis of results of boundary and finite element simulations using the sigma simulation software. Polym. Eng. Sci. 2000, 40, 727–737. [Google Scholar] [CrossRef]

- Peters, G.W.M.; Hansen, S.; Meijer, H.E.H. Constitutive modeling of dispersive mixtures. J. Rheol. 2001, 45, 659–689. [Google Scholar] [CrossRef] [Green Version]

- Lee, H.M.; Park, O.O. Rheology and dynamics of immiscible polymer blends. J. Rheol. 1994, 38, 1405–1425. [Google Scholar] [CrossRef]

- Wong, W.-H.B.; Janssen, P.J.A.; Hulsen, M.A.; Anderson, P.D. Numerical simulations of the polydisperse droplet size distribution of disperse blends in complex flow. Rheol. Acta 2021, 60, 187–207. [Google Scholar] [CrossRef]

- Spencer, R.; Gilmore, G. Some flow phenomena in the injection molding of polystyrene. J. Colloid Sci. 1951, 6, 118–132. [Google Scholar] [CrossRef]

- Kovács, M.; Larsson, S.; Mesforush, A. Finite element approximation of the Cahn–Hilliard–Cook equation. SIAM J. Numer. Anal. 2011, 49, 2407–2429. [Google Scholar] [CrossRef] [Green Version]

- Prusty, M.; Keestra, B.; Goossens, J.; Anderson, P. Experimental and computational study on structure development of PMMA/SAN blends. Chem. Eng. Sci. 2007, 62, 1825–1837. [Google Scholar] [CrossRef]

- Koehler, W.; Krekhov, A.; Zimmermann, W. Thermal diffusion in polymer blends: Criticality and pattern formation. In Complex Macromolecular Systems I; Muller, A.H.E., Schmidt, H.W., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; Volume 227, pp. 145–198. [Google Scholar]

- Keestra, B.J.; Goossens, J.G.P.; Anderson, P.D. Structure development of PMMA/SAN blends in shear flow. Chem. Eng. Sci. 2011, 66, 4960–4971. [Google Scholar] [CrossRef]

- Parsa, M.A.; Ghiass, M.; Moghbeli, M.R. Mathematical modelling and phase separation kinetics of polystyrene/polyvinylmethylether blend. Iran. Polym. J. 2011, 20, 689–696. [Google Scholar]

- Carolan, D.; Chong, H.M.; Ivankovic, A.; Kinloch, A.J.; Taylor, A.C. Co-continuous polymer systems: A numerical investigation. Comput. Mater. Sci. 2015, 98, 24–33. [Google Scholar] [CrossRef] [Green Version]

- Tabatabaieyazdi, M.; Chan, P.K.; Wu, J. A computational study of long range surface-directed phase separation in polymer blends under a temperature gradient. Comput. Mater. Sci. 2016, 111, 387–394. [Google Scholar] [CrossRef]

- Jelic, A.; Ilg, P.; Ottinger, H.C. Bridging length and time scales in sheared demixing systems: From the Cahn-Hilliard to the Doi-Ohta model. Phys. Rev. E 2010, 81, 011131. [Google Scholar] [CrossRef] [Green Version]

- Zander, C.; Hopp-Hirschler, M.; Nieken, U. Mesoscopic simulation and characterization of the morphological evolution in phase separating fluid mixtures. Comput. Mater. Sci. 2018, 149, 267–281. [Google Scholar] [CrossRef]

- Rothman, D.H.; Keller, J.M. Immiscible cellular-automaton fluids. J. Stat. Phys. 1988, 52, 1119–1127. [Google Scholar] [CrossRef]

- Gunstensen, A.K.; Rothman, D.H.; Zaleski, S.; Zanetti, G. Lattice Boltzmann model of immiscible fluids. Phys. Rev. A 1991, 43, 4320. [Google Scholar] [CrossRef]

- Shan, X.; Chen, H. Simulation of nonideal gases and liquid-gas phase transitions by the lattice Boltzmann equation. Phys. Rev. E 1994, 49, 2941–2948. [Google Scholar] [CrossRef] [Green Version]

- Swift, M.R.; Orlandini, E.; Osborn, W.R.; Yeomans, J.M. Lattice Boltzmann simulations of liquid-gas and binary fluid systems. Phys. Rev. E 1996, 54, 5041. [Google Scholar] [CrossRef] [PubMed]

- He, X.Y.; Chen, S.Y.; Zhang, R.Y. A lattice Boltzmann scheme for incompressible multiphase flow and its application in simulation of Rayleigh-Taylor instability. J. Comput. Phys. 1999, 152, 642–663. [Google Scholar] [CrossRef]

- Shan, X.; Doolen, G. Multicomponent lattice-Boltzmann model with interparticle interaction. J. Stat. Phys. 1995, 81, 379–393. [Google Scholar] [CrossRef] [Green Version]

- Pantani, R.; Speranza, V.; Titomanlio, G. Thirty years of modeling of injection molding. A brief review of the contribution of UNISA code to the Field. Int. Polym. Proc. 2016, 31, 655–663. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Pantani, R.; Titomanlio, G. Modeling of the injection molding process coupled with the fast mold temperature evolution. J. Electrochem. Soc. 2019, 166, B3148–B3155. [Google Scholar] [CrossRef]

- Li, Q.; Ouyang, J.; Wu, G.; Xu, X. Numerical simulation of melt filling and gas penetration in gas assisted injection molding. Comput. Model. Eng. Sci. 2011, 82, 215–232. [Google Scholar] [CrossRef]

- Vietri, U.; Sorrentino, A.; Speranza, V.; Pantani, R. Improving the predictions of injection molding simulation software. Polym. Eng. Sci. 2011, 51, 2542–2551. [Google Scholar] [CrossRef]

- He, L.; Lu, G.; Chen, D.; Li, W.; Lu, C. Three-dimensional smoothed particle hydrodynamics simulation for injection molding flow of short fiber-reinforced polymer composites. Model. Simul. Mater. Sci. Eng. 2017, 25, aa6dc9. [Google Scholar] [CrossRef]

- Liang, J.; Luo, W.; Huang, Z.; Zhou, H.; Zhang, Y.; Zhang, Y.; Fu, Y. A robust finite volume method for three-dimensional filling simulation of plastic injection molding. Eng. Comput. 2017, 34, 814–831. [Google Scholar] [CrossRef]

- Xu, X.Y.; Yu, P. Modeling and simulation of injection molding process of polymer melt by a robust SPH method. Appl. Math. Model. 2017, 48, 384–409. [Google Scholar] [CrossRef]

- Liu, Q.S.; Liu, Y.Q.; Jiang, C.T.; Wang, X.H. Numerical simulation of viscoelastic flows during injection mold filling based on Rolie–Poly model. J. Non-Newton. Fluid Mech. 2019, 263, 140–153. [Google Scholar] [CrossRef]

- Yu, W.; Zhou, C. A simple constitutive equation for immiscible blends. J. Rheol. 2007, 51, 179–194. [Google Scholar] [CrossRef]

- Zou, F.S.; Dong, X.; Lin, D.M.; Liu, W.; Wang, D.J.; Han, C.C. Morphological and rheological responses to the transient and steady shear flow for a phase-separated polybutadiene/polyisoprene blend. Polymer 2012, 53, 4818–4826. [Google Scholar] [CrossRef]

- Mwasame, P.M.; Wagner, N.J.; Beris, A.N. On the macroscopic modelling of dilute emulsions under flow. J. Fluid Mech. 2017, 831, 433–473. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Wang, J.; Fan, X.; Kong, Y.; Gao, H. An effective bead–spring model for polymer simulation. J. Comput. Phys. 2008, 227, 2794–2807. [Google Scholar] [CrossRef]

- Datta, R.; Yelash, L.; Schmid, F.; Kummer, F.; Oberlack, M.; Lukáčová-Medvid’ová, M.; Virnau, P. Shear-thinning in oligomer melts—Molecular origins and applications. Polymers 2021, 13, 2806. [Google Scholar] [CrossRef]

- Ryder, J.F.; Yeomans, J.M. Shear thinning in dilute polymer solutions. J. Chem. Phys. 2006, 125, 194906. [Google Scholar] [CrossRef] [PubMed]

- Cruz, C.; Chinesta, F.; Regnier, G. Review on the brownian dynamics simulation of bead-rod-spring models encountered in computational rheology. Arch. Comput. Methods Eng. 2012, 19, 227–259. [Google Scholar] [CrossRef] [Green Version]

- Fetsko, S.W.; Cummings, P.T. Brownian dynamics simulation of bead–spring chain models for dilute polymer solutions in elongational flow. J. Rheol. 1995, 39, 285–299. [Google Scholar] [CrossRef] [Green Version]

- Townsend, A.K.; Wilson, H.J. Small-and large-amplitude oscillatory rheometry with bead–spring dumbbells in Stokesian Dynamics to mimic viscoelasticity. J. Non-Newton. Fluid Mech. 2018, 261, 136–152. [Google Scholar] [CrossRef]

- Vladkov, M.; Barrat, J.-L. Linear and nonlinear viscoelasticity of a model unentangled polymer melt: Molecular dynamics and rouse modes analysis. Macromol. Theory Simul. 2006, 15, 252–262. [Google Scholar] [CrossRef]

- Gennes, P.G.D. Reptation of a polymer chain in the presence of fixed obstacles. J. Chem. Phys. 1971, 55, 572–579. [Google Scholar] [CrossRef]

- Doi, M.; Edwards, S.F. Dynamics of concentrated polymer systems. Part 3—The constitutive equation. J. Chem. Soc. Faraday Trans. 2 Mol. Chem. Phys. 1978, 74, 1818–1832. [Google Scholar] [CrossRef]

- Likhtman, A.E.; Graham, R.S. Simple constitutive equation for linear polymer melts derived from molecular theory: Rolie–Poly equation. J. Non-Newton. Fluid Mech. 2003, 114, 1–12. [Google Scholar] [CrossRef]

- Hua, C.C.; Schieber, J.D. Segment connectivity, chain-length breathing, segmental stretch, and constraint release in reptation models. I. Theory and single-step strain predictions. J. Chem. Phys. 1998, 109, 10018–10027. [Google Scholar] [CrossRef]

- Andreev, M.; Rutledge, G.C. A slip-link model for rheology of entangled polymer melts with crystallization. J. Rheol. 2020, 64, 213–222. [Google Scholar] [CrossRef]

- Taletskiy, K. Entangled Polymer Rheology: Efficient Algorithms and Coarse-Graining of Slip-Link Model; Illinois Institute of Technology: Chicago, IL, USA, 2018. [Google Scholar]

- Becerra, D.; Cordoba, A.; Katzarova, M.; Andreev, M.; Venerus, D.C.; Schieber, J.D. Polymer rheology predictions from first principles using the slip-link model. J. Rheol. 2020, 64, 1035–1043. [Google Scholar] [CrossRef]

- Masubuchi, Y.; Takimoto, J.-I.; Koyama, K.; Ianniruberto, G.; Marrucci, G.; Greco, F. Brownian simulations of a network of reptating primitive chains. J. Chem. Phys. 2001, 115, 4387–4394. [Google Scholar] [CrossRef]

- Takeda, K.; Sukumaran, S.K.; Sugimoto, M.; Koyama, K.; Masubuchi, Y. Primitive chain network simulations for elongational viscosity of bidisperse polystyrene melts. Adv. Model. Simul. Eng. Sci. 2015, 2, 11. [Google Scholar] [CrossRef]

- Masubuchi, Y.; Ianniruberto, G.; Greco, F.; Marrucci, G. Primitive chain network model for block copolymers. J. Non-Crystalline Solids 2006, 352, 5001–5007. [Google Scholar] [CrossRef]

- Masubuchi, Y.; Ianniruberto, G.; Marrucci, G. Primitive chain network simulations of entangled melts of symmetric and asymmetric star polymers in uniaxial elongational flows. arXiv 2021, arXiv:2101.06819. [Google Scholar]

- Li, Y.; Kröger, M.; Liu, W.K. Primitive chain network study on uncrosslinked and crosslinked cis-polyisoprene polymers. Polymer 2011, 52, 5867–5878. [Google Scholar] [CrossRef]

- Masubuchi, Y.; Matsumiya, Y.; Watanabe, H.; Marrucci, G.; Ianniruberto, G. Primitive chain network simulations for pom-pom polymers in uniaxial elongational flows. Macromolecules 2014, 47, 3511–3519. [Google Scholar] [CrossRef]

- Masubuchi, Y. PASTA and NAPLES: Rheology simulator. In Computer Simulation of Polymeric Materials: Applications of the OCTA System; Springer: Singapore, 2016; pp. 101–127. [Google Scholar] [CrossRef]

- Huang, L.H.; Wu, C.H.; Hua, C.C.; Huang, T.J. Multiscale simulations of coupled composition-stress-morphology of binary polymer blend. Polymer 2020, 193, 122366. [Google Scholar] [CrossRef]

- Sha, W.; Li, Y.; Tang, S.; Tian, J.; Zhao, Y.; Guo, Y.; Zhang, W.; Zhang, X.; Lu, S.; Cao, Y.-C.; et al. Machine learning in polymer informatics. InfoMat 2021, 3, 353–361. [Google Scholar] [CrossRef]

- Tran, H.D.; Kim, C.; Chen, L.H.; Chandrasekaran, A.; Batra, R.; Venkatram, S.; Kamal, D.; Lightstone, J.P.; Gurnani, R.; Shetty, P.; et al. Machine-learning predictions of polymer properties with Polymer Genome. J. Appl. Phys. 2020, 128, 171104. [Google Scholar] [CrossRef]

- Alqahtani, A.S. New Polymer Rheology Models Based on Machine Learning. Ph.D. Thesis, The University of Texas at Austin, Austin, TX, USA, 2019. [Google Scholar]

- Larson, R.G.; Desai, P.S. Modeling the rheology of polymer melts and solutions. Annu. Rev. Fluid Mech. 2015, 47, 47–65. [Google Scholar] [CrossRef]

- Lucy, L.B. A numerical approach to the testing of the fission hypothesis. Astron. J. 1977, 82, 1013–1024. [Google Scholar] [CrossRef]

- Gingold, R.A.; Monaghan, J.J. Smoothed particle hydrodynamics: Theory and application to non-spherical stars. Mon. Not. R. Astron. Soc. 1977, 181, 375–389. [Google Scholar] [CrossRef]

- de Campos Galuppo, W.; Magalhães, A.; Ferrás, L.L.; Nóbrega, J.M.; Fernandes, C. New boundary conditions for simulating the filling stage of the injection molding process. Eng. Comput. 2021, 38, 762–778. [Google Scholar] [CrossRef]

- Murashima, T.; Yasuda, S.; Taniguchi, T.; Yamamoto, R. Multiscale modeling for polymeric flow: Particle-fluid bridging scale methods. J. Phys. Soc. Jpn. 2013, 82, 012001. [Google Scholar] [CrossRef] [Green Version]

- Murashima, T.; Taniguchi, T. Multiscale lagrangian fluid dynamics simulation for polymeric fluid. J. Polym. Sci. Pol. Phys. 2010, 48, 886–893. [Google Scholar] [CrossRef] [Green Version]

- Sato, T.; Taniguchi, T. Multiscale simulations for entangled polymer melt spinning process. J. Non-Newton. Fluid Mech. 2017, 241, 34–42. [Google Scholar] [CrossRef]

- Lee, J.; Dunweg, B.; Schumacher, J. Multiscale modelling strategy using the lattice Boltzmann method for polymer dynamics in a turbulent flow. Comput. Math. Appl. 2010, 59, 2374–2379. [Google Scholar] [CrossRef] [Green Version]

| Ellipsoid Models | Phase Field Models | LBM | |

|---|---|---|---|

| Morphology | ellipsoid | arbitrary | arbitrary |

| Interface tracking | √ | × | × |

| Interface type | sharp | diffuse | diffuse |

| Flow filed inside drops | × | √ | √ |

| Physical domain size | large | medium | small |

| Source of model parameters | physical properties | first-principles calculations | physical properties |

| Solving method | implicit | implicit | explicit |

| Computation cost | low | medium | high |

| External field incorporation | × | √ | √ |

| Phase transition incorporation | × | √ | √ |

| Mid-Plane Model | Surface Model | Solid Model | |

|---|---|---|---|

| Thin-wall laminar flow assumptions | √ | √ | × |

| Incompressibility assumption | √ | √ | √ |

| Inertia and volume forces | × | × | × |

| Heat transfer in direction of flow | √ | √ | × |

| Internal heat source items | × | × | × |

| Constant physical parameters | √ | √ | √ |

| Planar-shaped flow front | √ | √ | × |

| Grid size | small | medium | large |

| Algorithm complexity | simple | complex | more complex |

| Calculation time | short | ordinary | long |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, L.; Fan, S.; Zhang, Y.; Huang, Z.; Zhou, H.; Jiang, S.; Li, J. Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review. Polymers 2021, 13, 3783. https://doi.org/10.3390/polym13213783

Deng L, Fan S, Zhang Y, Huang Z, Zhou H, Jiang S, Li J. Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review. Polymers. 2021; 13(21):3783. https://doi.org/10.3390/polym13213783

Chicago/Turabian StyleDeng, Lin, Suo Fan, Yun Zhang, Zhigao Huang, Huamin Zhou, Shaofei Jiang, and Jiquan Li. 2021. "Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review" Polymers 13, no. 21: 3783. https://doi.org/10.3390/polym13213783

APA StyleDeng, L., Fan, S., Zhang, Y., Huang, Z., Zhou, H., Jiang, S., & Li, J. (2021). Multiscale Modeling and Simulation of Polymer Blends in Injection Molding: A Review. Polymers, 13(21), 3783. https://doi.org/10.3390/polym13213783