N,N′-Bis(3-methylphenyl)-N,N′-dyphenylbenzidine Based Distributed Feedback Lasers with Holographically Fabricated Polymeric Resonators

Abstract

:1. Introduction

2. Experimental Techniques for DFB Laser Fabrication

2.1. DCG Surface Relief Gratings Fabrication

2.2. Active Film Fabrication

2.3. DFB Laser Assemmbling

2.4. Optical Characterization

3. Results and Discussion

3.1. Active Film Optical Properties

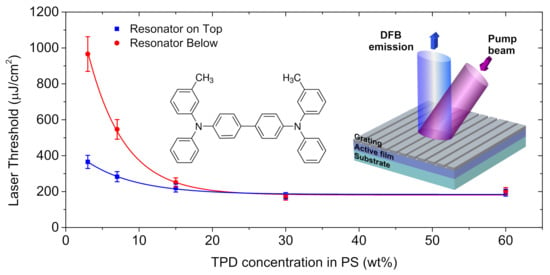

3.2. Laser Threshold

3.3. Photostability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Anni, M.; Lattante, S. Organic Lasers Fundamentals, Developments, and Applications; Pan Stanford Publishing: Singapore, 2018; ISBN 9789814774468. [Google Scholar]

- Kuehne, A.J.C.; Gather, M.C. Organic Lasers: Recent Developments on Materials, Device Geometries, and Fabrication Techniques. Chem. Rev. 2016, 116, 12823–12864. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Sandanayaka, A.S.D.; Matsushima, T.; Bencheikh, F.; Terakawa, S.; Potscavage, W.J.; Qin, C.; Fujihara, T.; Goushi, K.; Ribierre, J.C.; Adachi, C. Indication of current-injection lasing from an organic semiconductor. Appl. Phys. Express 2019, 12, 061010. [Google Scholar] [CrossRef] [Green Version]

- Chénais, S.; Forget, S. Recent advances in solid-state organic lasers. Polym. Int. 2012, 61, 390–406. [Google Scholar] [CrossRef] [Green Version]

- Heydari, E.; Buller, J.; Wischerhoff, E.; Laschewsky, A.; Döring, S.; Stumpe, J. Label-free biosensor based on an all-polymer DFB laser. Adv. Opt. Mater. 2014, 2, 137–141. [Google Scholar] [CrossRef]

- Wang, Y.; Morawska, P.O.; Kanibolotsky, A.L.; Skabara, P.J.; Turnbull, G.A.; Samuel, I.D.W. LED pumped polymer laser sensor for explosives. Laser Photonics Rev. 2013, 7, 71–76. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Morales-Vidal, M.; Boj, P.G.; Quintana, J.A.; Villalvilla, J.M.; Retolaza, A.; Merino, S.; Díaz-García, M.A. Distributed feedback lasers based on perylenediimide dyes for label-free refractive index sensing. Sens. Actuators B Chem. 2015, 220, 1368–1375. [Google Scholar] [CrossRef] [Green Version]

- Jiang, Y.; Liu, Y.Y.; Liu, X.; Lin, H.; Gao, K.; Lai, W.Y.; Huang, W. Organic solid-state lasers: A materials view and future development. Chem. Soc. Rev. 2020, 49, 5885–5944. [Google Scholar] [CrossRef] [PubMed]

- Ang, P.Y.; Cehovski, M.; Lompa, F.; Hänisch, C.; Samigullina, D.; Reineke, S.; Kowalsky, W.; Johannes, H.-H. Organic Dye-Doped PMMA Lasing. Polymers 2021, 13, 3566. [Google Scholar] [CrossRef]

- Smirnov, J.R.C.; Zhang, Q.; Wannemacher, R.; Wu, L.; Casado, S.; Xia, R.; Rodriguez, I.; Cabanillas-González, J. Flexible all-polymer waveguide for low threshold amplified spontaneous emission. Sci. Rep. 2016, 6, 34565. [Google Scholar] [CrossRef] [PubMed]

- Tsutsumi, N.; Nagi, S.; Kinashi, K.; Sakai, W. Re-evaluation of all-plastic organic dye laser with DFB structure fabricated using photoresists. Sci. Rep. 2016, 6, 34741. [Google Scholar] [CrossRef] [PubMed]

- Quintana, J.A.; Villalvilla, J.M.; Morales-Vidal, M.; Boj, P.G.; Zhu, X.; Ruangsupapichat, N.; Tsuji, H.; Nakamura, E.; Díaz-García, M.A. An Efficient and Color-Tunable Solution-Processed Organic Thin-Film Laser with a Polymeric Top-Layer Resonator. Adv. Opt. Mater. 2017, 5, 1700238. [Google Scholar] [CrossRef]

- Bonal, V.; Quintana, J.A.; Villalvilla, J.M.; Boj, P.G.; Díaz-García, M.A. Controlling the emission properties of solution-processed organic distributed feedback lasers through resonator design. Sci. Rep. 2019, 9, 11159. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bonal, V.; Villalvilla, J.M.; Quintana, J.A.; Boj, P.G.; Lin, N.; Watanabe, S.; Kazlauskas, K.; Adomeniene, O.; Jursenas, S.; Tsuji, H.; et al. Blue and Deep-Blue-Emitting Organic Lasers with Top-Layer Distributed Feedback Resonators. Adv. Opt. Mater. 2020, 8, 2001153. [Google Scholar] [CrossRef]

- Bonal, V.; Muñoz-Mármol, R.; Gordillo Gámez, F.; Morales-Vidal, M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Gu, Y.; Wu, J.; Casado, J.; et al. Solution-processed nanographene distributed feedback lasers. Nat. Commun. 2019, 10, 3327. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Muñoz-Mármol, R.; Gordillo, F.; Bonal, V.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Ross, A.M.; Paternò, G.M.; Scotognella, F.; Lanzani, G.; et al. Near-Infrared Lasing in Four-Zigzag Edged Nanographenes by 1D versus 2D Electronic π-Conjugation. Adv. Funct. Mater. 2021, 31, 2105073. [Google Scholar] [CrossRef]

- Zhai, T.; Zhang, X.; Pang, Z. Polymer laser based on active waveguide grating structures. Opt. Express 2011, 19, 6487–6492. [Google Scholar] [CrossRef] [PubMed]

- Huang, W.; Shen, S.; Pu, D.; Wei, G.; Ye, Y.; Peng, C.; Chen, L. Working characteristics of external distributed feedback polymer lasers with varying waveguiding structures. J. Phys. D Appl. Phys. 2015, 48, 495105. [Google Scholar] [CrossRef]

- Campbell, A.J.; Bradley, D.D.C.; Laubender, J.; Sokolowski, M. Thermally activated injection limited conduction in single layer N,N′-diphenyl-N,N′-bis(3-methylphenyl)1-1′-biphenyl-4,4′ -diamine light emitting diodes. J. Appl. Phys. 1999, 86, 5004–5011. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, D.; Yang, G.; Yu, J. Exceeding 19% efficiency for inverted perovskite solar cells used conventional organic small molecule TPD as hole transport layer. Appl. Phys. Lett. 2021, 118, 183301. [Google Scholar] [CrossRef]

- Scholz, R.; Gisslén, L.; Himcinschi, C.; Vragović, I.; Calzado, E.M.; Louis, E.; Maroto, E.S.F.; Díaz-García, M.A. Asymmetry between absorption and photoluminescence line shapes of TPD: Spectroscopic fingerprint of the twisted biphenyl core. J. Phys. Chem. A 2009, 113, 315–324. [Google Scholar] [CrossRef]

- Díaz-García, M.A.; Fernández De Ávila, S.; Kuzyk, M.G. Dye-doped polymers for blue organic diode lasers. Appl. Phys. Lett. 2002, 80, 4486–4488. [Google Scholar] [CrossRef] [Green Version]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Díaz-García, M.A. Tuneability of amplified spontaneous emission through control of the thickness in organic-based waveguides. J. Appl. Phys. 2005, 97, 093103. [Google Scholar] [CrossRef]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Díaz-García, M.A. Concentration dependence of amplified spontaneous emission in organic-based waveguides. Org. Electron. 2006, 7, 319–329. [Google Scholar] [CrossRef]

- Calzado, E.M.; Villalvilla, J.M.; Boj, P.G.; Quintana, J.A.; Postigo, P.A.; Díaz-García, M.A. Blue surface-emitting distributed feedback lasers based on TPD-doped films. Appl. Opt. 2010, 49, 463–470. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ichikawa, M.; Tanaka, Y.; Suganuma, N.; Koyama, T.; Taniguchi, Y. Low-threshold photopumped distributed feedback plastic laser made by replica molding. Jpn. J. Appl. Phys. Part 1 Regul. Pap. Short Notes Rev. Pap. 2003, 42, 5590–5593. [Google Scholar] [CrossRef]

- Zhang, Q.; Tao, W.; Huang, J.; Xia, R.; Cabanillas-Gonzalez, J. Toward Electrically Pumped Organic Lasers: A Review and Outlook on Material Developments and Resonator Architectures. Adv. Photonics Res. 2021, 2, 2000155. [Google Scholar] [CrossRef]

- Ramirez, M.G.; Boj, P.G.; Navarro-Fuster, V.; Vragovic, I.; Villalvilla, J.M.; Alonso, I.; Trabadelo, V.; Merino, S.; Díaz-García, M.A. Efficient organic distributed feedback lasers with imprinted active films. Opt. Express 2011, 19, 22443–22454. [Google Scholar] [CrossRef] [PubMed]

- Van Wolferen, H.; Abelmann, L. Laser Interference Lithography. In Lithography: Principles, Processes and Materials; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2011; pp. 133–148. ISBN 978-1-61761-837-6. [Google Scholar]

- Pang, L.; Zhu, J.; Zeng, Y.; Xiao, H.; Guo, L. Improvement on spatial resolution of relief holograms in dichromated gelatin. Hologr. Displays Opt. Elem. II 1998, 3559, 60–64. [Google Scholar] [CrossRef]

- Bonal, V.; Quintana, J.A.; Villalvilla, J.M.; Muñoz-Mármol, R.; Mira-Martínez, J.C.; Boj, P.G.; Cruz, M.E.; Castro, Y.; Díaz-García, M.A. Simultaneous determination of refractive index and thickness of submicron optical polymer films from transmission spectra. Polymers 2021, 13, 2545. [Google Scholar] [CrossRef]

- Ramírez, M.G.; Villalvilla, J.M.; Quintana, J.A.; Boj, P.G.; Díaz-García, M.A. Distributed feedback lasers based on dichromated poly(vinyl alcohol) reusable surface-relief gratings. Opt. Mater. Express 2014, 4, 733–738. [Google Scholar] [CrossRef] [Green Version]

- Kogelnik, H.; Shank, C.V. Coupled-wave theory of distributed feedback lasers. J. Appl. Phys. 1972, 43, 2327–2335. [Google Scholar] [CrossRef]

- Navarro-Fuster, V.; Vragovic, I.; Calzado, E.M.; Boj, P.G.; Quintana, J.A.; Villalvilla, J.M.; Retolaza, A.; Juarros, A.; Otaduy, D.; Merino, S.; et al. Film thickness and grating depth variation in organic second-order distributed feedback lasers. J. Appl. Phys. 2012, 112, 043104. [Google Scholar] [CrossRef]

- Heliotis, G.; Xia, R.; Bradley, D.D.C.; Turnbull, G.A.; Samuel, I.D.W.; Andrew, P.; Barnes, W.L. Two-dimensional distributed feedback lasers using a broadband, red polyfluorene gain medium. J. Appl. Phys. 2004, 96, 6959–6965. [Google Scholar] [CrossRef]

- Anni, M.; Perulli, A.; Monti, G. Thickness dependence of the amplified spontaneous emission threshold and operational stability in poly(9,9-dioctylfluorene) active waveguides. J. Appl. Phys. 2012, 111, 093109. [Google Scholar] [CrossRef]

- Hammer, M. 1-D Mode Solver for Dielectric Multilayer Slab Waveguides. Available online: https://www.computational-photonics.eu/oms.html (accessed on 24 June 2021).

- Ramírez, M.G.; Quintana, J.A.; Villalvilla, J.M.; Boj, P.G.; Retolaza, A.; Merino, S.; Díaz-García, M.A. Perylenediimide-based distributed feedback lasers with holographic relief gratings on dichromated gelatine. J. Appl. Phys. 2013, 114, 033107. [Google Scholar] [CrossRef] [Green Version]

- Miasojedovas, A.; Kazlauskas, K.; Armonaite, G.; Sivamurugan, V.; Valiyaveettil, S.; Grazulevicius, J.V.; Jursenas, S. Concentration effects on emission of bay-substituted perylene diimide derivatives in a polymer matrix. Dyes Pigment 2012, 92, 1285–1291. [Google Scholar] [CrossRef]

- Cerdán, L.; Costela, A.; Durán-Sampedro, G.; García-Moreno, I.; Calle, M.; Juan-Y-Seva, M.; De Abajo, J.; Turnbull, G.A. New perylene-doped polymeric thin films for efficient and long-lasting lasers. J. Mater. Chem. 2012, 22, 8938–8947. [Google Scholar] [CrossRef] [Green Version]

- Qiu, Y.; Qiao, J. Photostability and morphological stability of hole transporting materials used in organic electroluminescence. Thin Solid Films 2000, 372, 265–270. [Google Scholar] [CrossRef]

- Nagai, M.; Nozoye, H. Crystallization and Aggregation Processes of Vacuum-Evaporated TPD Films. J. Electrochem. Soc. 2007, 154, J239–J245. [Google Scholar] [CrossRef]

- Tomovic, A.Z.; Durisic, I.; Zikic, R.; Pejic, M.; Jovanovic, V.P. Interaction of UV Irradiation with Thin Films of Organic Molecules. In Proceedings of the IV Advanced Ceramics and Applications Conference, Belgrade, Serbia, 4–8 September 2017; Atlantis Press: Paris, France, 2017. ISBN 9789462392137. [Google Scholar]

| A. DCG film preparation |

|

| B. Exposure |

|

| C. Desensitization |

|

| D. Development |

|

|

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bonal, V.; Quintana, J.A.; Villalvilla, J.M.; Boj, P.G.; Muñoz-Mármol, R.; Mira-Martínez, J.C.; Díaz-García, M.A. N,N′-Bis(3-methylphenyl)-N,N′-dyphenylbenzidine Based Distributed Feedback Lasers with Holographically Fabricated Polymeric Resonators. Polymers 2021, 13, 3843. https://doi.org/10.3390/polym13213843

Bonal V, Quintana JA, Villalvilla JM, Boj PG, Muñoz-Mármol R, Mira-Martínez JC, Díaz-García MA. N,N′-Bis(3-methylphenyl)-N,N′-dyphenylbenzidine Based Distributed Feedback Lasers with Holographically Fabricated Polymeric Resonators. Polymers. 2021; 13(21):3843. https://doi.org/10.3390/polym13213843

Chicago/Turabian StyleBonal, Víctor, José A. Quintana, José M. Villalvilla, Pedro G. Boj, Rafael Muñoz-Mármol, Jose C. Mira-Martínez, and María A. Díaz-García. 2021. "N,N′-Bis(3-methylphenyl)-N,N′-dyphenylbenzidine Based Distributed Feedback Lasers with Holographically Fabricated Polymeric Resonators" Polymers 13, no. 21: 3843. https://doi.org/10.3390/polym13213843

APA StyleBonal, V., Quintana, J. A., Villalvilla, J. M., Boj, P. G., Muñoz-Mármol, R., Mira-Martínez, J. C., & Díaz-García, M. A. (2021). N,N′-Bis(3-methylphenyl)-N,N′-dyphenylbenzidine Based Distributed Feedback Lasers with Holographically Fabricated Polymeric Resonators. Polymers, 13(21), 3843. https://doi.org/10.3390/polym13213843