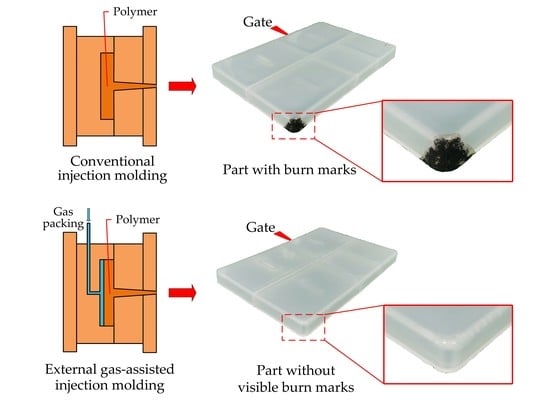

Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding

Abstract

:1. Introduction

2. Materials and Methods

2.1. Experiment

2.2. Evaluation of Burn Marks

2.3. Regression Analysis

3. Results and Discussion

3.1. Quantification of Burn Marks

3.2. Reduction in Burn Marks by EGAIM

3.3. Influence of Gas Parameters on Burn Marks

3.4. Regression Analysis for the Gas Parameters and Burn Marks

4. Conclusions

- (1)

- EGAIM is an applicable process to reduce burn marks in injection molding without changing the structure of the part or the mold. The proportions of burnt area in parts molded by EGAIM were all lower than the 4.98% that was found for those molded by CIM, and the burn marks could be eliminated by EGAIM with reasonable gas parameters.

- (2)

- The burn marks were quantified into specific values by the quantitative method proposed in this paper, and this provides a possible method for evaluating other visible defects in injection-molded parts.

- (3)

- Different gas parameters play different roles in reducing burn marks. The most important gas parameter is gas delay time. The burn marks were eliminated when the gas delay time was 0 s and varied slightly with changes in gas pressure and gas packing time.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Stormonth-Darling, J.M.; Pedersen, R.H.; How, C.; Gadegaard, N. Injection moulding of ultra high aspect ratio nanostructures using coated polymer tooling. J. Micromech. Microeng. 2014, 24, 75019. [Google Scholar] [CrossRef]

- Matschuk, M.; Larsen, N.B. Injection molding of high aspect ratio sub-100 nm nanostructures. J. Micromech. Microeng. 2013, 23, 25003. [Google Scholar] [CrossRef]

- Khosravani, M.R.; Nasiri, S. Injection molding manufacturing process: Review of case-based reasoning applications. J. Intell. Manuf. 2020, 31, 847–864. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, B.; Zhu, S.; Chen, X. Online quality optimization of the injection molding process via digital image processing and model-free optimization. J. Mater. Process. Technol. 2015, 226, 85–98. [Google Scholar] [CrossRef]

- Li, J.; Bei, J.; Liu, W.; Xia, X.; Zhou, B.; Peng, X.; Jiang, S. Warpage prediction of RHCM crystalline parts based on multi-layers. Polymers 2021, 13, 1814. [Google Scholar] [CrossRef]

- Ozcelik, B.; Kuram, E.; Topal, M.M. Investigation the effects of obstacle geometries and injection molding parameters on weld line strength using experimental and finite element methods in plastic injection molding. Int. Commun. Heat Mass Transf. 2012, 39, 275–281. [Google Scholar] [CrossRef]

- Kim, B.; Gim, J.; Han, E.; Rhee, B. Development of the vent clogging monitoring methods for injection molding. CIRP J. Manuf. Sci. Technol. 2021, 32, 277–286. [Google Scholar] [CrossRef]

- Gruber, D.P.; Berger, G.; Pacher, G.; Friesenbichler, W. Novel approach to the measurement of the visual perceptibility of sink marks on injection molding parts. Polym. Test. 2011, 30, 651–656. [Google Scholar] [CrossRef]

- Yao, D.; Kim, B. Direct-Search-Based automatic minimization of weldlines in injection-molded parts. Polym. Plast. Technol. Eng. 1998, 37, 509–525. [Google Scholar] [CrossRef]

- Mesgaran, S.B.; Nik, F.E.; Mousavi, S.E.S. (Eds.) Experimental and numerical analysis of burn marks and shrinkage effect on injection molding. In Proceedings of the ASME 2017 12th International Manufacturing Science and Engineering Conference, Los Angeles, CA, USA, 4–8 June 2017. [Google Scholar]

- Fukushima, Y.; Suzuki, T.; Onda, K.; Komatsu, H.; Kuroiwa, H.; Kaburagi, T. Study on the online monitoring of burn marks by gas sensor. Int. J. Autom. Technol. 2017, 11, 112–119. [Google Scholar] [CrossRef]

- Kapila, A.; Singh, K.; Arora, G.; Agarwal, N. Effect of varying gate size on the air traps in injection molding. Int. J. Curr. Eng. Technol. 2015, 5, 161–166. [Google Scholar]

- Chen, S.-C.; Lin, Y.-C.; Huang, S.-W. Study on the packing effects of external gas-assisted injection molding on part shrinkage in comparison with conventional injection molding. Polym. Eng. Sci. 2010, 50, 2085–2092. [Google Scholar] [CrossRef]

- Xiao, Q.; Liu, H.; Huang, Y. Coupled finite element analysis of warpage of part by external gas-assisted injection molding. Plastics 2020, 49, 105–108. [Google Scholar]

- Nian, S.-C.; Li, M.-H.; Huang, M.-S. Warpage control of headlight lampshades fabricated using external gas-assisted injection molding. Int. J. Heat Mass Transf. 2015, 86, 358–368. [Google Scholar] [CrossRef]

- Jiang, S.; Li, T.; Xia, X.; Peng, X.; Li, J. Reducing the sink marks of a crystalline polymer using external gas-assisted injection molding. Adv. Polym. Technol. 2020, 2020, 1–8. [Google Scholar] [CrossRef]

- Su, H.-Y.; Nian, S.-C.; Huang, M.-S. Reducing ghost marks in injection-molded plastic parts by using external gas-assisted holding pressure. Int. Commun. Heat Mass Transf. 2015, 66, 1–10. [Google Scholar] [CrossRef]

- Suda, T.; Kuroiwa, H.; Fukushima, Y.; Suzuki, T.; Terauchi, F. (Eds.) Detection of the Burn Mark on the Plastic Surface Using Image Analysis: Fundamental study for reduction the environmental impact by unpainted plastic products. In Proceedings of the International Conference on Leading Edge Manufacturing in 21st Century: LEM21, Matsushima, Japan, 7–8 November 2013. [Google Scholar]

- Chakraborty, R.; Sushil, R.; Garg, M.L. An improved PSO-based multilevel image segmentation technique using minimum cross-entropy thresholding. Arab. J. Sci. Eng. 2019, 44, 3005–3020. [Google Scholar] [CrossRef]

- Kowaluk, T.; Wozniak, A. A new threshold selection method for X-ray computed tomography for dimensional metrology. Precis. Eng. 2017, 50, 449–454. [Google Scholar] [CrossRef]

- Sharma, A.; Kumar, S.; Singh, S.N. Brain tumor segmentation using DE embedded OTSU method and neural network. Multidimens. Syst. Signal Process. 2019, 30, 1263–1291. [Google Scholar] [CrossRef]

- Mensah, R.A.; Xiao, J.; Das, O.; Jiang, L.; Xu, Q.; Alhassan, M.O. Application of adaptive neuro-fuzzy inference system in flammability parameter prediction. Polymers 2020, 12, 122. [Google Scholar] [CrossRef] [Green Version]

- Kim, K.-H.; Park, J.C.; Suh, Y.S.; Koo, B.-H. Interactive Robust optimal design of plastic injection products with minimum weldlines. Int. J. Adv. Manuf. Technol. 2017, 88, 1333–1344. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Chatterjee, S.; Hadi, A.S. Regression Analysis by Example, 5th ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012. [Google Scholar]

- Wu, C.-Y.; Lui, W.-B.; Peng, J. Optimization of extrusion variables and maleic anhydride content on biopolymer blends based on poly(hydroxybutyrate-co-hydroxyvalerate)/poly(vinyl acetate) with tapioca starch. Polymers 2018, 10, 827. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Melt Temperature (°C) | Mold Temperature (°C) | Injection Pressure (MPa) | Injection Speed (mm/s) | Holding Pressure (MPa) | Holding Time (s) | Cooling Time (s) |

|---|---|---|---|---|---|---|

| 220 | 40 | 60 | 55 | 50 | 5 | 35 |

| Level 1 | Level 2 | Level 3 | |

|---|---|---|---|

| Gas pressure (MPa) | 5 | 7 | 9 |

| Gas packing time (s) | 10 | 20 | 30 |

| Gas delay time (s) | 0 | 1 | 2 |

| No. | Gas Pressure (MPa) | Gas Packing Time (s) | Gas Delay Time (s) | Severity of Burn Marks (%) |

|---|---|---|---|---|

| 1 | 9 | 30 | 2 | 3.57 |

| 2 | 5 | 30 | 0 | 0 |

| 3 | 9 | 20 | 2 | 3.61 |

| 4 | 5 | 30 | 1 | 4.79 |

| 5 | 9 | 20 | 1 | 3.11 |

| 6 | 7 | 10 | 0 | 0 |

| 7 | 7 | 20 | 0 | 0 |

| 8 | 7 | 30 | 2 | 3.99 |

| 9 | 5 | 10 | 1 | 4.08 |

| 10 | 9 | 30 | 0 | 0 |

| 11 | 9 | 10 | 1 | 2.14 |

| 12 | 9 | 10 | 0 | 0 |

| 13 | 5 | 20 | 0 | 0 |

| 14 | 5 | 20 | 1 | 3.83 |

| 15 | 5 | 30 | 2 | 4.76 |

| 16 | 7 | 20 | 2 | 4.03 |

| 17 | 7 | 10 | 2 | 4.07 |

| 18 | 5 | 10 | 2 | 4.22 |

| 19 | 7 | 10 | 1 | 3.56 |

| 20 | 5 | 20 | 2 | 4.03 |

| 21 | 9 | 30 | 1 | 3.14 |

| 22 | 9 | 10 | 2 | 3.44 |

| 23 | 9 | 20 | 0 | 0 |

| 24 | 5 | 10 | 0 | 0 |

| 25 | 7 | 20 | 1 | 4.01 |

| 26 | 7 | 30 | 1 | 3.94 |

| 27 | 7 | 30 | 0 | 0 |

| The Model Established in Minitab | p-Value | F-Value | R2 | R2adjust |

|---|---|---|---|---|

| Severity of burn marks = 0.393 − 0.0865 Gas pressure + 0.0047 Gas packing time + 5.957 Gas delay time + 0.00026 Gas packing time × Gas packing time − 1.638 Gas delay time × Gas delay time − 0.0996 Gas pressure × Gas delay time | 1.1 × 10−14 | 122.16 | 97.34% | 96.55% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, J.; Liu, W.; Xia, X.; Zhou, H.; Jing, L.; Peng, X.; Jiang, S. Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding. Polymers 2021, 13, 4087. https://doi.org/10.3390/polym13234087

Li J, Liu W, Xia X, Zhou H, Jing L, Peng X, Jiang S. Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding. Polymers. 2021; 13(23):4087. https://doi.org/10.3390/polym13234087

Chicago/Turabian StyleLi, Jiquan, Wenyong Liu, Xinxin Xia, Hangchao Zhou, Liting Jing, Xiang Peng, and Shaofei Jiang. 2021. "Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding" Polymers 13, no. 23: 4087. https://doi.org/10.3390/polym13234087

APA StyleLi, J., Liu, W., Xia, X., Zhou, H., Jing, L., Peng, X., & Jiang, S. (2021). Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding. Polymers, 13(23), 4087. https://doi.org/10.3390/polym13234087