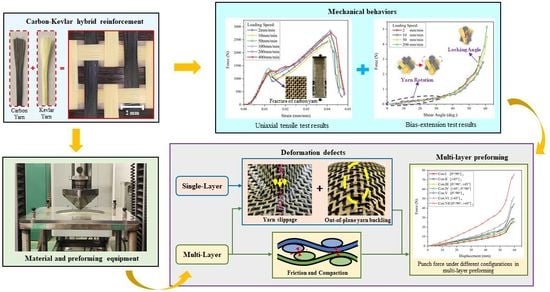

Analysis of the Mechanical and Preforming Behaviors of Carbon-Kevlar Hybrid Woven Reinforcement

Abstract

:1. Introduction

2. Materials and Methods

2.1. Tested Materials

2.2. Mechanical Behavior Characterizations

2.3. Preforming Tests

3. Results and Discussion

3.1. Mechanical Behavior Characterization

3.1.1. Tensile Behaviors

3.1.2. In-Plane Shear Behaviors

3.2. Preforming of Hybrid Woven Reinforcement

3.2.1. Single-Layer Preforming

Deformation of Preforms with Different Initial Yarn Directions

Preforming Defect Description of Hybrid Woven Reinforcement

Influence of Blank Holder Pressure on Defects

3.2.2. Multi-Layer Preforming

Defects in Multi-Layer Preforms with Different Stacking Configurations

Inter-Ply Friction Mechanism in Multi-Layer Preforming

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Meola, C.; Boccardi, S.; Carlomagno, G.M. (Eds.) Chapter 1-Composite Materials in the Aeronautical Industry. In Infrared Thermography in the Evaluation of Aerospace Composite Materials; Woodhead Publishing: Philadelphia, PA, USA, 2017; pp. 1–24. [Google Scholar]

- Xiao, S.; Lanceron, C.; Wang, P.; Soulat, D.; Gao, H. Mechanical and thermal behaviors of ultra-high molecular weight polyethylene triaxial braids: The influence of structural parameters. Text. Res. J. 2018, 89, 3362–3373. [Google Scholar] [CrossRef]

- Omrani, F.; Wang, P.; Soulat, D.; Ferreira, M.; Ouagne, P. Analysis of the deformability of flax-fibre nonwoven fabrics during manufacturing. Compos. Part B Eng. 2017, 116, 471–485. [Google Scholar] [CrossRef] [Green Version]

- Dufour, C.; Wang, P.; Boussu, F.; Soulat, D. Experimental Investigation About Stamping Behaviour of 3D Warp Interlock Composite Preforms. Appl. Compos. Mater. 2014, 21, 725–738. [Google Scholar] [CrossRef]

- Shen, H.; Wang, P.; Legrand, X. In-plane shear characteristics during the forming of tufted carbon woven fabrics. Compos. Part A Appl. Sci. Manuf. 2021, 141, 106196. [Google Scholar] [CrossRef]

- Kim, D.-J.; Yu, M.-H.; Lim, J.; Nam, B.; Kim, H.-S. Prediction of the mechanical behavior of fiber-reinforced composite structure considering its shear angle distribution generated during thermo-compression molding process. Compos. Struct. 2019, 220, 441–450. [Google Scholar] [CrossRef]

- Sevkat, E.; Liaw, B.; Delale, F. Drop-weight impact response of hybrid composites impacted by impactor of various geometries. Mater. Des. 2013, 52, 67–77. [Google Scholar] [CrossRef]

- Bunea, M.; Cîrciumaru, A.; Buciumeanu, M.; Bîrsan, I.G.; Silva, F.S. Low velocity impact response of fabric reinforced hybrid composites with stratified filled epoxy matrix. Compos. Sci. Technol. 2019, 169, 242–248. [Google Scholar] [CrossRef]

- Hashim, N.; Majid, D.L.A.; Mahdi, E.-S.; Zahari, R.; Yidris, N. Effect of fiber loading directions on the low cycle fatigue of intraply carbon-Kevlar reinforced epoxy hybrid composites. Compos. Struct. 2019, 212, 476–483. [Google Scholar] [CrossRef]

- Woo, S.-C.; Kim, T.-W. High strain-rate failure in carbon/Kevlar hybrid woven composites via a novel SHPB-AE coupled test. Compos. Part B Eng. 2016, 97, 317–332. [Google Scholar] [CrossRef]

- Liang, B.; Hamila, N.; Peillon, M.; Boisse, P. Analysis of thermoplastic prepreg bending stiffness during manufacturing and of its influence on wrinkling simulations. Compos. Part A Appl. Sci. Manuf. 2014, 67, 111–122. [Google Scholar] [CrossRef]

- Gao, J.; Liang, B.; Zhang, W.; Liu, Z.; Cheng, P.; Bostanabad, R.; Cao, J.; Chen, W.; Liu, W.K.; Su, X.; et al. Multiscale Modeling of Carbon Fiber Reinforced Polymer (CFRP) for Integrated Computational Materials Engineering Process; Ford Motor Company: Detroit, MI, USA, 2017. [Google Scholar]

- Liang, B.; Colmars, J.; Boisse, P. A shell formulation for fibrous reinforcement forming simulations. Compos. Part A Appl. Sci. Manuf. 2017, 100, 81–96. [Google Scholar] [CrossRef]

- Zhang, W.; Ren, H.; Liang, B.; Zeng, D.; Su, X.; Dahl, J.; Mirdamadi, M.; Zhao, Q.; Cao, J. A non-orthogonal material model of woven composites in the preforming process. CIRP Ann. 2017, 66, 257–260. [Google Scholar] [CrossRef]

- Boisse, P.; Hamila, N.; Vidal-Sallé, E.; Dumont, F. Simulation of wrinkling during textile composite reinforcement forming. Influence of tensile, in-plane shear and bending stiffnesses. Compos. Sci. Technol. 2011, 71, 683–692. [Google Scholar] [CrossRef] [Green Version]

- Boisse, P.; Hamila, N.; Guzmán Maldonado, E.; Madeo, A.; Hivet, G.; dell’Isola, F. The bias-extension test for the analysis of in-plane shear properties of textile composite reinforcements and prepregs: A review. Int. J. Mater. Form. 2017, 10, 473–492. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Vidal-Sallé, E.; Boisse, P.; Park, C.H.; Saouab, A.; Bréard, J.; Hivet, G. Mesoscopic scale analyses of textile composite reinforcement compaction. Compos. Part B Eng. 2013, 44, 231–241. [Google Scholar] [CrossRef]

- Yao, Y.; Peng, X.; Youkun, G. Influence of tension–shear coupling on draping of plain weave fabrics. J. Mater. Sci. 2019, 54, 6310–6322. [Google Scholar] [CrossRef]

- Zhang, W.; Bostanabad, R.; Liang, B.; Su, X.; Zeng, D.; Bessa, M.A.; Wang, Y.; Chen, W.; Cao, J. A numerical Bayesian-calibrated characterization method for multiscale prepreg preforming simulations with tension-shear coupling. Compos. Sci. Technol. 2019, 170, 15–24. [Google Scholar] [CrossRef]

- Hallander, P.; Akermo, M.; Mattei, C.; Petersson, M.; Nyman, T. An experimental study of mechanisms behind wrinkle development during forming of composite laminates. Compos. Part A Appl. Sci. Manuf. 2013, 50, 54–64. [Google Scholar] [CrossRef]

- Zhu, B.; Yu, T.X.; Zhang, H.; Tao, X.M. Experimental investigation of formability of commingled woven composite preform in stamping operation. Compos. Part B Eng. 2011, 42, 289–295. [Google Scholar] [CrossRef]

- Labanieh, A.R.; Garnier, C.; Ouagne, P.; Dalverny, O.; Soulat, D. Intra-ply yarn sliding defect in hemisphere preforming of a woven preform. Compos. Part A Appl. Sci. Manuf. 2018, 107, 432–446. [Google Scholar] [CrossRef] [Green Version]

- Azzouz, R.; Allaoui, S.; Moulart, R. Composite preforming defects: A review and a classification. Int. J. Mater. Form. 2021, 1–20. [Google Scholar] [CrossRef]

- Peng, X.; Rehman, Z.U. Textile composite double dome stamping simulation using a non-orthogonal constitutive model. Compos. Sci. Technol. 2011, 71, 1075–1081. [Google Scholar] [CrossRef]

- Peng, X.; Guo, Z.; Du, T.; Yu, W.-R. A simple anisotropic hyperelastic constitutive model for textile fabrics with application to forming simulation. Compos. Part B Eng. 2013, 52, 275–281. [Google Scholar] [CrossRef]

- Aimene, Y. Approche Hyperélastique pour la Simulation des Renforts Fibreux en Grandes Transformations. Ph.D. Thesis, INSA Lyon, Lyon, France, 2007. [Google Scholar]

- Youkun, G.; Xu, P.; Peng, X.; Wei, R.; Yao, Y.; Zhao, K. A Lamination Model for Forming Simulation of Woven Fabric Reinforced Thermoplastic Prepregs. Compos. Struct. 2018, 196, 89–95. [Google Scholar]

- Gatouillat, S.; Bareggi, A.; Vidal-Sallé, E.; Boisse, P. Meso modelling for composite preform shaping–Simulation of the loss of cohesion of the woven fibre network. Compos. Part A Appl. Sci. Manuf. 2013, 54, 135–144. [Google Scholar] [CrossRef]

- Capelle, E.; Ouagne, P.; Soulat, D.; Duriatti, D. Complex shape forming of flax woven fabrics: Design of specific blank-holder shapes to prevent defects. Compos. Part B Eng. 2014, 62, 29–36. [Google Scholar] [CrossRef]

- Shanwan, A.; Allaoui, S.; Gillibert, J.; Hivet, G. Development of an experimental approach to study preforming mesoscopic defects of woven fabrics. In Proceedings of the ESAFORM 2021, 24th International Conference on Material Forming, Liège, Belgium, 14–16 April 2021. [Google Scholar]

- Allaoui, S.; Cellard, C.; Hivet, G. Effect of inter-ply sliding on the quality of multilayer interlock dry fabric preforms. Compos. Part A Appl. Sci. Manuf. 2015, 68, 336–345. [Google Scholar] [CrossRef] [Green Version]

- Guzman-Maldonado, E.; Wang, P.; Hamila, N.; Boisse, P. Experimental and numerical analysis of wrinkling during forming of multi-layered textile composites. Compos. Struct. 2019, 208, 213–223. [Google Scholar] [CrossRef]

- Nosrat Nezami, F.; Gereke, T.; Cherif, C. Analyses of interaction mechanisms during forming of multilayer carbon woven fabrics for composite applications. Compos. Part A Appl. Sci. Manuf. 2016, 84, 406–416. [Google Scholar] [CrossRef]

- Vanclooster, K.; Lomov, S.; Verpoest, I. Simulation of Multi-layered Composites Forming. Int. J. Mater. Form. 2010, 3, 695–698. [Google Scholar] [CrossRef]

- Thompson, A.; Belnoue, J.; Hallett, S. Modelling defect formation in textiles during the double diaphragm forming process. Compos. Part B Eng. 2020, 202, 108357. [Google Scholar] [CrossRef]

- Huang, J.; Boisse, P.; Hamila, N. Simulation of the forming of tufted multilayer composite preforms. Compos. Part B Eng. 2021, 220, 108981. [Google Scholar] [CrossRef]

- Wagih, A.; Sebaey, T.A.; Yudhanto, A.; Lubineau, G. Post-impact flexural behavior of carbon-aramid/epoxy hybrid composites. Compos. Struct. 2020, 239, 112022. [Google Scholar] [CrossRef]

- Guled, F.; Chittappa, H. Influence of interply arrangement on inter-laminar shear strength of carbon-Kevlar/epoxy hybrid composites. In Proceedings of the AIP Conference Proceedings, Surathkal, India, 15–16 December 2018. [Google Scholar]

- Jacquot, P.-B.; Wang, P.; Soulat, D.; Legrand, X. Analysis of the preforming behaviour of the braided and woven flax/polyamide fabrics. J. Ind. Text. 2015, 46, 698–718. [Google Scholar] [CrossRef]

- Hamila, N.; Boisse, P.; Chatel, S. Semi-Discrete Shell Finite Elements for Textile Composite Forming Simulation. Int. J. Mater. Form. 2009, 2, 169–172. [Google Scholar] [CrossRef]

- Allaoui, S.; Hivet, G.; Soulat, D.; Wendling, A.; Ouagne, P.; Chatel, S. Experimental preforming of highly double curved shapes with a case corner using an interlock reinforcement. Int. J. Mater. Form. 2014, 7, 155–165. [Google Scholar] [CrossRef]

- Lee, J.S.; Hong, S.J.; Yu, W.-R.; Kang, T.J. The effect of blank holder force on the stamp forming behavior of non-crimp fabric with a chain stitch. Compos. Sci. Technol. 2007, 67, 357–366. [Google Scholar] [CrossRef]

- Ouagne, P.; Soulat, D.; Moothoo, J.; Capelle, E.; Gueret, S. Complex shape forming of a flax woven fabric; analysis of the tow buckling and misalignment defect. Compos. Part A Appl. Sci. Manuf. 2013, 51, 1–10. [Google Scholar] [CrossRef]

- Iwata, A.; Inoue, T.; Naouar, N.; Boisse, P.; Lomov, S.V. Coupled meso-macro simulation of woven fabric local deformation during draping. Compos. Part A Appl. Sci. Manuf. 2019, 118, 267–280. [Google Scholar] [CrossRef]

- White, K.D.; Campshure, B.; Sherwood, J.A. Effects of Thickness Changes and Friction during the Thermoforming of Composite Sheets. In Proceedings of the ESAFORM 2021, 24th International Conference on Material Forming, Liège, Belgium, 14–16 April 2021. [Google Scholar]

- Shanwan, A.; Allaoui, S. Different experimental ways to minimize the preforming defects of multi-layered interlock dry fabric. Int. J. Mater. Form. 2019, 12, 69–78. [Google Scholar] [CrossRef] [Green Version]

| Material | Yarn Count (Yarn/cm2) | Woven Structure | Areal Density (g/m2) | Thickness (mm) | Yarn Type | Linear Density (g/m) | Bulk Density (g/cm3) |

|---|---|---|---|---|---|---|---|

| Carbon-Kevlar hybrid reinforcement | 5 × 5 | 1/3 twill | 220 | 0.3 | |||

| Carbon yarn | T300 3K | 0.198 | 1.76 | ||||

| Kevlar yarn | 1500D | 0.1679 | 1.414 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qu, Z.; Gao, S.; Zhang, Y.; Jia, J. Analysis of the Mechanical and Preforming Behaviors of Carbon-Kevlar Hybrid Woven Reinforcement. Polymers 2021, 13, 4088. https://doi.org/10.3390/polym13234088

Qu Z, Gao S, Zhang Y, Jia J. Analysis of the Mechanical and Preforming Behaviors of Carbon-Kevlar Hybrid Woven Reinforcement. Polymers. 2021; 13(23):4088. https://doi.org/10.3390/polym13234088

Chicago/Turabian StyleQu, Zhengtao, Sasa Gao, Yunjie Zhang, and Junhong Jia. 2021. "Analysis of the Mechanical and Preforming Behaviors of Carbon-Kevlar Hybrid Woven Reinforcement" Polymers 13, no. 23: 4088. https://doi.org/10.3390/polym13234088

APA StyleQu, Z., Gao, S., Zhang, Y., & Jia, J. (2021). Analysis of the Mechanical and Preforming Behaviors of Carbon-Kevlar Hybrid Woven Reinforcement. Polymers, 13(23), 4088. https://doi.org/10.3390/polym13234088