Preparation and Finite Element Analysis of Fly Ash/HDPE Composites for Large Diameter Bellows

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. ATPS-Modified FA

2.3. Preparation of FA Masterbatch

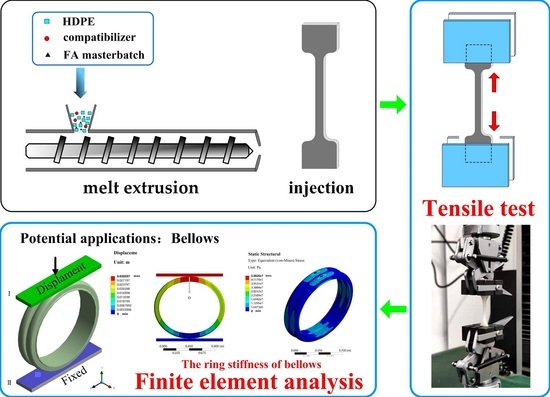

2.4. Preparation of the Composites

2.5. Characterization

2.6. Finite Element Model

2.6.1. Geometry

2.6.2. Material Parameters

2.6.3. Mesh Parameters

2.6.4. Boundary and Initial Conditions

3. Results

3.1. FT–IR Spectroscopic Analysis

3.2. SEM Analysis of FA

3.3. Effect of FA on the Tensile Properties of the Composites

3.4. Effect of the Compatibilizer on the Properties of the Composites

3.5. Composite Morphology

3.6. Thermogravimetric Analysis (TGA)

3.7. Finite Element Analysis

4. Discussion

5. Conclusions

- (1)

- The tensile strength and Young’s modulus of the composite increased at first and then decreased with the increase in FA masterbatch content, and the elongation at break decreased with the addition of FA. The existence of LDPE in the FA masterbatch could alleviate the decreases in strength, stiffness and elongation at break caused by excessive addition of FA. When 10% modified FA masterbatch was added to HDPE, the tensile strength of the composite material reached the maximum. Compared with pure HDPE, the tensile yield strength of 10% FA masterbatch/90% HDPE composites was increased by approximately 24.5%, and the tensile breaking strength was increased by approximately 30.7%.

- (2)

- A small amount of compatibilizer could enhance the tensile strength of the composite, but too much compatibilizer would reduce the tensile strength of the composite. The addition of compatibilizer to FA masterbatch/HDPE composite could make FA and HDPE have a stronger interaction. After adding the compatibilizer to the FA masterbatch/HDPE composite materials, the elongation at break of the composite materials would increase, while the rigidity would decrease. When 5% compatibilizer was added to the 10% FA masterbatch/HDPE composite, the comprehensive mechanical properties of the composite were the best. Compared with the 10% FA masterbatch/HDPE composite, the tensile yield strength, tensile breaking strength and elongation at break of the composite increased by 4.6%, 7.4% and 9.1%, respectively.

- (3)

- The ring stiffness of bellows made of 10% modified FA masterbatch/5% HDPE-MAH/85% HDPE composite was calculated by finite element analysis, and it was found that the bellows made of this composite could achieve higher ring stiffness. Compared with the common diameter bellows made from common commercially available materials, the ring stiffness increased by approximately 23%. Therefore, this composite is expected to be a material for the preparation of large diameter HDPE bellows.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yang, S.Q.; Bai, S.B.; Wang, Q. Morphology, mechanical and thermal oxidative aging properties of HDPE composites reinforced by nonmetals recycled from waste printed circuit boards. Waste Manag. 2016, 57, 168–175. [Google Scholar] [CrossRef] [PubMed]

- Chrissafis, K.; Paraskevopoulos, K.M.; Tsiaoussis, I.; Bikiaris, D. Comparative study of the effect of different nanoparticles on the mechanical properties, Permeability, and Thermal Degradation Mechanism of HDPE. J. Appl. Polym. Sci. 2009, 114, 1606–1618. [Google Scholar] [CrossRef]

- Elzubair, A.; Suarez, J.C.M. Mechanical behavior of recycled polyethylene/piassava fiber composites. Mater. Sci. Eng. A 2012, 557, 29–35. [Google Scholar] [CrossRef]

- Savini, G.; Orefice, R.L. Comparative study of HDPE composites reinforced with micro-talc and nano-talc: High performance filler for improving ductility at low concentration levels. J. Mater. Res. Technol. 2020, 9, 16387–16398. [Google Scholar] [CrossRef]

- Mahmoud, M.E.; Khalif, M.A.; El-Sharkawy, R.M.; Youssef, M.R. Effects of Al2O3 and BaO nano-additives on mechanical characteristics of HDPE. Mater. Chem. Phys. 2021, 262, 124251. [Google Scholar] [CrossRef]

- Kumar, D.K.M.; Udaiyakumar, K.C. Investigation on mechanical properties of sugarcane bagasse ash reinforced with incorporation of HDPE-montmorillonite composite materials. Mater. Today Proc. 2020, 2214–7853. [Google Scholar]

- Ran, L.; Liu, S.Y. Preparation and characterization of fly ash modified by silane coupling agent. N. Chem. Mater. 2019, 47, 275–277. [Google Scholar]

- Lv, Z.M.; Li, X.F.; Ren, F.M. Comprehensive utilization of heavy metals in fly ash of power plant. Environ. Sustain. Dev. 2006, 4, 57–59. [Google Scholar]

- Brostow, W.; Datashvili, T.; Jiang, P.; Miller, H. Recycled HDPE reinforced with sol–gel silica modified wood sawdust. Eur. Polym. J. 2016, 76, 28–39. [Google Scholar] [CrossRef]

- Deepthi, M.V.; Sharma, M.; Sailaja, R.R.N.; Anantha, P.; Sampathkumaran, P.; Seetharamu, S. Mechanical and thermal characteristics of high-density polyethylene–fly ash Cenosphere composites. Mater. Des. 2009, 31, 2051–2060. [Google Scholar] [CrossRef]

- Guo, D.; Xue, B.; Bao, J.J. Preparation and properties of HDPE composites filled with ultrafine fly ash. Sci. Eng. Polym. Mater. 2013, 29, 149–152. [Google Scholar] [CrossRef]

- Wu, T.T. Study on Preparation and Properties of Fly Ash/Steel Slag-HDPE Composites; Shanxi University: Taiyuan, China, 2018. [Google Scholar]

- Luo, C.H. A Special Reinforced Composite Plastic for Large Diameter Sewage Pipe and Its Preparation Method. China Patent CN110396262A, 1 January 2019. [Google Scholar]

- Wang, X.P.; Lian, Q. Evaluation of Uncertainty of Ring Stiffness of Double Walled Corrugated Pipe with High Polyethylene (PE). Mater. Appl. 2020, 42, 34–36. [Google Scholar]

- Fan, L.; Hu, S.; Xing, C.P. Study on properties of fly ash/HDPE composites. Plast. Ind. 2014, 42, 73–76. [Google Scholar]

- Qiao, Z.Y. Surface Modification of Fly Ash and Its Application in Polyurethane Elastomer; Shanxi University: Taiyuan, China, 2019. [Google Scholar]

- Huang, Y.; Liu, J.H.; Zhou, S.L.; Wu, T.; Ren, Z. Effect of fly ash filling masterbatch on properties of HDPE composites. Biol. Degrad. Mater. 2018, 46, 44–48. [Google Scholar]

- Grigoriadou, I.; Paraskevopoulos, K.M.; Karavasili, M.; Karagiannis, G.; Vasileiou, A.; Bikiaris, D. HDPE/Cu-nanofiber nanocomposites with enhanced mechanical and UV stability properties. Compos. Part B 2013, 55, 407–420. [Google Scholar] [CrossRef]

- Sun, J.M.; Xu, J.S. Research and development of reinforced and toughened modification material for HDPE large diameter bellows. Plast. Process. 2003, 38, 16–18. [Google Scholar]

- Zhi, C.; Daly, M.; Geever, L.M.; Major, I.; Higginbotham, C.L.; Devine, D.M. Synthesis and characterization of HDPE/peat ash composites. Compos. Part B 2016, 94, 312–321. [Google Scholar]

| Composition | Mass Fraction | Statistical Error |

|---|---|---|

| Carbon | 2.72 | 2 |

| Moisture | 0.87 | 2.8 |

| SiO2 | 46.1 | 0.2 |

| Al2O3 | 40.5 | 0.18 |

| CaO | 2.58 | 0.47 |

| TiO2 | 1.91 | 0.52 |

| SO3 | 1.85 | 0.75 |

| Fe2O3 | 1.65 | 0.25 |

| K2O | 0.58 | 0.96 |

| MgO | 0.56 | 1.79 |

| Na2O | 0.12 | 3.01 |

| BaO | 0.07 | 7.14 |

| ZrO2 | 0.06 | 4.58 |

| SrO | 0.06 | 0.44 |

| CeO2 | 0.05 | 0.51 |

| V2O5 | 0.03 | 5.34 |

| Chlorine | 0.01 | 9.15 |

| Parameter | Structural Steel | Material a 1 | Material b 2 |

|---|---|---|---|

| Density | 7850 kg/m3 | 970 kg/m3 | 970 kg/m3 |

| Young’s modulus | 2 × 105 MPa | 1451.1 MPa | 1181.0 MPa |

| Poisson ratio | 0.3 | 0.38 | 0.38 |

| Blend Composition | Tensile Strength at Yield | Tensile Strength at Break | Young’s Modulus | Elongation at Break |

|---|---|---|---|---|

| Pure HDPE | 22.13 ± 2.23 MPa | 16.54 ± 1.57 MPa | 500.00% ± 0% | |

| 5% FA masterbatch/95% HDPE | 25.60 ± 1.09 MPa | 19.63 ± 0.01 MPa | 1495.0 ± 35.4 MPa | 252.85% ± 56.56% |

| 10%FA masterbatch/90% HDPE | 27.55 ± 1.25 MPa | 21.62 ± 1.01 MPa | 1477.2 ± 49.9 MPa | 325.55% ± 51.97% |

| 15%FA masterbatch/85% HDPE | 26.06 ± 1.03 MPa | 20.93 ± 0.60 MPa | 1370.1 ± 23.2 MPa | 344.20% ± 22.56% |

| 20%FA masterbatch/80% HDPE | 27.13 ± 1.15 MPa | 22.03 ± 1.47 MPa | 1327.5 ± 92.3 MPa | 399.61% ± 40.10% |

| Blend Composition | Tensile Strength at Yield | Tensile Strength at Break | Young’s Modulus | Elongation at Break |

|---|---|---|---|---|

| 10% FA masterbatch/90% HDPE | 27.55 ± 1.25 MPa | 21.62 ± 1.01 MPa | 1477.2 ± 49.9 MPa | 325.55% ± 51.97% |

| 10% FA masterbatch/5% compatibilizer/85% HDPE | 28.82 ± 2.54 MPa | 23.23 ± 2.80 MPa | 1451.1 ± 10.8 MPa | 355.15% ± 9.05% |

| 10% FA masterbatch/10% compatibilizer/80% HDPE | 27.22 ± 1.16 MPa | 22.62 ± 1.01 MPa | 1360.8 ± 18.8 MPa | 411.28% ± 51.33% |

| 10%FA masterbatch/15% compatibilizer/75% HDPE | 25.56 ± 0.74 MPa | 21.35 ± 0.36 MPa | 1297.1 ± 17.1 MPa | 420.33% ± 61.47% |

| Blend Composition | Initial Temperature | Fastest Temperature | Peak | Initial Temperature |

|---|---|---|---|---|

| Pure HDPE | 390.00 °C | 465.00 °C | 514.00 °C | 0% |

| 95%HDPE/5%FA masterbatch | 220.80 °C | 431.34 °C | 571.75 °C | 2.1% |

| 90%HDPE/10%FA masterbatch | 239.58 °C | 432.18 °C | 569.60 °C | 4.6% |

| 85%HDPE/15%FA masterbatch | 229.13 °C | 439.55 °C | 590.46 °C | 7.1% |

| 80%HDPE/20%FA masterbatch | 221.93 °C | 430.74 °C | 568.05 °C | 8.0% |

| Bellows Diameter | S1 | S2 | Percentage Increase |

|---|---|---|---|

| DN400 | 11.5 KN/m2 | 9.4 KN/m2 | 22.9% |

| DN500 | 10.6 KN/m2 | 8.7 KN/m2 | 22.9% |

| DN600 | 11.8 KN/m2 | 9.6 KN/m2 | 22.8% |

| DN800 | 18.7 KN/m2 | 15.2 KN/m2 | 22.9% |

| DN1000 | 18.4 KN/m2 | 15.0 KN/m2 | 22.8% |

| DN1200 | 16.9 KN/m2 | 13.7 KN/m2 | 22.9% |

| DN1500 | 18.2 KN/m2 | 14.8 KN/m2 | 22.9% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, A.; Jia, L.; Yu, W.; Zhu, F.; Liu, F.; Wang, Y.; Lu, G.; Qin, S.; Gao, D.; Wang, H.; et al. Preparation and Finite Element Analysis of Fly Ash/HDPE Composites for Large Diameter Bellows. Polymers 2021, 13, 4204. https://doi.org/10.3390/polym13234204

Wu A, Jia L, Yu W, Zhu F, Liu F, Wang Y, Lu G, Qin S, Gao D, Wang H, et al. Preparation and Finite Element Analysis of Fly Ash/HDPE Composites for Large Diameter Bellows. Polymers. 2021; 13(23):4204. https://doi.org/10.3390/polym13234204

Chicago/Turabian StyleWu, Angxuan, Lan Jia, Wenwen Yu, Fengbo Zhu, Fuyong Liu, Yanqin Wang, Guoyun Lu, Shuhao Qin, Dongyang Gao, Hua Wang, and et al. 2021. "Preparation and Finite Element Analysis of Fly Ash/HDPE Composites for Large Diameter Bellows" Polymers 13, no. 23: 4204. https://doi.org/10.3390/polym13234204

APA StyleWu, A., Jia, L., Yu, W., Zhu, F., Liu, F., Wang, Y., Lu, G., Qin, S., Gao, D., Wang, H., Wu, X., & Zheng, Q. (2021). Preparation and Finite Element Analysis of Fly Ash/HDPE Composites for Large Diameter Bellows. Polymers, 13(23), 4204. https://doi.org/10.3390/polym13234204