Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives

Abstract

:1. Introduction

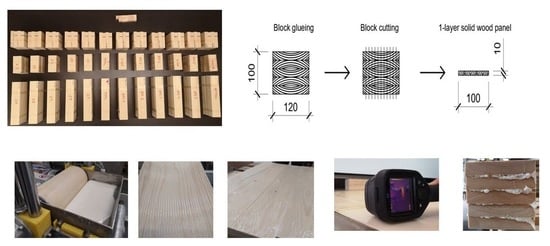

2. Materials and Methods

3. Results and Discussion

3.1. Compression Shear Strength

3.2. Modulus of Rupture and Modulus of Elasticity in Three-Point Bending Test

3.3. Screw Withdrawal Resistance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Acknowledgments

Conflicts of Interest

References

- Fay, P.A. A history of adhesive bonding. In Adhesive Bonding (Second Edition), Science, Technology and Applications; Adams, R.D., Ed.; Woodhead Publishing Series; Welding and Other Joining Technologies: Sawston, UK, 2021; pp. 3–40. [Google Scholar]

- Ebnesajjad, S.; Landrock, A.H. Characteristics of Adhesive Materials. Adhesives Technology Handbook; Elsevier: Amsterdam, The Netherlands, 2015; pp. 84–159. ISBN 9780323355957. [Google Scholar]

- Schwarzenbrunner, R.; Barbu, M.C.; Petutschnigg, A.; Tudor, E.M. Water-Resistant Casein-Based Adhesives for Veneer Bonding in Biodegradable Ski Cores. Polymers 2020, 12, 1745. [Google Scholar] [CrossRef]

- Antov, P.; Savov, V.; Trichkov, N.; Krišťák, L.; Réh, R.; Papadopoulos, A.N.; Taghiyari, H.R.; Pizzi, A.; Kunecová, D.; Pachikova, M. Properties of High-Density Fiberboard Bonded with Urea-Formaldehyde Resin and Ammonium Lignosulfonate as a Bio-Based Additive. Polymers 2021, 13, 2775. [Google Scholar] [CrossRef] [PubMed]

- Bekhta, P.; Noshchenko, G.; Réh, R.; Kristak, L.; Sedliačik, J.; Antov, P.; Mirski, R.; Savov, V. Properties of Eco-Friendly Particleboards Bonded with Lignosulfonate-Urea-Formaldehyde Adhesives and pMDI as a Crosslinker. Materials 2021, 14, 4875. [Google Scholar] [CrossRef] [PubMed]

- Réh, R.; Krišťák, L.; Sedliačik, J.; Bekhta, P.; Božiková, M.; Kunecová, D.; Vozárová, V.; Tudor, E.M.; Antov, P.; Savov, V. Utilization of Birch Bark as an Eco-Friendly Filler in Urea-Formaldehyde Adhesives for Plywood Manufacturing. Polymers 2021, 13, 511. [Google Scholar] [CrossRef] [PubMed]

- Guo, M.; Wang, G. Milk Protein Polymer and Its Application in Environmentally Safe Adhesives. Polymers 2016, 8, 324. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pizzi, A. Types, processing and properties of bioadhesives for wood and fibers. In Advances in Biorefineries; Elsevier: Amsterdam, The Netherlands, 2014; pp. 736–770. ISBN 9780857095213. [Google Scholar]

- Echard, J.P.; Bertrand, L.; Bohlen, A.; Le Hô, A.S.; Paris, C.; Bellot-Gurlet, L.; Soulier, B.; Lattuati-Derieux, A.; Thao, S.; Robinet, L.; et al. The nature of the extraordinary finish of Stradivari’s instruments. Angew. Chem. Int. Ed. 2010, 49, 197–201. [Google Scholar] [CrossRef] [PubMed]

- Driver, D. Adhesive bonding for aerospace applications. In High Performance Materials in Aerospace; Flower, H.M., Ed.; Springer: Dordrecht, The Netherlands, 1995; pp. 318–339. ISBN 978-94-010-4296-3. [Google Scholar]

- Konnerth, J.; Müller, U.; Gindl, W.; Buksnowitz, C. Reliability of wood adhesive bonds in a 50 years old glider construction. Eur. J. Wood Wood Prod. 2012, 70, 381–384. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Wood Handbook: Wood as an Engineering Material; U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 2010. [Google Scholar]

- Vale, B. Building materials. In Materials for a Healthy, Ecological and Sustainable Built Environment; Elsevier: Amsterdam, The Netherlands, 2017; pp. 67–112. ISBN 9780081007075. [Google Scholar]

- Bye, C.N. Casein and Mixed Protein Adhesives. In Handbook of Adhesives; Skeist, I., Ed.; Springer: Boston, MA, USA, 1990; pp. 135–152. ISBN 978-1-4612-8019-4. [Google Scholar]

- Umemura, K.; Inoue, A.; Kawai, S. Development of new natural polymer-based wood adhesives I: Dry bond strength and water resistance of konjac glucomannan, chitosan, and their composites. J. Wood Sci. 2003, 49, 221–226. [Google Scholar] [CrossRef]

- Audic, J.L.; Chaufer, B.; Daufin, G. Non-food applications of milk components and dairy co-products: A review. Lait 2003, 83, 417–438. [Google Scholar] [CrossRef]

- Forest Products Laboratory. Casein Glues: Their Manufacture, Preparation and Application, Report; U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 1967. [Google Scholar]

- McGann, T.C.A.; Fox, P.F. Physico-chemical properties of casein micelles reformed from urea-treated milk. J. Dairy Res. 1974, 41, 45–53. [Google Scholar] [CrossRef]

- Konnerth, J.; Gindl, W.; Harm, M.; Müller, U. Comparing dry bond strength of spruce and beech wood glued with different adhesives by means of scarf- and lap joint testing method. Eur. J. Wood Wood Prod. 2006, 64, 269–271. [Google Scholar] [CrossRef]

- Mitani, A.; Barboutis, I. Bonding strength of polyvinyl acetate (PVAc) and casein adhesives in small diameter beech wood. Biol. Divers. Conserv. 2008, 9, 36–40. [Google Scholar]

- Bierwirth, R.A.; Hoyler, C.N. Radio-Frequency Heating Applied to Wood Gluing. Proc. IRE 1943, 31, 529–537. [Google Scholar] [CrossRef]

- Thelandersson, S.; Larsen, H. Timber Engineering; Wiley: Chichester, UK, 2003; ISBN 0470844698. [Google Scholar]

- Hong, M.-K.; Park, B.-D.; Kim, K.-H.; Shim, K. Performance of Melamine-Urea-Formaldehyde Resin Adhesives at Various Melamine Contents for Bonding Glued Laminated Timber Under High Frequency Heating. J. Korea Wood Sci. Technol. 2017, 45, 409–418. [Google Scholar] [CrossRef]

- Paulitsch, M.; Barbu, M.C. Holzwerkstoffe der Moderne, 1. Aufl.; DRW: Leinfelden-Echterdingen, Germany, 2015; ISBN 9783871818912. [Google Scholar]

- EN 13354:2009. Solid Wood Panels (SWP)-Bonding Quality-Test Method European Committee for Standardization; European Committee for Standardization: Brussels, Belgium, 2009. [Google Scholar]

- EN 310:2005-12-01. Wood-Based Panels-Determination of Modulus of Elasticity in Bending and of Bending Strength; European Committee for Standardization: Brussels, Belgium, 2005. [Google Scholar]

- EN 320:2011. Particleboards and Fibreboards-Determination of Resistance to Axial Withdrawal of Screws; European Committee for Standardization: Brussels, Belgium, 2011. [Google Scholar]

| Sample | Press Process | Press Time | Casein Type | Casein (pbw) | Water (pbw) | Lime (pbw) | Adhesive Amount (g/m2) |

|---|---|---|---|---|---|---|---|

| PVAc-D3 | CP | 24 h | - | - | - | - | 200 |

| HFPVAc-D3 | HF | 4 min | - | - | - | - | 200 |

| HF-AK1 | HF | 2 min | Acid (Kremer) | 1.5 | 3.5 | 1.0 | 400 |

| HF-AK2 | HF | 4 min | Acid (Kremer) | 1.5 | 3.5 | 1.0 | 400 |

| HF-AK3 | HF | 2 min | Acid (Kremer) | 1.5 | 4.5 | 1.0 | 400 |

| HF-AK4 | HF | 4 min | Acid (Kremer) | 1.5 | 4.5 | 1.0 | 400 |

| HF-AK5 | HF | 4 min | Acid (Kremer) | 1.5 | 4.5 | 1.0 | 200 |

| HF-RW | HF | 4 min | Rennin (Woerle) | 1.5 | 3.5 | 1.0 | 400 |

| HF-AW | HF | 4 min | Acid (Woerle) | 1.5 | 3.5 | 1.0 | 400 |

| CP-AK1 | CP | 24 h | Acid (Kremer) | 1.5 | 3.5 | 1.0 | 400 |

| CP-AK2 | CP | 24 h | Acid (Kremer) | 1.5 | 4.5 | 1.0 | 400 |

| CP-AK3 * | CP | 24 h | Acid (Kremer) | 1.5 | 3.5 | 1.0 | 400 |

| CP-AK4 ** | CP | 24 h | Acid (Kremer) | 1.5 | 4.5 | 1.0 | 400 |

| CP-AK5 *** | CP | 24 h | Acid (Kremer) | 1.5 | 3.5 | 1.0 | 400 |

| CP-RW6 | CP | 24 h | Rennin (Woerle) | 1.5 | 3.5 | 1.0 | 400 |

| CP-AW7 | CP | 24 h | Acid (Woerle) | 1.5 | 3.5 | 1.0 | 400 |

| CP-RW8 | CP | 24 h | Rennin (Woerle) | 1.5 | 6.5 | 1.0 | 400 |

| CP-AW9 | CP | 24 h | Acid (Woerle) | 1.0 | 2.5 | 1.0 | 400 |

| Shear Strength (N/mm2) | ||||

|---|---|---|---|---|

| Sample | Mean | Minimum | Maximum | p |

| PVAc-D3 | 1.17 a (0.24) | 0.84 | 1.60 | |

| HFPVAc-D3 | 1.77 c (0.30) | 1.38 | 2.21 | . |

| HF-AK1 | 1.41 b (0.28) | 0.97 | 1.87 | . |

| HF-AK2 | 1.53 b (0.46) | 0.70 | 2.19 | . |

| HF-AK3 | 1.16 a 0.36) | 0.65 | 1.69 | |

| HF-AK4 | 1.88 c (0.21) | 1.60 | 2.28 | . |

| HF-AK5 | 2.07 d (0.40) | 1.40 | 2.81 | . |

| HF-RW | 1.66 c (0.27) | 1.23 | 2.07 | . |

| HF-AW | 1.32 b (0.29) | 1.03 | 1.81 | . |

| CP-AK1 | 2.18 d (0.18) | 1.93 | 2.41 | . |

| CP-AK2 | 2.28 d (0.39) | 1.25 | 2.65 | . |

| CP-AK3 | 1.74 c (0.21) | 1.47 | 2.12 | . |

| CP-AK4 | 2.10 d (0.16) | 1.91 | 2.33 | . |

| CP-AK5 | 1.69 c (0.15) | 1.45 | 1.94 | . |

| CP-RW6 | 1.52 b (0.22) | 1.11 | 1.87 | . |

| CP-AW7 | 1.54 b (0.25) | 1.23 | 2.06 | . |

| CP-RW8 | 1.45 b (0.22) | 0.92 | 1.81 | . |

| CP-AW9 | 1.47 b (0.27) | 1.17 | 2.08 | . |

| Modulus of Rupture (N/mm2) | Modulus of Elasticity (N/mm2) | |||||||

|---|---|---|---|---|---|---|---|---|

| Sample | Mean | Min. | Max. | p | Mean | Min. | Max. | p |

| PVAc-D3 | 98 d (7.7) | 88 | 106 | . | 13,706 c (1441) | 11,641 | 15,301 | . |

| HFPVAc-D3 | 89 a (8.3) | 80 | 104 | 12,177 b (2214) | 10,363 | 15,302 | ||

| HF-AK1 | 93 b (3.3) | 87 | 97 | . | 13,265 c (369) | 12,279 | 13,607 | . |

| HF-AK2 | 91 b (2.8) | 83 | 93 | . | 13,244 c (336) | 12,543 | 13,732 | . |

| HF-AK3 | 90 b (4.9) | 84 | 100 | . | 13,187 c (790) | 12,283 | 14,149 | . |

| HF-AK4 | 86 a (2.6) | 81 | 90 | 12,484 b (423) | 11,842 | 13,205 | ||

| HF-AK5 | 85 a (4.2) | 77 | 91 | 10,614 a (1054) | 9260 | 12,260 | ||

| HF-RW | 97 d (9.0) | 83 | 110 | . | 13,830 c (1025) | 12,521 | 15,121 | . |

| HF-AW | 94 b (3.9) | 89 | 101 | . | 12,685 b (661) | 11,185 | 13,352 | . |

| CP-AK1 | 90 b (3.2) | 86 | 96 | . | 12,237 b (340) | 11,749 | 12,739 | . |

| CP-AK2 | 89 a (5.6) | 81 | 95 | 12,298 b (1180) | 10,665 | 13,411 | ||

| CP-AK3 | 97 d (4.4) | 92 | 105 | . | 14,342 d (560) | 13,635 | 15,293 | . |

| CP-AK4 | 92 b (3.8) | 88 | 101 | . | 12,961 b (520) | 11,964 | 13,681 | . |

| CP-AK5 | 93 b (3.5) | 85 | 97 | 13,866 c (392) | 13,019 | 14,341 | . | |

| CP-RW6 | 90 b (7.6) | 78 | 104 | 12,131 b (1202) | 9225 | 15,469 | . | |

| CP-AW7 | 95 c (6.2) | 84 | 106 | 13,753 c (901) | 11,824 | 14,905 | . | |

| CP-RW8 | 101 d (7.7) | 89 | 110 | 14,238 d (1143) | 12,338 | 15,395 | . | |

| CP-AW9 | 96 d (5.0) | 88 | 102 | 14,137 d (482) | 13,323 | 15,043 | ||

| Screw Withdrawal Resistance (N/mm) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Wood | Adhesive Line | |||||||

| Sample | Mean | Min. | Max. | p | Mean | Min. | Max. | p |

| PVAc-D3 | 98 b (8.7) | 9127 | 117 | . | 114 d (13.4) | 92 | 132 | . |

| HFPVAc-D3 | 102 b (5) | 93 | 108 | . | 109 c (9.5) | 99 | 125 | . |

| HF-AK1 | 115 d (10.5) | 97 | 130 | . | 118 d (9) | 104 | 128 | . |

| HF-AK2 | 99 b (14) | 90 | 133 | . | 108 c (17) | 83 | 131 | . |

| HF-AK3 | 92 a (5.3) | 86 | 101 | 91 a (5) | 85 | 99 | ||

| HF-AK4 | 95 a (3.8) | 87 | 100 | . | 103 b (9.4) | 89 | 123 | . |

| HF-AK5 | 114 d (23) | 81 | 145 | . | 108 c (7) | 98 | 122 | . |

| HF-RW | 108 c (23.4) | 78 | 141 | . | 106 c (12) | 86 | 121 | . |

| HF-AW | 101 b (8.1) | 85 | 108 | 103 b (10) | 90 | 117 | . | |

| CP-AK1 | 117 d (13.1) | 103 | 141 | . | 112 d (5.3) | 104 | 120 | . |

| CP-AK2 | 104 b (2.7) | 98 | 108 | 104 b (6) | 98 | 114 | . | |

| CP-AK3 | 97 b (10.5) | 85 | 110 | 112 d (6) | 100 | 121 | . | |

| CP-AK4 | 110 c (16.3) | 93 | 141 | . | 103 b (8.6) | 96 | 125 | . |

| CP-AK5 | 91 a (5.5) | 80 | 100 | . | 99 b (3) | 96 | 106 | . |

| CP-RW6 | 94 a (6.4) | 85 | 107 | . | 103 b (15) | 84 | 129 | . |

| CP-AW7 | 95 a (7.3) | 83 | 107 | . | 96 a (6) | 87 | 104 | |

| CP-RW8 | 90 a (9) | 75 | 102 | . | 95 a (8.3) | 84 | 108 | |

| CP-AW9 | 108 c (8.3) | 98 | 120 | . | 96 a (11.2) | 82 | 116 | . |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Herzog, A.; Kerschbaumer, T.; Schwarzenbrunner, R.; Barbu, M.-C.; Petutschnigg, A.; Tudor, E.M. Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives. Polymers 2021, 13, 4237. https://doi.org/10.3390/polym13234237

Herzog A, Kerschbaumer T, Schwarzenbrunner R, Barbu M-C, Petutschnigg A, Tudor EM. Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives. Polymers. 2021; 13(23):4237. https://doi.org/10.3390/polym13234237

Chicago/Turabian StyleHerzog, Andreas, Tobias Kerschbaumer, Ronald Schwarzenbrunner, Marius-Cătălin Barbu, Alexander Petutschnigg, and Eugenia Mariana Tudor. 2021. "Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives" Polymers 13, no. 23: 4237. https://doi.org/10.3390/polym13234237

APA StyleHerzog, A., Kerschbaumer, T., Schwarzenbrunner, R., Barbu, M. -C., Petutschnigg, A., & Tudor, E. M. (2021). Efficiency of High-Frequency Pressing of Spruce Laminated Timber Bonded with Casein Adhesives. Polymers, 13(23), 4237. https://doi.org/10.3390/polym13234237