3.1. Principle Mechanical Properties of Plywood Building Material (Veneer Sheets)

Figure 4 shows the compressive strength measurements in longitudinal, tangential and radial directions along with the trend lines used to determine the failure force for the compressive strength calculation, while

Figure 5 shows compressed specimens. In the initial phase of the measurement, the forces increase nonlinearly due to the adaptation of the specimen to the table of the testing machine. The nonlinear part is followed by a linear part and then again, a nonlinear part due to the local tissue failure.

Table 3 shows the test results. The average compressive strengths in the longitudinal, tangential and radial directions are 65.4 MPa, 11.4 MPa and 11.1 MPa, respectively, while the average tensile strengths in the longitudinal and tangential directions are 96.8 MPa and 3.7 MPa, respectively. The tensile strength in the longitudinal direction is greater than the compressive strength and comparable to that in the literature [

44,

45] while the tensile strength in the tangential direction is much lower than the compressive one and also lower than stated in the literature which gives 9 MPa for beech in the tangential direction [

1]. The reason for the lower tensile strength are microcracks that form when the veneer is peeled, and due to the microcracks, stress concentrations occur at tensile load. For the tensile strength in radial direction, the same value as in tangential direction was used as the plane stress state in TL plane is considered.

The average shear strength in the TL direction determined from the asymmetric four-point bending test is 9.3 MPa, which is higher than the literature data for LVL beech specimens [

46,

47]. The shear strength in the TL direction was also calculated using Equation (10), where the results was 10.9 MPa. Since the difference was not great a reasonable applicability of Equation (10) can be confirmed and further used to calculate shear strength in the TR direction where the result was 1.6 MPa, while the shear strength in RL direction was taken the same as in TL direction.

The results for the modulus of elasticity and shear modulus are shown in

Table 4. The average value of modulus of elasticity in longitudinal and tangential directions is 14,854 MPa and 984 MPa, respectively, and is comparable with the literature [

44,

45,

46], while the modulus of elasticity in radial direction was taken from the literature [

1]. The average value of the shear modulus in TL direction is 593 MPa, while the theoretically calculated value according to Equation (14) is 619 MPa, which corresponds to a difference of 4.2%. Since the difference was negligible, the applicability of Equation (14) was confirmed, and it was used to calculate the moduli in RL and RT directions, which were 1464 MPa and 388 MPa, respectively. The standard deviations of the measurements as well as the coefficient of variation were very small, which can be attributed to the relatively homogeneous specimens.

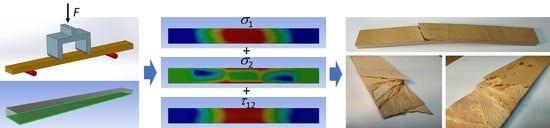

3.2. Failure of Four-Point Plywood Bending Specimens

Figure 6 shows the forces and deformations of the four-point bending loaded 11-layer specimen cut from plate 11A and with the direction of the first layer of 0° and −45°, while

Figure 7 shows the corresponding specimens. The transition from the linear to the nonlinear part occurs for specimens 11A0° and 11A−45° at failure forces of 1688 N and 1209 N, while the final breaking force is 3003 and 2007 N, respectively.

Table 5 and

Table 6 show the min-max mid-sample FOS values for each layer for samples 11A0° and 11A−45°, respectively, for different failure criteria along with the failure mode according to the Puck, max stress and Hashin criteria, where the Tsai-Wu criterion has a constant

axy equal to 1 and the Puck criterion has a constant

p equal to 0.01. In

Table 5, the sample 11A0° has the weakest upper layer No. 1, as it has the lowest min FOS value for all criteria and ranges from 1.33 to 1.54 for different criteria. The distribution of the FOS values together with failure mode is shown in

Figure 8. For the first layer, all three criteria determined the same failure mode of compression failure in the fibre direction, which was expected since the angle of the fibres was 0°. The next weakest layer was the lowest layer No. 11, with the same fibre angle of 0°, but with tensile stresses. Again, all three criteria predict failure in the fibre direction, which is confirmed by

Figure 7b, which nicely shows the failure of the lowest layer No. 11 in the fibre direction. This is to be expected, as compressive strength in longitudinal direction is lower than the tensile one. According to the measurement, the compressive failure of the top layer No. 1 occurred at the force of 1688 N, where the force of 1540 N was calculated by the Puck criteria, but the specimen did not break into two pieces as the top layer can still bear the compressive load despite the local compressive failure. By increasing the force and deformation, the failure of the bottom layer No. 11 followed at a measured force of 3003 N. According to the Puck criterion, the failure force of the lower layer is expected to be 2300 N, and according to the Tsai-Wu failure criterion, it is expected to be 2910 N. The theoretical forces are valid only under the assumption that the stress increases linearly with the force, which is not true in our case because the compressive stress in the upper layer does not increase with increasing force due to the failure of the tissue, and as such the calculated failure force for the lower layer No. 11 cannot be considered as completely valid. In the event that we wish to determine the actual failure force of the specimen at which the bottom layer would also fail, a nonlinear finite element model would be required, which is beyond the scope of the current research.

The situation is opposite for sample 11A−45°, whose min-max mid-sample FOS are listed in

Table 6. Here, layer No. 11 is the weakest, having the lowest min FOS for various criteria ranging from 0.8 to 0.87. Unlike sample 11A0°, where layer No. 1 had a uniform FOS distribution across the width, the FOS distribution in layer No. 11 of sample 11A−45° varied considerably from 0.87 to 1.13 for the max stress criterion as shown in

Figure 9. The transverse tensile failure of the lower layer No. 11 occurs first, followed by layer No. 9, and only then occurs compressive failure at the top part of the specimen, as the tensile and compressive strengths in tangential direction were 3.7 MPa and 11.4 MPa, respectively.

All the criteria predicted the failure of layers No. 11 and 9 in the transverse or shear direction, which can also be seen in

Figure 7b. Puck’s criterion predicted failure under the combination of normal and shear stress (mode A), while the max stress and Hashin’s criterion predicted matrix failure due to transverse tension. According to Puck’s criterion, the lowest layer No. 11 would fail at a force of 820 N, whereas a force of 1209 N was determined in the experiment. The reason for the difference could be that despite the failure of layer No. 11 in the transverse direction, the stiffness drop is not affected because the load carrying capacity of layer No. 11 in the transverse direction is much lower than the load carrying capacity of layer No. 10, which transmits the load in the longitudinal direction of the failing layer No. 11.

The cross-section distribution of longitudinal and tangential stresses for sample 11A0° at a load of 1688 N is shown in

Figure 10a. For all layers, the longitudinal stress predominates, while the maximum tangential stress is 1.5 MPa, much lower than the tensile and compressive strengths, which are 3.7 MPa and 11.4 MPa, respectively. In addition, the maximum shear stresses do not exceed 4 MPa, which is again much lower than the shear strength of 9.3 MPa. Due to the predominant longitudinal stresses, all the outer layers break in the direction of the fibres, which is also predicted by all three failure criteria.

The situation is different for the sample of 11A−45 ° shown in

Figure 10b for the loading force of 1209 N. The stresses in the outer layers are larger in tangential direction and are −4.6 and 4.6 MPa on the compression and tension sides of the specimen, respectively, which is more than the tensile strength of −3.7 MPa and implies to the failure of the corresponding layer.

Figure 11 shows the experimentally determined and theoretically calculated forces of the four-point bending loaded 11-ply specimens. The measured forces vary a little and show a clear trend related to the different orientations of layers. The maximum load capacity for 11A specimen is at 0° and −22° for first ply orientation angle and then the forces decrease.

Figure 11a,b shows the theoretically calculated failure forces according to the criteria of Tsai-Wu and Puck, respectively, based on a minimum factor of safety over the entire specimen cross-section for different values of the constants

axy and

p. The differences between individual values calculated with Tsai-Wu are not large, but they agree best with the criterion with constant

axy = 1. The latter can also be seen in

Table 7, where the coefficient of determination

R2 between the calculated values and the average of the measured forces is 0.551. In addition, for the Puck calculations, the differences are minimal for different constant values of

p, where

R2 for

p = 0.01 is 0.636.

The results for 11P samples are shown in

Figure 11d-f. The Tsai-Wu criterion (

Figure 11d) predicts the failure values well at smaller orientations, while at higher angles the deviation between the predicted and measured values is larger. The best prediction is at

axy = 0, where

R2 is 0.367. Even using the Puck criterion (

Figure 11e), the forces differ only slightly at different

p values, and the

R2 is highest at 0.421 for a value of

p = 0.01.

Figure 11c,f shows the results of all criteria for 11A and 11P samples, respectively. The max stress failure criterion has the best correlation with the highest

R2, which is 0.674 for 11A samples and 0.538 for 11P samples. Max stress is followed by Hashin and Puck criteria in both groups. For the 11A samples, the difference is not very large, while it is larger for the 11P samples. For the 11A samples, then the criteria of Tsai Hill, Tsai Wu and Hoffman are followed, while for the 11P samples, the criteria of Hoffman, Tsai Wu and Tsai Hill are followed.

The results for seven ply samples are shown in

Figure 12. For 7A specimens the forces calculated by using the Tsai-Wu criterion (

Figure 12a) differ only slightly for different values of

axy, having the best

R2 (

Table 7) of 0.133 for an

axy = 0.3, while the forces calculated with the Puck criterion (

Figure 12b) practically do not differ from each other and the highest coefficient of determination of 0.338 has a criterion with

p = 0.01, as was the case for the 11-layer samples. The calculations for 7P samples are shown in

Figure 12d,e. As with the 11P samples, Tsai-Wu (

Figure 12d) predicts the forces well at smaller angles, while the deviation is larger at larger angles. The largest

R2 has a criterion with

axy = −1, while Puck’s criterion (

Figure 12e) again has the largest

R2 at a value of

p = 0.01.

Figure 12c,f shows the results of all criteria for 7A and 7P samples, respectively. As with the 11-layer plates, the max stress criterion has the best

R2, followed by Hashin, Puck, Tsai-Hill, Tsai-Wu and Hoffman for the 7A specimens, and Tsai-Wu, Hoffmann, Hashin and Tsai-Hill for the 7P specimens.

Figure 13 shows the results for the 3-layer samples. Tsai-Wu criterion (

Figure 13a) has slightly larger deviations even at smaller angles and the best

R2 at

a = −1, similar to the 7P samples, while the Puck criterion (

Figure 13b) has the largest

R2 at

p = 0.01. Comparison of all criteria is shown in

Figure 13c. Tsai-Wu and Hoffmann criteria have a slightly better

R2 than the max stress criterion, followed by the Hashin, Puck and Tsai-Hill failure criteria.