Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials Characterization

2.2. Fabrication of Kevlar-Reinforced Epoxy F-MWCNTs Nanocomposites

2.3. Testing of Kevlar/Epoxy Functionalized MWCNTs Composites

2.3.1. Mechanical Testing

2.3.2. Surface Morphology

2.4. Wind Turbine Model

2.5. Finite Element Analysis Modeling

2.5.1. Geometry

2.5.2. Material Properties

2.5.3. Finite Element Analysis Mesh

2.5.4. Boundary Conditions

2.5.5. Solve and Postprocessing Results

3. Results and Discussion

3.1. Mechanical Testing

3.2. Surface Morphology

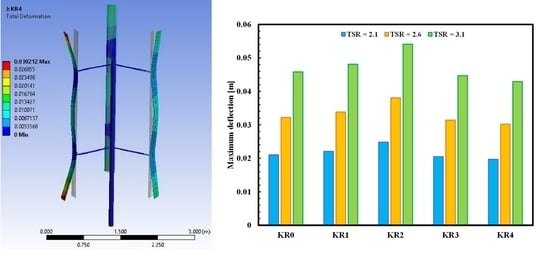

3.3. Finite Element Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elhenawy, Y.; Hafez, G.; Abdel-Hamid, S.; Marwa Elbany. Prediction and assessment of automated lifting system performance for multi-storey parking lots powered by solar energy. J. Cleaner Prod. 2020, 266, 121859. [Google Scholar] [CrossRef]

- Piasecka, I.; Bałdowska-Witos, P.; Flizikowski, J.; Piotrowska, K.; Tomporowski, A. Control the system and environment of post-production wind turbine blade waste using life cycle models. Part 1. Environmental transformation models. Polymers 2020, 12, 1828. [Google Scholar] [CrossRef] [PubMed]

- Al-Qabandi, O.; De Silva, A.; Al-Enezi, S.; Bassyouni, M. Synthesis, fabrication and mechanical characterization of reinforced epoxy and polypropylene composites for wind turbine blades. J. Reinf. Plast. Compos. 2014, 33, 2287–2299. [Google Scholar] [CrossRef]

- Jasper, S.; Stalin, B.; Ravichandran, M. Experimental investigation and Taguchi optimization of turning process parameters for glass fiber reinforced plastics (GFRP). Int. J. Adv. Technol. Eng. Explor. 2018, 5, 394–399. [Google Scholar] [CrossRef]

- Chandler, H. Wind Energy, The Facts an Analysis of Wind Energy in the EU-25; European Wind Energy Association: Brussels, Belgium, 2007. [Google Scholar]

- Mostovoy, A.S.; Yakovlev, A.V.; Tseluikin, V.N.; Lopukhova, M. Epoxy nanocomposites reinforced with functionalized carbon nanotubes. Polymers 2020, 12, 1816. [Google Scholar] [CrossRef]

- Roy, S.; Petrova, R.S.; Mitra, S. Effect of carbon nanotube (CNT) functionalization in epoxy-CNT composites. Nanotechnol. Rev. 2018, 7, 475–485. [Google Scholar] [CrossRef]

- Elsakka, M.M.; Ingham, D.B.; Ma, L.; Pourkashanian, M. CFD analysis of the angle of attack for a vertical axis wind turbine blade. Energy Convers. Manag. 2019, 182, 154–165. [Google Scholar] [CrossRef]

- Dong, W.; Li, Z.; Sun, H.; Zhang, J. Modeling and analysis of a deflection type permanent magnet synchronous wind generator system. Energies 2020, 13, 1524. [Google Scholar] [CrossRef] [Green Version]

- Pan, L.; Shi, Z.; Xiao, H. Parameter design and optimization for camber of vertical axis offshore wind turbine using CFD. J. Ocean Eng. Mar. Energy 2020, 6, 339–357. [Google Scholar] [CrossRef]

- Wang, L.; Kolios, A.; Nishino, T.; Delafin, P.-L.; Bird, T. Structural optimisation of vertical-axis wind turbine composite blades based on finite element analysis and genetic algorithm. Compos. Struct. 2016, 153, 123–138. [Google Scholar] [CrossRef] [Green Version]

- Muhammed, K.A.; Kannan, C.R.; Stalin, B.; Ravichandran, M. Experimental investigation on AW 106 Epoxy/E-Glass fiber/nano clay composite for wind turbine blade. Mater. Today Proc. 2020, 21, 202–205. [Google Scholar] [CrossRef]

- Muhammed, K.A.; Kannan, C.R.; Stalin, B. Performance analysis of wind turbine blade materials using nanocomposites. Mater. Today Proc. 2020, 33, 4353–4361. [Google Scholar] [CrossRef]

- Ullah, H.; Ullah, B.; Silberschmidt, V.V. Structural integrity analysis and damage assessment of a long composite wind turbine blade under extreme loading. Compos. Struct. 2020, 246, 112426. [Google Scholar] [CrossRef]

- Amjith, L.; Bavanish, B. Design and analysis of 5 MW horizontal axis wind turbine. Mater. Today Proc. 2020, in press. [Google Scholar]

- Ziegler, L.; Gonzalez, E.; Rubert, T.; Smolka, U.; Melero, J.J. Lifetime extension of onshore wind turbines: A review covering Germany, Spain, Denmark, and the UK. Renew. Sustain. Energy Rev. 2018, 82, 1261–1271. [Google Scholar] [CrossRef] [Green Version]

- García, V.; Vargas, L.; Acuña, A.; Sosa, J.B.; Durazo, E.; Ballesteros, R.; Ocampo, J. Evaluation of basalt fibers on wind turbine blades through finite element analysis. Adv. Mater. Sci. Eng. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Alanezi, A.A.; Safaei, M.R.; Goodarzi, M.; Elhenawy, Y. The effect of inclination angle and reynolds number on the performance of a direct contact membrane distillation (DCMD) process. Energies 2020, 13, 2824. [Google Scholar] [CrossRef]

- Condruz, M.R.; Malael, I.; Vintila, I.S.; Cernat, M.P. Manufacturing of advanced composite wind turbine blades for counter rotating vertical wind turbine. Mater. Plast. 2019, 57, 45–56. [Google Scholar] [CrossRef]

- Song, F.; Ni, Y.; Tan, Z. Optimization design, modeling and dynamic analysis for composite wind turbine blade. Procedia Eng. 2011, 16, 369–375. [Google Scholar] [CrossRef] [Green Version]

- Barnes, R.H.; Morozov, E.V.; Shankar, K. Evaluation of simplified loading models for finite element analysis of composite wind turbine blades. In Proceedings of the 20th International Conference on Composite Materials (ICCM-20), Copenhagen, Denmark, 19–24 July 2015; pp. 19–24. [Google Scholar]

- Ravikumar, K.; Subbiah, R.; Ranganathan, N.; Bensingh, J.; Kader, A.; Nayak, S.K. A review on fatigue damages in the wind turbines: Challenges in determining and reducing fatigue failures in wind turbine blades. Wind. Eng. 2019, 44, 434–451. [Google Scholar] [CrossRef]

- Sathish, T. Fluid flow analysis of composite material-based wind turbine blades using Ansys. Int. J. Ambient. Energy 2019, 1–4. [Google Scholar] [CrossRef]

- Beaumont, P.W.R.; Zweben, C.H.; Gdutos, E.; Talreja, R.; Poursartip, A.; Clyne, T.; Ruggles-Wrenn, M.B. Comprehensive Composite Materials, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Zhang, T.T.; Elsakka, M.; Huang, W.; Wang, Z.G.; Ingham, D.B.; Ma, L.; Pourkashanian, M. Winglet design for vertical axis wind turbines based on a design of experiment and CFD approach. Energy Convers. Manag. 2019, 195, 712–726. [Google Scholar] [CrossRef]

- Moheimani, R.; Sarayloo, R.; Dalir, H. Failure study of fiber/epoxy composite laminate interface using cohesive multiscale model. Adv. Compos. Lett. 2020, 29, 1–19. [Google Scholar] [CrossRef]

- Sobri, S.A.; Whitehead, D.; Mohamed, M.; Mohamed, J.J.; Amini, M.H.M.; Hermawan, A.; Rasat, M.S.M.; Sofi, A.Z.M.; Ismail, W.O.A.S.W.; Norizan, M.N. Augmentation of the delamination factor in drilling of carbon fibre-reinforced polymer composites (CFRP). Polymers 2020, 12, 2461. [Google Scholar] [CrossRef] [PubMed]

- Wong, K.J.; Johar, M.; Koloor, S.S.R.; Petrů, M.; Tamin, M.N. Moisture Absorption effects on mode II delamination of carbon/epoxy composites. Polymers 2020, 12, 2162. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Yang, T.; Liu, C.; Du, Y.; Gong, W. Investigation of hole quality during drilling of KFRP based on the interaction between collars and cutter. Int. J. Adv. Manuf. Technol. 2018, 95, 4101–4116. [Google Scholar] [CrossRef]

- Saravanakumar, K.; Arumugam, V.; Souhith, R.; Santulli, C. Influence of milled glass fiber fillers on mode i & mode II interlaminar fracture toughness of epoxy resin for fabrication of glass/epoxy composites. Fibers 2020, 8, 36. [Google Scholar] [CrossRef]

- Bassyouni, M.; Gutub, S.A. Materials selection strategy and surface treatment of polymer composites for wind turbine blades fabrication. Polym. Polym. Compos. 2013, 21, 463–472. [Google Scholar] [CrossRef]

- Xiao, J.; Shi, H.; Tao, L.; Qi, L.; Min, W.; Zhang, H.; Yu, M.; Sun, Z. Effect of fibres on the failure mechanism of composite tubes under low-velocity impact. Materials 2020, 13, 4143. [Google Scholar] [CrossRef]

- Mandell, J.F.; Cairns, D.S.; Samborsky, D.D.; Morehead, R.B.; Haugen, D.J. Prediction of delamination in wind turbine blade structural details. J. Sol. Energy Eng. 2003, 125, 522–530. [Google Scholar] [CrossRef] [Green Version]

- Zhang, W.; Deng, X.; Sui, G.; Yang, X. Improving interfacial and mechanical properties of carbon nanotube-sized carbon fiber/epoxy composites. Carbon 2019, 145, 629–639. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Average diameter (nm) | 9.5 nm |

| Length (µm) | 0.5–1 |

| Purity (wt.%) | 90% MWCNTs 10% Metal oxides |

| Surface area (m2/g) | 250–300 |

| Thickness (nm) | ~3 |

| Bulk density (kg/m3) | 215 |

| Specific surface area (m2/g) | ~25 |

| Zeta potential (mv) | −30 |

| Property | Value |

|---|---|

| Outside diameter (nm) | 10–30 n |

| Purity (wt.%) | >90 |

| Length(um) | 10–30 |

| Surface area (m2/g) | 250–300 |

| Tapped density (kg/m3) | 140 |

| —COOH content (wt.%) | ~1.5 |

| Parameter | Epoxy (AMPRO™ Slow Hardener) | Kevlar 49 |

|---|---|---|

| Tensile strength (MPa) | 48.1 | 3600 |

| Tg (°C) | 45 | 455 |

| Bulk density kg/m3 | 1120 | 1440 |

| Hardness (HV) | 15 | 27 |

| Young’s modulus (GPa) | 2.7 | 127 |

| Viscosity (cP) | 800 | - |

| Sample | Matrix | MWCNTs (wt.%) | MWCNTs | Reinforced | Kevlar Mass Fraction | Processing |

|---|---|---|---|---|---|---|

| KR0 | Epoxy | 0 | 0 | Kevlar | 0.63 | VIP |

| KR1 | 0.1 | Unmodified | ||||

| KR2 | 0.5 | Unmodified | ||||

| KR3 | 0.1 | –COOH | ||||

| KR4 | 0.5 | –COOH |

| Parameters | Values | Units |

|---|---|---|

| Number of blades | 3 | - |

| Rotor radius, r | 0.9 | m |

| Blade length | 3.6 | m |

| Rated wind speed, | 7 | m/s |

| Rated rotor speed,Φ | 20.222 | rad/s |

| Airfoil | NACA0015 |

| Coarse Mesh | Baseline Mesh | Fine Mesh | |

|---|---|---|---|

| Nodes | 32,198 | 94,809 | 13,5317 |

| Elements | 6692 | 19,935 | 26,672 |

| Maximum Deflection [m] | 0.0265 | 0.0541 | 0.0571 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elhenawy, Y.; Fouad, Y.; Marouani, H.; Bassyouni, M. Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade. Polymers 2021, 13, 422. https://doi.org/10.3390/polym13030422

Elhenawy Y, Fouad Y, Marouani H, Bassyouni M. Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade. Polymers. 2021; 13(3):422. https://doi.org/10.3390/polym13030422

Chicago/Turabian StyleElhenawy, Yasser, Yasser Fouad, Haykel Marouani, and Mohamed Bassyouni. 2021. "Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade" Polymers 13, no. 3: 422. https://doi.org/10.3390/polym13030422

APA StyleElhenawy, Y., Fouad, Y., Marouani, H., & Bassyouni, M. (2021). Performance Analysis of Reinforced Epoxy Functionalized Carbon Nanotubes Composites for Vertical Axis Wind Turbine Blade. Polymers, 13(3), 422. https://doi.org/10.3390/polym13030422