Fabrication of Core-Shell Chopped Cf-Phenolic Resin Composite Powder for Laser Additive Manufacturing of Cf/SiC Composites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

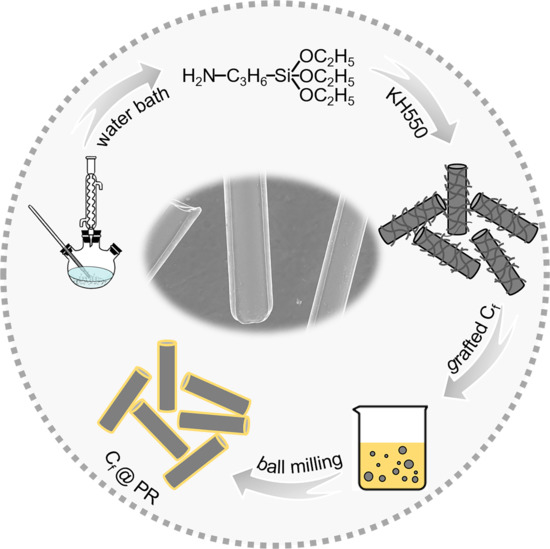

2.2. Experimental Process

2.3. Characterizations

3. Results and Discussion

3.1. FTIR Spectra Analysis

3.2. Raman Spectra Analysis

3.3. Surface Elemental Composition Analysis

3.4. Surface Morphology of Cf @PR

3.5. The Laser Absorption Analysis of Cf @PR

4. Conclusions

- (1)

- The FTIR, Raman, and XPS indicated that the KH550 has been grafted onto the surface of carbon surface successfully. After the surface modification, the concentration of the Si and N elements on the surface of the fiber changed significantly.

- (2)

- The introduction of KH550 improves the wettability and compatibility between the carbon fiber and phenolic resin, which resulted in a homogeneous PR coating on the surface of carbon fiber. When the content of PR was higher than 20 vol%, an interface between the fiber and the PR was observed.

- (3)

- The Cf @PR composite powder exhibited excellent laser absorption, ranging from 1500 cm−1 to 550 cm−1 (6.67~18.18 μm), which may be applicable for a CO2 laser during laser additive manufacturing. The optimal PR content was 25 vol%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, W.; Yamashita, S.; Kita, H. Progress in tribological research of SiC ceramics in unlubricated sliding-A review. Mater. Des. 2020, 190, 108528. [Google Scholar] [CrossRef]

- Li, J.; Ren, X.; Zhang, Y.; Hou, H. Significant improvements of the relative density, microhardness, and fracture toughness of SiC via the addition of Ni3Al and Mg2Si. Ceram. Int. 2020, 47, 1472–1477. [Google Scholar] [CrossRef]

- Han, D.; Mei, H.; Xiao, S.; Dassios, K.G.; Cheng, L. A review on the processing technologies of carbon nanotube/silicon carbide composites. J. Eur. Ceram. Soc. 2018, 38, 3695–3708. [Google Scholar] [CrossRef]

- Ma, R.; Shi, J.; Lin, W.; Chen, J. Synthesis and sintering of nanocrystalline SiC ceramic powders. Mater. Chem. Phys. 2020, 253, 123445. [Google Scholar] [CrossRef]

- Dinesh, V.; Swarna, S.; Sanjay, J.; Meenu, V.; Khenata, R. Mechanically induced stiffening, thermally driven softening, and brittle nature of SiC. J. Adv. Ceram. 2016, 5, 13–34. [Google Scholar] [CrossRef] [Green Version]

- Alireza, M.; Hamidreza, B.; Mehdi, T.; Hamidreza, L.; Jukka, M. Determination of fracture toughness using the area of micro-crack tracks left in brittle materials by Vickers indentation test. J. Adv. Ceram. 2013, 2, 87–102. [Google Scholar] [CrossRef]

- Lu, Z.; Xia, Y.; Miao, K.; Li, S.; Zhu, L.; Nan, H.; Cao, J.; Li, D. Microstructure control of highly oriented short carbon fibres in SiC matrix composites fabricated by direct ink writing. Ceram. Int. 2019, 45, 17262–17267. [Google Scholar] [CrossRef]

- Naslain, R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Meng, X.; Wu, X.; Pei, B.; Zhu, Y.; Huang, Z. Preparation and Mechanical Properties of Short Carbon Fiber Reinforced Silicon Carbide Matrix Composites. J. Inorg. Mater. 2019, 34, 1015–1020. [Google Scholar] [CrossRef]

- Ding, Y.; Dong, S.; Huang, Z.; Jiang, D. Fabrication of short C fiber-reinforced SiC composites by spark plasma sintering. Ceram. Int. 2007, 33, 101–105. [Google Scholar] [CrossRef]

- He, X.; Guo, Y.; Yu, Z.; Zhou, Y.; Jia, D. Study on microstructures and mechanical properties of short-carbon-fiber-reinforced SiC composites prepared by hot-pressing. Mater. Sci. Eng. A 2009, 527, 334–338. [Google Scholar] [CrossRef]

- Nath, S.D.; Nilufar, S. An Overview of Additive Manufacturing of Polymers and Associated Composites. Polymers 2020, 12, 2719. [Google Scholar] [CrossRef] [PubMed]

- Niño, E.D.V.; Lonne, Q.; Lantada, A.D.; Ospino, E.M.; Hernández, H.A.E.D.R.C.; Ramírez-Caballero, G.; Endrino, J.L. Physical and Chemical Properties Characterization of 3D-Printed Substrates Loaded with Copper-Nickel Nanowires. Polymers 2020, 12, 2680. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.; Lim, C.H.J.; Low, M.J.; Tham, N.; Murukeshan, V.M.; Kim, Y. Lasers in additive manufacturing: A review. Int. J. Precis. Eng. Manuf.-Green Technol. 2017, 4, 307–322. [Google Scholar] [CrossRef]

- Li, Z.; Zhou, W.; Yang, L.; Chen, P.; Yan, C.; Cai, C.; Li, H.; Li, L.; Shi, Y. Glass Fiber-Reinforced Phenol Formaldehyde Resin-Based Electrical Insulating Composites Fabricated by Selective Laser Sintering. Polymers 2019, 11, 135. [Google Scholar] [CrossRef] [Green Version]

- Sze, S.M.; Ng, K.K. Physics of Semiconductor Devices, 3rd ed.; A John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Zocca, A.; Colombo, P.; Gomes, C.M.; Günster, J.; Green, D.J. Additive Manufacturing of Ceramics: Issues, Potentialities, and Opportunities. J. Am. Ceram. Soc. 2015, 98, 1983–2001. [Google Scholar] [CrossRef]

- Wang, J.; Dommati, H.; Hsieh, S. Review of additive manufacturing methods for high-performance ceramic materials. Int. J. Adv. Manuf. Technol. 2019, 103, 2627–2647. [Google Scholar] [CrossRef]

- Xu, T.; Cheng, S.; Jin, L.; Zhang, K.; Zeng, T. High-temperature flexural strength of SiC ceramics prepared by additive manufacturing. Int. J. Appl. Ceram. Technol. 2020, 17, 438–448. [Google Scholar] [CrossRef]

- Zhu, W.; Fu, H.; Xu, Z.; Liu, R.; Jiang, P.; Shao, X.; Shi, Y.; Yan, C. Fabrication and characterization of carbon fiber reinforced SiC ceramic matrix composites based on 3D printing technology. J. Eur. Ceram. Soc. 2018, 38, 4604–4613. [Google Scholar] [CrossRef]

- Park, S.J.; Jin, J.S. Effect of Silane Coupling Agent on Interphase and Performance of Glass Fibers/Unsaturated Polyester Composites. J. Colloid Interface Sci. 2001, 242, 174–179. [Google Scholar] [CrossRef]

- Zhu, W.; Yan, C.; Shi, Y.; Wen, S.; Liu, J.; Wei, Q.; Shi, Y. A novel method based on selective laser sintering for preparing high-performance carbon fibres/polyamide12/epoxy ternary composites. Sci. Rep. 2016, 6, 33780. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shang, X.; Zhu, Y.; Li, Z. Surface modification of silicon carbide with silane coupling agent and hexadecyl iodiele. Appl. Surf. Sci. 2017, 394, 169–177. [Google Scholar] [CrossRef]

- Cui, H.; Jin, Z.; Zheng, D.; Tang, W.; Li, Y.; Yun, Y.; Lo, T.Y.; Xing, F. Effect of carbon fibers grafted with carbon nanotubes on mechanical properties of cement-based composites. Constr. Build. Mater. 2018, 181, 713–720. [Google Scholar] [CrossRef]

- Peng, C.; Chen, P.; You, Z.; Lv, S.; Zhang, R.; Xu, F.; Zhang, H.; Chen, H. Effect of silane coupling agent on improving the adhesive properties between asphalt binder and aggregates. Constr. Build. Mater. 2018, 169, 591–600. [Google Scholar] [CrossRef]

- Wei, B.; Chang, Q.; Bao, C.; Dai, L.; Zhang, G.; Wu, F. Surface modification of filter medium particles with silane coupling agent KH550. Colloid. Surf. A 2013, 434, 276–280. [Google Scholar] [CrossRef]

- Zhang, R.L.; Gao, B.; Du, W.T.; Zhang, J.; Cui, H.Z.; Liu, L.; Ma, Q.H.; Wang, C.G.; Li, F.H. Enhanced mechanical properties of multiscale carbon fiber/epoxy composites by fiber surface treatment with graphene oxide/polyhedral oligomeric silsesquioxane. Compos. Part A 2016, 84, 455–463. [Google Scholar] [CrossRef]

- Dong, J.; Li, Y.; Wen, J.; Xiao, X.; Zhu, X.; Man, Y. Research on Hydrolysis Process of KH550 Silane Coupling Agent. J. Salt Lake Res. 2020, 28, 28–33. [Google Scholar]

- Wen, Z.; Xu, C.; Qian, X.; Zhang, Y.; Wang, X.; Song, S.; Dai, M.; Zhang, C. A two-step carbon fiber surface treatment and its effect on the interfacial properties of CF/EP composites: The electrochemical oxidation followed by grafting of silane coupling agent. Appl. Surf. Sci. 2019, 486, 546–554. [Google Scholar] [CrossRef]

- Liu, J.; Tian, Y.; Chen, Y.; Liang, J. Interfacial and mechanical properties of carbon fibers modified by electrochemical oxidation in (NH4HCO3)/(NH4)2C2O4·H2O aqueous compound solution. Appl. Surf. Sci. 2010, 256, 6199–6204. [Google Scholar] [CrossRef]

- Yuan, H.; Wang, C.; Zhang, S.; Lin, X. Effect of surface modification on carbon fiber and its reinforced phenolic matrix composite. Appl. Surf. Sci. 2012, 259, 288–293. [Google Scholar] [CrossRef]

- Sze, S.K.; Siddique, N.; Sloan, J.J.; Escribano, R. Raman spectroscopic characterization of carbonaceous aerosols. Atmos. Environ. 2001, 35, 561–568. [Google Scholar] [CrossRef]

- Mahdavipour, B.; Elahi, A.S. Growth and Characterization of Boron-Carbon Structures with the Hot Filament Chemical Vapor Deposition Technique. Silicon 2018, 10, 1731–1736. [Google Scholar] [CrossRef]

- Zhao, Y.; Ma, Z.; Song, H.; Chen, M.; Zhou, Z. Synthesis and Characterization of Carbon Fibers Multi-scale Reinforcement with Grafted Graphene Oxide. Chin. J. Mater. Res. 2016, 30, 229–234. [Google Scholar] [CrossRef]

- Kumar, R.; Dhawan, S.K.; Singh, H.K.; Kaur, A. Charge transport mechanism of thermally reduced graphene oxide and their fabrication for high performance shield against electromagnetic pollution. Mater. Chem. Phys. 2016, 180, 413–421. [Google Scholar] [CrossRef]

- Lin, J.; Sun, C.; Min, J.; Wan, H.; Wang, S. Effect of atmospheric pressure plasma treatment on surface physicochemical properties of carbon fiber reinforced polymer and its interfacial bonding strength with adhesive. Compos. Part B Eng. 2020, 199. [Google Scholar] [CrossRef]

- Yenier, Z.; Altay, L.; Sarikanat, M. Effect of Surface Modification of Carbon Fiber on Mechanical Properties of Carbon/Epoxy Composites. Emerg. Mater. Res. 2020, 9, 1–8. [Google Scholar] [CrossRef]

- Feng, P.; Song, G.; Li, X.; Xu, H.; Xu, L.; Lv, D.; Zhu, X.; Huang, Y.; Ma, L. Effects of different “rigid-flexible” structures of carbon fibers surface on the interfacial microstructure and mechanical properties of carbon fiber/epoxy resin composites. J. Colloid Interface Sci. 2021, 583, 13–23. [Google Scholar] [CrossRef]

- Pittman, C.U.; Jiang, W.; Yue, Z.R.; Gardner, S.; Wang, L.; Toghiani, H.; Leon, C.A.L. Surface properties of electrochemically oxidized carbon fibers. Carbon 1999, 37, 1797–1807. [Google Scholar] [CrossRef]

- Xiao, H.; Lu, Y.; Zhao, W.; Qin, X. The effect of heat treatment temperature and time on the microstructure and mechanical properties of PAN-based carbon fibers. J. Mater. Sci. 2013, 49, 794–804. [Google Scholar] [CrossRef]

- Wen, Z.; Qian, X.; Zhang, Y.; Wang, X.; Wang, W.; Song, S. Electrochemical polymerization of carbon fibers and its effect on the interfacial properties of carbon reinforced epoxy resin composites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 21–29. [Google Scholar] [CrossRef]

- Zhou, P.; Qi, H.; Zhu, Z.; Qin, H.; Li, H.; Chu, C.; Yan, M. Development of SiC/PVB Composite Powders for Selective Laser Sintering Additive Manufacturing of SiC. Materials 2018, 11, 2012. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Becker, A.F.A. Characterization and Prediction of SLS Processability of Polymer Powders with Respect to Powder Flow and Part Warpage. Ph.D. Thesis, Pontificia Universidad Católica de Chile, Santiago, Chile, 2016. [Google Scholar]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef] [Green Version]

- Chen, A.; Wu, J.; Liu, K.; Chen, J.; Xiao, H.; Chen, P.; Li, C.; Shi, Y. High-performance ceramic parts with complex shape prepared by selective laser sintering: A review. Adv. Appl. Ceram. 2017, 1–18. [Google Scholar] [CrossRef]

- Streek, A.; Regenfuss, P.; Exner, H. Fundamentals of Energy Conversion and Dissipation in Powder Layers during Laser Micro Sintering—ScienceDirect. Phys. Procedia 2013, 41, 851–862. [Google Scholar] [CrossRef] [Green Version]

- Thomas, M.; Heinrich, J. Slurry-Based Additive Manufacturing of Ceramics. Int. J. Appl. Ceram. Technol. 2013, 1–8. [Google Scholar] [CrossRef]

- Graf, S.; Staupendahl, G.; Gerling, P.; Muller, F.A. Optical constants n and κ of various technical and optical glasses at λ=10.59μm. J. Appl. Phys. 2013, 113, 1080. [Google Scholar] [CrossRef]

| Item | Specification |

|---|---|

| Density | 1.76 g/cm3 |

| Monofilament diameter | 6–8 μm |

| Oxygen content | 0.58 wt% |

| Samples | D-Band | G-Band | R = ID/IG | ||

|---|---|---|---|---|---|

| Position/cm−1 | FWHM/cm−1 | Position/cm−1 | FWHM/cm−1 | ||

| Cf | 1361.81 | 239.23 | 1582.00 | 96.37 | 2.49 |

| Cf-KH550 | 1363.11 | 247.75 | 1585.52 | 95.32 | 2.64 |

| Samples | Peak Designation | Band (eV) | At% Conc. | Atomic Ratio | ||

|---|---|---|---|---|---|---|

| N/C | O/C | Si/C | ||||

| Cf | C1s | 284.64 | 81.49 | 0.0250 | 0.1936 | 0.0086 |

| N1s | 400.36 | 2.04 | ||||

| O1s | 532.17 | 15.78 | ||||

| Si2p | 101.94 | 0.7 | ||||

| Cf-KH550 | C1s | 284.63 | 69.92 | 0.0774 | 0.2719 | 0.0810 |

| N1s | 399.5 | 5.41 | ||||

| O1s | 532.16 | 19.01 | ||||

| Si2p | 102.48 | 5.66 | ||||

| Sample | –C–C | –C–OH | –COOH |

|---|---|---|---|

| Cf | 68.34% | 18.68% | 12.98% |

| Cf-KH550 | 73.96% | 20.65% | 5.39% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Yin, J.; Liu, X.; Xia, A.; Huang, Z. Fabrication of Core-Shell Chopped Cf-Phenolic Resin Composite Powder for Laser Additive Manufacturing of Cf/SiC Composites. Polymers 2021, 13, 463. https://doi.org/10.3390/polym13030463

Chen X, Yin J, Liu X, Xia A, Huang Z. Fabrication of Core-Shell Chopped Cf-Phenolic Resin Composite Powder for Laser Additive Manufacturing of Cf/SiC Composites. Polymers. 2021; 13(3):463. https://doi.org/10.3390/polym13030463

Chicago/Turabian StyleChen, Xiao, Jie Yin, Xuejian Liu, Aidong Xia, and Zhengren Huang. 2021. "Fabrication of Core-Shell Chopped Cf-Phenolic Resin Composite Powder for Laser Additive Manufacturing of Cf/SiC Composites" Polymers 13, no. 3: 463. https://doi.org/10.3390/polym13030463

APA StyleChen, X., Yin, J., Liu, X., Xia, A., & Huang, Z. (2021). Fabrication of Core-Shell Chopped Cf-Phenolic Resin Composite Powder for Laser Additive Manufacturing of Cf/SiC Composites. Polymers, 13(3), 463. https://doi.org/10.3390/polym13030463