Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite

Abstract

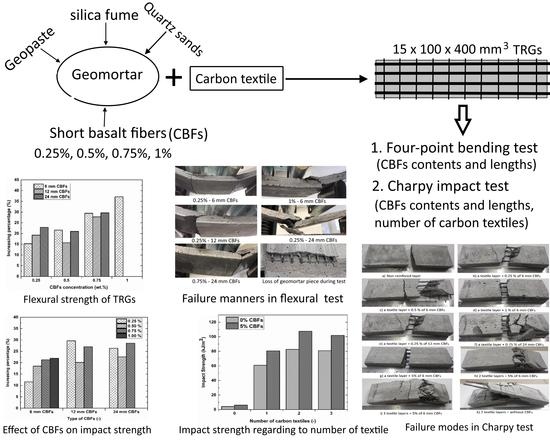

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. The Mixing Process of the Fresh Geomortar and Specimens Preparation

2.3. Test Methods

3. Results

3.1. Self-Flowability of the Fresh Geomortar Matrix

3.2. Flexural Load-Displacement Response of the TRG Composites and Their Flexural Properties

3.3. Failure Modes

3.4. Charpy Impact Performance of the TRG Composites

4. Comparison with our Previous Research and General Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cevallos, O.; Olivito, R. Effects of fabric parameters on the tensile behaviour of sustainable cementitious composites. Compos. Part B Eng. 2015, 69, 256–266. [Google Scholar] [CrossRef]

- D’Antino, T.; Papanicolaou, C. Mechanical characterization of textile reinforced inorganic-matrix composites. Compos. Part B Eng. 2017, 127, 78–91. [Google Scholar] [CrossRef]

- Lignola, G.P.; Caggegi, C.; Ceroni, F.; de Santis, S.; Krajewski, P.; Lourenço, P.B.; Morganti, M.; Papanicolaou, C.; Pellegrino, C.; Prota, A.; et al. Performance assessment of basalt FRCM for retrofit applications on masonry. Compos. Part B. Eng. 2017, 128, 1–18. [Google Scholar] [CrossRef]

- Ferrara, G.; Coppola, B.; Di Maio, L.; Incarnato, L.; Martinelli, E. Tensile strength of flax fabrics to be used as reinforcement in cement-based composites: Experimental tests under different environmental exposures. Compos. Part B Eng. 2019, 168, 511–523. [Google Scholar] [CrossRef]

- Colombo, I.G.; Colombo, M.; Di Prisco, M. Bending behaviour of Textile Reinforced Concrete sandwich beams. Constr. Build. Mater. 2015, 95, 675–685. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Portal, N.W.; Flansbjer, M.; Zandi, K.; Wlasak, L.; Malaga, K. Bending behaviour of novel Textile Reinforced Concrete-foamed concrete (TRC-FC) sandwich elements. Compos. Struct. 2017, 177, 104–118. [Google Scholar] [CrossRef]

- Dey, V.; Zani, G.; Colombo, M.; Di Prisco, M.; Mobasher, B. Flexural impact response of textile-reinforced aerated concrete sandwich panels. Mater. Des. 2015, 86, 187–197. [Google Scholar] [CrossRef]

- Yin, S.; Wang, B.; Wang, F.; Xu, S. Bond investigation of hybrid textile with self-compacting fine-grain concrete. J. Ind. Text. 2017, 46, 1616–1632. [Google Scholar] [CrossRef]

- Shiping, Y.I.N.; Shilang, X.U.; Hedong, L.I. Improved Mechanical Properties of Textile Reinforced Concrete Thin Plate. J. Wuhan Univ. Technol. Mat. Sci. Edit. 2013, 28, 11–12. [Google Scholar]

- Li, Q.; Xu, S. Experimental Research on Mechanical Performance of Hybrid Fiber Reinforced Cementitious Composites with Polyvinyl Alcohol Short Fiber and Carbon Textile. J. Compos. Mater. 2010, 45, 5–28. [Google Scholar] [CrossRef]

- Dvorkin, D.; Peled, A. Cement and concrete research effect of reinforcement with carbon fabrics impregnated with nanoparticles on the tensile behavior of cement-based composites. Cem. Concr. Res. 2016, 85, 28–38. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, X.; Zhou, F.; Zhu, D.; Zhang, M.; Pan, W. Flexural behavior of basalt textile-reinforced concrete. Constr. Build. Mater. 2018, 183, 7–21. [Google Scholar] [CrossRef]

- Ding, Y.; Wang, Q.; Pacheco-Torgal, F.; Zhang, Y. Hybrid effect of basalt fiber textile and macro polypropylene fiber on flexural load-bearing capacity and toughness of two-way concrete slabs. Constr. Build. Mater. 2020, 261, 119881. [Google Scholar] [CrossRef]

- Zhu, D.; Liu, S.; Yao, Y.; Li, G.; Du, Y.; Shi, C. Effects of short fiber and pre-tension on the tensile behavior of basalt textile reinforced concrete. Cem. Concr. Compos. 2019, 96, 33–45. [Google Scholar] [CrossRef]

- Liu, S.; Zhu, D.; Li, G.; Yao, Y.; Ou, Y.; Shi, C.; Du, Y. Flexural response of basalt textile reinforced concrete with pre-tension and short fibers under low-velocity impact loads. Constr. Build. Mater. 2018, 169, 859–876. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, M.; Zhou, F.; Zhu, D. Experimental study on basalt textile reinforced concrete under uniaxial tensile loading. Constr. Build. Mater. 2017, 138, 88–100. [Google Scholar] [CrossRef]

- Barhum, R.; Mechtcherine, V. Influence of short dispersed and short integral glass fibres on the mechanical behaviour of textile-reinforced concrete. Mater. Struct. 2013, 46, 557–572. [Google Scholar] [CrossRef]

- Du, Y.; Zhang, X.; Liu, L.; Zhou, F.; Zhu, D.; Pan, W. Flexural Behaviour of Carbon Textile-Reinforced Concrete with Prestress and Steel Fibres. Polymers 2018, 10, 98. [Google Scholar] [CrossRef] [Green Version]

- Pakravan, H.R.; Jamshidi, M.; Rezaei, H. Effect of textile surface treatment on the flexural properties of cementitious composites. J. Ind. Text. 2016, 46, 116–129. [Google Scholar] [CrossRef]

- Peled, A.; Zaguri, E.; Marom, G. Bonding characteristics of multifilament polymer yarns and cement matrices. Compos. Part A 2008, 39, 930–939. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymers and geopolymeric materials. J. Therm. Anal. 1989, 35, 429–441. [Google Scholar] [CrossRef]

- Duxson, P.; Mallicoat, S.; Lukey, G.; Kriven, W.; van Deventer, J. The effect of alkali and Si/Al ratio on the development of mechanical properties of metakaolin-based geopolymers. Colloids Surf. A Physicochem. Eng. Asp. 2007, 292, 8–20. [Google Scholar] [CrossRef]

- Da Silva Rocha, T.; Dias, D.P.; França, F.C.C.; de Salles Guerra, R.R.; da Costa de Oliveira Marques, L.R. Metakaolin-based geopolymer mortars with different alkaline activators. Constr. Build. Mater. 2018, 178, 453–461. [Google Scholar] [CrossRef]

- Yu, X.; Chen, L.; Komarneni, S.; Hui, C. Fly ash-based geopolymer: Clean production, properties and applications. J. Clean. Prod. 2016, 125, 253–267. [Google Scholar]

- Abdalqader, A.F.; Jin, F.; Al-Tabbaa, A. Development of greener alkali-activated cement: Utilisation of sodium carbonate for activating slag and fly ash mixtures. J. Clean. Prod. 2016, 113, 66–75. [Google Scholar] [CrossRef]

- Tennakoon, C.; Shayan, A.; Sanjayan, J.G.; Xu, A. Chloride ingress and steel corrosion in geopolymer concrete based on long term tests. Mater. Des. 2017, 116, 287–299. [Google Scholar] [CrossRef]

- Singh, B.; Rahman, M.; Paswan, R.; Bhattacharyya, S. Effect of activator concentration on the strength, ITZ and drying shrinkage of fly ash/slag geopolymer concrete. Constr. Build. Mater. 2016, 118, 171–179. [Google Scholar] [CrossRef]

- Nazari, A.; Bagheri, A.; Sanjayan, J.G.; Dao, M.; Mallawa, C.; Zannis, P.; Zumbo, S. Thermal shock reactions of Ordinary Portland cement and geopolymer concrete: Microstructural and mechanical investigation. Constr. Build. Mater. 2019, 196, 492–498. [Google Scholar] [CrossRef]

- Hussin, M.W.; Bhutta, M.A.R.; Azreen, M.; Ramadhansyah, P.J.; Mirza, J. Performance of blended ash geopolymer concrete at elevated temperatures. Mater. Struct. 2015, 48, 709–720. [Google Scholar] [CrossRef]

- Menna, C.; Asprone, D.; Ferone, C.; Colangelo, F.; Balsamo, A.; Prota, A.; Cioffi, R.; Manfredi, G. Use of geopolymers for composite external reinforcement of RC members. Compos. Part B Eng. 2013, 45, 1667–1676. [Google Scholar] [CrossRef]

- Hung, T.D.; Louda, P.; Kroisova, D.; Bortnovsky, O.; Xiem, N.T. New Generation of Geopolymer Composite for Fire-Resistance. In Advances in Composite Materials—Analysis of Natural and Man-Made Materials; Těšinova, P., Ed.; IntechOpen: London, UK, 2012. [Google Scholar]

- Khalid, H.R.; Ha, S.; Park, S.M.; Kim, G.; Lee, H. Interfacial bond behavior of FRP fabrics bonded to fiber-reinforced geopolymer mortar. Compos. Struct. 2015, 134, 353–368. [Google Scholar] [CrossRef]

- Samal, S.; Marvalová, B.; Petríková, I.; Vallons, K.A.M.; Lomov, S.V.; Rahier, H. Impact and post impact behavior of fabric reinforced geopolymer composite. Constr. Build. Mater. 2016, 127, 111–124. [Google Scholar] [CrossRef]

- Rill, E.; Lowry, D.R.; Kriven, W.M. Properties of Basalt Fiber Reinforced Geopolymer Composites. In Strategic Materials and Computational Design—A Collection of Papers Presented at the 34th International Conference on Advanced Ceramics and Composites; Wiley: Hoboken, NJ, USA, 2010; Volume 31, pp. 57–67. [Google Scholar]

- Ribero, D.; Kriven, W.M. Properties of Geopolymer Composites Reinforced with Basalt Chopped Strand Mat or Woven Fabric. J. Am. Ceram. Soc. 2016, 99, 1192–1199. [Google Scholar] [CrossRef]

- Shaikh, F.; Haque, S. Behaviour of Carbon and Basalt Fibres Reinforced Fly Ash Geopolymer at Elevated Temperatures. Int. J. Concr. Struct. Mater. 2018, 12, 35. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.Y.; Yan, J.; Kodur, V.; Cao, L. Mechanical behavior of concrete beams shear strengthened with textile reinforced geopolymer mortar. Eng. Struct. 2019, 196, 109348. [Google Scholar] [CrossRef]

- Tamburini, S.; Natali, M.; Garbin, E.; Panizza, M.; Favaro, M.; Valluzzi, M.R. Geopolymer matrix for fibre reinforced composites aimed at strengthening masonry structures. Constr. Build. Mater. 2017, 141, 542–552. [Google Scholar] [CrossRef]

- Najm, H.; Secaras, J.; Balaguru, P. Compression Tests of Circular Timber Column Confined with Carbon Fibers Using Inorganic Matrix. J. Mater. Civ. Eng. 2007, 19, 198–204. [Google Scholar] [CrossRef]

- Zhang, H.-Y.; Hao, X.; Fan, W. Experimental Study on High Temperature Properties of Carbon Fiber Sheets Strengthened Concrete Cylinders Using Geopolymer as Adhesive. Procedia Eng. 2016, 135, 47–55. [Google Scholar] [CrossRef]

- Kurtz, S.; Balaguru, P. Comparison of Inorganic and Organic Matrices for Strengthening of RC Beams with Carbon Sheets. J. Struct. Eng. 2001, 127, 35–42. [Google Scholar] [CrossRef]

- Le Chi, H.; Louda, P.; Periyasamy, A.P.; Bakalova, T.; Kovacic, V. Flexural Behavior of Carbon Textile-Reinforced Geopolymer Composite Thin Plate. Fibers 2018, 6, 87. [Google Scholar] [CrossRef] [Green Version]

- Chi, H.L.E.; Louda, P. Flexural performance evaluation of various carbon fibre fabric reinforced geopolymer composite. Ceramics-Silikáty 2020, 64, 215–226. [Google Scholar] [CrossRef] [Green Version]

- Engineering, M.; Safi, S.; Zadhoush, A.; Ahmadi, M. Flexural and Charpy impact behaviour of epoxy/glass fabric treated by nano-SiO2 and silane blend. Plast. Rubber Compos. 2017, 46, 314–321. [Google Scholar]

| Fiber Type | Carbon HTC 10/15–40 |

|---|---|

| Fiber density | 1.77 g/cm3 |

| Number of threads/m | 78 (lengthways); 55 (crossways) |

| Weight | 350 g/m2 |

| Tex | 3200 g/km |

| Stitch spacing | 10 × 15 mm2 (center to center distance) |

| Tensile strength | 2551 MPa (lengthways); 2847 MPa (crossways) |

| Young’s Modulus | 228 GPa (lengthways) 252 GPa (crossways) |

| Elongation | 1.17% (lengthways) 1.24% (crossways) |

| Geocement | Activator | Rough Sand | Micro-Milled Sand | Silica Fume | CBFs |

|---|---|---|---|---|---|

| 1 | 0.8 | 1.5 | 0.2 | 0.1 | 0, 0.25, 0.5, 0.75, 1.0 |

| Type (-) | Fiber Dosage (wt.%) | Flexural Strength (MPa) | Compressive Strength (MPa) |

|---|---|---|---|

| 0.00 | 11.78 ± 0.48 | 79.56 ± 3.32 | |

| 6 mm CBFs | 0.25 | 11.96 ± 0.27 | 80.05 ± 5.67 |

| 0.50 | 13.43 ± 0.85 | 77.01 ± 3.13 | |

| 0.75 | 12.28 ± 0.33 | 76.56 ± 4.68 | |

| 1.00 | 13.33 ± 0.56 | 75.24 ± 4.01 | |

| 12 mm CBFs | 0.25 | 12.96 ± 0.50 | 77.18 ± 1.27 |

| 0.50 | 11.85 ± 0.13 | 83.37 ± 1.31 | |

| 0.75 | 12.65 ± 0.15 | 83.77 ± 1.06 | |

| 24 mm CBFs | 0.25 | 12.25 ± 0.78 | 81.82 ± 1.08 |

| 0.50 | 13.05 ± 0.65 | 82.47 ± 3.10 | |

| 0.75 | 14.10 ± 0.77 | 78.51 ± 2.25 |

| Value | F1 (kN) | F2 (kN) | σ1 (MPa) | σ2 (MPa) | y (mm) | Toughness (kN.mm) | Cr. (-) | |

|---|---|---|---|---|---|---|---|---|

| Sample | ||||||||

| 0.00% | 0.53 ± 0.09 | 2.26 ± 0.71 | 7.04 ± 1.15 | 30.14 ± 1.29 | 16.59 ± 2.65 | 23.43 ± 2.57 | 8.66 | |

| 6 mm CBFs | 0.25% | 0.61 ± 0.04 | 2.69 ± 0.44 | 8.13 ± 0.50 | 34.74 ± 1.72 | 14.47 ± 1.27 | 23.71 ± 1.49 | 11.33 |

| 0.50% | 0.56 ± 0.04 | 2.75 ± 0.28 | 7.44 ± 0.49 | 36.65 ± 3.77 | 13.73 ± 1.19 | 21.37 ± 1.78 | 12.33 | |

| 0.75% | 0.63± 0.02 | 2.93± 0.18 | 8.34 ± 0.24 | 39.01 ± 2.36 | 15.03 ± 1.08 | 27.36 ± 3.37 | 11.67 | |

| 1.00% | 0.63 ± 0.04 | 3.10 ± 0.11 | 8.41 ± 0.52 | 41.33 ± 1.41 | 12.83 ± 2.30 | 23.13 ± 5.30 | 13.33 | |

| 12 mm CBFs | 0.25% | 0.57 ± 0.06 | 2.69 ± 0.18 | 7.63 ±0.85 | 35.94 ± 2.45 | 15.65 ± 2.51 | 23.98 ± 3.86 | 12.00 |

| 0.50% | 0.58 ± 0.09 | 2.57 ± 0.12 | 7.69 ± 1.33 | 34.87 ± 1.65 | 14.68 ± 1.61 | 22.63 ± 2.49 | 12.00 | |

| 0.75% | 0.64 ± 0.04 | 2.81 ± 0.24 | 8.60 ± 0.50 | 38.51± 3.24 | 14.72 ± 1.34 | 24.97± 4.76 | 12.67 | |

| 24 mm CBFs | 0.25% | 0.64 ± 0.02 | 2.77 ± 0.22 | 8.54 ± 0.25 | 37.04 ± 2.93 | 15.28 ± 1.91 | 26.21± 5.40 | 13.33 |

| 0.50% | 0.65 ± 0.02 | 2.74 ± 0.29 | 8.77 ± 0.25 | 36.47 ± 3.88 | 13.65 ± 1.18 | 22.02 ± 4.13 | 11.67 | |

| 0.75% | 0.66 ± 0.04 | 2.93 ± 0.27 | 8.79 ± 0.55 | 39.07 ± 3.57 | 13.41 ± 1.43 | 22.77 ± 4.35 | 13.67 |

| The TRG Specimens with Varied Additions of CBFs | |||

|---|---|---|---|

| Type | CBFs [wt.%] | K [J] | KC [kJ/m2] |

| Non CBFs | 0.00 | 46.07 ± 7.27 | 60.86 ± 09.27 |

| 6 mm CBFs | 0.25 | 51.79 ± 9.10 | 67.92 ± 12.32 |

| 0.50 | 54.67 ± 10.33 | 72.12 ± 14.04 | |

| 0.75 | 56.63 ± 8.94 | 73.81 ± 12.54 | |

| 1.00 | 56.13 ± 6.22 | 74.23 ± 08.16 | |

| 2.50 | 58.38 ± 5.98 | 76.41 ± 06.71 | |

| 5.00 | 61.46 ± 6.42 | 80.55 ± 08.74 | |

| 7.50 | 61.17 ± 8.32 | 79.26 ± 09.10 | |

| 12 mm CBFs | 0.25 | 59.49 ± 7.04 | 78.90 ± 08.63 |

| 0.50 | 56.17 ± 9.80 | 73.11 ± 12.66 | |

| 0.75 | 58.92 ± 4.07 | 77.32 ± 08.46 | |

| 24 mm CBFs | 0.25 | 58.96 ± 6.90 | 76.90 ± 11.10 |

| 0.50 | 56.50 ± 10.07 | 74.59 ± 14.07 | |

| 0.75 | 59.13 ± 7.64 | 78.26 ± 08.53 | |

| Value | Geomortar without CBF Addition | Geomortar with 5% CBF Addition | ||||

|---|---|---|---|---|---|---|

| Sample | No. Layer | K [J] | KC [kJ/m2] | K [J] | KC [kJ/m2] | |

| Non-reinforced sample | 0L | 3.14 ± 1.04 | 04.16 ± 1.35 | 4.63 ± 1.34 | 06.10 ± 1.64 | |

| TRGs | 1L | 46.07 ± 7.27 | 60.86 ± 07.27 | 61.46 ± 6.42 | 80.55 ± 8.74 | |

| 2L | 62.42 ± 13.23 | 82.67 ± 13.84 | 82.63 ±13.23 | 107.55 ± 16.61 | ||

| 3L | 60.59 ± 14.93 | 81.85 ± 16.58 | 77.96 ±14.93 | 101.88 ± 18.69 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Le, C.H.; Louda, P.; Ewa Buczkowska, K.; Dufkova, I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers 2021, 13, 751. https://doi.org/10.3390/polym13050751

Le CH, Louda P, Ewa Buczkowska K, Dufkova I. Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers. 2021; 13(5):751. https://doi.org/10.3390/polym13050751

Chicago/Turabian StyleLe, Chi Hiep, Petr Louda, Katarzyna Ewa Buczkowska, and Iva Dufkova. 2021. "Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite" Polymers 13, no. 5: 751. https://doi.org/10.3390/polym13050751

APA StyleLe, C. H., Louda, P., Ewa Buczkowska, K., & Dufkova, I. (2021). Investigation on Flexural Behavior of Geopolymer-Based Carbon Textile/Basalt Fiber Hybrid Composite. Polymers, 13(5), 751. https://doi.org/10.3390/polym13050751