Effect of the Process Parameters on the Adhesive Strength of Dissimilar Polymers Obtained by Multicomponent Injection Molding

Abstract

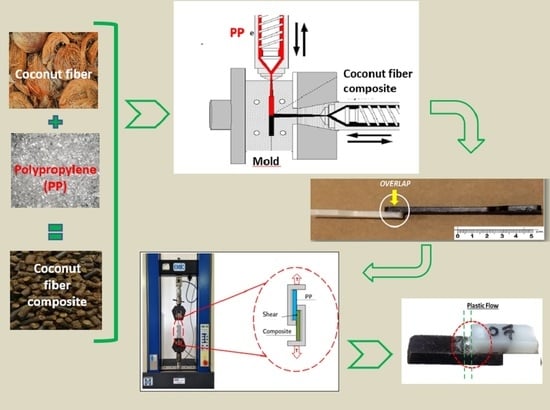

:1. Introduction

2. Materials and Methods

3. Results and Discussions

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Estacio, K.C. Simulation of the 2D Injection Molding Process Using Unstructured Meshes. Master’s Thesis, University of São Paulo—USP, São Paulo, Brazil, 2004. [Google Scholar]

- Cavalheiro, A.Z. Influence of Molding Parameters on the Structure and Properties of Thick and Thin Wall Pieces of Isotac-Tic Polypropylene Injected into Prototype Molds Manufactured by Pouring Epoxy Resin. Ph.D. Thesis, Federal University of Santa Catarina-UFSC, Florianópolis, Brazil, 2007. [Google Scholar]

- Peixoto, F.L. Application of the Over Injection Process in Thermoplastic Inserts Using Quick Manufacturing Molds. Ph.D. Thesis, Federal University of Santa Catarina—UFSC, Florianópolis, Brazil, 2009. [Google Scholar]

- Wargnier, H.; Kromm, F.; Danis, M.; Brechet, Y. Proposal for a multi-material design procedure. Mater. Des. 2014, 56, 44–49. [Google Scholar] [CrossRef]

- Banerjee, A.G.; Li, X.; Fowler, G.; Gupta, S.K. Incorporating manufacturability considerations during design of injection molded multi-material objects. Res. Eng. Des. 2007, 17, 207–231. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, S.; Pérez, C.J.; DeSimone, P.M.; Pastor, J.M.; Tomba, J.P.; Carella, J.M. Adhesion control for injection overmolding of elastomeric propylene copolymers on polypropylene. Effects of block and random microstructures. Int. J. Adhes. Adhes. 2013, 46, 44–55. [Google Scholar] [CrossRef]

- Kraus, E.; Horvat, S.; Deubel, C.; Staudigel, C.; Baudrit, B.; Heidemeyer, P.; Bastian, M.; Starostina, I. Relevance of the acid-base approach in pre-diction of adhesion properties in two-component injection moulding. J. Appl. Polym. Sci. 2015, 43048, 1–7. [Google Scholar]

- Machado, B.D.S.; Martins, V.S.; Pisanu, L.; Nascimento, M.L.F. Transition characteristics of Brazilian vegetable fibers investigated by heating microscopy. J. Nat. Fibers 2018, 17, 450–462. [Google Scholar] [CrossRef]

- Patcharaphun, S. Characterization and Simulation of Material Distribution and Fiber Orientation in Sandwich Injection Molded Parts. Ph.D. Thesis, Chemnitz University of Technology, Chemnitz, Germany, 2006. [Google Scholar]

- Karthikeyan, R. Analysis of Natural Fiber Orientation in Polymer Composites Produced by Injection Molding Process. Ph.D. Thesis, University of Toronto, Toronto, ON, Canada, 2017. [Google Scholar]

- Akay, M.; Barkley, D. Fibre orientation and mechanical behaviour in reinforced thermoplastic injection mouldings. J. Mater. Sci. 1991, 26, 2731–2742. [Google Scholar] [CrossRef]

- Bright, P.F.; Crowson, R.J.; Folkes, M.J. A study of the effect of injection speed on fibre orientation in simple mouldings of short glass fibre-filled polypropylene. J. Mater. Sci. 1978, 13, 2497–2506. [Google Scholar] [CrossRef]

- Resistance, P. Peel Resistance of Adhesives (T-Peel Test). Current 2001, 2, 3–5. [Google Scholar] [CrossRef]

- Li, J.; Shanks, R.A.; Olley, R.H.; Greenway, G.R. Miscibility and isothermal crystallisation of polypropylene in polyethylene melts. Polymer 2001, 42, 7685–7694. [Google Scholar] [CrossRef]

- ASTM D 3163-01. Standard Test Method for Determining Strength of Adhesively Bonded Rigid Plastic Lap-Shear Joints in Shear by Tension Loading. Standards 2001, 1, 1–3. [Google Scholar]

- Bamberg, P.A.M.G.P.; Reisgen, U.; Schiebahn, A.; Barbosa, J.D.V.; Marx, B.; Coelho, R.S. Digital Image Correlation Analysis of the Effects of the Overlap Length, Adhesive Thickness and Adherends Yield Strength Over Similar and Dissimilar Joints of High Strength Steel and Aluminum Alloys. Int. J. Adhes. Adhes. 2018, 83, 69–75. [Google Scholar] [CrossRef]

- Pisanu, L.; Nascimento, J.V.D.B.L.F.; Silva, A.Q. Device for Evaluation of the Strength of Adhesion between Superimposed Polymers, Metals, Wood and Hybrid Joints between Polymers, Metals, Mixed Wood by Adhesives and other Improved Products. Applied Brazilian Patent BR10201602105, 25 March 2021. Available online: https://www.gov.br/inpi/pt-br (accessed on 25 March 2021).

- Pisanu, L.; Santiago, L.C.; Barbosa, J.D.V.; Beal, V.E.; Nascimento, M.L.F. Strength shear test for adhesive joints between dis-similar materials obtained by multicomponent injection. Int. J. Adhes. Adhes. 2018, 86, 22–28. [Google Scholar] [CrossRef]

- Pisanu, L.; Barbosa, J.; Souza, R.; Nascimento, M.L.F.; Barbosa, J.; De Sousa, R.A. Evaluating the influence of coupling agents in the structural properties of polypropylene coconut fiber composites. Mater. Res. Express 2019, 6, 115320. [Google Scholar] [CrossRef]

- Pisanu, L.; Barbosa, J.; Bamberg, P.; Marx, B.; Schiebahn, A.; Souza, R.; Nascimento, M. Influence of coupling agents on the adhesion force of dissimilar overmolded polymers: A digital image correlation analysis. Matéria (Rio de Janeiro) 2019, 24, 12438. [Google Scholar] [CrossRef]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing—Engineering Pro Collection; Wiley: Hoboken, NJ, USA, 2006; 984p, ISBN1 0471792764. ISBN2 9780471792765. [Google Scholar]

- Michaeli, W.; Lindner, F. Influence of mould materials on the morphological and mechanical properties of injec-tion-moulded prototypes. Macromol. Mater. Eng. 2001, 286, 232–236. [Google Scholar] [CrossRef]

- Candal, M.V.; Gordillo, A.; Santana, O.O.; Sánchez, J.J. Study of the adhesion strength on overmoulded plastic materials using the essential work of interfacial fracture (EWIF) concept. J. Mater. Sci. 2008, 43, 5052–5060. [Google Scholar] [CrossRef]

- Chen, C.P.; Chuang, M.T.; Hsiao, Y.H.; Yang, Y.K.; Tsai, C.H. Simulation and experimental study in determining injection mold-ing process parameters for thin-shell plastic parts via design of experiments analysis. Expert. Syst. Appl. 2009, 36, 10752–10759. [Google Scholar] [CrossRef]

- Patankar, M.P. The Evaluation of the Effect of Processing Parameters on Adhesion Performance of Polyether based TPU over mold on to Polycarbonate Substrate. Master’s Thesis, Stony Brook University, New York, NY, USA, 2010. [Google Scholar]

- Raia, D.C.; David, C. Raia 2009:5. Available online: https://www.starthermoplastics.com/?s=multicomponente%5CDavidRaia-coinjetcionTPE.html (accessed on 14 April 2014).

| Process Variables | Injection Unit 1 | Injection Unit 2 (L–H) a |

|---|---|---|

| Injection pressure (bar) | 800 | 400 |

| Holding pressure (bar) | 400 | (200–300) |

| Injection flow rate (cm3/s) | 100 | (30–90) |

| Injection temperature (°C) | 210 | (220–260) |

| Cooling time (s) | 25 | 30 |

| Run | Holding Pressure (bar) | Injection Temperature (°C) | Overlap Length (mm) | Injection Flow Rate (cm3/s) |

|---|---|---|---|---|

| 1 | 300 | 260 | 12 | 90 |

| 2 | 200 | 220 | 16 | 90 |

| 3 | 300 | 220 | 12 | 90 |

| 4 | 200 | 260 | 12 | 90 |

| 5 | 200 | 260 | 16 | 30 |

| 6 | 200 | 220 | 12 | 90 |

| 7 | 200 | 220 | 12 | 30 |

| 8 | 300 | 260 | 12 | 30 |

| 9 | 200 | 260 | 12 | 30 |

| 10 | 300 | 220 | 12 | 30 |

| 11 | 300 | 260 | 16 | 90 |

| 12 | 200 | 220 | 16 | 30 |

| 13 | 300 | 260 | 16 | 30 |

| 14 | 200 | 260 | 16 | 90 |

| 15 | 300 | 220 | 16 | 30 |

| 16 | 300 | 220 | 16 | 90 |

| Source | DF | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 15 | 2,147,656 | 143,177 | 62.16 | 0 |

| Linear | 4 | 1,841,923 | 460,481 | 199.9 | 0 |

| HP (bar) | 1 | 340 | 340 | 0.15 | 0.701 |

| T (°C) | 1 | 67,339 | 67,339 | 29.23 | 0 |

| Fr (cm3/s) | 1 | 105,438 | 105,438 | 45.77 | 0 |

| O (mm) | 1 | 1,668,805 | 1,668,805 | 724.45 | 0 |

| 2-Way Interactions | 6 | 202,921 | 33,820 | 14.68 | 0 |

| HP (bar)*T (°C) | 1 | 37,813 | 37,813 | 16.42 | 0 |

| HP (bar)* Fr (cm3/s) | 1 | 19,857 | 19,857 | 8.62 | 0.004 |

| HP (bar)*O (mm) | 1 | 192 | 192 | 0.08 | 0.773 |

| T (°C)* Fr (cm3/s) | 1 | 90,014 | 90,014 | 39.08 | 0 |

| T (°C)*O (mm) | 1 | 9905 | 9905 | 4.3 | 0.04 |

| Fr (cm3/s)*O (mm) | 1 | 45,139 | 45,139 | 19.6 | 0 |

| 3-Way Interactions | 4 | 100,071 | 25,018 | 10.86 | 0 |

| HP (bar)*T (°C)* Fr (cm3/s) | 1 | 46 | 46 | 0.02 | 0.888 |

| HP (bar)*T (°C)*O (mm) | 1 | 37,202 | 37,202 | 16.15 | 0 |

| HP (bar)* Fr (cm3/s)*O (mm) | 1 | 17,404 | 17,404 | 7.56 | 0.007 |

| T (°C)* Fr (cm3/s)*O (mm) | 1 | 45,419 | 45,419 | 19.72 | 0 |

| 4-Way Interactions | 1 | 2742 | 2742 | 1.19 | 0.278 |

| HP (bar)*T (°C)*Fr (cm3/s)*O (mm) | 1 | 2742 | 2742 | 1.19 | 0.278 |

| Error | 112 | 257,997 | 2178 | ||

| Total | 127 | 2,405,653 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pisanu, L.; Santiago, L.C.; Barbosa, J.D.V.; Beal, V.E.; Nascimento, M.L.F. Effect of the Process Parameters on the Adhesive Strength of Dissimilar Polymers Obtained by Multicomponent Injection Molding. Polymers 2021, 13, 1039. https://doi.org/10.3390/polym13071039

Pisanu L, Santiago LC, Barbosa JDV, Beal VE, Nascimento MLF. Effect of the Process Parameters on the Adhesive Strength of Dissimilar Polymers Obtained by Multicomponent Injection Molding. Polymers. 2021; 13(7):1039. https://doi.org/10.3390/polym13071039

Chicago/Turabian StylePisanu, Luciano, Leonardo Costa Santiago, Josiane Dantas Viana Barbosa, Valter Estevão Beal, and Marcio Luis Ferreira Nascimento. 2021. "Effect of the Process Parameters on the Adhesive Strength of Dissimilar Polymers Obtained by Multicomponent Injection Molding" Polymers 13, no. 7: 1039. https://doi.org/10.3390/polym13071039

APA StylePisanu, L., Santiago, L. C., Barbosa, J. D. V., Beal, V. E., & Nascimento, M. L. F. (2021). Effect of the Process Parameters on the Adhesive Strength of Dissimilar Polymers Obtained by Multicomponent Injection Molding. Polymers, 13(7), 1039. https://doi.org/10.3390/polym13071039