Lignin-Based Phenolic Foam Reinforced by Poplar Fiber and Isocyanate-Terminated Polyurethane Prepolymer

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of Phenolated Depolymerized Lignin (DL)

2.3. Preparation of DL-Based PF (DLPF)

2.4. Preparation of Blocked Isocyanate-Terminated PU Prepolymer

2.5. Characterization of Blocked Isocyanate-Terminated PU Prepolymer

2.6. Preparation of DLPF-20 Modified by PU with Different Proportions and 1% Poplar Wood Powder

2.7. Characterization of FDLPF 1 Modified with Different Proportions of PU

3. Results

3.1. Optimization of PU Prepolymer

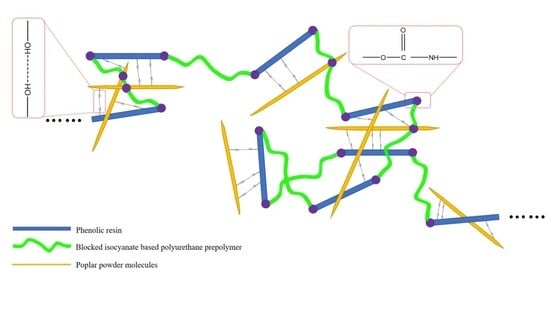

3.2. Mechanism Analysis of PU Prepolymer/Poplar Wood Flour Hybrid Enhanced PF

3.3. Morphology of Hybrid Enhanced PF

3.4. Mechanical Properties of Hybrid Enhanced PF

3.5. Thermal Properties of Hybrid Enhanced PF

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iwasaki, K. Phenolic foams. In Handbook of Plastic Foams: Types, Properties, Manufacture and Applications; Noyes Publications: William Andrew, Norwich, NJ, USA, 1995; pp. 183–220. [Google Scholar]

- Benning, C.J. Plastic Foams: The Physics and Chemistry of Product Performance and Process Technology; Wiley-Interscience: New York, NY, USA, 1969. [Google Scholar]

- Shen, H.; Lavoie, A.J.; Nutt, S.R. Enhanced peel resistance of fiber reinforced phenolic foams. Compos. Part A Appl. Sci. Manuf. 2003, 34, 941–948. [Google Scholar] [CrossRef]

- Shen, H.; Nutt, S. Mechanical characterization of short fiber reinforced phenolic foam. Compos. Part A Appl. Sci. Manuf. 2003, 34, 899–906. [Google Scholar] [CrossRef]

- Canetti, M.; Bertini, F. Supermolecular structure and thermal properties of poly(ethylene terephthalate)/lignin composites. Compos. Sci. Technol. 2007, 67, 3151–3157. [Google Scholar] [CrossRef]

- Guigo, N.; Mija, A.; Vincent, L.; Sbirrazzuoli, N. Eco-friendly composite resins based on renewable biomass resources: Polyfurfuryl alcohol/lignin thermosets. Eur. Polym. J. 2010, 46, 1016–1023. [Google Scholar] [CrossRef]

- Luz, S.M.; Caldeira-Pires, A.; Ferrão, P.M. Environmental benefits of substituting talc by sugarcane bagasse fibers as reinforcement in polypropylene composites: Ecodesign and LCA as strategy for automotive components. Resour. Conserv. Recycl. 2010, 54, 1135–1144. [Google Scholar] [CrossRef]

- Modniks, J.; Joffe, R.; Andersons, J. Model of the mechanical response of short flax fiber reinforced polymer matrix composites. Procedia Eng. 2011, 10, 2016–2021. [Google Scholar] [CrossRef] [Green Version]

- Park, Y.; Doherty, W.O.; Halley, P.J. Developing lignin-based resin coatings and composites. Ind. Crop. Prod. 2008, 27, 163–167. [Google Scholar] [CrossRef]

- Bo, C.; Yang, X.; Hu, L.; Zhang, M.; Jia, P.; Zhou, Y. Enhancement of flame-retardant and mechanical performance of phenolic foam with the incorporation of cardanol-based siloxane. Polym. Compos. 2019, 40, 2539–2547. [Google Scholar] [CrossRef]

- Wang, G.; Liu, X.; Zhang, J.; Sui, W.; Jang, J.; Si, C. One-pot lignin depolymerization and activation by solid acid catalytic phenolation for lightweight phenolic foam preparation. Ind. Crop. Prod. 2018, 124, 216–225. [Google Scholar] [CrossRef]

- Huang, Y.B.; Zheng, Z.F.; Feng, H.; Pan, H. Phenolic Foam from Liquefied Products of Walnut Shell in Phenol. Adv. Mater. Res. 2011, 236–238, 241–246. [Google Scholar] [CrossRef]

- Yu, Y.; Wang, Y.; Xu, P.; Chang, J. Preparation and Characterization of Phenolic Foam Modified with Bio-Oil. Materials 2018, 11, 2228. [Google Scholar] [CrossRef] [Green Version]

- Bo, C.; Hu, L.; Chen, Y.; Yang, X.; Zhang, M.; Zhou, Y. Synthesis of a novel cardanol-based compound and environmentally sustainable production of phenolic foam. J. Mater. Sci. 2018, 53, 10784–10797. [Google Scholar] [CrossRef]

- Song, F.; Li, Z.; Jia, P.; Bo, C.; Zhang, M.; Hu, L.; Zhou, Y. Phosphorus-containing tung oil-based siloxane toughened phenolic foam with good mechanical properties, fire performance and low thermal conductivity. Mater. Des. 2020, 192, 108668. [Google Scholar] [CrossRef]

- Gao, C.; Li, M.; Zhu, C.; Hu, Y.; Shen, T.; Li, M.; Ji, X.; Lyu, G.; Zhuang, W. One-pot depolymerization, demethylation and phenolation of lignin catalyzed by HBr under microwave irradiation for phenolic foam preparation. Compos. Part B Eng. 2021, 205, 108530. [Google Scholar] [CrossRef]

- Xu, P.; Yu, Y.; Chang, M.; Chang, J. Preparation and Characterization of Bio-oil Phenolic Foam Reinforced with Montmorillonite. Polymer 2019, 11, 1471. [Google Scholar] [CrossRef] [Green Version]

- Mougel, C.; Garnier, T.; Cassagnau, P.; Sintes-Zydowicz, N. Phenolic foams: A review of mechanical properties, fire resistance and new trends in phenol substitution. Polymer 2019, 164, 86–117. [Google Scholar] [CrossRef]

- Zhang, J.P.; Du, M.H. Bamboo Powder Liquefaction and Resinification: Application on the Phenolic Foam. Mater. Sci. Forum 2013, 743–744, 306–311. [Google Scholar] [CrossRef]

- Xiao, W.; Huang, Z.; Ding, J. The mechanical and thermal characteristics of phenolic foam reinforced with kaolin powder and glass fiber fabric. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Busan, Korea, 25–27 August 2017; p. 274. [Google Scholar] [CrossRef]

- Zhou, J.; Yao, Z.; Chen, Y.; Wei, D.; Wu, Y. Thermomechanical analyses of phenolic foam reinforced with glass fiber mat. Mater. Des. 2013, 51, 131–135. [Google Scholar] [CrossRef]

- Del Saz-Orozco, B.; Alonso, M.V.; Oliet, M.; Domínguez, J.C.; Rodriguez, F. Mechanical, thermal and morphological characterization of cellulose fiber-reinforced phenolic foams. Compos. Part B Eng. 2015, 75, 367–372. [Google Scholar] [CrossRef]

- Choe, J.; Kim, M.; Kim, J.; Gil Lee, D. A microwave foaming method for fabricating glass fiber reinforced phenolic foam. Compos. Struct. 2016, 152, 239–246. [Google Scholar] [CrossRef]

- Yuan, H.; Xing, W.; Yang, H.; Song, L.; Hu, Y.; Yeoh, G.H. Mechanical and thermal properties of phenolic/glass fiber foam modified with phosphorus-containing polyurethane prepolymer. Polym. Int. 2012, 62, 273–279. [Google Scholar] [CrossRef]

- Desai, A.; Nutt, S.R.; Alonso, M.V. Modeling of fiber-reinforced phenolic foam. J. Cell. Plast. 2008, 44, 391–413. [Google Scholar] [CrossRef]

- Zhang, N.; Hu, L.H.; Guo, Y.J.; Bo, C.Y.; Jia, P.Y.; Zhang, B.F.; Zhou, Y.H. Mechanical property of lignin-modified phenolic foam enhanced by whisker silicon. J. Dispers. Sci. Technol. 2020, 41, 348–354. [Google Scholar] [CrossRef]

- Song, F.; Jia, P.; Bo, C.; Ren, X.; Hu, L.; Zhou, Y. The mechanical and flame retardant characteristics of lignin-based phenolic foams reinforced with MWCNTs by in-situ polymerization. J. Dispers. Sci. Technol. 2020, 1–10, 1–10. [Google Scholar] [CrossRef]

- Li, J.; Zhang, A.; Zhang, S.; Gao, Q.; Zhang, W.; Li, J. Larch tannin-based rigid phenolic foam with high compressive strength, low friability, and low thermal conductivity reinforced by cork powder. Compos. Part B Eng. 2019, 156, 368–377. [Google Scholar] [CrossRef]

- Liu, J.; Wang, L.; Zhang, W.; Han, Y. Phenolic Resin Foam Composites Reinforced by Acetylated Poplar Fiber with High Mechanical Properties, Low Pulverization Ratio, and Good Thermal Insulation and Flame Retardant Performance. Materials 2019, 13, 148. [Google Scholar] [CrossRef] [Green Version]

- Ding, H.Y.; Wang, J.F.; Liu, J.; Xu, Y.Z.; Chen, R.Q.; Wang, C.P.; Chu, F.X. Preparation and properties of a novel flame retardant polyurethane quasi-prepolymer for toughening phenolic foam. J. Appl. Polym. Sci. 2015, 132, 42424. [Google Scholar] [CrossRef]

- Xu, W.; Chen, R.; Xu, J.; Wang, G.; Cheng, C.; Yan, H. Preparation and mechanism of polyurethane prepolymer and boric acid co-modified phenolic foam composite: Mechanical properties, thermal stability, and flame retardant properties. Polym. Adv. Technol. 2019, 30, 1738–1750. [Google Scholar] [CrossRef]

- Yang, H.; Wang, X.; Yu, B.; Yuan, H.; Song, L.; Hu, Y.; Yuen, R.K.; Yeoh, G.H. A novel polyurethane prepolymer as toughening agent: Preparation, characterization, and its influence on mechanical and flame retardant properties of phenolic foam. J. Appl. Polym. Sci. 2012, 128, 2720–2728. [Google Scholar] [CrossRef]

- Yang, Y.; He, J. Mechanical characterization of phenolic foams modified by short glass fibers and polyurethane prepolymer. Polym. Compos. 2014, 36, 1584–1589. [Google Scholar] [CrossRef]

- Cellular Plastics and Rubbers. Determination of Apparent Density (GB/T6343-2009); Standardization Management Committee of the People’s Republic of China: Beijing, China, 2009.

- Standard Test Method for Compressive Properties of Rigid Cellular (ASTMD D1621-10); American Society for Testing and Materials: West Conshohocken, PA, USA, 2010.

- Zhou, M.F.; Shi, H.Q.; Li, C.; Sheng, X.R.; Sun, Y.N.; Hou, M.J.; Niu, M.; Pan, X. Depolymerization and Activation of Alkali Lignin by Solid Acid-Catalyzed Phenolation for Preparation of Lignin-Based Phenolic Foams. Ind. Eng. Chem. Res. 2020, 59, 14296–14305. [Google Scholar] [CrossRef]

- Standard Test Method for Measuring the Minimum Oxygen Concentration to Support Candle-Like Combustion of Plastics (Oxygen Index) (ASTMD D2863); American Society for Testing and Materials: West Conshohocken, PA, USA, 2017.

- Liang, M.L.; Jin, G.T.; Zhu, J. Polyurethane modified phenolic foam. J. Beijing Univ. Chem. Technol. 2002, 29, 47–50. [Google Scholar]

- Cheng, J.; Liang, M.L.; Jin, G.T. Study of brittleness of phenolic foam modified by urethane oligom. China Plast. Ind. 2004, 32, 7–9. [Google Scholar]

- Bo, C.Y.; Hu, L.H.; Zhou, J.; Zhou, Y. Preparation and characterization of phenolic foams modified by castor oil-based polyurethane prepolymer. Chem. Ind. For. Prod. 2015, 35, 8–14. [Google Scholar]

- Marsavina, L.; Constantinescu, D.M.; Linul, E.; Apostol, D.A.; Voiconi, T.; Sadowski, T. Refinements on fracture toughness of PUR foams. Eng. Fract. Mech. 2014, 129, 54–66. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A Fractal Model for capillary flow through a single tortuous capillary with roughened surfaces in fibrous porous media. Fractals 2021, 29. [Google Scholar] [CrossRef]

- Pietras, D.; Linul, E.; Sadowski, T.; Rusinek, A. Out-of-plane crushing response of aluminum honeycombs in-situ filled with graphene-reinforced polyurethane foam. Compos. Struct. 2020, 249, 112548. [Google Scholar] [CrossRef]

- Marsavina, L.; Sadowski, T. Dynamic fracture toughness of polyurethane foam. Polym. Test. 2008, 27, 941–944. [Google Scholar] [CrossRef]

- Marsavina, L.; Linul, E.; Voiconi, T.; Sadowski, T. A comparison between dynamic and static fracture toughness of polyurethane foams. Polym. Test. 2013, 32, 673–680. [Google Scholar] [CrossRef]

- Xiao, B.; Wang, S.; Wang, Y.; Jiang, G.; Zhang, Y.; Chen, H.; Liang, M.; Long, G.; Chen, X. Effective thermal Conductivity of Porous Media with Roughened Surfaces by fractal-monte carlo simulations. Fractals 2020, 28. [Google Scholar] [CrossRef]

| PU Prepolymer | PPG (mol) | MDI (mol) |

|---|---|---|

| PU-1.5 | 1 | 1.5 |

| PU-2 | 1 | 2 |

| PU-3 | 1 | 3 |

| PU-4 | 1 | 4 |

| Foam Name | Phosphoric Acid (%) | Tween-80 (%) | Vesicant (%) | Compound Acid Curing Agent (%) | Fiber (%) | PU-2 Content (%) |

|---|---|---|---|---|---|---|

| PF | 13.3 | 13.3 | 6.67 | 13.3 | 0 | 0 |

| PUPF0 | 13.3 | 13.3 | 6.67 | 13.3 | 1 | 0 |

| PUPF2 | 13.3 | 13.3 | 6.67 | 13.3 | 1 | 2 |

| PUPF5 | 13.3 | 13.3 | 6.67 | 13.3 | 1 | 5 |

| PUPF7 | 13.3 | 13.3 | 6.67 | 13.3 | 1 | 7 |

| PUPF9 | 13.3 | 13.3 | 6.67 | 13.3 | 1 | 9 |

| Sample | MDI (mol) | PPG (mol) | -NCO % |

|---|---|---|---|

| PU-1.5 | 1.5 | 1 | 1.8 |

| PU-2 | 2 | 1 | 3.9 |

| PU-3 | 3 | 1 | 5.7 |

| PU-4 | 4 | 1 | 8.6 |

| Sample Name | Apparent Density (kg/m3) | Median Cell Diameter (μm) | Cell Density NF (105 cells/cm3) | Porosity (%) |

|---|---|---|---|---|

| PF | 46.31 ± 1.19 | 103.31 ± 1.33 | 4.47 ± 0.23 | 94.27 ± 1.03 |

| PUPF0 | 42.16 ± 2.18 | 93.97 ± 1.97 | 6.24 ± 0.14 | 93.07 ± 1.01 |

| PUPF2 | 43.27 ± 1.73 | 94.36 ± 1.51 | 5.69 ± 0.21 | 93.79 ± 0.99 |

| PUPF5 | 42.16 ± 2.21 | 93.97 ± 1.88 | 6.24 ± 0.31 | 93.07 ± 1.04 |

| PUPF7 | 44.17 ± 2.36 | 97.32 ± 1.35 | 6.13 ± 0.19 | 92.13 ± 1.01 |

| PUPF9 | 42.91 ± 1.93 | 96.31 ± 1.62 | 5.31 ± 0.11 | 91.87 ± 1.05 |

| Sample | TTI (s) | PHRR (kW/m2) | THR (MJ/m2) | ASEA (m2/kg) | AMLR (g/s·m2) |

|---|---|---|---|---|---|

| PUPF0 | 4.3 | 55.98 | 7.64 | 229.1 | 2.166 |

| PUPF5 | 3.6 | 107.32 | 9.10 | 114.67 | 2.048 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, G.; Liu, J.; Zhang, W.; Han, Y.; Zhang, D.; Li, J.; Zhang, S. Lignin-Based Phenolic Foam Reinforced by Poplar Fiber and Isocyanate-Terminated Polyurethane Prepolymer. Polymers 2021, 13, 1068. https://doi.org/10.3390/polym13071068

Chen G, Liu J, Zhang W, Han Y, Zhang D, Li J, Zhang S. Lignin-Based Phenolic Foam Reinforced by Poplar Fiber and Isocyanate-Terminated Polyurethane Prepolymer. Polymers. 2021; 13(7):1068. https://doi.org/10.3390/polym13071068

Chicago/Turabian StyleChen, Guoliang, Jian Liu, Wei Zhang, Yanming Han, Derong Zhang, Jianzhang Li, and Shifeng Zhang. 2021. "Lignin-Based Phenolic Foam Reinforced by Poplar Fiber and Isocyanate-Terminated Polyurethane Prepolymer" Polymers 13, no. 7: 1068. https://doi.org/10.3390/polym13071068

APA StyleChen, G., Liu, J., Zhang, W., Han, Y., Zhang, D., Li, J., & Zhang, S. (2021). Lignin-Based Phenolic Foam Reinforced by Poplar Fiber and Isocyanate-Terminated Polyurethane Prepolymer. Polymers, 13(7), 1068. https://doi.org/10.3390/polym13071068