Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Fabrication of Carbon Nanofiber/Polydimethylsiloxane (CF/PDMS) Composites

2.3. Characterization and Measurements

2.3.1. Tension

2.3.2. Hardness

2.3.3. Thermogravimetric Analysis (TGA)

2.3.4. Differential Scanning Calorimetry (DSC)

2.3.5. Solvent Swelling Ratio (%)

2.3.6. Fourier-Transform Infrared (FTIR) Spectroscopy

2.3.7. Rheology

2.3.8. Coefficient of Thermal Expansion (CTE)

3. Results and Discussion

3.1. Preparation of Carbon Fiber Filled Sylgard™ 186

3.2. FTIR Spectroscopy

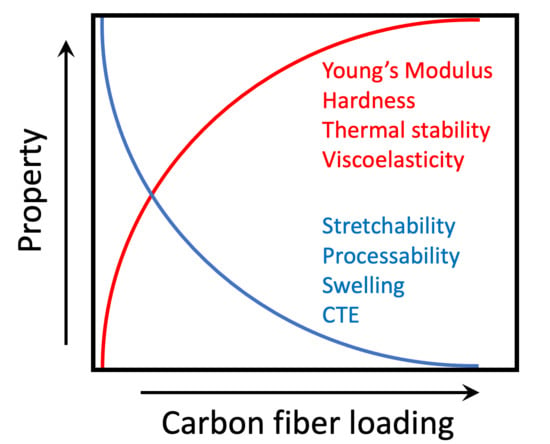

3.3. Effects of the CF Filler on Mechanical Properties and Dimensional Stability

3.4. Effect of the Amount of CF Filler on Thermal Behaviors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cong, H.; Pan, T. Photopatternable Conductive PDMS Materials for Microfabrication. Adv. Funct. Mater. 2008, 18, 1912–1921. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with designer functionalities—Properties, modifications strategies, and applications. Prog. Polym. Sci. 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Andriot, M.; Chao, S.; Colas, A.; Cray, S.; de Buyl, F.; De Groot, J.; Dupont, A.; Easton, T.; Garaud, J.; Gerlach, E. Chapter 2 Silicones in industrial applications. In Inorganic Polymers; Nova Science Publishers: New York, NY, USA, 2007; pp. 61–161. [Google Scholar]

- Yue, Y.; Zhang, H.; Zhang, Z.; Chen, Y.J. Polymer–filler interaction of fumed silica filled polydimethylsiloxane investigated by bound rubber. Compos. Sci. Technol. 2013, 86, 1–8. [Google Scholar] [CrossRef]

- Yue, Y.; Zhang, H.; Zhang, Z.; Chen, Y.J. Tensile properties of fumed silica filled polydimethylsiloxane networks. Compos. Part A Appl. Sci. Manuf. 2013, 54, 20–27. [Google Scholar] [CrossRef]

- Murphy, E.C.; Dumont, J.H.; Park, C.H.; Kestell, G.; Lee, K.-S.; Labouriau, A. Tailoring properties and processing of Sylgard 184: Curing time, adhesion, and water affinity. J. Appl. Polym. Sci. 2020, 137, 48530. [Google Scholar] [CrossRef]

- Liu, J.; Wu, S.; Zou, M.; Zheng, X.; Cai, Z. Surface modification of silica and its compounding with polydimethylsiloxane matrix: Interaction of modified silica filler with PDMS. Iran. Polym. J. 2012, 21, 583–589. [Google Scholar] [CrossRef]

- Armani, D.; Liu, C.; Aluru, N. Re-configurable fluid circuits by PDMS elastomer micromachining. In Proceedings of the Technical Digest. IEEE International MEMS 99 Conference. Twelfth IEEE International Conference on Micro Electro Mechanical Systems (Cat. No. 99CH36291), Orlando, FL, USA, 17–21 January 1999; pp. 222–227. [Google Scholar]

- Schneider, F.; Fellner, T.; Wilde, J.; Wallrabe, U.J. Mechanical properties of silicones for MEMS. J. Micromech. Microeng. 2008, 18, 065008. [Google Scholar] [CrossRef]

- Cruz-Félix, A.S.; Santiago-Alvarado, A.; Márquez-García, J.; González-García, J. PDMS samples characterization with variations of synthesis parameters for tunable optics applications. Heliyon 2019, 5, e03064. [Google Scholar] [CrossRef] [Green Version]

- Waddell, E.A.; Shreeves, S.; Carrell, H.; Perry, C.; Reid, B.A.; McKee, J. Surface modification of Sylgard 184 polydimethylsiloxane by 254 nm excimer radiation and characterization by contact angle goniometry, infrared spectroscopy, atomic force and scanning electron microscopy. Appl. Surf. Sci. 2008, 254, 5314–5318. [Google Scholar] [CrossRef]

- Berean, K.; Ou, J.Z.; Nour, M.; Latham, K.; McSweeney, C.; Paull, D.; Halim, A.; Kentish, S.; Doherty, C.M.; Hill, A.J.; et al. The effect of crosslinking temperature on the permeability of PDMS membranes: Evidence of extraordinary CO2 and CH4 gas permeation. Sep. Purif. Technol. 2014, 122, 96–104. [Google Scholar] [CrossRef]

- Li, L.; Huang, Z.; Wang, Y.; Brown, K.A. Design of elastomer-cnt film photoactuators for nanolithography. Polymers 2019, 11, 314. [Google Scholar] [CrossRef] [Green Version]

- Duan, L.; D’Hooge, D.R.; Cardon, L. Recent progress on flexible and stretchable piezoresistive strain sensors: From design to application. Prog. Polym. Sci. 2020, 114, 100617. [Google Scholar] [CrossRef]

- Liu, J.; Zong, G.; He, L.; Zhang, Y.; Liu, C.; Wang, L. Effects of Fumed and Mesoporous Silica Nanoparticles on the Properties of Sylgard 184 Polydimethylsiloxane. Micromachines 2015, 6, 855–864. [Google Scholar] [CrossRef] [Green Version]

- He, X.; Huang, Y.; Wan, C.; Zheng, X.; Kormakov, S.; Gao, X.; Sun, J.; Zheng, X.; Wu, D.J. Enhancing thermal conductivity of polydimethylsiloxane composites through spatially confined network of hybrid fillers. Compos. Sci. Technol. 2019, 172, 163–171. [Google Scholar] [CrossRef]

- Wei, J.; Liao, M.; Ma, A.; Chen, Y.; Duan, Z.; Hou, X.; Li, M.; Jiang, N.; Yu, J.J. Enhanced thermal conductivity of polydimethylsiloxane composites with carbon fiber. Compos. Commun. 2020, 17, 141–146. [Google Scholar] [CrossRef]

- Ma, P.-C.; Liu, M.-Y.; Zhang, H.; Wang, S.-Q.; Wang, R.; Wang, K.; Wong, Y.-K.; Tang, B.-Z.; Hong, S.-H.; Paik, K.-W.; et al. Enhanced electrical conductivity of nanocomposites containing hybrid fillers of carbon nanotubes and carbon black. ACS Appl. Mater. Interfaces 2009, 1, 1090–1096. [Google Scholar] [CrossRef] [PubMed]

- Xiao, C.; Leng, X.; Zhang, X.; Zheng, K.; Tian, X.J. Improved thermal properties by controlling selective distribution of AlN and MWCNT in immiscible polycarbonate (PC)/Polyamide 66 (PA66) composites. Compos. Part A Appl. Sci. Manuf. 2018, 110, 133–141. [Google Scholar] [CrossRef]

- Jung, Y.; Jung, K.K.; Kim, D.H.; Kwak, D.H.; Ko, J.S. Linearly Sensitive and Flexible Pressure Sensor Based on Porous Carbon Nanotube/Polydimethylsiloxane Composite Structure. Polymers 2020, 12, 1499. [Google Scholar] [CrossRef]

- Talley, S.J.; Branch, B.; Welch, C.F.; Park, C.H.; Watt, J.; Kuettner, L.; Patterson, B.; Dattelbaum, D.M.; Lee, K.-S. Impact of filler composition on mechanical and dynamic response of 3-D printed silicone-based nanocomposite elastomers. Compos. Sci. Technol. 2020, 198, 108258. [Google Scholar] [CrossRef]

- Liu, A.; Ni, Z.; Chen, J.; Huang, Y. Highly sensitive graphene/polydimethylsiloxane composite films near the threshold concentration with biaxial stretching. Polymers 2020, 12, 71. [Google Scholar] [CrossRef] [Green Version]

- Zhao, X.; Wang, T.; Li, Y.; Huang, L.; Handschuh-Wang, S. Polydimethylsiloxane/nanodiamond composite sponge for enhanced mechanical or wettability performance. Polymers 2019, 11, 948. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hanson, D.E.; Hawley, M.; Houlton, R.; Chitanvis, K.; Rae, P.; Orler, E.B.; Wrobleski, D.A. Stress softening experiments in silica-filled polydimethylsiloxane provide insight into a mechanism for the Mullins effect. Polymer 2005, 46, 10989–10995. [Google Scholar] [CrossRef]

- Nazari, A.M.; Miri, A.K.; Shinozaki, D.M. Mechanical characterization of nanoclay-filled PDMS thin films. Polym. Test. 2016, 52, 85–88. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and properties of carbon fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Newcomb, B.A.J. Processing, structure, and properties of carbon fibers. Compos. Part A Appl. Sci. Manuf. 2016, 91, 262–282. [Google Scholar] [CrossRef]

- Chowdhury, S.; Olima, M.; Liu, Y.; Saha, M.; Bergman, J.; Robison, T.J. Poly dimethylsiloxane/carbon nanofiber nanocomposites: Fabrication and characterization of electrical and thermal properties. Int. J. Smart Nano Mater. 2016, 7, 236–247. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Z.; Lai, C.; Zhang, L.; Qian, Y.; Hou, H.; Reneker, D.H.; Fong, H. Development of carbon nanofibers from aligned electrospun polyacrylonitrile nanofiber bundles and characterization of their microstructural, electrical, and mechanical properties. Polymer 2009, 50, 2999–3006. [Google Scholar] [CrossRef]

- Poveda, R.L.P.; Achar, S.; Gupta, N. Thermal expansion of carbon nanofiber-reinforced multiscale polymer composites. JOM 2012, 64, 1148–1157. [Google Scholar] [CrossRef]

- Flowers, G.; Switzer, S.T. Background Material Properties of Selected Silicone Potting Compounds and Raw Materials for Their Substitutes; Mason and Hanger-Silas Mason Co., Inc.: Amarillo, TX, USA, 1978. [Google Scholar]

- Xia, Y.; Whitesides, G.M. Soft Lithography. Annu. Rev. Mater. Sci. 1998, 28, 153–184. [Google Scholar] [CrossRef]

- Lisensky, G.C.; Campbell, D.J.; Beckman, K.J.; Calderon, C.E.; Doolan, P.W.; Ottosen, R.M.; Ellis, A.B. Replication and Compression of Surface Structures with Polydimethylsiloxane Elastomer. J. Chem. Educ. 1999, 76, 537. [Google Scholar] [CrossRef]

- Pyrograf®-III Carbon Nanofiber. Available online: http://pyrografproducts.com/Merchant5/merchant.mvc?Screen=cp_nanofiber (accessed on 11 March 2021).

- Wang, B.; Krause, S. Properties of dimethylsiloxane microphases in phase-separated dimethylsiloxane block copolymers. Macromolecules 1987, 20, 2201–2208. [Google Scholar] [CrossRef]

- Hyun, K.; Wilhelm, M.; Klein, C.O.; Cho, K.S.; Nam, J.G.; Ahn, K.H.; Lee, S.J.; Ewoldt, R.H.; McKinley, G.H. A review of nonlinear oscillatory shear tests: Analysis and application of large amplitude oscillatory shear (LAOS). Prog. Polym. Sci. 2011, 36, 1697–1753. [Google Scholar] [CrossRef]

- Esteves, A.; Brokken-Zijp, J.; Laven, J.; Huinink, H.; Reuvers, N.; Van, M.; De With, G. Influence of cross-linker concentration on the cross-linking of PDMS and the network structures formed. Polymer 2009, 50, 3955–3966. [Google Scholar] [CrossRef]

- Stafie, N.; Stamatialis, D.; Wessling, M. Effect of PDMS cross-linking degree on the permeation performance of PAN/PDMS composite nanofiltration membranes. Sep. Purif. Technol. 2005, 45, 220–231. [Google Scholar] [CrossRef]

- Mazurek, P.; Vudayagiri, S.; Skov, A.L. How to tailor flexible silicone elastomers with mechanical integrity: A tutorial review. Chem. Soc. Rev. 2019, 48, 1448–1464. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Information about Dow Corning® Brand Silicone Encapsulants. Available online: http://bdml.stanford.edu/twiki/pub/Rise/PDMSProceSS/PDMSdatasheet.pdf (accessed on 31 March 2021).

- Konku-Asase, Y.; Yaya, A.; Kan-Dapaah, K. Curing Temperature Effects on the Tensile Properties and Hardness of Reinforced g-Fe2O3 PDMS Nanocomposites. Adv. Mater. Sci. Eng. 2020, 2020, 6562373. [Google Scholar] [CrossRef]

- Prabowo, F.; Wing-Keung, A.L.; Shen, H.H. Effect of curing temperature and cross-linker to pre-polymer ratio on the viscoelastic properties of a PDMS elastomer. Proc. Adv. Mater. Res. 2015, 1112, 410–413. [Google Scholar] [CrossRef]

- Agaoglu, S.; Robles, M.C.; Smith, C.D.; Quake, S.R.; Araci, I.E. The effect of pre-polymer/cross-linker storage on the elasticity and reliability of PDMS microfluidic devices. Microfluid. Nanofluidics 2017, 21, 117. [Google Scholar] [CrossRef]

- Wu, S.; Ladani, R.B.; Zhang, J.; Kinloch, A.J.; Zhao, Z.; Ma, J.; Zhang, X.; Mouritz, A.P.; Ghorbani, K.; Wang, C.H. Epoxy nanocomposites containing magnetite-carbon nanofibers aligned using a weak magnetic field. Polymer 2015, 68, 25–34. [Google Scholar] [CrossRef] [Green Version]

- Shi, D.; He, P.; Lian, J.; Chaud, X.; Bud’ko, S.L.; Beaugnon, E.; Wang, L.; Ewing, R.C.; Tournier, R.J. Magnetic alignment of carbon nanofibers in polymer composites and anisotropy of mechanical properties. J. Appl. Phys. 2005, 97, 064312. [Google Scholar] [CrossRef] [Green Version]

- Slipher, G.A.; Hairston, W.D.; Bradford, J.C.; Bain, E.D.; Mrozek, R.A.J.P.o. Carbon nanofiber-filled conductive silicone elastomers as soft, dry bioelectronic interfaces. PLoS ONE 2018, 13, e0189415. [Google Scholar] [CrossRef]

- Wang, S.; D’hooge, D.R.; Daelemans, L.; Xia, H.; Clerck, K.D.; Cardon, L. The Transferability and Design of Commercial Printer Settings in PLA/PBAT Fused Filament Fabrication. Polymers 2020, 12, 2573. [Google Scholar] [CrossRef]

- Lee, K.-S.; Jeong, M.-H.; Lee, J.-P.; Lee, J.-S.J.M. End-group cross-linked poly (arylene ether) for proton exchange membranes. Macromolecules 2009, 42, 584–590. [Google Scholar] [CrossRef]

- Hiemenz, P.C.; Lodge, T.P. Polymer Chemistry; CRC Press Taylor & Francis Group: Boca Raton, FL, USA, 2007; pp. 412–416. [Google Scholar]

- Chen, D.; Chen, F.; Hu, X.; Zhang, H.; Yin, X.; Zhou, Y. Thermal stability, mechanical and optical properties of novel addition cured PDMS composites with nano-silica sol and MQ silicone resin. Compos. Sci. Technol. 2015, 117, 307–314. [Google Scholar] [CrossRef]

- Kumar, S.; Rath, T.; Mahaling, R.N.; Das, C.K. Processing and characterization of carbon nanofiber/syndiotactic polystyrene composites in the absence and presence of liquid crystalline polymer. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1304–1317. [Google Scholar] [CrossRef]

- Camino, G.; Lomakin, S.M.; Lazzari, M. Polydimethylsiloxane thermal degradation Part 1. Kinetic aspects. Polymer 2001, 42, 2395–2402. [Google Scholar] [CrossRef]

- Schick, C. 2.31—Calorimetry. In Polymer Science: A Comprehensive Reference; Matyjaszewski, K., Möller, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2012; pp. 793–823. [Google Scholar]

| Elongation (%) | Ultimate Strength (MPa) | Toughness (MPa) | Young’s Modulus (MPa) | ||

|---|---|---|---|---|---|

| Initial | After 100% Elongation | ||||

| PDMS pristine | 461 | 4.92 | 8.44 | 1.13 | 1.13 |

| CF-0.5/PDMS | 394 | 3.95 | 6.41 | 1.48 | 1.42 |

| CF-1.0/PDMS | 422 | 4.48 | 8.03 | 1.65 | 1.52 |

| CF-2.0/PDMS | 356 | 3.60 | 5.88 | 1.72 | 1.53 |

| CF-4.0/PDMS | 335 | 3.47 | 5.87 | 1.76 | 1.52 |

| Td (5% Wt. Loss) (°C) | Degradation Peak 1 (°C) | Degradation Peak 2 (°C) | Degradation Peak 3 (°C) | |

|---|---|---|---|---|

| PDMS pristine | 410.9 | 298.6 | 491.0 | 620.4 |

| CF-0.5/PDMS | 415.7 | 317.5 | 479.4 | 625.7 |

| CF-1.0/PDMS | 420.4 | 309.7 | 478.2 | 624.0 |

| CF-2.0/PDMS | 430.4 | 315.9 | 484.7 | 623.1 |

| CF-4.0/PDMS | 437.8 | 314.2 | 490.1 | 622.3 |

| Tg (°C) | Tm (°C) | ΔHf (J/g) | Tc (°C) | ΔHc (J/g) | Χc (%) * | |

|---|---|---|---|---|---|---|

| PDMS pristine | −123.3 | −47.5 | 23.7 | −78.4 | 24.1 | 38.7 |

| CF-0.5/PDMS | −123.6 | −47.7 | 23.8 | −80.7 | 23.2 | 38.9 |

| CF-1.0/PDMS | −123.2 | −47.8 | 23.6 | −78.9 | 23.1 | 38.6 |

| CF-2.0/PDMS | −121.0 | −46.8 | 23.3 | −77.4 | 25.0 | 38.1 |

| CF-4.0/PDMS | −123.3 | −46.05 | 23.4 | −77.4 | 23.1 | 38.2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gupta, N.S.; Lee, K.-S.; Labouriau, A. Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers. Polymers 2021, 13, 1141. https://doi.org/10.3390/polym13071141

Gupta NS, Lee K-S, Labouriau A. Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers. Polymers. 2021; 13(7):1141. https://doi.org/10.3390/polym13071141

Chicago/Turabian StyleGupta, Nevin Stephen, Kwan-Soo Lee, and Andrea Labouriau. 2021. "Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers" Polymers 13, no. 7: 1141. https://doi.org/10.3390/polym13071141

APA StyleGupta, N. S., Lee, K. -S., & Labouriau, A. (2021). Tuning Thermal and Mechanical Properties of Polydimethylsiloxane with Carbon Fibers. Polymers, 13(7), 1141. https://doi.org/10.3390/polym13071141