Interlayer Bonding Capability of Additively Manufactured Polymer Structures under High Strain Rate Tensile and Shear Loading

Abstract

:1. Introduction

2. Materials and Methods

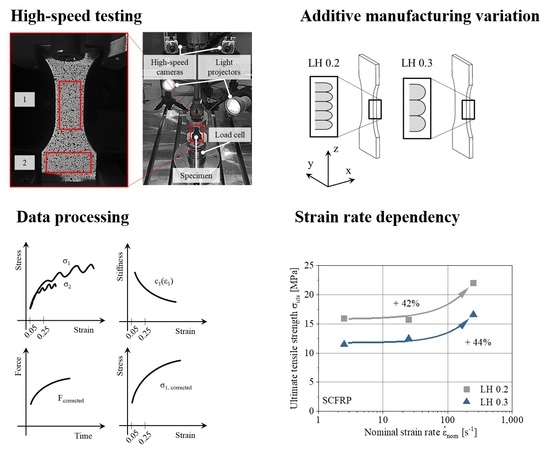

2.1. Experimental Setup

2.2. Data Processing

- No oscillations present at the beginning of the test since the stress wave travels a certain amount of time from the impact location until reaching the load cell.

- Identical stress-strain behavior in gage section (1) and dynamometer section (2).

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Eftekhari, M.; Fatemi, A. Tensile, creep and fatigue behaviours of short fibre reinforced polymer composites at elevated temperatures: A literature survey. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1395–1418. [Google Scholar] [CrossRef]

- Kaji, F.; Barari, A. Evaluation of the surface roughness of additive manufacturing parts based on the modelling of cusp geometry. Int. Fed. Autom. Control 2015, 48, 658–663. [Google Scholar] [CrossRef]

- Pertuz, A.D.; Díaz-Cardona, S.; González-Estrada, O.A. Static and fatigue behaviour of continuous fibre reinforced thermoplastic composites manufactured by fused deposition modelling technique. Int. J. Fatigue 2020, 130, 105275. [Google Scholar] [CrossRef]

- Eiliat, H.; Urbanic, J. Determining the relationships between the build orientation, process parameters and voids in additive manufacturing material extrusion processes. Int. J. Adv. Manuf. Technol. 2019, 100, 683–705. [Google Scholar] [CrossRef]

- Hart, K.R.; Wetzel, E.D. Fracture behavior of additively manufactured acrylonitrile butadiene styrene (ABS) materials. Eng. Fract. Mech. 2017, 177, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Zaldivar, R.J.; Witkin, D.B.; McLouth, T.; Patel, D.N.; Schmitt, K.; Nokes, J.P. Influence of processing and orientation print effects on the mechanical and thermal behavior of 3D-printed ULTEM® 9085 Material. Addit. Manuf. 2017, 13, 71–80. [Google Scholar] [CrossRef]

- Koch, C.; van Hulle, L.; Rudolph, N. Investigation of mechanical anisotropy of the fused filament fabrication process via customized tool path generation. Addit. Manuf. 2017, 16, 138–145. [Google Scholar] [CrossRef]

- Striemann, P.; Huelsbusch, D.; Niedermeier, M.; Walther, F. Quasi-static characterization of polyamide-based discontinuous CFRP manufactured by additive manufacturing and injection molding. Key Eng. Mater. 2019, 809, 386–391. [Google Scholar] [CrossRef]

- Striemann, P.; Hülsbusch, D.; Mrzljak, S.; Niedermeier, M.; Walther, F. Systematic approach for the characterization of additive manufactured and injection molded short carbon fiber-reinforced polymers under tensile loading. Mater. Test. 2020, 62, 561–567. [Google Scholar] [CrossRef]

- Arbeiter, F.; Spoerk, M.; Wiener, J.; Gosch, A.; Pinter, G. Fracture mechanical characterization and lifetime estimation of near-homogeneous components produced by fused filament fabrication. Polym. Test. 2018, 66, 105–113. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.-Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Sood, A.K.; Ohdar, R.K.; Mahapatra, S.S. Experimental investigation and empirical modelling of FDM process for compressive strength improvement. J. Adv. Res. 2012, 3, 81–90. [Google Scholar] [CrossRef] [Green Version]

- Bartolai, J.; Simpson, T.W.; Xie, R. Predicting strength of additively manufactured thermoplastic polymer parts produced using material extrusion. Rapid Prototyp. J. 2018, 24, 321–332. [Google Scholar] [CrossRef]

- Kuznetsov, V.; Solonin, A.; Urzhumtsev, O.; Schilling, R.; Tavitov, A. Strength of PLA components fabricated with fused deposition technology using a desktop 3D printer as a function of geometrical parameters of the process. Polymers 2018, 10, 313. [Google Scholar] [CrossRef] [Green Version]

- Boschetto, A.; Bottini, L.; Veniali, F. Finishing of fused deposition modeling parts by CNC machining. Rob. Comput. Integr. Manuf. 2016, 41, 92–101. [Google Scholar] [CrossRef]

- Pandey, P.M.; Reddy, V.; Dhande, S.G. Improvement of surface finish by staircase machining in fused deposition modeling. J. Mater. Process. Technol. 2003, 132, 323–331. [Google Scholar] [CrossRef]

- Chohan, J.S.; Singh, R.; Boparai, K.S. Mathematical modelling of surface roughness for vapour processing of ABS parts fabricated with fused deposition modelling. J. Manuf. Processes 2016, 24, 161–169. [Google Scholar] [CrossRef]

- Garg, A.; Bhattacharya, A.; Batish, A. Chemical vapor treatment of ABS parts built by FDM: Analysis of surface finish and mechanical strength. Int. J. Adv. Manuf. Technol. 2017, 89, 2175–2191. [Google Scholar] [CrossRef]

- Alsoufi, M.S.; Elsayed, A.E. How surface roughness performance of printed parts manufactured by desktop FDM 3D printer with PLA+ is influenced by measuring direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Valerga, A.P.; Batista, M.; Fernandez, S.R.; Gomez-Parra, A.; Barcena, M. Preliminary study of the influence of manufacturing parameters in fused deposition modeling. In Proceedings of the 26th DAAAM International Symposium, Zadar, Croatia, 18–25 October 2015; pp. 1004–1008. [Google Scholar]

- Mohamed, O.A.; Masood, S.H.; Bhowmik, J.L. Mathematical modeling and FDM process parameters optimization using response surface methodology based on Q-optimal design. Appl. Math. Modell. 2016, 40, 10052–10073. [Google Scholar] [CrossRef]

- Thrimurthulu, K.; Pandey, P.M.; Venkata Reddy, N. Optimum part deposition orientation in fused deposition modeling. Int. J. Mach. Tools Manuf. 2004, 44, 585–594. [Google Scholar] [CrossRef]

- Terekhina, S.; Tarasova, T.; Egorov, S.; Skornyakov, I.; Guillaumat, L.; Hattali, M.L. The effect of build orientation on both flexural quasi-static and fatigue behaviours of filament deposited PA6 polymer. Int. J. Fatigue 2020, 140, 105825. [Google Scholar] [CrossRef] [PubMed]

- Faes, M.; Ferraris, E.; Moens, D. Influence of inter-layer cooling time on the quasi-static properties of ABS components produced via fused deposition modelling. Procedia CIRP 2016, 42, 748–753. [Google Scholar] [CrossRef]

- Striemann, P.; Hülsbusch, D.; Niedermeier, M.; Walther, F. Optimization and quality evaluation of the interlayer bonding performance of additively manufactured polymer structures. Polymers 2020, 12, 1166. [Google Scholar] [CrossRef] [PubMed]

- Bhandari, S.; Lopez-Anido, R.A.; Gardner, D.J. Enhancing the interlayer tensile strength of 3D printed short carbon fiber reinforced PETG and PLA composites via annealing. Addit. Manuf. 2019, 30, 100922. [Google Scholar] [CrossRef]

- Tymrak, B.M.; Kreiger, M.; Pearce, J.M. Mechanical properties of components fabricated with open-source 3-D printers under realistic environmental conditions. Mater. Des. 2014, 58, 242–246. [Google Scholar] [CrossRef] [Green Version]

- García Plaza, E.; López, P.J.N.; Torija, M.Á.C.; Muñoz, J.M.C. Analysis of PLA geometric properties processed by FFF additive manufacturing: Effects of process parameters and plate-extruder precision motion. Polymers 2019, 11, 1581. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Armillotta, A.; Bianchi, S.; Cavallaro, M.; Minnella, S. Edge quality in fused deposition modeling: II. experimental verification. Rapid Prototyp. J. 2017, 23, 686–695. [Google Scholar] [CrossRef]

- Zrida, M.; Laurent, H.; Grolleau, V.; Rio, G.; Khlif, M.; Guines, D.; Masmoudi, N.; Bradai, C. High-speed tensile tests on a polypropylene material. Polym. Test. 2010, 29, 685–692. [Google Scholar] [CrossRef]

- Chen, W.; Lu, F.; Cheng, M. Tension and compression tests of two polymers under quasi-static and dynamic loading. Polym. Test. 2002, 21, 113–121. [Google Scholar] [CrossRef]

- Fang, X. A one-dimensional stress wave model for analytical design and optimization of oscillation-free force measurement in high-speed tensile test specimens. Int. J. Impact Eng. 2021, 149, 103770. [Google Scholar] [CrossRef]

- Striemann, P.; Bulach, S.; Hülsbusch, D.; Niedermeier, M.; Walther, F. Shear characterization of additively manufactured short carbon fiber-reinforced polymer. Macromol. Symp. 2021, 395, 2000247. [Google Scholar] [CrossRef]

- Schoßig, M.; Bierögel, C.; Grellmann, W.; Mecklenburg, T. Mechanical behavior of glass-fiber reinforced thermoplastic materials under high strain rates. Polym. Test. 2008, 27, 893–900. [Google Scholar] [CrossRef]

- Rankouhi, B.; Javadpour, S.; Delfanian, F.; Letcher, T. Failure analysis and mechanical characterization of 3D printed ABS with respect to layer thickness and orientation. J. Fail. Anal. Prev. 2016, 16, 467–481. [Google Scholar] [CrossRef]

- Cui, J.; Wang, S.; Wang, S.; Li, G.; Wang, P.; Liang, C. The effects of strain rates on mechanical properties and failure behavior of long glass fiber reinforced thermoplastic composites. Polymers 2019, 11, 2019. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Parameter | Unit | CarbonX™ |

|---|---|---|

| Nozzle diameter (ND) | mm | 0.4 |

| Extrusion bead | mm | 0.5 |

| Layer height (LH) | mm | 0.2 and 0.3 |

| Extrusion temperature | °C | 260 |

| Printing bed temperature | °C | 80 |

| Extrusion velocity | mm·s−1 | 10 |

| Specimen orientation | - | ZYX |

| Infill percentage | % | 100 |

| Raster pattern | - | unidirectional 0° |

| Number of contours | - | 1 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Striemann, P.; Gerdes, L.; Huelsbusch, D.; Niedermeier, M.; Walther, F. Interlayer Bonding Capability of Additively Manufactured Polymer Structures under High Strain Rate Tensile and Shear Loading. Polymers 2021, 13, 1301. https://doi.org/10.3390/polym13081301

Striemann P, Gerdes L, Huelsbusch D, Niedermeier M, Walther F. Interlayer Bonding Capability of Additively Manufactured Polymer Structures under High Strain Rate Tensile and Shear Loading. Polymers. 2021; 13(8):1301. https://doi.org/10.3390/polym13081301

Chicago/Turabian StyleStriemann, Patrick, Lars Gerdes, Daniel Huelsbusch, Michael Niedermeier, and Frank Walther. 2021. "Interlayer Bonding Capability of Additively Manufactured Polymer Structures under High Strain Rate Tensile and Shear Loading" Polymers 13, no. 8: 1301. https://doi.org/10.3390/polym13081301

APA StyleStriemann, P., Gerdes, L., Huelsbusch, D., Niedermeier, M., & Walther, F. (2021). Interlayer Bonding Capability of Additively Manufactured Polymer Structures under High Strain Rate Tensile and Shear Loading. Polymers, 13(8), 1301. https://doi.org/10.3390/polym13081301