Nanocomposites of PCL and SBA-15 Particles Prepared by Extrusion: Structural Characteristics, Confinement of PCL Chains within SBA-15 Nanometric Channels and Mechanical Behavior

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Nano Composite and Film Preparation

2.3. Transmission Electron Microscopy

2.4. Scanning Electron Microscopy

2.5. Thermogravimetric Analysis

2.6. Differential Scanning Calorimetry

2.7. X-ray Experiments with Synchrotron Radiation

2.8. Mechanical Behavior by Means of Stress–Strain Tests

3. Results and Discussion

3.1. Morphological Characteristics

3.2. Thermal Stability

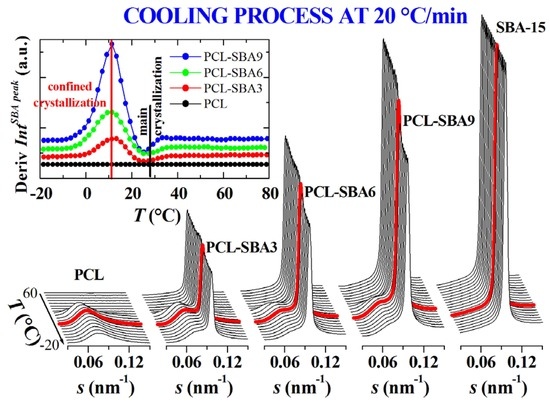

3.3. Phase Transitions, Crystalline Characteristics and Confinement of PCL Chains

3.4. Mechanical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chandra, R.; Rustgi, R. Biodegradable polymers. Prog. Polym. Sci. 1998, 23, 1273–1335. [Google Scholar] [CrossRef]

- Lim, J.S.; Ki, C.S.; Kim, J.W.; Lee, K.G.; Kang, S.W.; Kweon, H.Y.; Park, Y.H. Fabrication and Evaluation of Poly(epsilon-caprolactone)/Silk Fibroin Blend Nanofibrous Scaffold. Biopolymers 2012, 97, 265–275. [Google Scholar] [CrossRef] [PubMed]

- Simoes, M.C.R.; Cragg, S.M.; Barbu, E.; De Sousa, F.B. The potential of electrospun poly(methyl methacrylate)/polycaprolactone core-sheath fibers for drug delivery applications. J. Mater. Sci. 2019, 54, 5712–5725. [Google Scholar] [CrossRef] [Green Version]

- Rosa, D.S.; Guedes, C.G.F.; Bardi, M.A.G. Evaluation of thermal, mechanical and morphological properties of PCL/CA and PCL/CA/PE-g-GMA blends. Polym. Test. 2007, 26, 209–215. [Google Scholar] [CrossRef]

- Arcana, M.; Bundjali, B.; Yudistira, I.; Jariah, B.; Sukria, L. Study on properties of polymer blends from polypropylene with polycaprolactone and their biodegradability. Polym. J. 2007, 39, 1337–1344. [Google Scholar] [CrossRef] [Green Version]

- Newman, D.; Laredo, E.; Bello, A.; Grillo, A.; Feijoo, J.L.; Müller, A.J. Molecular Mobilities in Biodegradable Poly(DL-lactide)/Poly(ε-caprolactone) Blends. Macromolecules 2009, 42, 5219–5225. [Google Scholar] [CrossRef]

- Ravati, S.; Favis, B.D. Interfacial coarsening of ternary polymer blends with partial and complete wetting structures. Polymer 2013, 54, 6739–6751. [Google Scholar] [CrossRef]

- Seggiani, M.; Altieri, R.; Puccini, M.; Stefanelli, E.; Esposito, A.; Castellani, F.; Stanzione, V.; Vitolo, S. Polycaprolactone-collagen hydrolysate thermoplastic blends: Processability and biodegradability/compostability. Polym. Degrad. Stab. 2018, 150, 13–24. [Google Scholar] [CrossRef]

- Blázquez-Blázquez, E.; Pérez, E.; Lorenzo, V.; Cerrada, M.L. Crystalline characteristics and their influence in the Mechanical Performance in Poly(ε-caprolactone)/High Density Polyethylene Blends. Polymers 2019, 11, 1874. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-H.; Teramoto, Y.; Endo, T. Cellulose nanofiber-reinforced polycaprolactone/polypropylene hybrid nanocomposite. Compos. Part A 2011, 42, 151–156. [Google Scholar] [CrossRef]

- Pan, L.; Pei, X.; He, R.; Wan, Q.; Wang, J. Multiwall carbon nanotubes/polycaprolactone composites for bone tissue engineering application. Colloid Surface B 2012, 93, 226–234. [Google Scholar] [CrossRef] [PubMed]

- Boujemaoui, A.; Sanchez, C.C.; Engstrom, J.; Bruce, C.; Fogelstrom, L.; Carlmark, A.; Malmstrom, E. Polycaprolactone Nanocomposites Reinforced with Cellulose Nanocrystals Surface-Modified via Covalent Grafting or Physisorption: A Comparative Study. ACS Appl. Mater. Interfaces 2017, 9, 35305–35318. [Google Scholar] [CrossRef]

- Mao, L.; Liu, Y.J.; Wu, H.Q.; Chen, J.H.; Yao, J. Poly(epsilon-caprolactone) filled with polydopamine-coated high aspect ratio layered double hydroxide: Simultaneous enhancement of mechanical and barrier properties. Appl. Clay Sci. 2017, 150, 202–209. [Google Scholar] [CrossRef]

- Beck, J.S.; Vartuli, J.C.; Roth, W.J.; Leonowicz, M.E.; Kresge, C.T.; Schmitt, K.D.; Chu, C.T.-W.; Olson, D.H.; Sheppard, E.W.; McCullen, S.B.; et al. A new family of mesoporous molecular sieves prepared with liquid crystal templates. J. Am. Chem. Soc. 1992, 114, 10834–10843. [Google Scholar] [CrossRef]

- Zhao, D.Y.; Feng, J.L.; Huo, Q.S.; Melosh, N.; Fredrickson, G.H.; Chmelka, B.F.; Stucky, G.D. Triblock Copolymer Syntheses of Mesoporous Silica with Periodic 50 to 300 Angstrom Pores. Science 1998, 279, 548–552. [Google Scholar] [CrossRef] [Green Version]

- Kageyama, K.; Tamazawa, J.; Aida, T. Extrusion Polymerization: Catalyzed Synthesis of Crystalline Linear Polyethylene Nanofibers Within a Mesoporous Silica. Science 1999, 285, 2113–2115. [Google Scholar] [CrossRef] [PubMed]

- Nakajima, H.; Yamada, K.; Iseki, Y.; Hosoda, S.; Hanai, A.; Oumi, Y.; Teranishi, T.; Sano, T. Preparation and characterization of polypropylene/mesoporous silica nanocomposites with confined polypropylene. J. Polym. Sci. Part B Polym. Phys. 2003, 41, 3324–3332. [Google Scholar] [CrossRef]

- Cerrada, M.L.; Pérez, E.; Lourenço, J.P.; Campos, J.M.; Ribeiro, M.R. Hybrid HDPE/MCM-41 Nanocomposites: Crystalline Structure and Viscoelastic Behaviour. Microporous Mesoporous Mater. 2010, 130, 215–223. [Google Scholar] [CrossRef]

- Kurek, A.; Mark, S.; Enders, M.; Kristen, M.O.; Mülhaupt, R. Mesoporous Silica Supported Multiple Single-Site Catalysts and Polyethylene Reactor Blends with Tailor-Made Trimodal and Ultra-Broad Molecular Weight Distributions. Macromol. Rapid Commun. 2010, 31, 1359–1363. [Google Scholar] [CrossRef]

- Campos, J.M.; Lourenço, J.P.; Cramail, H.; Ribeiro, M.R. Nanostructured silica materials in olefin polymerisation: From catalytic behaviour to polymer characteristics. Prog. Polym. Sci. 2012, 37, 1764–1804. [Google Scholar] [CrossRef]

- Dong, X.C.; Wang, L.; Jiang, G.H.; Zhao, Z.R.; Sun, T.X.; Yu, H.J.; Wang, W.Q. MCM-41 and SBA-15 supported Cp2ZrCl2 catalysts for the preparation of nano-polyethylene fibres via in situ ethylene extrusion polymerization. J. Mol. Catal. A Chem. 2005, 240, 239–244. [Google Scholar]

- Ferreira, A.E.; Cerrada, M.L.; Pérez, E.; Lorenzo, V.; Cramail, H.; Lourenço, J.P.; Ribeiro, M.R. UHMWPE/SBA-15 nanocomposites synthesized by in situ polymerization. Microporous Mesoporous Mater. 2016, 232, 13–25. [Google Scholar] [CrossRef]

- Ferreira, A.E.; Cerrada, M.L.; Pérez, E.; Lorenzo, V.; Cramail, H.; Lourenço, J.P.; Quijada, R.; Ribeiro, M.R. Hafnocene catalyst for polyethylene and its nanocomposites with SBA-15 by in situ polymerization: Immobilization approaches, catalytic behavior and properties evaluation. Eur. Polym. J. 2016, 85, 298–312. [Google Scholar] [CrossRef]

- Barranco-García, R.; Ferreira, A.E.; Ribeiro, M.R.; Lorenzo, V.; García-Peñas, A.; Gómez-Elvira, J.M.; Pérez, E.; Cerrada, M.L. Hybrid materials obtained by in situ polymerization based on polypropylene and mesoporous SBA-15 silica particles: Catalytic aspects, crystalline details and mechanical behavior. Polymer 2018, 151, 218–230. [Google Scholar] [CrossRef]

- Ferreira, A.E.; Ribeiro, M.R.; Cramail, H.; Lourenço, J.P.; Lorenzo, V.; Pérez, E.; Cerrada, M.L. Extraordinary Mechanical Performance in Disentangled UHMWPE Films Processed by Compression Molding. J. Mech. Behav. Biomed. Mater. 2019, 90, 202–207. [Google Scholar] [CrossRef] [PubMed]

- Cerrada, M.L.; Pérez, E.; Lourenço, J.P.; Bento, A.; Ribeiro, M.R. Decorated MCM-41/polyethylene hybrids: Crystalline Details and Viscoelastic Behavior. Polymer 2013, 54, 2611–2620. [Google Scholar] [CrossRef] [Green Version]

- Cerrada, M.L.; Bento, A.; Pérez, E.; Lorenzo, V.; Lourenço, J.P.; Ribeiro, M.R. Hybrid Materials Based on Polyethylene and MCM-41 Particles Functionalized with Silanes: Catalytic Aspects of In Situ Polymerization, Crystalline Features and Mechanical Properties. Microporous Mesoporous Mater. 2016, 232, 86–96. [Google Scholar] [CrossRef]

- Deryło-Marczewska, A.; Zienkiewicz-Strzałka, M.; Skrzypczyńska, K.; Światkowski, A.; Kuśmierek, K. Evaluation of the SBA-15 materials ability to accumulation of 4-chlorophenol on carbon paste electrode. Adsorption 2016, 22, 801–812. [Google Scholar] [CrossRef] [Green Version]

- Nakagawa, S.; Kadena, K.; Ishizone, T.; Nojima, S.; Shimizu, T.; Yamaguchi, K.; Nakahama, S. Crystallization Behavior and Crystal Orientation of Poly(ε-caprolactone) Homopolymers Confined in Nanocylinders: Effects of Nanocylinder Dimension. Macromolecules 2012, 45, 1892–1900. [Google Scholar] [CrossRef]

- Muñoz-Bonilla, A.; Cerrada, M.L.; Fernández-García, M.; Kubacka, A.; Ferrer, M.; Fernández-García, M. Biodegradable Polycaprolactone-Titania Nanocomposites: Preparation, Characterization and Antimicrobial Properties. Int. J. Mol. Sci. 2013, 14, 9249–9266. [Google Scholar] [CrossRef] [Green Version]

- Marcilla, A.; Gómez-Siurana, A.; Menargues, S.; Ruiz-Femenia, R.; García-Quesada, J.C. Oxidative degradation of EVA copolymers in the presence of MCM-41. J. Anal. Appl. Pyrolysis 2006, 76, 138–143. [Google Scholar] [CrossRef]

- Aguado, J.; Serrano, D.P.; Romero, M.D.; Escola, J.M. Catalytic conversion of polyethylene into fuels over mesoporous MCM-41. Chem. Commun. 1996, 6, 725–726. [Google Scholar] [CrossRef]

- Campos, J.M.; Lourenço, J.P.; Pérez, E.; Cerrada, M.L.; Ribeiro, M.R. Self-reinforced Hybrid Polyethylene/MCM-41 Nanocomposites: In-situ Polymerisation and Effect of MCM-41 Content on Rigidity. J. Nanosci. Nanotech. 2009, 9, 3966–3974. [Google Scholar] [CrossRef] [Green Version]

- Bento, A.; Lourenço, J.P.; Fernandes, A.; Ribeiro, M.R.; Arranz-Andrés, J.; Lorenzo, V.; Cerrada, M.L. Gas permeability properties of decorated MCM 41/polyethylene hybrids prepared by in situ polymerization. J. Membr. Sci. 2012, 415–416, 702–711. [Google Scholar] [CrossRef]

- Persenaire, O.; Alexandre, M.; Degée, P.; Dubois, P. Mechanisms and Kinetics of Thermal Degradation of Poly(ε-caprolactone). Biomacromolecules 2001, 2, 288–294. [Google Scholar] [CrossRef]

- Mofokeng, J.P.; Kelnar, I.; Luyt, A.S. Effect of layered silicates on the thermal stability of PCL/PLA microfibrillar composites. Polym. Test. 2016, 50, 9–14. [Google Scholar] [CrossRef]

- Bensason, S.; Minick, J.; Moet, A.; Chum, S.; Hiltner, A.; Baer, E. Classification of homogeneous ethylene-octene copolymers based on comonomer content. J. Polym. Sci. Part B Polym. Phys. 1996, 34, 1301–1315. [Google Scholar] [CrossRef]

- Alizadeh, A.; Richardson, L.; Xu, J.; McCartney, S.; Marand, H.; Cheung, Y.W.; Chum, S. Influence of Structural and Topological Constraints on the Crystallization and Melting Behavior of Polymers. 1. Ethylene/1-Octene Copolymers. Macromolecules 1999, 32, 6221–6235. [Google Scholar] [CrossRef]

- Polo-Corpa, M.J.; Benavente, R.; Velilla, T.; Quijada, R.; Pérez, E.; Cerrada, M.L. Development of mesomorphic form in propene/higher α-olefin copolymers at intermediate comonomer content and its effect on properties. Eur. Polym. J. 2010, 46, 1345–1354. [Google Scholar] [CrossRef] [Green Version]

- García-Peñas, A.; Gómez-Elvira, J.M.; Blázquez-Blázquez, E.; Barranco-García, R.; Pérez, E.; Cerrada, M.L. Microstructural Details and Polymorphs in Poly(propylene-co-1-nonene) Copolymers Synthesized at Different Polymerization Temperatures. Polym. Cryst. 2021, 4, e10150. [Google Scholar] [CrossRef]

- Wunderlich, B. Macromolecular Physics; Academic Press: New York, NY, USA, 1980; Volume 3. [Google Scholar]

- Darras, O.; Séguéla, R. Surface free energy of the chain-folding crystal faces of ethylene-butene random copolymers. Polymer 1993, 34, 2946–2950. [Google Scholar] [CrossRef]

- Lu, L.; Alamo, R.G.; Mandelkern, L. Lamellar thickness distribution in linear polyethylene and ethylene copolymers. Macromolecules 1994, 27, 6571–6576. [Google Scholar] [CrossRef]

- Gedde, U.W. Polymer Physics; Chapman & Hall: London, UK, 1995. [Google Scholar]

- Shin, K.; Woo, E.; Jeong, Y.G.; Kim, C.; Huh, J.; Kim, K.-W. Crystalline structures, melting, and crystallization of linear polyethylene in cylindrical nanopores. Macromolecules 2007, 40, 6617–6623. [Google Scholar] [CrossRef]

- Jackson, C.L.; McKenna, G.B. The melting behavior of organic materials confined in porous solids. J. Chem. Phys. 1990, 93, 9002–9011. [Google Scholar] [CrossRef]

- Ferreira, A.E.; Cerrada, M.L.; Pérez, E.; Lorenzo, V.; Vallés, E.; Ressia, J.; Cramail, H.; Lourenço, J.P.; Ribeiro, M.R. UHMWPE/HDPE in-reactor blends, prepared by in situ polymerization: Synthetic aspects and characterization. eXPRESS Polym. Lett. 2017, 11, 344–361. [Google Scholar] [CrossRef] [Green Version]

- Barranco-García, R.; López-Majada, J.M.; Martínez, J.C.; Gómez-Elvira, J.M.; Pérez, E.; Cerrada, M.L. Confinement of iPP crystallites within mesoporous SBA-15 channels in extruded iPP-SBA-15 nanocomposites by Small Angle X-ray Scattering. Microporous Mesoporous Mater. 2018, 272, 209–216. [Google Scholar] [CrossRef]

- Barranco-García, R.; López-Majada, J.M.; Lorenzo, V.; Gómez-Elvira, J.M.; Pérez, E.; Cerrada, M.L. Confinement of iPP chains in the interior of SBA-15 mesostructure ascertained by gas transport properties in iPP-SBA-15 nanocomposites prepared by extrusion. J. Membrane Sci. 2019, 569, 137–148. [Google Scholar] [CrossRef]

- Hu, H.; Dorset, D.L. Crystal Structure of Poly(ε-capro1actone). Macromolecules 1990, 23, 4604–4607. [Google Scholar] [CrossRef]

- Alexander, L.E. X-ray Diffraction Methods in Polymer Science; Wiley-Interscience: Malabar, FL, USA, 1969. [Google Scholar]

- Zhao, D.Y.; Huo, Q.S.; Feng, J.L.; Chmelka, B.F.; Stucky, G.D. Nonionic Triblock and Star Diblock Copolymer and Oligomeric Surfactant Syntheses of Highly Ordered, Hydrothermally Stable, Mesoporous Silica Structures. J. Am. Chem. Soc. 1998, 120, 6024–6036. [Google Scholar] [CrossRef]

- Xu, X.; Song, C.; Andrésen, J.M.; Miller, B.G.; Scaroni, A.W. Preparation and characterization of novel CO2 “molecular basket” adsorbents based on polymer-modified mesoporous molecular sieve MCM-41. Microporous Mesoporous Mater. 2003, 62, 29–45. [Google Scholar] [CrossRef]

- Son, W.J.; Choi, J.S.; Ahn, W.S. Adsorptive removal of carbon dioxide using polyethyleneimine-loaded mesoporous silica materials. Microporous Mesoporous Mater. 2008, 113, 31–40. [Google Scholar] [CrossRef]

- Wang, X.; Ma, X.; Song, C.; Locke, D.R.; Siefert, S.; Winans, R.E.; Möllmer, J.; Lange, M.; Möller, A.; Gläser, R. Molecular basket sorbents polyethylenimine–SBA-15 for CO2 capture from flue gas: Characterization and sorption properties. Microporous Mesoporous Mater. 2013, 169, 103–111. [Google Scholar] [CrossRef]

- Barranco-García, R.; Gómez-Elvira, J.M.; Ressia, J.A.; Quinzani, L.; Vallés, E.M.; Pérez, E.; Cerrada, M.L. Effect of iPP molecular weight on its confinement within mesoporous SBA-15 silica in extruded iPP-SBA-15 nanocomposites. Microporous Mesoporous Mater. 2020, 294, 109945. [Google Scholar] [CrossRef]

- Hammond, W.; Prouzet, E.; Mahanti, S.D.; Pinnavaia, T.J. Structure factor for the periodic walls of mesoporous MCM-41 molecular sieves. Microporous Mesoporous Mater. 1999, 27, 19–25. [Google Scholar] [CrossRef]

- Sauer, J.; Marlow, F.; Schüth, F. Simulation of powder diffraction patterns of modified ordered mesoporous materials. Phys. Chem. Chem. Phys. 2001, 3, 5579–5584. [Google Scholar] [CrossRef]

- Cecílio, D.M.; Cerrada, M.L.; Pérez, E.; Fernandes, A.; Lourenço, J.P.; McKenna, T.F.L.; Ribeiro, M.R. Unique stiffness-deformability features of dendrimeric silica reinforced HDPE nanocomposites obtained by an innovative route. Microporous Mesoporous Mater. 2022, 331, 111619. [Google Scholar] [CrossRef]

| Sample | Average SBA-15 wt.% | Inert Atmosphere | Oxidative Atmosphere | ||||

|---|---|---|---|---|---|---|---|

| T10% (°C) | Tmax (°C) | SBA-15 wt.% | T10% (°C) | Tmax (°C) | SBA-15 wt.% | ||

| PCL | 0 | 359.0 | 360.0 | 0 | 344.5 | 356.0 | 0 |

| PCL-SBA3 | 3.3 | 357.5 | 359.5 | 3.8 | 350.5 | 354.5 | 2.8 |

| PCL-SBA6 | 6.0 | 358.0 | 359.5 | 6.0 | 353.0 | 357.5 | 6.0 |

| PCL-SBA9 | 9.0 | 358.5 | 361.0 | 9.3 | 347.0 | 355.5 | 8.6 |

| Sample | SBA-15 wt.% | Tg (°C) | Tm1 (°C) | fcm1NORM | Tc (°C) | fcCNORM | Tm2 (°C) | fcm2NORM |

|---|---|---|---|---|---|---|---|---|

| PCL | 0 | −64.5 | 59.0 | 0.51 | 27.5 | 0.42 | 55.5 | 0.42 |

| PCL-SBA3 | 3.3 | −64.5 | 58.5 | 0.50 | 30.5 | 0.41 | 55.0 | 0.41 |

| PCL-SBA6 | 6.0 | −64.0 | 59.0 | 0.50 | 29.5 | 0.41 | 55.5 | 0.41 |

| PCL-SBA9 | 9.0 | −64.0 | 59.0 | 0.51 | 29.0 | 0.40 | 55.5 | 0.40 |

| Sample | SBA-15 wt.% | fcPCLWAXS | LPCLSAXS (nm) | lc (nm) |

|---|---|---|---|---|

| PCL | 0 | 0.54 | 17.1 | 9.2 |

| PCL-SBA3 | 3.3 | 0.53 | 17.6 | 9.3 |

| PCL-SBA6 | 6.0 | 0.52 | 17.8 | 9.3 |

| PCL-SBA9 | 9.0 | 0.52 | 18.1 | 9.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díez-Rodríguez, T.M.; Blázquez-Blázquez, E.; Antunes, N.L.C.; Ribeiro, M.R.; Pérez, E.; Cerrada, M.L. Nanocomposites of PCL and SBA-15 Particles Prepared by Extrusion: Structural Characteristics, Confinement of PCL Chains within SBA-15 Nanometric Channels and Mechanical Behavior. Polymers 2022, 14, 129. https://doi.org/10.3390/polym14010129

Díez-Rodríguez TM, Blázquez-Blázquez E, Antunes NLC, Ribeiro MR, Pérez E, Cerrada ML. Nanocomposites of PCL and SBA-15 Particles Prepared by Extrusion: Structural Characteristics, Confinement of PCL Chains within SBA-15 Nanometric Channels and Mechanical Behavior. Polymers. 2022; 14(1):129. https://doi.org/10.3390/polym14010129

Chicago/Turabian StyleDíez-Rodríguez, Tamara M., Enrique Blázquez-Blázquez, Nadine L. C. Antunes, M. Rosário Ribeiro, Ernesto Pérez, and María L. Cerrada. 2022. "Nanocomposites of PCL and SBA-15 Particles Prepared by Extrusion: Structural Characteristics, Confinement of PCL Chains within SBA-15 Nanometric Channels and Mechanical Behavior" Polymers 14, no. 1: 129. https://doi.org/10.3390/polym14010129

APA StyleDíez-Rodríguez, T. M., Blázquez-Blázquez, E., Antunes, N. L. C., Ribeiro, M. R., Pérez, E., & Cerrada, M. L. (2022). Nanocomposites of PCL and SBA-15 Particles Prepared by Extrusion: Structural Characteristics, Confinement of PCL Chains within SBA-15 Nanometric Channels and Mechanical Behavior. Polymers, 14(1), 129. https://doi.org/10.3390/polym14010129