PLA Biocomposites: Evaluation of Resistance to Mold

Abstract

:1. Introduction

2. Materials and Methods

- (1)

- Particles passing through a 2 mm sieve (approx. 10 mesh) and remaining on a 0.49 mm sieve (approx. 35 mesh);

- (2)

- Particles passing 0.49 mm sieve (greater than 35 mesh).

- (1)

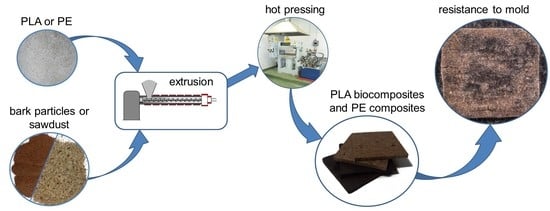

- First, WPC granules with an appropriate formulation were produced (Table 1 and Table 2) using an extruder (Leistritz Extrusionstechnik GmbH, Nürnberg, Germany) (temperatures in individual sections of the extruder were 170–180 °C), the obtained continuous composite band was then ground in a hammer mill.

- (2)

- Secondly, the obtained granulate was used to produce plates with nominal dimensions 300 × 300 × 2.5 mm3. The process consisted of flat pressing in a mold, using a one-shelf press (AB AK Eriksson, Mariannelund, Sweden) at a temperature of 200 °C and a maximum unit pressing pressure pmax = 1.25 MPa (the pressure during pressing, along with the plasticization of the material, was gradually increased from 0 to pmax). The pressing time was 6 min. After hot pressing, the plates were cooled in the mold for 6 min in the cold press.

2.1. Resistance to Moulds

2.2. Porosity

3. Results

4. Discussion

5. Conclusions

- PLA composites are characterized by a higher growth rate by Aspergillus niger Tiegh mold fungi compared to HDPE composites.

- The type of filler (bark, sawdust) had a greater impact on fouling by mold fungi in the case of HDPE composites.

- Composites filled with bark were characterized by a higher growth rate of mold fungi compared to composites filled with sawdust.

- In the case of sawdust filler, composites filled with small particles revealed a higher fouling rate.

- In the case of bark filler, PLA composites displayed a higher fouling rate when filled with large particles, while HDPE composites revealed higher fouling rate when filled with small particles.

- The introduction of additional substances (CaO in PLA composites and MAHPE in HDPE composites) generally increased the rate of mold growth on the composites.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Partanen, A.; Carus, M. Biocomposites, find the real alternative to plastic—An examination of biocomposites in the market. Reinf. Plast. 2019, 63, 317–321. [Google Scholar] [CrossRef]

- Markarian, J. Biopolymers present new market opportunities for additives in packaging. Plast. Addit. Compd. 2008, 10, 22–25. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug. Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Auras, R.; Harte, B.; Selke, S. An Overview of Polylactides as Packaging Materials. Macromol. Biosci. 2004, 4, 835–864. [Google Scholar] [CrossRef]

- Pilla, S.; Gong, S.; O’Neill, E.; Yang, L.; Rowell, R.M. Polylactide-recycled wood fiber composites. J. Appl. Polym. Sci. 2009, 111, 37–47. [Google Scholar] [CrossRef]

- Peltola, H.; Pääkkönen, E.; Jetsu, P.; Heinemann, S. Wood based PLA and PP composites: Effect of fibre type and matrix polymer on fibre morphology, dispersion and composite properties. Compos. A Appl. Sci. Manuf. 2014, 61, 13–22. [Google Scholar] [CrossRef]

- Georgiopoulos, P.; Kontou, E.; Christopoulos, A. Short-term creep behavior of a biodegradable polymer reinforced with wood-fibers. Compos. B Eng. 2015, 80, 134–144. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Szostak, M.; Barczewski, M.; Łuczak, P. Cork-wood hybrid filler system for polypropylene and poly(lactic acid) based injection molded composites. Structure evaluation and mechanical performance. Compos. B Eng. 2019, 163, 655–668. [Google Scholar] [CrossRef]

- Dalu, M.; Temiz, A.; Altuntaş, E.; Demirel, G.K.; Aslan, M. Characterization of tanalith E treated wood flour filled polylactic acid composites. Polym. Test. 2019, 76, 376–384. [Google Scholar] [CrossRef]

- Kamau-Devers, K.; Kortum, Z.; Miller, S.A. Hydrothermal aging of bio-based poly (lactic acid) (PLA) wood polymer composites: Studies on sorption behavior, morphology, and heat conductance. Constr. Build. Mater. 2019, 214, 290–302. [Google Scholar] [CrossRef]

- Ying-Chen, Z.; Hong-Yan, W.; Yi-Ping, Q. Morphology and properties of hybrid composites based on polypropylene/polylactic acid blend and bamboo fiber. Bioresour. Technol. 2010, 101, 7944–7950. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Scherzer, D. Mechanical properties of PLA composites with man-made cellulose and abaca fibres. Compos. A Appl. Sci. Manuf. 2009, 40, 404–412. [Google Scholar] [CrossRef]

- Petchwattana, N.; Covavisaruch, S. Mechanical and Morphological Properties of Wood Plastic Biocomposites Prepared from Toughened Poly(lactic acid) and Rubber Wood Sawdust (Hevea brasiliensis). J. Bionic Eng. 2014, 11, 630–637. [Google Scholar] [CrossRef]

- Borysiuk, P.; Boruszewski, P.; Auriga, R.; Danecki, L.; Auriga, A.; Rybak, K.; Nowacka, M. Influence of a bark-filler on the properties of PLA biocomposites. J. Mater. Sci. 2021, 56, 9196–9208. [Google Scholar] [CrossRef]

- Khavkine, M.; Kazayawoko, M.; Law, S.; Balatinecz, J.J. Durability of Wood Flour-Thermoplastic Composites under Extreme Environmental Conditions and Fungal Exposure. Int. J. Polym. Mater. 2000, 46, 255–269. [Google Scholar] [CrossRef]

- Laks, P.E.; Richter, D.L.; Larkin, G.M. Biological deterioration of wood-base composite panels. Wood Des. Focus 2000, 11, 7–11. [Google Scholar]

- Mankowski, M.; Morrell, J.J. Patterns of fungal attack in wood-plastic composites following exposure in a soil block test. Wood Fiber Sci. 2000, 32, 340–345. [Google Scholar]

- Verhey, S.; Laks, P.; Richter, D. Laboratory decay resistance of woodfiber/thermoplastic composites. Prod. J. 2001, 51, 44–49. [Google Scholar]

- Verhey, S.A.; Laks, P.E.; Richter, D.L.; Keranen, E.D.; Larkin, G.M. Use of field stakes to evaluate the decay resistance of woodfiber-thermoplastic composites. Prod. J. 2003, 53, 67–74. [Google Scholar]

- Clemons, C.M.; Ibach, R.E. Application of laboratory fungal resistance tests to solid wood and wood-plastic composite. Plast. Build. Constr. 2002, 27, 7–14. [Google Scholar]

- Pendleton, D.E.; Hoffard, T.A.; Adcock, T.; Woodward, B.; Wolcott, M.P. Durability of an extruded HDPE/wood composite. Prod. J. 2002, 52, 21–27. [Google Scholar]

- Lopez, J.L.; Cooper, P.A.; Sain, M. Evaluation of Proposed Standard Test Method to Determine Decay Resistance of Natural Fiber Plastic Composites. Prod. J. 2005, 55, 95–99. [Google Scholar]

- Schirp, A.; Wolcott, M.P. Influence of fungal decay and moisture absorption on mechanical properties of extruded wood-plastic composites. Wood Fiber Sci. 2005, 37, 643–652. [Google Scholar]

- Verhey, S.A.; Laks, P.E. Wood particle size affects the decay resistance of woodfiber/thermoplastic composites. Prod. J. 2002, 52, 78–81. [Google Scholar]

- Stark, N. Influence of moisture absorption on mechanical properties of wood flour-polypropylene composites. J. Compos. Mater. 2001, 14, 421–432. [Google Scholar] [CrossRef]

- Clemons, C.M.; Ibach, R.E. Effects of processing method and moisture history on laboratory fungal resistance of wood-HDPE composites. Prod. J. 2004, 54, 50–57. [Google Scholar]

- Wang, W.; Morrell, J.J. Water sorption characteristics of two wood-plastic composites. For. Prod. J. 2004, 54, 209–212. [Google Scholar]

- Klysov, A.A. Wood-Plastic Composites; Wiley-Interscience: Hoboken, NJ, USA, 2007. [Google Scholar]

- Jaakkola, M.S.; Quansah, R.; Hugg, T.T.; Heikkinen, S.A.; Jaakkola, J.J. Association of indoor dampness and molds with rhinitis risk: A systematic review and meta-analysis. J. Allergy Clin. Immunol. 2013, 132, 1099–1110.e18. [Google Scholar] [CrossRef] [PubMed]

- Hernberg, S.; Sripaiboonkij, P.; Quansah, R.; Jaakkola, J.J.; Jaakkola, M.S. Indoor molds and lung function in healthy adults. Respir. Med. 2014, 108, 677–684. [Google Scholar] [CrossRef] [Green Version]

- Schirp, A.; Ibach, R.E.; Pendleton, D.E.; Wolcott, M.P. Biological degradation of Wood-Plastic Composites (WPC) and strategies for improving the resistance of WPC against biological decay. In Development of Commercial Wood Preservatives; ACS Symposium Series; American Chemical Society: Washington, DC, USA, 2008; Volume 982, pp. 480–507. [Google Scholar]

- Kartal, S.N.; Aysal, S.; Terzi, E.; Yilgör, N.; Yoshimura, T.; Tsunoda, K. Wood and Bamboo-PP Composites: Fungal and Termite Resistance, Water Absorption, and FT-IR Analyses. BioResources 2013, 8, 1222–1244. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Shi, Q.; Chen, Y.; Huang, X. Mold Resistance and Water Absorption of Wood/HDPE and Bamboo/HDPE Composites. J. Appl. Sci. 2014, 14, 776–783. [Google Scholar] [CrossRef] [Green Version]

- Feng, J.; Zhang, H.; He, H.; Huang, X.; Shi, Q. Effects of fungicides on mold resistance and mechanical properties of wood and bamboo flour/high-density polyethylene composites. BioResources 2016, 11, 4069–4085. [Google Scholar] [CrossRef]

- Schindelin, J.; Arganda-Carreras, I.; Frise, E.; Kaynig, V.; Longair, M.; Pietzsch, T.; Preibisch, S.; Rueden, C.; Saalfeld, S.; Schmid, B.; et al. Fiji: An open-source platform for biological-image analysis. Nat. Methods 2012, 9, 676–682. [Google Scholar] [CrossRef] [Green Version]

- Tinevez, J.Y.; Perry, N.; Schindelin, J.; Hoopes, G.M.; Reynolds, G.D.; Laplantine, E.; Bednarek, S.Y.; Shorte, S.L.; Eliceiri, K.W. TrackMate: An open and extensible platform for single-particle tracking. Methods 2017, 115, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Zimmermann, W. Degradation of Plastics by Fungi. In Encyclopedia of Mycology; Elsevier: Amsterdam, The Netherlands, 2021; pp. 650–661. [Google Scholar]

- Maeda, H.; Yamagata, Y.; Abe, K.; Hasegawa, F.; Machida, M.; Ishioka, R.; Gomi, K.; Nakajima, T. Purification and characterization of a biodegradable plastic-degrading enzyme from Aspergillus oryzae. Appl. Microbiol. Biotechnol. 2005, 67, 778–788. [Google Scholar] [CrossRef] [PubMed]

- Yeh, S.-K.; Hu, C.-R.; Rizkiana, M.B.; Kuo, C.-H. Effect of fiber size, cyclic moisture absorption and fungal decay on the durability of natural fiber composites. Constr. Build. Mater. 2021, 286, 122819. [Google Scholar] [CrossRef]

- European Commission (EC). Commission Delegated Regulation (EU) No 1062/2014 of 4 August 2014 on the Work Programme for the Systematic Examination of All Existing Active Substances Contained in Biocidal Products Referred to in Regulation (EU) No 528/2012 of the European Parliament and of the Council Text. Off. J. Eur. Union 2014, 294, 20–30. [Google Scholar]

- Borysiuk, P.; Wikowski, J.; Krajewski, K.; Auriga, R.; Skomorucha, A.; Auriga, A. Selected properties of flat-pressed wood-polymer composites for high humidity conditions. BioResources 2020, 15, 5141–5155. [Google Scholar] [CrossRef]

- Xu, K.; Feng, J.; Zhong, T.; Zheng, Z.; Chen, T. Effects of volatile chemical components of wood species on mould growth susceptibility and termite attack resistance of wood plastic composites. Int. Biodeterior. Biodegrad. 2015, 100, 106–115. [Google Scholar] [CrossRef]

- Feng, J.; Dong, P.; Li, R.; Li, C.; Xie, X.; Shi, Q. Effects of wood fiber properties on mold resistance of wood polypropylene composites. Int. Biodeterior. Biodegrad. 2019, 140, 152–159. [Google Scholar] [CrossRef]

- Valentín, L.; Kluczek-Turpeinen, B.; Willför, S.; Hemming, J.; Hatakka, A.; Steffen, K.; Tuomela, M. Scots pine (Pinus sylvestris) bark composition and degradation by fungi: Potential substrate for bioremediation. Bioresour. Technol. 2010, 101, 2203–2209. [Google Scholar] [CrossRef] [PubMed]

- So, D.T.; Dick, J.W.; Holleman, K.A.; Labosky, P. Mold Spore Populations in Bark Residues Used as Broiler Litter. Poult. Sci. 1978, 57, 870–874. [Google Scholar] [CrossRef]

- Hosseinaei, O.; Wang, S.; Taylor, A.M.; Kim, J.-W. Effect of hemicellulose extraction on water absorption and mold susceptibility of wood–plastic composites. Int. Biodeterior. Biodegrad. 2012, 71, 29–35. [Google Scholar] [CrossRef]

| Variant | Matrix | Share of the Matix (%) | Additvies (CaO) (%) | Share of the Filler [%] | |

|---|---|---|---|---|---|

| Small Particles ˃35 Mesh | Large Particles 10–35 Mesh | ||||

| 1P | PLA | 60 | 40 s | ||

| 2P | PLA | 60 | 40 b | ||

| 3P | PLA | 60 | 40 b | ||

| 4P | PLA | 60 | 40 s | ||

| 5P | PLA | 50 | 50 s | ||

| 6P | PLA | 50 | 50 b | ||

| 7P | PLA | 50 | 50 b | ||

| 8P | PLA | 50 | 50 s | ||

| 9P | PLA | 40 | 60 s | ||

| 10P | PLA | 40 | 60 b | ||

| 11P | PLA | 40 | 60 b | ||

| 12P | PLA | 40 | 60 s | ||

| 13P | PLA | 57 | 3 | 40 s | |

| 14P | PLA | 57 | 3 | 40 b | |

| 15P | PLA | 47 | 3 | 50 s | |

| 16P | PLA | 47 | 3 | 50 b | |

| 17P | PLA | 37 | 3 | 60 s | |

| 18P | PLA | 37 | 3 | 60 b | |

| Variant | Matrix | Share of the Matix (%) | Additvies (MAHPE) (%) | Share of the Filler [%] | |

|---|---|---|---|---|---|

| Small Particles ˃35 Mesh | Large Particles 10–35 Mesh | ||||

| 1H | HDPE | 60 | 40 s | ||

| 2H | HDPE | 60 | 40 b | ||

| 3H | HDPE | 60 | 40 b | ||

| 4H | HDPE | 60 | 40 s | ||

| 5H | HDPE | 50 | 50 s | ||

| 6H | HDPE | 50 | 50 b | ||

| 7H | HDPE | 50 | 50 b | ||

| 8H | HDPE | 50 | 50 s | ||

| 9H | HDPE | 40 | 60 s | ||

| 10H | HDPE | 40 | 60 b | ||

| 11H | HDPE | 40 | 60 b | ||

| 12H | HDPE | 40 | 60 s | ||

| 13H | HDPE | 57 | 3 | 40 s | |

| 14H | HDPE | 57 | 3 | 40 b | |

| 15H | HDPE | 47 | 3 | 50 s | |

| 16H | HDPE | 47 | 3 | 50 b | |

| 17H | HDPE | 37 | 3 | 60 s | |

| 18H | HDPE | 37 | 3 | 60 b | |

| Day | Factors | Interaction between Factors | Error | |||||

|---|---|---|---|---|---|---|---|---|

| FC | PS | F | FCxPS | FCxF | PSxF | FCxPSxF | ||

| 2 | 8.83 S | 20.11 S | 0.09 N | 19.18 S | 27.46 S | 0.39 S | 22.87 S | 1.04 |

| 3 | 10.44 S | 18.54 S | 0.08 N | 18.48 S | 27.55 S | 4.61 S | 16.27 S | 4.33 |

| 4 | 8.37 S | 4.51 S | 5.72 S | 16.56 S | 19.16 S | 34.84 S | 6.63 S | 4.19 |

| 5 | 5.71 S | 8.41 S | 6.35 S | 14.61 S | 12.28 S | 22.35 S | 5.61 S | 24.66 |

| 7 | 15.12 S | 9.96 S | 3.55 N | 5.52 N | 16.68 S | 0.39 N | 0.82 N | 47.96 |

| 9 | 14.67 S | 9.51 S | 9.29 S | 6.34 N | 18.78 S | 1.06 N | 2.09 N | 38.25 |

| 12 | 14.13 S | 2.35 N | 21.18 S | 4.71 N | 14.13 S | 2.35 N | 4.71 N | 36.43 |

| 15 | 24.65 S | 0.00 S | 12.33 S | 0.00 S | 24.65 S | 0.00 S | 0.00 S | 38.37 |

| Day | Factors | Interaction between Factors | Error | |||||

|---|---|---|---|---|---|---|---|---|

| FC | PS | F | FCxPS | FCxF | PSxF | FSxPSxF | ||

| 2 | 2.78 S | 24.00 S | 10.07 S | 13.19 S | 11.73 S | 0.05 N | 31.92 S | 6.26 |

| 3 | 24.91 S | 35.85 S | 0.02 N | 9.37 S | 9.53 S | 1.08 S | 13.33 S | 5.91 |

| 4 | 16.37 S | 51.02 S | 1.01 S | 10.34 S | 14.89 S | 0.10 N | 1.13 S | 5.13 |

| 5 | 9.38 S | 43.31 S | 8.90 S | 4.39 S | 24.15 S | 0.62 N | 0.71 N | 8.54 |

| 7 | 11.65 S | 29.56 S | 15.37 S | 4.56 S | 23.52 S | 1.78 S | 4.67 S | 8.88 |

| 9 | 13.41 S | 18.52 S | 24.54 S | 2.72 S | 17.78 S | 6.14 S | 5.06 S | 11.74 |

| 12 | 21.75 S | 16.20 S | 26.19 S | 1.93 S | 12.38 S | 9.57 S | 3.59 S | 8.40 |

| 15 | 23.22 S | 15.48 S | 25.99 S | 1.46 S | 12.95 S | 8.66 N | 3.00 S | 9.24 |

| Day | Bark Large Particles | Bark Small Particles | ||||||

|---|---|---|---|---|---|---|---|---|

| K | FC | KxFC | Error | K | FC | KxFC | Error | |

| 2 | 31.80 S | 9.47 S | 56.19 S | 2.54 | 0.03 N | 33.62 S | 62.90 S | 3.45 |

| 3 | 26.35 S | 58.06 S | 11.96 S | 3.64 | 41.85 S | 3.39 S | 50.32 S | 4.45 |

| 4 | 29.96 S | 49.03 S | 18.69 S | 2.31 | 50.31 S | 0.53 N | 40.44 S | 8.71 |

| 5 | 11.96 S | 44.63 S | 22.90 S | 20.52 | 20.91 S | 2.34 N | 45.62 S | 31.13 |

| 7 | 0.26 N | 46.93 S | 10.98 N | 41.83 | 0.00 N | 14.96 N | 14.86 N | 70.19 |

| 9 | 9.28 N | 32.64 S | 4.73 N | 53.34 | 14.04 S | 28.08 S | 28.08 S | 29.80 |

| 12 | 4.54 N | 26.77 S | 8.99 N | 59.70 | ||||

| 15 | 4.54 N | 26.77 S | 8.99 N | 59.70 | ||||

| Day | Sawdust large Particles | Bark Small Particles | ||||||

|---|---|---|---|---|---|---|---|---|

| K | FC | KxFC | Error | K | FC | KxFC | Error | |

| 2 | 72.87 S | 11.21 S | 11.21 S | 4.70 | 19.79 S | 44.51 S | 26.57 S | 9.14 |

| 3 | 15.73 S | 60.40 S | 16.16 S | 7.71 | 28.03 S | 31.70 S | 37.52 S | 2.75 |

| 4 | 44.68 S | 29.95 S | 22.92 S | 2.45 | 32.75 S | 26.81 S | 29.88 S | 10.56 |

| 5 | 39.23 S | 47.53 S | 10.07 S | 3.18 | 51.77 S | 6.35 N | 10.60 N | 31.28 |

| 7 | 18.20 S | 58.94 S | 20.14 S | 2.71 | 15.44 N | 4.65 N | 4.64 N | 75.27 |

| 9 | 15.77 S | 61.44 S | 19.86 S | 2.93 | 1.92 N | 3.78 N | 3.80 N | 90.51 |

| 12 | 12.85 S | 65.79 S | 17.79 S | 3.57 | 18.45 S | 4.11 N | 12.23 N | 65.21 |

| 15 | 11.78 S | 68.75 S | 16.03 S | 3.44 | 18.45 S | 4.11 N | 12.23 N | 65.21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Borysiuk, P.; Krajewski, K.; Auriga, A.; Auriga, R.; Betlej, I.; Rybak, K.; Nowacka, M.; Boruszewski, P. PLA Biocomposites: Evaluation of Resistance to Mold. Polymers 2022, 14, 157. https://doi.org/10.3390/polym14010157

Borysiuk P, Krajewski K, Auriga A, Auriga R, Betlej I, Rybak K, Nowacka M, Boruszewski P. PLA Biocomposites: Evaluation of Resistance to Mold. Polymers. 2022; 14(1):157. https://doi.org/10.3390/polym14010157

Chicago/Turabian StyleBorysiuk, Piotr, Krzysztof Krajewski, Alicja Auriga, Radosław Auriga, Izabela Betlej, Katarzyna Rybak, Małgorzata Nowacka, and Piotr Boruszewski. 2022. "PLA Biocomposites: Evaluation of Resistance to Mold" Polymers 14, no. 1: 157. https://doi.org/10.3390/polym14010157

APA StyleBorysiuk, P., Krajewski, K., Auriga, A., Auriga, R., Betlej, I., Rybak, K., Nowacka, M., & Boruszewski, P. (2022). PLA Biocomposites: Evaluation of Resistance to Mold. Polymers, 14(1), 157. https://doi.org/10.3390/polym14010157