The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens

Abstract

:1. Introduction

- −

- The type of the filament (material, color, diameter, producer) and the storage conditions before the printing process (environmental humidity, UV-irradiation).

- −

- The model design and the infill parameters (infill pattern, infill density).

- −

- The process parameters (layer thickness, printing speed, printing temperature, build plate temperature, number of identical specimens printed at once, build orientation, raster angle).

- −

- The type of 3D printing equipment (producer, open or closed workspace).

- −

- Post-process treatments, storage conditions after the printing process, and aging.

- −

- The test methods and the test parameters applied.

2. Materials and Methods

- −

- Prismatic specimens (length a1 = 30 mm, width a2 = 30 mm, and height h = 10 mm) for the evaluation of the dimensional accuracy and friction performance.

- −

- ISO 527-2:2012 type 1A [38] tensile specimens for mechanical testing.

3. Results and Discussions

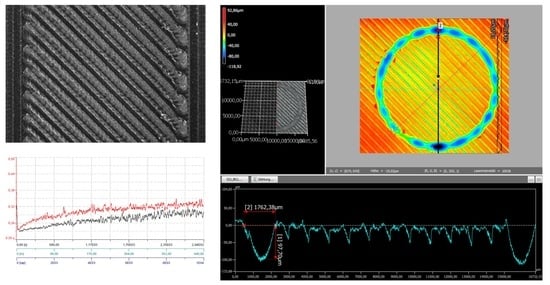

3.1. Dimensional Accuracy

3.2. Tensile Behavior

3.3. Wear

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Valerga, A.P.; Batista, M.; Puyana, R.; Sambruno, A.; Wendt, C.; Marcos, M. Preliminary study of PLA wire colour effects on geometric characteristics of parts manufactured by FDM. Procedia Manuf. 2017, 13, 924–931. [Google Scholar] [CrossRef]

- International Organization for Standardization. ISO/ASTM 52900:2021; Additive Manufacturing—General Principles—Terminology; International Organization for Standardization: Geneva, Switzerland, 2021. [Google Scholar]

- Kim, J.-W.; Kim, H.; Ko, J. Effect of changing printing parameters on mechanical properties of printed PLA and nylon 645. J. Adv. Mech. Des. Syst. Manuf. 2020, 14, JAMDSM0056. [Google Scholar] [CrossRef]

- Alafaghani, A.; Qattawi, A.; Alrawi, B.; Guzman, A. Experimental optimization of fused deposition modelling processing parameters: A design-for-manufacturing approach. Procedia Manuf. 2017, 10, 791–803. [Google Scholar] [CrossRef]

- Raquel, G.; Figueiredo-Pina, C.G.; Serro, A.P. Additive manufacturing of ceramics for dental applications: A review. Dent. Mater. 2019, 35, 825–846. [Google Scholar] [CrossRef]

- Xie, K.; Wang, N.Q.; Guo, Y.; Zhao, S.; Tan, J.; Wang, L.; Li, G.Y.; Wu, J.X.; Yang, Y.Z.; Xu, W.Y.; et al. Additively manufactured biodegradable porous magnesium implants for elimination of implant-related infections: An in vitro and in vivo study. Bioact. Mater. 2022, 8, 140–152. [Google Scholar] [CrossRef] [PubMed]

- Wach, R.A.; Wolszczak, P.; Adamus-Wlodarczyk, A. Enhancement of mechanical properties of FDM-PLA parts via thermal annealing. Macromol. Mater. Eng. 2018, 303, 9. [Google Scholar] [CrossRef]

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom. J. Vis. Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef] [Green Version]

- Brighenti, R.; Cosma, M.P.; Marsavina, L.; Spagnoli, A.; Terzano, M. Laser-based additively manufactured polymers: A review on processes and mechanical models. J. Mater. Sci. 2021, 56, 961–998. [Google Scholar] [CrossRef]

- Cuan-Urquizo, E.; Barocio, E.; Tejada-Ortigoza, V.; Pipes, R.B.; Rodriguez, C.A.; Roman-Flores, A. Characterization of the mechanical properties of FFF structures and materials: A review on the experimental, computational and theoretical approaches. Materials 2019, 12, 895. [Google Scholar] [CrossRef] [Green Version]

- Kuznetsov, V.E.; Solonin, A.N.; Tavitov, A.; Urzhumtsev, O.; Vakulik, A. Increasing strength of FFF three-dimensional printed parts by influencing on temperature-related parameters of the process. Rapid Prototyp. J. 2020, 26, 107–121. [Google Scholar] [CrossRef]

- Cojocaru, V.; Frunzaverde, D.; Miclosina, C.-O.; Marginean, G. The influence of the process parameters on the mechanical properties of PLA specimens produced by fused filament fabrication—A review. Polymers 2022, 14, 886. [Google Scholar] [CrossRef] [PubMed]

- Vanaei, H.; Shirinbayan, M.; Deligant, M.; Raissi, K.; Fitoussi, J.; Khelladi, S.; Tcharkhtchi, A. Influence of process parameters on thermal and mechanical properties of polylactic acid fabricated by fused filament fabrication. Polym. Eng. Sci. 2020, 60, 1822–1831. [Google Scholar] [CrossRef]

- Nyiranzeyimana, G.; Mutua, J.M.; Mose, B.R.; Mbuya, T.O. Optimization of process parameters in fused deposition modelling of thermoplastics: A review. Materialwiss. Werkstofftech. 2021, 52, 682–694. [Google Scholar] [CrossRef]

- Behzadnasab, M.; Yousefi, A.A.; Ebrahimibagha, D.; Nasiri, F. Effects of processing conditions on mechanical properties of PLA printed parts. Rapid Prototyp. J. 2020, 26, 381–389. [Google Scholar] [CrossRef]

- Kristiawan, R.B.; Imaduddin, F.; Ariawan, D.; Arifin, Z. A review of the fused deposition modeling (FDM) 3D printing: Filament processing, materials, and printing parameters. Open Eng. 2021, 11, 639–649. [Google Scholar] [CrossRef]

- Beniak, J.; Šooš, Ľ.; Križan, P.; Matúš, M.; Ruprich, V. Resistance and strength of conductive PLA processed by FDM additive manufacturing. Polymers 2022, 14, 678. [Google Scholar] [CrossRef]

- Zheng, Y.; Huang, X.; Chen, J.; Wu, K.; Wang, J.; Zhang, X. A review of conductive carbon materials for 3D printing: Materials, technologies, properties, and applications. Materials 2021, 14, 3911. [Google Scholar] [CrossRef]

- Kim, H.; Lee, S. Characterization of electrical heating of graphene/PLA honeycomb structure composite manufactured by CFDM 3D printer. Fash. Text. 2020, 7, 1. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L.; Ma, Q. Accuracy investigation of 3D printed PLA with various process parameters and different colors. Mater. Today-Proc. 2021, 42, 3089–3096. [Google Scholar] [CrossRef]

- Valerga, A.P.; Batista, M.; Salguero, J.; Girot, F. Influence of PLA filament conditions on characteristics of FDM parts. Materials 2018, 11, 1322. [Google Scholar] [CrossRef] [Green Version]

- Benwood, C.; Anstey, A.; Andrzejewski, J.; Misra, M.; Mohanty, A.K. Improving the impact strength and heat resistance of 3D printed models: Structure, property, and processing correlationships during fused deposition modeling (FDM) of poly (Lactic acid). ACS Omega 2018, 3, 4400–4411. [Google Scholar] [CrossRef] [PubMed]

- Alafaghani, A.; Qattawi, A. Investigating the effect of fused deposition modeling processing parameters using Taguchi design of experiment method. J. Manuf. Process. 2018, 36, 164–174. [Google Scholar] [CrossRef]

- Butt, J.; Bhaskar, R.; Mohaghegh, V. Investigating the effects of extrusion temperatures and material extrusion rates on FFF-printed thermoplastics. Int. J. Adv. Manuf. Technol. 2021, 117, 2679–2699. [Google Scholar] [CrossRef]

- Vanaei, H.R.; Shirinbayan, M.; Deligant, M.; Khelladi, S.; Tcharkhtchi, A. In-process monitoring of temperature evolution during fused filament fabrication: A journey from numerical to experimental approaches. Thermo 2021, 3, 21. [Google Scholar] [CrossRef]

- Altan, M.; Eryildiz, M.; Gumus, B.; Kahraman, Y. Effects of process parameters on the quality of PLA products fabricated by fused deposition modeling (FDM): Surface roughness and tensile strength. Mater. Test. 2018, 60, 471–477. [Google Scholar] [CrossRef]

- Wittbrodt, B.; Pearce, J.M. The effects of PLA color on material properties of 3-D printed components. Addit. Manuf. 2015, 8, 110–116. [Google Scholar] [CrossRef] [Green Version]

- Spina, R. Performance analysis of colored PLA products with a fused filament fabrication process. Polymers 2019, 11, 1984. [Google Scholar] [CrossRef] [Green Version]

- Sedlak, J.; Hrusecka, D.; Jurickova, E.; Hrbackova, l.; Spisak, L.; Joska, Z. Analysis of test plastic samples printed by the additive method fused filament fabrication. MM Sci. J. 2021, 1, 4283–4290. [Google Scholar] [CrossRef]

- Renganathan, S.; Saritha, D. Effect of fill pattern and printing speed on friction characteristics of FDM printed polylactic acid polymer. Adv. Mater. Process. Technol. 2021, 7, 1–10. [Google Scholar] [CrossRef]

- Luzanin, O.; Movrin, D.; Stathopoulos, V.; Pandis, P.; Radusin, T.; Guduric, V. Impact of processing parameters on tensile strength, in-process crystallinity and mesostructure in FDM-fabricated PLA specimens. Rapid Prototyp. J. 2019, 25, 1398–1410. [Google Scholar] [CrossRef]

- Farah, S.; Anderson, D.G.; Langer, R. Physical and mechanical properties of PLA, and their functions in widespread applications—A comprehensive review. Adv. Drug Deliv. Rev. 2016, 107, 367–392. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Balani, K.; Verma, V.; Agarwal, A.; Narayan, R. Physical, thermal, and mechanical properties of polymers. In Biosurfaces A Materials Science and Engineering Perspective; Balani, K., Verma, V., Agarwal, A., Narayan, R., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2015; pp. 329–344. [Google Scholar] [CrossRef]

- Soares, J.B.; Finamor, J.; Silva, F.P.; Roldo, L.; Candido, L.H. Analysis of the influence of polylactic acid (PLA) colour on FDM 3D printing temperature and part finishing. Rapid Prototyp. J. 2018, 24, 1305–1316. [Google Scholar] [CrossRef]

- Hanon, M.M.; Zsidai, L. Comprehending the role of process parameters and filament color on the structure and tribological performance of 3D printed PLA. J. Mater. Res. Technol. 2021, 15, 647–660. [Google Scholar] [CrossRef]

- Pant, M.; Singari, R.M.; Arora, P.K.; Moona, G.; Kumar, H. Wear assessment of 3–D printed parts of PLA (polylactic acid) using Taguchi design and artificial neural network (ANN) technique. Mater. Res. Express. 2020, 7, 115307. [Google Scholar] [CrossRef]

- Singh, M.; Bharti, P.S. Parametric influence of process parameters on the wear rate of 3D printed polylactic acid specimens. Indian J. Pure Appl. Phys. 2021, 59, 244–251. Available online: http://nopr.niscair.res.in/handle/123456789/56505 (accessed on 25 February 2022).

- ISO 527-2:2012; Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Molding and Extrusion Plastics. International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO/ASTM 52921:2013; Standard Terminology for Additive Manufacturing—Coordinate Systems and Test Methodologies. International Organization for Standardization: Geneva, Switzerland, 2013.

- ISO 2602:1980; Statistical Interpretation of the Test Results—Estimation of the Mean—Confidence Interval. International Organization for Standardization: Geneva, Switzerland, 1980.

- ISO 527-1:2019; Plastics—Determination of Tensile Properties—Part 1: General Principles. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 7148-2:2012; Plain Bearings—Testing of the Tribological Behaviour of Bearing Materials—Part 2: Testing of Polymer-Based Bearing Materials. International Organization for Standardization: Geneva, Switzerland, 2012.

- Pszczółkowski, B.; Nowak, K.W.; Rejmer, W.; Bramowicz, M.; Dzadz, Ł.; Gałęcki, R. A comparative analysis of selected methods for determining young’s modulus in polylactic acid samples manufactured with the FDM method. Materials 2022, 15, 149. [Google Scholar] [CrossRef]

- Ansari, A.A.; Kamil, M. Effect of print speed and extrusion temperature on properties of 3D printed PLA using fused deposition modeling process. Mater. Today-Proc. 2021, 45, 5462–5468. [Google Scholar] [CrossRef]

| Parameters | Values | |

|---|---|---|

| Fixed process parameters | Layer thickness, t | 0.2 mm |

| Printing speed, sp | 50 mm/s | |

| Build plate temperature, TB | 60 °C | |

| Nozzle diameter, dn | 0.40 mm | |

| Filament diameter, df | 1.75 mm | |

| Build orientation (acc. to [39]) | YX | |

| Raster angle, θ | 45°/−45° | |

| Infill density | 100 % | |

| Number of wall lines, WL (-) | 2 | |

| Variable parameters | Printing head temperature, TH | 200 °C; 210 °C; 220 °C; 230 °C; 240 °C |

| Material/Filament color | PLA Natural; PLA Black | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Frunzaverde, D.; Cojocaru, V.; Ciubotariu, C.-R.; Miclosina, C.-O.; Ardeljan, D.D.; Ignat, E.F.; Marginean, G. The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens. Polymers 2022, 14, 1978. https://doi.org/10.3390/polym14101978

Frunzaverde D, Cojocaru V, Ciubotariu C-R, Miclosina C-O, Ardeljan DD, Ignat EF, Marginean G. The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens. Polymers. 2022; 14(10):1978. https://doi.org/10.3390/polym14101978

Chicago/Turabian StyleFrunzaverde, Doina, Vasile Cojocaru, Costel-Relu Ciubotariu, Calin-Octavian Miclosina, Deian Dorel Ardeljan, Emil Florin Ignat, and Gabriela Marginean. 2022. "The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens" Polymers 14, no. 10: 1978. https://doi.org/10.3390/polym14101978

APA StyleFrunzaverde, D., Cojocaru, V., Ciubotariu, C. -R., Miclosina, C. -O., Ardeljan, D. D., Ignat, E. F., & Marginean, G. (2022). The Influence of the Printing Temperature and the Filament Color on the Dimensional Accuracy, Tensile Strength, and Friction Performance of FFF-Printed PLA Specimens. Polymers, 14(10), 1978. https://doi.org/10.3390/polym14101978