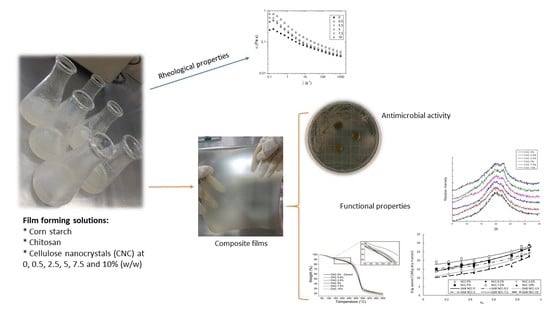

Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Film Forming Solutions Preparation

2.3. Rheology

2.4. Antimicrobial Activity

2.5. Morphology by SEM

2.6. Thermal Properties

2.7. X-ray Diffraction

2.8. Water Vapor Adsorption Isotherms

2.9. Mechanical Properties

2.10. Water Vapor Permeability

2.11. Statistical Analysis

3. Results and Discussion

3.1. Rheology Behavior of Film Forming Solutions

3.2. Antimicrobial Activity of the Nanocomposite Films

3.3. Surface Morphology

3.4. Thermal Properties

3.5. X-ray Diffraction

3.6. Water Vapor Adsorption Isotherms

3.7. Mechanical and Gas Barrier Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- ONU. PLÁSTICOS DE UN SOLO USO: Una Hoja de Ruta Para la Sostenibilidad; Programa de las Naciones Unidas para el Medio Ambiente: Nairobi, Kenia, 2018. [Google Scholar]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-based films and coatings for food packaging: A review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Luo, Q.; Hossen, M.A.; Zeng, Y.; Dai, J.; Li, S.; Qin, W.; Liu, Y. Gelatin-based composite films and their application in food packaging: A review. J. Food Eng. 2022, 313, 110762. [Google Scholar] [CrossRef]

- Chaudhary, B.U.; Lingayat, S.; Banerjee, A.N.; Kale, R.D. Development of multifunctional food packaging films based on waste Garlic peel extract and Chitosan. Int. J. Biol. Macromol. 2021, 192, 479–490. [Google Scholar] [CrossRef]

- Wang, J.; Euring, M.; Ostendorf, K.; Zhang, K. Biobased materials for food packaging. J. Bioresour. Bioprod. 2022, 7, 1–13. [Google Scholar] [CrossRef]

- Oyeoka, H.C.; Ewulonu, C.M.; Nwuzor, I.C.; Obele, C.M.; Nwabanne, J.T. Packaging and degradability properties of polyvinyl alcohol/gelatin nanocomposite films filled water hyacinth cellulose nanocrystals. J. Bioresour. Bioprod. 2021, 6, 168–185. [Google Scholar] [CrossRef]

- Combrzyński, M.; Oniszczuk, T.; Kupryaniuk, K.; Wójtowicz, A.; Mitrus, M.; Milanowski, M.; Soja, J.; Budziak-Wieczorek, I.; Karcz, D.; Kamiński, D.; et al. Physical Properties, Spectroscopic, Microscopic, X-ray, and Chemometric Analysis of Starch Films Enriched with Selected Functional Additives. Materials 2021, 14, 2673. [Google Scholar] [CrossRef]

- Tiozon, R.J.N.; Bonto, A.P.; Sreenivasulu, N. Enhancing the functional properties of rice starch through biopolymer blending for industrial applications: A review. Int. J. Biol. Macromol. 2021, 192, 100–117. [Google Scholar] [CrossRef] [PubMed]

- Gómez-Aldapa, C.A.; Velazquez, G.; Gutierrez, M.C.; Castro-Rosas, J.; Jiménez-Regalado, E.J.; Aguirre-Loredo, R.Y. Characterization of Functional Properties of Biodegradable Films Based on Starches from Different Botanical Sources. Starch-Stärke 2020, 72, 1900282. [Google Scholar] [CrossRef]

- Mohan, K.; Ganesan, A.R.; Ezhilarasi, P.N.; Kondamareddy, K.K.; Rajan, D.K.; Sathishkumar, P.; Rajarajeswaran, J.; Conterno, L. Green and eco-friendly approaches for the extraction of chitin and chitosan: A review. Carbohydr. Polym. 2022, 287, 119349. [Google Scholar] [CrossRef]

- Pakizeh, M.; Moradi, A.; Ghassemi, T. Chemical extraction and modification of chitin and chitosan from shrimp shells. Eur. Polym. J. 2021, 159, 110709. [Google Scholar] [CrossRef]

- Molina-Ramírez, C.; Mazo, P.; Zuluaga, R.; Gañán, P.; Álvarez-Caballero, J. Characterization of Chitosan Extracted from Fish Scales of the Colombian Endemic Species Prochilodus magdalenae as a Novel Source for Antibacterial Starch-Based Films. Polymers 2021, 13, 2079. [Google Scholar] [CrossRef] [PubMed]

- Jiménez-Regalado, E.J.; Caicedo, C.; Fonseca-García, A.; Rivera-Vallejo, C.C.; Aguirre-Loredo, R.Y. Preparation and Physicochemical Properties of Modified Corn Starch-Chitosan Biodegradable Films. Polymers 2021, 13, 4431. [Google Scholar] [CrossRef] [PubMed]

- Hasan, M.; Gopakumar, D.A.; Olaiya, N.G.; Zarlaida, F.; Alfian, A.; Aprinasari, C.; Alfatah, T.; Rizal, S.; Khalil, H.P.S.A. Evaluation of the thermomechanical properties and biodegradation of brown rice starch-based chitosan biodegradable composite films. Int. J. Biol. Macromol. 2020. [Google Scholar] [CrossRef] [PubMed]

- Madni, A.; Kousar, R.; Naeem, N.; Wahid, F. Recent advancements in applications of chitosan-based biomaterials for skin tissue engineering. J. Bioresour. Bioprod. 2021, 6, 11–25. [Google Scholar] [CrossRef]

- Calambas, H.L.; Fonseca, A.; Adames, D.; Aguirre-Loredo, Y.; Caicedo, C. Physical-Mechanical Behavior and Water-Barrier Properties of Biopolymers-Clay Nanocomposites. Molecules 2021, 26, 6734. [Google Scholar] [CrossRef]

- Reshmy, R.; Madhavan, A.; Philip, E.; Paul, S.A.; Sindhu, R.; Binod, P.; Pugazhendhi, A.; Sirohi, R.; Pandey, A. Sugarcane bagasse derived nanocellulose reinforced with frankincense (Boswellia serrata): Physicochemical properties, biodegradability and antimicrobial effect for controlling microbial growth for food packaging application. Environ. Technol. Innov. 2021, 21, 101335. [Google Scholar] [CrossRef]

- Gao, C.; Wang, S.; Liu, B.; Yao, S.; Dai, Y.; Zhou, L.; Qin, C.; Fatehi, P. Sustainable Chitosan-Dialdehyde Cellulose Nanocrystal Film. Materials 2021, 14, 5851. [Google Scholar] [CrossRef]

- Chen, Y.; Hanshe, M.; Sun, Z.; Zhou, Y.; Mei, C.; Duan, G.; Zheng, J.; E, S.; Jiang, S. Lightweight and anisotropic cellulose nanofibril/rectorite composite sponges for efficient dye adsorption and selective separation. Int. J. Biol. Macromol. 2022, 207, 130–139. [Google Scholar] [CrossRef]

- Chen, Q.; Shi, Y.; Chen, G.; Cai, M. Enhanced mechanical and hydrophobic properties of composite cassava starch films with stearic acid modified MCC (microcrystalline cellulose)/NCC (nanocellulose) as strength agent. Int. J. Biol. Macromol. 2020, 142, 846–854. [Google Scholar] [CrossRef]

- Shaikh, H.M.; Anis, A.; Poulose, A.M.; Al-Zahrani, S.M.; Madhar, N.A.; Alhamidi, A.; Alam, M.A. Isolation and Characterization of Alpha and Nanocrystalline Cellulose from Date Palm (Phoenix dactylifera L.) Trunk Mesh. Polymers 2021, 13, 1893. [Google Scholar]

- Valdés, A.; Martínez, C.; Garrigos, M.C.; Jimenez, A. Multilayer Films Based on Poly(lactic acid)/Gelatin Supplemented with Cellulose Nanocrystals and Antioxidant Extract from Almond Shell By-Product and Its Application on Hass Avocado Preservation. Polymers 2021, 13, 3615. [Google Scholar] [CrossRef]

- Butron, A.; Llorente, O.; Fernandez, J.; Meaurio, E.; Sarasua, J.-R. Morphology and mechanical properties of poly(ethylene brassylate)/cellulose nanocrystal composites. Carbohydr. Polym. 2019, 221, 137–145. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Hu, C.; Shao, L. The antimicrobial activity of nanoparticles: Present situation and prospects for the future. Int. J. Nanomed. 2017, 12, 1227–1249. [Google Scholar] [CrossRef] [Green Version]

- Hajipour, M.J.; Fromm, K.M.; Akbar Ashkarran, A.; Jimenez de Aberasturi, D.; Larramendi, I.R.d.; Rojo, T.; Serpooshan, V.; Parak, W.J.; Mahmoudi, M. Antibacterial properties of nanoparticles. Trends Biotechnol. 2012, 30, 499–511. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dehnad, D.; Emam-Djomeh, Z.; Mirzaei, H.; Jafari, S.-M.; Dadashi, S. Optimization of physical and mechanical properties for chitosan–nanocellulose biocomposites. Carbohydr. Polym. 2014, 105, 222–228. [Google Scholar] [CrossRef] [PubMed]

- Ascencio Carvente, P.; Maldonado Textle, H.; Soriano Moro, G.; Rivera Vallejo, C.C.; González Coronel, V.; Jiménez Regalado, E.J.; St Thomas, C. Synthesis of linear and branched hydrophobically associating multiblock copolymers via a one-pot process. J. Polym. Res. 2020, 27, 200. [Google Scholar] [CrossRef]

- Gómez-Aldapa, C.A.; Díaz-Cruz, C.A.; Castro-Rosas, J.; Jiménez-Regalado, E.J.; Velazquez, G.; Gutierrez, M.C.; Aguirre-Loredo, R.Y. Development of Antimicrobial Biodegradable Films Based on Corn Starch with Aqueous Extract of Hibiscus sabdariffa L. Starch-Stärke 2021, 73, 2000096. [Google Scholar] [CrossRef]

- Fonseca-García, A.; Jiménez-Regalado, E.J.; Aguirre-Loredo, R.Y. Preparation of a novel biodegradable packaging film based on corn starch-chitosan and poloxamers. Carbohydr. Polym. 2021, 251, 117009. [Google Scholar] [CrossRef]

- Aguirre-Loredo, R.Y.; Rodriguez-Hernandez, A.I.; Velazquez, G. Modelling the effect of temperature on the water sorption isotherms of chitosan films. Food Sci. Technol. 2017, 37, 112–118. [Google Scholar] [CrossRef] [Green Version]

- ASTM. D882; Standard Test Method for Tensile Properties of Thin Plastic Sheeting. ASTM International: West Conshohocken, PA, USA, 2012. Available online: http://www.randb.co.kr/wp-content/uploads/2017/12/ASTM-D882-Tensile-Properties-of-Thin-Plastic-Sheeting-%ED%95%9C%EA%B8%80.pdf?ckattempt=1 (accessed on 25 April 2022).

- ASTM. E96; Standard Test Methods for Water Vapor Transmission of Materials. ASTM International: West Conshohocken, PA, USA, 2002. Available online: https://www.astm.org/standards/e96 (accessed on 25 April 2022).

- Silva-Weiss, A.; Bifani, V.; Ihl, M.; Sobral, P.J.A.; Gómez-Guillén, M.C. Structural properties of films and rheology of film-forming solutions based on chitosan and chitosan-starch blend enriched with murta leaf extract. Food Hydrocoll. 2013, 31, 458–466. [Google Scholar] [CrossRef] [Green Version]

- Costa, S.M.; Ferreira, D.P.; Teixeira, P.; Ballesteros, L.F.; Teixeira, J.A.; Fangueiro, R. Active natural-based films for food packaging applications: The combined effect of chitosan and nanocellulose. Int. J. Biol. Macromol. 2021, 177, 241–251. [Google Scholar] [CrossRef] [PubMed]

- Serio, A.; Chaves-López, C.; Sacchetti, G.; Rossi, C.; Paparella, A. Chitosan Coating Inhibits the Growth of Listeria monocytogenes and Extends the Shelf Life of Vacuum-Packed Pork Loins at 4 °C. Foods 2018, 7, 155. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Al-Tayyar, N.A.; Youssef, A.M.; Al-Hindi, R.R. Antimicrobial packaging efficiency of ZnO-SiO2 nanocomposites infused into PVA/CS film for enhancing the shelf life of food products. Food Packag. Shelf Life 2020, 25, 100523. [Google Scholar] [CrossRef]

- Ke, C.-L.; Deng, F.-S.; Chuang, C.-Y.; Lin, C.-H. Antimicrobial Actions and Applications of Chitosan. Polymers 2021, 13, 904. [Google Scholar] [CrossRef] [PubMed]

- Beyth, N.; Houri-Haddad, Y.; Domb, A.; Khan, W.; Hazan, R. Alternative Antimicrobial Approach: Nano-Antimicrobial Materials. Evid.-Based Complementary Altern. Med. 2015, 2015, 246012. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, Y.; Huerta, R.R.; Saldaña, M.D.A. Use of subcritical water technology to develop cassava starch/chitosan/gallic acid bioactive films reinforced with cellulose nanofibers from canola straw. J. Supercrit. Fluids 2019, 148, 55–65. [Google Scholar] [CrossRef]

- Bangar, S.P.; Whiteside, W.S. Nano-cellulose reinforced starch bio composite films- A review on green composites. Int. J. Biol. Macromol. 2021, 185, 849–860. [Google Scholar] [CrossRef]

- Caicedo, C.; Aguirre Loredo, R.Y.; Fonseca García, A.; Ossa, O.H.; Vázquez Arce, A.; Calambás Pulgarin, H.L.; Ávila Torres, Y. Rheological, Thermal, Superficial, and Morphological Properties of Thermoplastic Achira Starch Modified with Lactic Acid and Oleic Acid. Molecules 2019, 24, 4433. [Google Scholar] [CrossRef] [Green Version]

- Nordmark, T.S.; Ziegler, G.R. Spherulitic crystallization of gelatinized maize starch and its fractions. Carbohydr. Polym. 2002, 49, 439–448. [Google Scholar] [CrossRef]

- Díaz de León, R.; Guzmán, E.; López González, R.; Díaz Elizondo, A.; Magaña, I.; Neira, G.; Castañeda Facio, A.; Valencia, L. Surface Modification of Cellulose Nanocrystals with Lactone Monomers via Plasma-Induced Polymerization and Their Application in ABS Nanocomposites. Polymers 2021, 13, 2699. [Google Scholar] [CrossRef]

- Aguirre-Loredo, R.Y.; Rodríguez-Hernández, A.I.; Morales-Sánchez, E.; Gómez-Aldapa, C.A.; Velazquez, G. Effect of equilibrium moisture content on barrier, mechanical and thermal properties of chitosan films. Food Chem. 2016, 196, 560–566. [Google Scholar] [CrossRef] [PubMed]

- Brunauer, S. The Adsorption of Gases and Vapors; Physical adsorption; Princeton University Press: Princeton, NJ, USA, 1945; Volume 1. [Google Scholar]

- Labuza, T.P.; Altunakar, B. Water Activity Prediction and Moisture Sorption Isotherms. Water Act. Foods 2020, 161–205. [Google Scholar] [CrossRef]

- Lin, S.-Y.; Wang, S.-L.; Wei, Y.-S.; Li, M.-J. Temperature effect on water desorption from methylcellulose films studied by thermal FT-IR microspectroscopy. Surf. Sci. 2007, 601, 781–785. [Google Scholar] [CrossRef]

- Trache, D.; Hussin, M.H.; Haafiz, M.K.M.; Thakur, V.K. Recent progress in cellulose nanocrystals: Sources and production. Nanoscale 2017, 9, 1763–1786. [Google Scholar] [CrossRef] [Green Version]

- Chen, J.; Long, Z.; Wang, J.; Wu, M.; Wang, F.; Wang, B.; Lv, W. Preparation and properties of microcrystalline cellulose/hydroxypropyl starch composite films. Cellulose 2017, 24, 4449–4459. [Google Scholar] [CrossRef]

- Karel, M.; Lund, D.B. Physical Principles of Food Preservation: Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003; Volume 129. [Google Scholar]

- Shih, Y.-T.; Zhao, Y. Development, characterization and validation of starch based biocomposite films reinforced by cellulose nanofiber as edible muffin liner. Food Packag. Shelf Life 2021, 28, 100655. [Google Scholar] [CrossRef]

- Maradini, G.d.S.; Oliveira, M.P.; Carreira, L.G.; Guimarães, D.; Profeti, D.; Dias Júnior, A.F.; Boschetti, W.T.N.; Oliveira, B.F.d.; Pereira, A.C.; Monteiro, S.N. Impact and Tensile Properties of Polyester Nanocomposites Reinforced with Conifer Fiber Cellulose Nanocrystal: A Previous Study Extension. Polymers 2021, 13, 1878. [Google Scholar] [CrossRef]

- Nascimento, N.R.d.; Pinheiro, I.F.; Alves, G.F.; Mei, L.H.I.; Macedo Neto, J.C.d.; Morales, A.R. Role of cellulose nanocrystals in epoxy-based nanocomposites: Mechanical properties, morphology and thermal behavior. Polímeros Ciência E Tecnologia 2022, 31. [Google Scholar] [CrossRef]

- López, O.V.; Castillo, L.A.; García, M.A.; Villar, M.A.; Barbosa, S.E. Food packaging bags based on thermoplastic corn starch reinforced with talc nanoparticles. Food Hydrocoll. 2015, 43, 18–24. [Google Scholar] [CrossRef]

- Azeredo, H.M.C.; Mattoso, L.H.C.; Avena-Bustillos, R.J.; Filho, G.C.; Munford, M.L.; Wood, D.; McHugh, T.H. Nanocellulose Reinforced Chitosan Composite Films as Affected by Nanofiller Loading and Plasticizer Content. J. Food Sci. 2010, 75, N1–N7. [Google Scholar] [CrossRef]

- Chou, C.-T.; Shi, S.-C.; Chen, C.-K. Sandwich-Structured, Hydrophobic, Nanocellulose-Reinforced Polyvinyl Alcohol as an Alternative Straw Material. Polymers 2021, 13, 4447. [Google Scholar] [CrossRef] [PubMed]

| CNC Content (w/w) in Starch–Chitosan Films | Inhibition Halo Diameter (mm) | |

|---|---|---|

| Listeria monocytogenes | Staphylococcus aureus | |

| 0% (control) | 11.02 ± 0.59 b | 11.00 ± 0.71 b |

| 0.5% | 12.52 ± 0.01 c | 8.79 ± 0.49 a |

| 2.5% | 11.35 ± 0.49 b | 11.32 ± 0.49 b |

| 5.0% | 9.39 ± 0.12 a | (--) |

| 7.5% | (--) | (--) |

| 10.0% | (--) | (--) |

| Starch–Chitosan Film Sample | TGA | DTG | DSC | ||

|---|---|---|---|---|---|

| T10 | T30 | Td | Tg | Tm | |

| CNC 0% | 166.9 | 290.7 | 326.1 | 54.7 | 144.9 |

| CNC 0.5% | 167.6 | 303.1 | 330.3 | -- | 154.3 |

| CNC 2.5% | 170.5 | 296.4 | 326.9 | 63.4 | 122.5 |

| CNC 5.0% | 156.8 | 295.1 | 328.8 | -- | 156.9 |

| CNC 7.5% | 214.6 | 304.9 | 327.8 | -- | 120.3 |

| CNC 10.0% | 181.6 | 298.2 | 329.8 | 61.9 | 127.6 |

| CNC Content (w/w) in Starch–Chitosan Films | Xm | C | K | R2 |

|---|---|---|---|---|

| 0% | 14.67 | 151.59 | 0.53 | 0.984 |

| 0.5% | 13.46 | 6283.33 | 0.50 | 0.993 |

| 2.5% | 11.57 | 106.25 | 0.58 | 0.997 |

| 5.0% | 14.32 | 7692.23 | 0.53 | 0.987 |

| 7.5% | 17.04 | 2863.44 | 0.43 | 0.991 |

| 10.0% | 9.73 | 958.54 | 0.62 | 0.987 |

| CNC Content (w/w) in Starch–Chitosan Films | Tensile Strength (MPa) | Elongation at Break (%) | WVP × 10−10 (g·m−1s−1Pa−1) |

|---|---|---|---|

| 0% | 3.49 ± 0.32 b | 74.67 ± 5.48 b | 3.01 ± 0.37 a |

| 0.5% | 2.89 ± 0.23 a | 140.40 ± 10.62 d | 4.84 ± 0.55 b |

| 2.5% | 6.16 ± 0.39 c | 88.96 ± 8.99 c | 2.46 ± 0.21 a |

| 5.0% | 6.72 ± 0.41 d | 145.13 ± 12.74 d | 4.33 ± 0.34 b |

| 7.5% | 13.61 ± 0.55 e | 5.32 ± 0.53 a | 4.35 ± 0.26 b |

| 10.0% | 6.00 ± 0.50 c | 90.57 ± 5.08 c | 4.30 ± 0.27 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Díaz-Cruz, C.A.; Caicedo, C.; Jiménez-Regalado, E.J.; Díaz de León, R.; López-González, R.; Aguirre-Loredo, R.Y. Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals. Polymers 2022, 14, 2166. https://doi.org/10.3390/polym14112166

Díaz-Cruz CA, Caicedo C, Jiménez-Regalado EJ, Díaz de León R, López-González R, Aguirre-Loredo RY. Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals. Polymers. 2022; 14(11):2166. https://doi.org/10.3390/polym14112166

Chicago/Turabian StyleDíaz-Cruz, Claudio Alonso, Carolina Caicedo, Enrique Javier Jiménez-Regalado, Ramón Díaz de León, Ricardo López-González, and Rocio Yaneli Aguirre-Loredo. 2022. "Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals" Polymers 14, no. 11: 2166. https://doi.org/10.3390/polym14112166

APA StyleDíaz-Cruz, C. A., Caicedo, C., Jiménez-Regalado, E. J., Díaz de León, R., López-González, R., & Aguirre-Loredo, R. Y. (2022). Evaluation of the Antimicrobial, Thermal, Mechanical, and Barrier Properties of Corn Starch–Chitosan Biodegradable Films Reinforced with Cellulose Nanocrystals. Polymers, 14(11), 2166. https://doi.org/10.3390/polym14112166