The Reinforcing Effect of Waste Polyester Fiber on Recycled Polyethylene

Abstract

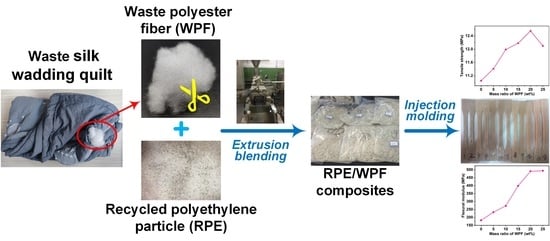

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of RPE/WPF Composites

2.3. Characterization

3. Results and Discussion

3.1. Mechanical Properties Analysis

3.2. Morphology of Fracture Surface

3.3. DSC Analysis

3.4. Thermogravimetric Analysis

3.5. DMA Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Loultcheva, M.; Proietto, M.; Jilov, N.; La Mantia, F. Recycling of high density polyethylene containers. Polym. Degrad. Stab. 1997, 57, 77–81. [Google Scholar] [CrossRef]

- Abbas, A.-G.N.; Aziz, F.N.A.A.; Abdan, K.; Nasir, N.A.M.; Huseien, G.F. A state-of-the-art review on fibre-reinforced geopolymer composites. Constr. Build. Mater. 2022, 330, 127187. [Google Scholar] [CrossRef]

- Al Zahmi, S.; Alhammadi, S.; ElHassan, A.; Ahmed, W. Carbon Fiber/PLA Recycled Composite. Polymers 2022, 14, 2194. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.; Xu, P.; Fan, L.; Li, J.; Terrasi, G.P.; Meier, U. Experimental Study of Fatigue and Fracture Behavior of Carbon Fiber-Reinforced Polymer (CFRP) Straps. Polymers 2022, 14, 2129. [Google Scholar] [CrossRef] [PubMed]

- Dun, M.; Fu, H.; Hao, J.; Shan, W.; Wang, W. Tailoring flexible interphases in bamboo fiber-reinforced linear low-density polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2021, 150, 106606. [Google Scholar] [CrossRef]

- Torres, F.G.; Cubillas, M. Study of the interfacial properties of natural fibre reinforced polyethylene. Polym. Test. 2005, 24, 694–698. [Google Scholar] [CrossRef]

- Jaffe, M.; Easts, A.J.; Feng, X. Polyester Fibers. In The Textile Institute Book Series, Thermal Analysis of Textiles and Fibers; Jaffe, M., Menczel, J.D., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 133–149. [Google Scholar] [CrossRef]

- Leng, Z.; Padhan, R.K.; Sreeram, A. Production of a sustainable paving material through chemical recycling of waste PET into crumb rubber modified asphalt. J. Clean. Prod. 2018, 180, 682–688. [Google Scholar] [CrossRef]

- Hong, R.-B.; Wu, J.-R.; Cai, H.-B. Low-temperature crack resistance of coal gangue powder and polyester fibre asphalt mixture. Constr. Build. Mater. 2019, 238, 117678. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z. Mechanical Properties of Natural as well as Synthetic Fiber Reinforced Concrete: A Review. Constr. Build. Mater. 2022, 333, 127353. [Google Scholar] [CrossRef]

- Zarei, M.; Kordani, A.A.; Ghamarimajd, Z.; Khajehzadeh, M.; Khanjari, M.; Zahedi, M. Evaluation of fracture resistance of asphalt concrete involving Calcium Lignosulfonate and Polyester fiber under freeze–thaw damage. Theor. Appl. Fract. Mech. 2021, 117, 103168. [Google Scholar] [CrossRef]

- Zhang, T.; Wu, J.; Hong, R.; Ye, S.; Jin, A. Research on low-temperature performance of steel slag/polyester fiber permeable asphalt mixture. Constr. Build. Mater. 2022, 334, 127214. [Google Scholar] [CrossRef]

- Sharma, K.; Khilari, V.; Chaudhary, B.; Jogi, A.B.; Pandit, A.; Kale, R.D. Cotton based composite fabric reinforced with waste polyester fibers for improved mechanical properties. Waste Manag. 2020, 107, 227–234. [Google Scholar] [CrossRef] [PubMed]

- Kamble, Z.; Behera, B.K. Fabrication and performance evaluation of waste cotton and polyester fiber-reinforced green composites for building and construction applications. Polym. Compos. 2021, 42, 3025–3037. [Google Scholar] [CrossRef]

- Erturk, A.T.; Vatansever, F. Abrasive wear performance of multi-layer interwoven polyester fiber & PTFE particle reinforced polyester composite. J. Compos. Mater. 2020, 54, 4415–4425. [Google Scholar] [CrossRef]

- Xu, F.; Zhou, M.; Chen, J.; Ruan, S. Mechanical performance evaluation of polyester fiber and SBR latex compound-modified cement concrete road overlay material. Constr. Build. Mater. 2014, 63, 142–149. [Google Scholar] [CrossRef]

- He, Y.; Guo, Z.; Wu, Z.; Yuan, C. Effect of polyester fiber orientation on the tribological properties of ultrahigh molecular weight polyethylene composites for water lubrication. Tribol. Int. 2021, 158, 106935. [Google Scholar] [CrossRef]

- He, M.; Chen, W.; Dong, X. Polymer Physics, 3rd ed.; Fudan University Press: Shanghai, China, 2007; pp. 254–257. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, J.; Jiang, Z.; Fang, C.; Yang, M.; Wu, L.; Huang, Z. The Reinforcing Effect of Waste Polyester Fiber on Recycled Polyethylene. Polymers 2022, 14, 3109. https://doi.org/10.3390/polym14153109

Su J, Jiang Z, Fang C, Yang M, Wu L, Huang Z. The Reinforcing Effect of Waste Polyester Fiber on Recycled Polyethylene. Polymers. 2022; 14(15):3109. https://doi.org/10.3390/polym14153109

Chicago/Turabian StyleSu, Jian, Zhiwei Jiang, Changqing Fang, Mannan Yang, Linlin Wu, and Zhigang Huang. 2022. "The Reinforcing Effect of Waste Polyester Fiber on Recycled Polyethylene" Polymers 14, no. 15: 3109. https://doi.org/10.3390/polym14153109

APA StyleSu, J., Jiang, Z., Fang, C., Yang, M., Wu, L., & Huang, Z. (2022). The Reinforcing Effect of Waste Polyester Fiber on Recycled Polyethylene. Polymers, 14(15), 3109. https://doi.org/10.3390/polym14153109