Influence of Processing Glass-Fiber Filled Plastics on Different Twin-Screw Extruders and Varying Screw Designs on Fiber Length and Particle Distribution

Abstract

:1. Introduction

2. Materials and Methods

2.1. Used Materials

2.2. Processing

2.3. Characterization

2.3.1. Dynamic Image Analysis

2.3.2. Material Characterization for Simulation

2.3.3. Simulation of the Compounding Process

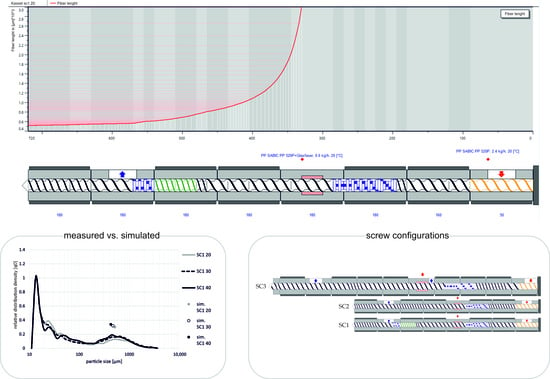

2.4. Extrusion Simulation of Fiber Length

3. Results and Discussion

3.1. Influence of Screw Configuration on the Fiber Length

3.2. Simulated Fiber Length

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delli, E.; Giliopoulos, D.; Bikiaris, D.; Chrissafis, K. Fibre length and loading impact on the properties of glass fibre reinforced polypropylene random composites. Compos. Struct. 2021, 263, 113678. [Google Scholar] [CrossRef]

- Nuruzzaman, D.M.; Kusaseh, N.M.; Ismail, N.M.; Iqbal, A.A.; Rahman, M.; Azhari, A.; Hamedon, Z.; ShinYi, C. Influence of glass fiber content on tensile properties of polyamide-polypropylene based polymer blend composites. Mater. Today Proc. 2020, 29, 133–137. [Google Scholar] [CrossRef]

- Fang, J.; Zhang, L.; Li, C. The combined effect of impregnated rollers configuration and glass fibers surface modification on the properties of continuous glass fibers reinforced polypropylene prepreg composites. Compos. Sci. Technol. 2020, 197, 108259. [Google Scholar] [CrossRef]

- Hariprasad, K.; Ravichandran, K.; Jayaseelan, V.; Muthuramalingam, T. Acoustic and mechanical characterisation of polypropylene composites reinforced by natural fibres for automotive applications. J. Mater. Res. Technol. 2020, 9, 14029–14035. [Google Scholar] [CrossRef]

- Wie, L.; Donald, A.; Freitag, C.; Morell, J. Effects of wood fiber esterification on properties, weatherability and biodurability of wood plastic composites. Polym. Degrad. Stab. 2013, 98, 1348–1361. [Google Scholar]

- Jamririchova, Z.; Akova, E. Mechanical Testing of natural fiber composites for automotive industry. Univ. Rev. 2013, 7, 20–25. [Google Scholar]

- Langer, B.; Bierögel, C.; Grellmann, W. Eigenschaften von Polypropylenen gezielt bewerten. Kunststoffe 2008, 5, 87–93. [Google Scholar]

- Hellerich, W.; Harsch, G.; Baur, E. Werkstoff-Führer Kunststoffe: Eigenschaften-Prüfungen-Kennwerte; Hanser: München, Germany, 2010. [Google Scholar]

- Lizama-Camara, Y.A.; Pinna, C.; Lu, Z.; Blagdon, M. Effect of the injection moulding fibre orientation distribution on the fatigue life of short glass fibre reinforced plastics for automotive applications. Procedia CIRP 2019, 85, 255–260. [Google Scholar] [CrossRef]

- Bondy, M.; Pinter, P.; Altenhof, W. Experimental characterization and modelling of the elastic properties of direct compounded compression molded carbon fibre/polyamide 6 long fibre thermoplastic. Mater. Des. 2017, 122, 184–196. [Google Scholar] [CrossRef]

- Sui, G.; Wong, S.-C.; Yue, C.-Y. Effect of extrusion compounding on the mechanical properties of rubber-toughened polymers containing short glass fibers. J. Mater. Processing Technol. 2001, 113, 167–171. [Google Scholar] [CrossRef]

- Yan, X.; Cao, S. Structure and interfacial shear strength of polypropylene-glass fiber/carbon fiber hybrid composites fabricated by direct fiber feeding injection molding. Compos. Struct. 2018, 185, 362–372. [Google Scholar] [CrossRef]

- Ville, J.; Inceoglu, F.; Ghamri, N.; Pradel, J.L.; Durin, A.; Valette, R.; Vergnes, B. Influence of Extrusion Conditions on Fiber Breakage along the Screw Profile during TwinScrew Compounding of Glass Fiber-reinforced PA. Int. Polym. Processing 2013, 28, 49–57. [Google Scholar] [CrossRef]

- Gamon, G.; Evon, P.; Riga, L. Twin-screw extrusion impact on natural fibre morphology and material properties in poly(lactic acid) based biocomposites. Ind. Crops Prod. 2013, 46, 173–185. [Google Scholar] [CrossRef] [Green Version]

- Durmaz, B.; Aytac, A. Investigation of the mechanical, thermal, morphological and rheological properties of bio-based polyamide11/poly(lactic acid) blend reinforced with short carbon fiber. Mater. Today Commun. 2022, 30, 103030. [Google Scholar] [CrossRef]

- Wang, J.; Geng, C.; Luo, F.; Liu, Y.; Wang, K.; Fu, Q.; He, B. Shear induced fiber orientation, fiber breakage and matrix molecular orientation in long glass fiber reinforced polypropylene composites. Mater. Sci. Eng. A 2011, 528, 3169–3176. [Google Scholar] [CrossRef]

- Durin, A.; Micheli, P.; Ville, J.; Inceoglu, F.; Valette, R.; Vergnes, B. A matricial approach of fibre breakage in twin-screw extrusion of glass fibres reinforced thermoplastics. Compos. Part A Appl. Sci. Manuf. 2013, 48, 47–56. [Google Scholar] [CrossRef]

- Zurawik, R.; Vilke, J.; Zarges, J.-C.; Heim, H.-P. Comparison of real and Simulated Fiber Orientations in Injection Molded Short Glass Fiber Reinforced Polyamide by X-ray Microtomography. Polymers 2022, 14, 29. [Google Scholar] [CrossRef]

- Ketata, N.; Seantier, B.; Guermazi, N.; Grohens, Y. Processing and properties of flax fibers reinforced PLA/PBS biocomposites. Mater. Today Proc. 2022, 53, 228–236. [Google Scholar] [CrossRef]

- Hietala, M.; Oksman, K. Pelletized cellulose fibres used in twin-screw extrusion for biocomposite manufacturing: Fibre breakage and dispersion. Compos. Part A Appl. Sci. Manuf. 2018, 109, 538–545. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.; Långström, R.; Nyström, B.; Joseph, K. The influence of fibre microstructure on fibre breakage and mechanical properties of natural fibre reinforced polypropylene. Compos. Sci. Technol. 2009, 69, 1847–1853. [Google Scholar] [CrossRef]

- Castellani, R.; Giuseppe, E.; Beagrand, J.; Dobosz, S.; Berzin, F.; Vergnes, B.; Budtova, T. Lignocellulosic fiber breakage in a molten polymer. Part 1. Qualitative analysis using rheo-optical observations. Compos. Part A Appl. Sci. Manuf. 2016, 91, 229–237. [Google Scholar] [CrossRef]

- Kahl, C.; Feldmann, M.; Sälzer, P.; Heim, H.-P. Advanced short fiber composites with hybrid reinforcement and selective fiber-matrix-adhesion based on polypropylene—Characterization of mechanical properties and fiber orientation using high-resolution X-ray tomography. Compos. Part A 2018, 111, 54–61. [Google Scholar] [CrossRef]

- Ghanbari, A.; Jalili, N.S.; Haddadi, S.A.; Arjmand, M.; Nofar, M. Mechanical properties of extruded glass fiber reinforced thermoplastic polyolefin composites. Polym. Compos. 2020, 41, 3748–3757. [Google Scholar] [CrossRef]

- Bumm, S.H.; White, J.L.; Isayev, A.I. Glass Fiber Breakup in Corotating Twin Screw Extruder: Simulation and Experiment. Polym. Compos. 2012, 33, 2147–2158. [Google Scholar] [CrossRef]

| Process Temperatures (°C) | Leistritz ZSE 18 | Coperion ZSK 25 |

|---|---|---|

| Feeding Section | 50 | 25 |

| Zone 1 | 160 | 160 |

| Zone 2 | 180 | 180 |

| Zone 3 | 180 | 180 |

| Zone 4 | 180 | 180 |

| Zone 5 | 180 | 180 |

| Zone 6 | 180 | 180 |

| Zone 7 | 180 | 180 |

| Zone 8 | 180 | |

| Zone 9 | 180 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rüppel, A.; Wolff, S.; Oldemeier, J.P.; Schöppner, V.; Heim, H.-P. Influence of Processing Glass-Fiber Filled Plastics on Different Twin-Screw Extruders and Varying Screw Designs on Fiber Length and Particle Distribution. Polymers 2022, 14, 3113. https://doi.org/10.3390/polym14153113

Rüppel A, Wolff S, Oldemeier JP, Schöppner V, Heim H-P. Influence of Processing Glass-Fiber Filled Plastics on Different Twin-Screw Extruders and Varying Screw Designs on Fiber Length and Particle Distribution. Polymers. 2022; 14(15):3113. https://doi.org/10.3390/polym14153113

Chicago/Turabian StyleRüppel, Annette, Susanne Wolff, Jan Philipp Oldemeier, Volker Schöppner, and Hans-Peter Heim. 2022. "Influence of Processing Glass-Fiber Filled Plastics on Different Twin-Screw Extruders and Varying Screw Designs on Fiber Length and Particle Distribution" Polymers 14, no. 15: 3113. https://doi.org/10.3390/polym14153113

APA StyleRüppel, A., Wolff, S., Oldemeier, J. P., Schöppner, V., & Heim, H.-P. (2022). Influence of Processing Glass-Fiber Filled Plastics on Different Twin-Screw Extruders and Varying Screw Designs on Fiber Length and Particle Distribution. Polymers, 14(15), 3113. https://doi.org/10.3390/polym14153113