Influence of Biofillers on the Properties of Regrind Crystalline Poly(ethylene terephthalate) (CPET)

Abstract

:1. Introduction

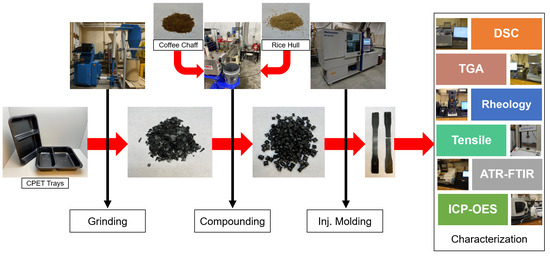

2. Materials and Methods

2.1. Preparation of Biofiller-CPET Blends

2.2. Microscope Imaging and Particle Size Analysis

2.3. Thermogravimetric Analysis

2.4. Differential Scanning Calorimetry

2.5. Electromechanical Testing

2.6. Fourier Transform Infrared Spectroscopy

2.7. Inductively Coupled Plasma—Optical Emission Spectroscopy

2.8. Parallel-Plate Oscillatory Melt Rheometry

2.9. Statistical Analysis

3. Results and Discussion

3.1. Biofiller Characterization and Sample Imaging

3.2. Impact of Biofillers on the Thermal Properties

3.3. Impact of Biofillers on the Mechanical Properties

3.4. Spectrometric Analysis of CPET/Biofiller Blends

3.5. Rheological Analysis

3.6. Metal Analysis of CPET/Biofiller Blends

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- PlasticsEurope. Plastics—the Facts 2021; An analysis of European plastics production, demand and waste data; PlasticsEurope: Brussels, Belgium, 2021. [Google Scholar]

- Patrício Silva, A.L.; Prata, J.C.; Walker, T.R.; Duarte, A.C.; Ouyang, W.; Barcelò, D.; Rocha-Santos, T. Increased plastic pollution due to COVID-19 pandemic: Challenges and recommendations. Chem. Eng. J. 2021, 405, 126683. [Google Scholar] [CrossRef] [PubMed]

- Thanakkasaranee, S.; Sadeghi, K.; Seo, J. Packaging materials and technologies for microwave applications: A review. Crit. Rev. Food Sci. Nutr. 2022, 1–20. [Google Scholar] [CrossRef] [PubMed]

- Throne, J.L. Thermoforming crystallizing poly(ethylene terephthalate) (CPET). Adv. Polym. Technol. 1988, 8, 131–176. [Google Scholar] [CrossRef]

- Throne, J.L. New Concepts in Thermoforming. Polym.-Plast. Technol. Eng. 1991, 30, 761–808. [Google Scholar] [CrossRef]

- Galdi, M.R.; Olivieri, R.; Liguori, L.; Albanese, D.; Di Matteo, M.; Di Maio, L. PET based nanocomposite films for microwave packaging applications. AIP Conf. Proc. 2015, 1695, 020059. [Google Scholar]

- Haldimann, M.; Blanc, A.; Dudler, V. Exposure to antimony from polyethylene terephthalate (PET) trays used in ready-to-eat meals. Food Addit. Contam. 2007, 24, 860–868. [Google Scholar] [CrossRef] [PubMed]

- Matos Costa, A.R.; Lima, J.C.; Santos, R.; Barreto, L.S.; Henrique, M.A.; Carvalho, L.H.; Almeida, Y.M.B. Rheological, thermal and morphological properties of polyethylene terephthalate/polyamide 6/rice husk ash composites. J. Appl. Polym. Sci. 2021, 138, 50916. [Google Scholar] [CrossRef]

- Arjmandi, R.; Hassan, A.; Majeed, K.; Zakaria, Z. Rice Husk Filled Polymer Composites. Int. J. Polym. Sci. 2015, 2015, 501471. [Google Scholar] [CrossRef]

- Garcia, C.V.; Kim, Y.-T. Spent Coffee Grounds and Coffee Silverskin as Potential Materials for Packaging: A Review. J. Polym. Environ. 2021, 29, 2372–2384. [Google Scholar] [CrossRef]

- FAO. Crops and Livestock Products. Available online: https://www.fao.org/faostat/en/#data/QCL/visualize (accessed on 17 July 2022).

- Battegazzore, D.; Salvetti, O.; Frache, A.; Peduto, N.; De Sio, A.; Marino, F. Thermo-mechanical properties enhancement of bio-polyamides (PA10.10 and PA6.10) by using rice husk ash and nanoclay. Compos. Part A Appl. Sci. Manuf. 2016, 81, 193–201. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of Wastes and Coproducts from the Coffee Industry for Composite Material Production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef] [Green Version]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, Functional, and Structural Properties of Spent Coffee Grounds and Coffee Silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef] [Green Version]

- International Coffee Organization. Coffee—Total Production by Crop Year. Available online: https://www.ico.org/historical/1990%20onwards/PDF/1a-total-production.pdf (accessed on 17 July 2022).

- Morales, M.; Atencio Martinez, C.; Maranon, A.; Hernandez, C.; Michaud, V.; Porras, A. Development and Characterization of Rice Husk and Recycled Polypropylene Composite Filaments for 3D Printing. Polymers 2021, 13, 1067. [Google Scholar] [CrossRef] [PubMed]

- Hidalgo-Salazar, M.A.; Salinas, E. Mechanical, thermal, viscoelastic performance and product application of PP-rice husk Colombian biocomposites. Compos. Part B-Eng. 2019, 176, 11. [Google Scholar] [CrossRef]

- Hejna, A.; Barczewski, M.; Kosmela, P.; Mysiukiewicz, O.; Kuzmin, A. Coffee Silverskin as a Multifunctional Waste Filler for High-Density Polyethylene Green Composites. J. Compos. Sci. 2021, 5, 44. [Google Scholar] [CrossRef]

- Wang, W.; Yang, X.; Bu, F.; Sui, S. Properties of rice husk-HDPE composites after exposure to thermo-treatment. Polym. Compos. 2014, 35, 2180–2186. [Google Scholar] [CrossRef]

- Fávaro, S.L.; Lopes, M.S.; Vieira de Carvalho Neto, A.G.; Rogério de Santana, R.; Radovanovic, E. Chemical, morphological, and mechanical analysis of rice husk/post-consumer polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 154–160. [Google Scholar] [CrossRef]

- Chen, R.S.; Ahmad, S.; Gan, S. Rice husk bio-filler reinforced polymer blends of recycled HDPE/PET: Three-dimensional stability under water immersion and mechanical performance. Polym. Compos. 2018, 39, 2695–2704. [Google Scholar] [CrossRef]

- Mort, R.; Peters, E.; Curtzwiler, G.; Jiang, S.; Vorst, K. Biofillers Improved Compression Modulus of Extruded PLA Foams. Sustainability 2022, 14, 5521. [Google Scholar] [CrossRef]

- Tsou, C.-H.; Yao, W.-H.; Wu, C.-S.; Tsou, C.-Y.; Hung, W.-S.; Chen, J.-C.; Guo, J.; Yuan, S.; Wen, E.; Wang, R.-Y.; et al. Preparation and characterization of renewable composites from Polylactide and Rice husk for 3D printing applications. J. Polym. Res. 2019, 26, 227. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, I.; Andreola, F.N.; Saccani, A. Formulation of Green Particulate Composites from PLA and PBS Matrix and Wastes Deriving from the Coffee Production. J. Polym. Environ. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Akindoyo, J.O.; Husney, N.A.A.B.; Ismail, N.H.; Mariatti, M. Structure and performance of poly(lactic acid)/poly(butylene succinate-co-L-lactate) blend reinforced with rice husk and coconut shell filler. Polym. Polym. Compos. 2021, 29, 992–1002. [Google Scholar] [CrossRef]

- Ghazvini, A.K.A.; Ormondroyd, G.; Curling, S.; Saccani, A.; Sisti, L. An investigation on the possible use of coffee silverskin in PLA/PBS composites. J. Appl. Polym. Sci. 2022, 139, 52264. [Google Scholar] [CrossRef]

- Sisti, L.; Totaro, G.; Rosato, A.; Bozzi Cionci, N.; Di Gioia, D.; Barbieri, L.; Saccani, A. Durability of biopolymeric composites formulated with fillers from a by-product of coffee roasting. Polym. Compos. 2022, 43, 1485–1493. [Google Scholar] [CrossRef]

- Yap, S.Y.; Sreekantan, S.; Hassan, M.; Sudesh, K.; Ong, M.T. Characterization and Biodegradability of Rice Husk-Filled Polymer Composites. Polymers 2020, 13, 104. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef] [Green Version]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Suriapparao, D.V.; Kumar, D.A.; Vinu, R. Microwave co-pyrolysis of PET bottle waste and rice husk: Effect of plastic waste loading on product formation. Sustain. Energy Technol. Assess. 2022, 49, 101781. [Google Scholar] [CrossRef]

- Coles, R.; Kirwan, M.J. Food and Beverage Packaging Technology; Blackwell Publishing: Hoboken, NJ, USA, 2011; p. 342. [Google Scholar] [CrossRef]

- Foundation, E.M. The Global Commitment 2021 Progress Report; Ellen McArthur Foundation: Cowes, UK, 2021. [Google Scholar]

- EPA, U.S. The New National Recycling Goal. Available online: https://www.epa.gov/sites/default/files/2020-12/documents/final_one_pager_to_print_508.pdf (accessed on 9 June 2022).

- EPA, U.S. Advancing Sustainable Materials Management: 2018 Tables and Figures. Available online: https://www.epa.gov/sites/default/files/2021-01/documents/2018_tables_and_figures_dec_2020_fnl_508.pdf (accessed on 9 June 2022).

- Mohanty, A.K.; Vivekanandhan, S.; Pin, J.-M.; Misra, M. Composites from renewable and sustainable resources: Challenges and innovations. Science 2018, 362, 536–542. [Google Scholar] [CrossRef] [Green Version]

- Vilaplana, F.; Strömberg, E.; Karlsson, S. Environmental and resource aspects of sustainable biocomposites. Polym. Degrad. Stab. 2010, 95, 2147–2161. [Google Scholar] [CrossRef]

- TPCH. Toxics in Packaging Clearinghouse—Fact Sheet; TPCH: Brattleboro, VT, USA, 2021. [Google Scholar]

- Goodlaxson, B.; Curtzwiler, G.; Vorst, K. Evaluation of methods for determining heavy metal content in polyethylene terephthalate food packaging. J. Plast. Film. Sheeting 2018, 34, 119–139. [Google Scholar] [CrossRef]

- Westerhoff, P.; Prapaipong, P.; Shock, E.; Hillaireau, A. Antimony leaching from polyethylene terephthalate (PET) plastic used for bottled drinking water. Water Res. 2008, 42, 551–556. [Google Scholar] [CrossRef] [PubMed]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.A.; Md Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef] [PubMed]

- Phan, H.T.Q.; Nguyen, B.T.; Pham, L.H.; Pham, C.T.; Do, T.V.V.; Hoang, C.N.; Nguyen, N.N.; Kim, J.; Hoang, D. Excellent Fireproof Characteristics and High Thermal Stability of Rice Husk-Filled Polyurethane with Halogen-Free Flame Retardant. Polymers 2019, 11, 1587. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gupta, A.; Mohanty, A.K.; Misra, M. Biocarbon from spent coffee ground and their sustainable biocomposites with recycled water bottle and bale wrap: A new life for waste plastics and waste food residues for industrial uses. Compos. Part A Appl. Sci. Manuf. 2022, 154, 106759. [Google Scholar] [CrossRef]

- Bahl, S.K.; Cornell, D.D.; Boerio, F.J.; McGraw, G.E. Interpretation of the vibrational spectra of poly (ethylene terephthalate). J. Polym. Sci. Polym. Lett. Ed. 1974, 12, 13–19. [Google Scholar] [CrossRef]

- Donelli, I.; Freddi, G.; Nierstrasz, V.A.; Taddei, P. Surface structure and properties of poly-(ethylene terephthalate) hydrolyzed by alkali and cutinase. Polym. Degrad. Stab. 2010, 95, 1542–1550. [Google Scholar] [CrossRef] [Green Version]

- Sajith, S. Investigation on effect of chemical composition of bio-fillers on filler/matrix interaction and properties of particle reinforced composites using FTIR. Compos. Part B Eng. 2019, 166, 21–30. [Google Scholar] [CrossRef]

- Cruz, S.A.; Zanin, M. PET recycling: Evaluation of the solid state polymerization process. J. Appl. Polym. Sci. 2006, 99, 2117–2123. [Google Scholar] [CrossRef]

- Tavares, A.A.; Silva, D.F.A.; Lima, P.S.; Andrade, D.L.A.C.S.; Silva, S.M.L.; Canedo, E.L. Chain extension of virgin and recycled polyethylene terephthalate. Polym. Test. 2016, 50, 26–32. [Google Scholar] [CrossRef]

- Union, E. European Parliament and Council Directive 94/62/EC of 20 December 1994 on Packaging and Packaging Waste. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A01994L0062-20180704 (accessed on 24 May 2022).

- Curtzwiler, G.; Vorst, K.; Danes, J.E.; Auras, R.; Singh, J. Effect of recycled poly(ethylene terephthalate) content on properties of extruded poly(ethylene terephthalate) sheets. J. Plast. Film. Sheeting 2011, 27, 65–86. [Google Scholar] [CrossRef]

- Friedman, E. INSIGHT: 2022 to Be a Pivotal Year for US R-PET Market. Available online: https://www.icis.com/explore/cn/resources/news/2022/03/04/10740575/insight-2022-to-be-a-pivotal-year-for-us-r-pet-market (accessed on 15 July 2022).

| Sample Name | CPET | Biofiller Type | Biofiller Content |

|---|---|---|---|

| CPET100 | 100 | - | - |

| CPET95_CC5 | 95 | Coffee Chaff | 5% |

| CPET90_CC10 | 90 | 10% | |

| CPET95_RH5 | 95 | Rice Hull | 5% |

| CPET90_RH10 | 90 | 10% |

| Extrusion | CPET100 | CPET95 CC5 | CPET90 CC10 | CPET95 RH5 | CPET90 RH10 |

|---|---|---|---|---|---|

| Zone 1 Temperature (°C) | 200 | 200 | 200 | 200 | 200 |

| Zone 2 Temperature (°C) | 265 | 250 | 250 | 265 | 250 |

| Zone 3 Temperature (°C) | 270 | 255 | 255 | 265 | 255 |

| Zone 4 Temperature (°C) | 270 | 255 | 255 | 270 | 255 |

| Zone 5 Temperature (°C) | 275 | 260 | 255 | 275 | 260 |

| Zone 6 Temperature (°C) | 285 | 260 | 255 | 280 | 260 |

| Zone 7 Temperature (°C) | 295 | 260 | 250 | 285 | 265 |

| Die Temperature (°C) | 300 | 255 | 245 | 285 | 265 |

| Injection Molding | |||||

| Feed Zone Temperature (°C) | 49 | ||||

| Zone 1 Temperature (°C) | 265 | ||||

| Zone 2 Temperature (°C) | 260 | ||||

| Zone 3 Temperature (°C) | 250 | ||||

| Nozzle Temperature (°C) | 285 | ||||

| Sample Name | Al (ppm) | Cr (ppm) | Fe (ppm) | Sb (ppm) |

|---|---|---|---|---|

| CPET100 | 50.92 | *b | 43.41 | 168.61 |

| CPET95_CC5 | 87.07 | *b | 53.61 | 159.13 |

| CPET90_CC10 | 15.87 | *b | 51.12 | 96.75 |

| CPET95_RH5 | *a | 2.58 | 33.55 | 162.41 |

| CPET90_RH10 | *b | 5.32 | 86.26 | 160.53 |

| LOD (ppm) | 0.0101 | 0.0009 | 0.0015 | 0.0156 |

| LOQ (ppm) | 0.0337 | 0.0030 | 0.0050 | 0.0520 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cecon, V.S.; Curtzwiler, G.W.; Vorst, K.L. Influence of Biofillers on the Properties of Regrind Crystalline Poly(ethylene terephthalate) (CPET). Polymers 2022, 14, 3210. https://doi.org/10.3390/polym14153210

Cecon VS, Curtzwiler GW, Vorst KL. Influence of Biofillers on the Properties of Regrind Crystalline Poly(ethylene terephthalate) (CPET). Polymers. 2022; 14(15):3210. https://doi.org/10.3390/polym14153210

Chicago/Turabian StyleCecon, Victor S., Greg W. Curtzwiler, and Keith L. Vorst. 2022. "Influence of Biofillers on the Properties of Regrind Crystalline Poly(ethylene terephthalate) (CPET)" Polymers 14, no. 15: 3210. https://doi.org/10.3390/polym14153210

APA StyleCecon, V. S., Curtzwiler, G. W., & Vorst, K. L. (2022). Influence of Biofillers on the Properties of Regrind Crystalline Poly(ethylene terephthalate) (CPET). Polymers, 14(15), 3210. https://doi.org/10.3390/polym14153210