Effect of Lignin Removal on the Hygroscopicity of PMMA/Wood Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Delignification Process

2.3. Preparation of PMMA/Delignified Wood (PMMA/DW) Composites

2.4. Characterization Methods

2.4.1. Determination of Lignin Content

2.4.2. Nitrogen Adsorption Test

2.4.3. Moisture Sorption Test

2.4.4. Sorption Isotherm Analysis by the Hailwood–Horrobin (H-H) Theory

2.4.5. Sorption Isotherm Analysis by the Generalized D’Arcy and Watt (GDW) Model

3. Results and Discussion

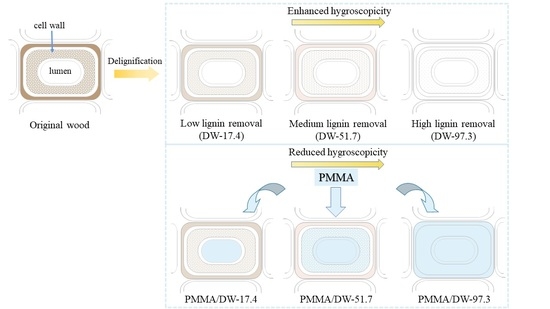

3.1. Lignin Removal Process

3.2. Pore Characteristics

3.3. Comparison of the Sorption Isotherm of the DW and PMMA/DW

3.4. Moisture Sorption Analysis Using the Hailwood–Horrobin Model

3.5. Moisture Sorption Analysis Using the GDW Model

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Chen, C.; Kuang, Y.; Zhu, S.; Burgert, I.; Keplinger, T.; Gong, A.; Li, T.; Berglund, L.; Eichhorn, S.J.; Hu, L. Structure–property–function relationships of natural and engineered wood. Nat. Rev. Mater. 2020, 5, 642–666. [Google Scholar] [CrossRef]

- Jiang, F.; Li, T.; Li, Y.; Zhang, Y.; Gong, A.; Dai, J.; Hitz, E.; Luo, W.; Hu, L. Wood-based nanotechnologies toward sustainability. Adv. Mater. 2018, 30, 1703453. [Google Scholar] [CrossRef] [PubMed]

- Zhu, H.; Luo, W.; Ciesielski, P.N.; Fang, Z.; Zhu, J.Y.; Henriksson, G.; Himmel, M.E.; Hu, L. Wood-derived materials for green electronics, biological devices, and energy applications. Chem. Rev. 2016, 116, 9305–9374. [Google Scholar] [CrossRef] [PubMed]

- Berglund, L.A.; Burgert, I. Bioinspired wood nanotechnology for functional materials. Adv. Mater. 2018, 30, 1704285. [Google Scholar] [CrossRef]

- Keplinger, T.; Cabane, E.; Chanana, M.; Hass, P.; Merk, V.; Gierlinger, N.; Burgert, I. A versatile strategy for grafting polymers to wood cell walls. Acta Biomater. 2015, 11, 256–263. [Google Scholar] [CrossRef]

- Fu, Q.; Ansari, F.; Zhou, Q.; Berglund, L.A. Wood nanotechnology for strong, mesoporous, and hydrophobic biocomposites for selective separation of oil/water mixtures. ACS Nano 2018, 12, 2222–2230. [Google Scholar] [CrossRef]

- Schwarzkopf, M. Densified wood impregnated with phenol resin for reduced set-recovery. Wood Mater. Sci. Eng. 2020, 16, 35–41. [Google Scholar] [CrossRef]

- Mi, R.; Chen, C.; Keplinger, T.; Pei, Y.; He, S.; Liu, D.; Li, J.; Dai, J.; Hitz, E.; Yang, B.; et al. Scalable aesthetic transparent wood for energy efficient buildings. Nat. Commun. 2020, 11, 3836. [Google Scholar] [CrossRef]

- Zhu, M.; Song, J.; Li, T.; Gong, A.; Wang, Y.; Dai, J.; Yao, Y.; Luo, W.; Henderson, D.; Hu, L. Highly anisotropic, highly transparent wood composites. Adv. Mater. 2016, 28, 5181–5187. [Google Scholar] [CrossRef]

- Wu, M.-B.; Huang, S.; Liu, C.; Wu, J.; Agarwal, S.; Greiner, A.; Xu, Z.-K. Carboxylated wood-based sponges with underoil super hydrophilicity for deep dehydration of crude oil. J. Mater. Chem. A 2020, 8, 11354–11361. [Google Scholar] [CrossRef]

- Liu, Y.; Zhou, J.; Chen, L.; Zhang, P.; Fu, W.; Zhao, H.; Ma, Y.; Pan, X.; Zhang, Z.; Han, W.; et al. Highly flexible freestanding porous carbon nanofibers for electrodes materials of high-performance all-carbon supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 23515–23520. [Google Scholar] [CrossRef]

- Zhu, Z.Q.; Zhu, Y.N.; Qin, H.; Li, Y.H.; Liang, Y.P.; Deng, H.; Liu, H.L. Preparation and properties of porous composite of hematite/magnetite/carbon with eucalyptus wood biotemplate. Mater. Manuf. Process. 2015, 30, 285–291. [Google Scholar] [CrossRef]

- Li, Y.; Fu, Q.; Yu, S.; Yan, M.; Berglund, L. Optically transparent wood from a nanoporous cellulosic template: Combining functional and structural performance. Biomacromolecules 2016, 17, 1358–1364. [Google Scholar] [CrossRef]

- Fu, Q.; Chen, Y.; Sorieul, M. Wood-based flexible electronics. ACS Nano 2020, 14, 3528–3538. [Google Scholar] [CrossRef]

- Yang, T.; Cao, J.; Ma, E. How does delignifification influence the furfurylation of wood? Ind. Crop. Prod. 2019, 135, 91–98. [Google Scholar] [CrossRef]

- Yang, T.; Zhou, H.; Ma, E.; Wang, J. Effects of removal of different chemical components on moisture sorption property of Populus euramericana Cv. under dynamic hygrothermal. Results Phys. 2018, 10, 61–68. [Google Scholar] [CrossRef]

- Ou, R.; Xie, Y.; Wolcott, M.P.; Sui, S.; Wang, Q. Morphology, mechanical properties, and dimensional stability of wood particle/high density polyethylene composites: Effect of removal of wood cell wall composition. Mater. Des. 2014, 58, 339–345. [Google Scholar] [CrossRef]

- Chen, P.; Li, Y.; Nishiyama, Y.; Pingali, S.V.; O’Neill, H.M.; Zhang, Q.; Berglund, L.A. Small angle neutron scattering shows nanoscale pmma distribution in transparent wood biocomposites. Nano Lett. 2021, 21, 2883–2890. [Google Scholar] [CrossRef]

- Hailwood, A.J.; Horrobin, S. Absorption of water by polymers: Analysis in terms of a simple model. Trans. Faraday Soc. 1946, 42, B084–B092. [Google Scholar] [CrossRef]

- Hill, C.A.S.; Ramsay, J.; Keating, B.; Laine, K.; Rautkari, L.; Hughes, M.; Constant, B. The water vapour sorption properties of thermally modified and densified wood. J. Mater. Sci. 2012, 47, 3191–3197. [Google Scholar] [CrossRef]

- Hill, C.A. The reduction in the fiber saturation point of wood due to chemical modification using anhydride reagents: A reappraisal. Holzforschung 2008, 62, 423–428. [Google Scholar] [CrossRef]

- Jalaludin, Z.; Hill, C.A.S.; Xie, Y.; Samsi, H.W.; Husain, H.; Awang, K.; Curling, S.F. Analysis of the water vapour sorption isotherms of thermally modified acacia and sesendok. Wood Mater. Sci. Eng. 2010, 5, 194–203. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A.; Rychlicki, G. Applicability of the generalized D’Arcy and Watt model to description of water sorption on pineapple and other foodstufs. J. Food Eng. 2007, 79, 718–723. [Google Scholar] [CrossRef]

- Furmaniak, S.; Terzyk, A.P.; Gauden, P.A. The general mechanism of water sorption on foodstufs—Importance of the multitemperature fifitting of data and the hierarchy of models. J. Food Eng. 2007, 82, 528–535. [Google Scholar] [CrossRef]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef]

- Kafle, K.; Shi, R.; Lee, C.M.; Mittal, A.; Park, Y.B.; Sun, Y.-H.; Park, S.; Chiang, V.; Kim, S.H. Vibrational sum-frequency-generation (SFG) spectroscopy study of the structural assembly of cellulose microfibrils in reaction woods. Cellulose 2014, 21, 2219–2231. [Google Scholar] [CrossRef]

- Papadopoulos, A.N.; Hill, C.A.S. The sorption of water vapour by anhydride modified softwood. Wood Sci. Technol. 2003, 37, 221–231. [Google Scholar] [CrossRef]

| Time (h) | Lignin Content (wt%) | Lignin Removal (%) |

|---|---|---|

| 0 | 22.8 (0.9) | 0 |

| 6 | 18.83 (1.27) | 17.4 |

| 9 | 15.98 (2.2) | 29.9 |

| 12 | 11.01 (1.76) | 51.7 |

| 18 | 6.11 (0.22) | 73.2 |

| 24 | 0.62 (0.03) | 97.3 |

| Simples | SBET (m2/g) | V Total (×10−3 cm−3/g) |

|---|---|---|

| Control | 15.1298 | 27.1 |

| DW-17.4 | 23.6308 | 40.1 |

| DW-29.9 | 27.0282 | 41.2 |

| DW-51.7 | 31.8868 | 47.8 |

| DW-73.2 | 36.2904 | 54.3 |

| DW-97.3 | 71.3155 | 94.8 |

| PMMA/DW-0 | 0.9975 | 3.482 |

| PMMA/DW-17.4 | 1.1676 | 3.560 |

| PMMA/DW-29.9 | 1.4671 | 2.623 |

| PMMA/DW-51.7 | 0.5046 | 1.848 |

| PMMA/DW-73.2 | 0.5848 | 2.288 |

| PMMA/DW-97.3 | 0.2946 | 1.526 |

| Simples | A | B | C | Kh | Kd | W (g/mol) | 1/W (mmol/g) | R2 |

|---|---|---|---|---|---|---|---|---|

| Control | 9.320 | 0.0263 | 0.000780 | 1.360 | 0.785 | 310.572 | 3.220 | 0.968 |

| DW-17.4 | 9.230 | 0.0216 | 0.000730 | 1.300 | 0.780 | 298.052 | 3.355 | 0.973 |

| DW-29.9 | 8.728 | 0.0242 | 0.000740 | 1.350 | 0.793 | 292.579 | 3.418 | 0.886 |

| DW-51.7 | 8.042 | 0.0218 | 0.000645 | 1.352 | 0.770 | 262.230 | 3.813 | 0.912 |

| DW-73.2 | 7.841 | 0.0136 | 0.000550 | 1.230 | 0.755 | 237.676 | 4.207 | 0.961 |

| DW-97.3 | 6.717 | 0.0266 | 0.000597 | 1.517 | 0.765 | 232.944 | 4.293 | 0.860 |

| PMMA/DW-0 | 45.362 | 0.500 | 0.00154 | 5.392 | 0.251 | 1309.59 | 0.764 | 0.894 |

| PMMA/DW-17.4 | 41.383 | 0.451 | 0.00140 | 5.323 | 0.252 | 1187.38 | 0.842 | 0.882 |

| PMMA/DW-29.9 | 53.853 | 0.559 | 0.00136 | 6.103 | 0.203 | 1400.58 | 0.714 | 0.982 |

| PMMA/DW-51.7 | 59.937 | 0.728 | 0.00247 | 5.395 | 0.276 | 1906.78 | 0.524 | 0.956 |

| PMMA/DW-73.2 | 65.539 | 0.765 | 0.00219 | 5.908 | 0.238 | 1938.11 | 0.516 | 0.968 |

| PMMA/DW-97.3 | 71.355 | 0.926 | 0.00345 | 5.294 | 0.302 | 2443.08 | 0.409 | 0.961 |

| Simples | m (%) | K | k | w | R2 |

|---|---|---|---|---|---|

| Control | 3.410 | 2.462 | 0.791 | 0.130 | 0.9966 |

| DW-17.4 | 3.573 | 2.550 | 0.812 | 0.155 | 0.9957 |

| DW-29.9 | 3.423 | 2.372 | 0.823 | 0.207 | 0.9943 |

| DW-51.7 | 3.964 | 2.834 | 0.859 | 0.221 | 0.9946 |

| DW-73.2 | 4.359 | 2.611 | 0.887 | 0.253 | 0.9967 |

| DW-97.3 | 4.621 | 2.987 | 0.904 | 0.271 | 0.9921 |

| PMMA/DW-0 | 0.641 | 5.813 | 0.349 | 0.009 | 0.9907 |

| PMMA/DW-17.4 | 0.762 | 5.834 | 0.338 | 0.012 | 0.9896 |

| PMMA/DW-29.9 | 0.696 | 5.973 | 0.197 | 0.008 | 0.9920 |

| PMMA/DW-51.7 | 0.482 | 5.814 | 0.284 | 0.006 | 0.9953 |

| PMMA/DW-73.2 | 0.491 | 5.781 | 0.212 | 0.004 | 0.9911 |

| PMMA/DW-97.3 | 0.380 | 5.427 | 0.291 | 0.003 | 0.9954 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, F.; Xu, L.; Zheng, C.; Wang, Y.; Zhang, H. Effect of Lignin Removal on the Hygroscopicity of PMMA/Wood Composites. Polymers 2022, 14, 3356. https://doi.org/10.3390/polym14163356

Xu F, Xu L, Zheng C, Wang Y, Zhang H. Effect of Lignin Removal on the Hygroscopicity of PMMA/Wood Composites. Polymers. 2022; 14(16):3356. https://doi.org/10.3390/polym14163356

Chicago/Turabian StyleXu, Fucheng, Linlin Xu, Chaowei Zheng, Yi Wang, and Haiyang Zhang. 2022. "Effect of Lignin Removal on the Hygroscopicity of PMMA/Wood Composites" Polymers 14, no. 16: 3356. https://doi.org/10.3390/polym14163356

APA StyleXu, F., Xu, L., Zheng, C., Wang, Y., & Zhang, H. (2022). Effect of Lignin Removal on the Hygroscopicity of PMMA/Wood Composites. Polymers, 14(16), 3356. https://doi.org/10.3390/polym14163356