Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

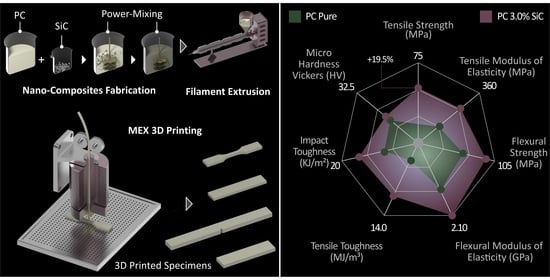

2.2. Production of the Nanocomposites in Filament Form

2.3. 3D Printing of the Samples for Mechanical Testing

2.4. Nanocomposites Thermal Properties and Structural Analysis

2.5. Evaluation of the Nanocomposites’ Filament Quality and Mechanical Performance

2.6. 3DP Specimens’ Mechanical Strength Characterization

- Dynamic mechanical analysis (DMA): Three-point-bending, 30–200 °C, step 5 °C/min, and a magnitude of 30 μm oscillation was set, utilizing a frequency of 1 Hz, and applying a preload of 0.1 N, following the ASTM D4065-12 standard, on a TA Instruments DHR 20 (New Castle, DE, USA) apparatus, prismatic specimen 122 mm × 12.7 mm;

- Tensile test: A Type V specimen was utilized (dogbone with 6.5 mm × 10 mm × 3.2 mm thickness), setting the elongation speed at 10 mm/min, according to the ASTM D638-02a standard, on an Imada model MX2 (Northbrook, IL, USA) apparatus;

- Flexural test: A three-point-bending test was carried out, with a span of 52 mm. Tests were conducted with an elongation speed of 10 mm/min, according to the ASTM D790 standard, on an Imada model MX2 (Northbrook, IL, USA) apparatus, prismatic specimen 64 mm × 12.7 mm × 3.2 mm thickness;

- Impact test: The type of test was Charpy notched. In all experiments, the release height was selected to be 367 mm, following the ASTM D6110, on a Terco MT 220 (Kungens Kurva, Sweden) device, prismatic notched specimen 122 mm × 12.7 mm × 5 mm thickness;

- Microhardness measurements: The type of the measurements accorded to the Vickers method, applying a load of 200 gF, for an indentation time of 10 s, following the ASTM E384-17 standard, on an Innova Test model 300 (Maastricht, The Netherlands) apparatus.

2.7. Examination of the Morphological Characteristics of the 3DP Specimens

3. Results and Discussion

3.1. Nanocomposites Thermal Properties and Structural Analysis

3.2. Evaluation of the Nanocomposites’ Filament Quality and Mechanical Performance

3.3. 3DP Specimens’ Mechanical Strength Characterization

3.4. Examination of the Morphological Characteristics of the 3DP Specimens

4. Conclusions

- It is feasible to produce PC/SiC nanocomposites with a thermomechanical extrusion process;

- SiC can act as a boosting agent for the mechanical response of the PC polymer;

- Such a reinforcing process, apart from improving the mechanical properties, exploits the benefits of 3DP in fields where special demands for enhanced mechanical performance of the parts are sought;

- In MEX 3D printing overall, the 3 wt.% loading nanocomposite achieved the highest response in the mechanical tests;

- The loadings that are higher than 3 wt.% lead to inferior mechanical properties, indicating the saturation of the filler in the matrix;

- The process that was followed here is cost-effective. Only the cost of the raw materials was increased, increasing the total cost of the process for the preparation of the materials by a negligible amount;

- The process can be directly adopted for industrial use.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, M.; Yang, S.; Gao, C. Scratch behavior of polycarbonate by Rockwell C diamond indenter under progressive loading. Polym. Test. 2020, 90, 106643. [Google Scholar] [CrossRef]

- Baek, Y.M.; Shin, P.S.; Kim, J.H.; Park, H.S.; DeVries, K.L.; Park, J.M. Thermal transfer, interfacial, and mechanical properties of carbon fiber/polycarbonate-CNT composites using infrared thermography. Polym. Test. 2020, 81, 106247. [Google Scholar] [CrossRef]

- Samsudin, H.; Iñiguez-Franco, F. Packaging and Consumer Goods. In Poly(Lactic Acid): Synthesis, Structures, Properties, Processing, Applications, and End of Life, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2022; pp. 605–618. [Google Scholar] [CrossRef]

- Meteab, M.H.; Hashim, A.; Rabee, B.H. Controlling the Structural and Dielectric Characteristics of PS-PC/Co2O3-SiC Hybrid Nanocomposites for Nanoelectronics Applications. Silicon 2022. [Google Scholar] [CrossRef]

- Zhang, W.; Suhr, J.; Koratkar, N. Carbon Nanotube/Polycarbonate Composites as Multifunctional Strain Sensors. J. Nanosci. Nanotechnol. 2006, 6, 960–964. [Google Scholar] [CrossRef] [PubMed]

- Scardaci, V.; Sun, Z.; Wang, F.; Rozhin, A.G.; Hasan, T.; Hennrich, F.; White, I.H.; Milne, W.I.; Ferrari, A.C. Carbon Nanotube Polycarbonate Composites for Ultrafast Lasers. Adv. Mater. 2008, 20, 4040–4043. [Google Scholar] [CrossRef]

- Feltz, K.P.; MacFadden, L.N.; Gieg, S.D.; Lough, C.P.; Bezold, W.A.; Skelley, N.W.M. Mechanical properties of 3D-printed orthopedic one-third tubular plates and cortical screws. J. 3D Print. Med. 2022, 6, 129–145. [Google Scholar] [CrossRef]

- Pan, K.; Zhang, W.; Shi, H.; Dai, M.; Wei, W.; Liu, X.; Li, X. Zinc Ion-crosslinked polycarbonate/heparin composite coatings for biodegradable Zn-alloy stent applications. Colloids Surf. B Biointerfaces 2022, 218, 112725. [Google Scholar] [CrossRef]

- Lin, Z.-I.; Tsai, H.-L.; Liu, G.-L.; Lu, X.-H.; Cheng, P.-W.; Chi, P.-L.; Wang, C.-K.; Tsai, T.-H.; Wang, C.-C.; Yang, J.H.C.; et al. Preparation of CO2-Based Cationic Polycarbonate/Polyacrylonitrile Nanofibers with an Optimal Fibrous Microstructure for Antibacterial Applications. Macromol. Biosci. 2022. [Google Scholar] [CrossRef]

- Bagotia, N.; Sharma, D.K. Systematic study of dynamic mechanical and thermal properties of multiwalled carbon nanotube reinforced polycarbonate/ethylene methyl acrylate nanocomposites. Polym. Test. 2019, 73, 425–432. [Google Scholar] [CrossRef]

- Jorik, S.; Lion, A.; Johlitz, M. Design of the novel tensile creep experimental setup, characterisation and description of the long-term creep performance of polycarbonate. Polym. Test. 2019, 75, 151–158. [Google Scholar] [CrossRef]

- Pötschke, P.; Fornes, T.D.; Paul, D.R. Rheological behavior of multiwalled carbon nanotube/polycarbonate composites. Polymer 2002, 43, 3247–3255. [Google Scholar] [CrossRef]

- Ding, W.; Eitan, A.; Fisher, F.T.; Chen, X.; Dikin, D.A.; Andrews, R.; Brinson, L.C.; Schadler, L.S.; Ruoff, R.S. Direct Observation of Polymer Sheathing in Carbon Nanotube-Polycarbonate Composites. Nano Lett. 2003, 3, 1593–1597. [Google Scholar] [CrossRef]

- Kechagias, J.D.; Vidakis, N.; Petousis, M.; Mountakis, N. A multi-parametric process evaluation of the mechanical response of PLA in FFF 3D printing. Mater. Manuf. Process. 2022, 1–13. [Google Scholar] [CrossRef]

- Petousis, M.; Vidakis, N.; Mountakis, N.; Papadakis, V.; Kanellopoulou, S.; Gaganatsiou, A.; Stefanoudakis, N.; Kechagias, J. Multifunctional Material Extrusion 3D-Printed Antibacterial Polylactic Acid (PLA) with Binary Inclusions: The Effect of Cuprous Oxide and Cellulose Nanofibers. Fibers 2022, 10, 52. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Boura, O.; Grammatikos, S.A. Multi-functional polyamide 12 (PA12)/multiwall carbon nanotube 3D printed nanocomposites with enhanced mechanical and electrical properties. Adv. Compos. Mater. 2022, 1–25. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Mountakis, N.; Maravelakis, E.; Zaoutsos, S.; Kechagias, J.D. Mechanical response assessment of antibacterial PA12/TiO2 3D printed parts: Parameters optimization through artificial neural networks modeling. Int. J. Adv. Manuf. Technol. 2022, 121, 785–803. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.A.; Tzounis, L. Mechanical reinforcement course of 3D printed polypropylene–antimony doped Tin Oxide nanocomposites versus filler loading. Adv. Compos. Mater. 2022, 31, 235–256. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Vairis, A.; Savvakis, K.; Maniadi, A. A parametric determination of bending and Charpy’s impact strength of ABS and ABS-plus fused deposition modeling specimens. Prog. Addit. Manuf. 2019, 4, 323–330. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kourinou, M.; Velidakis, E.; Mountakis, N.; Fischer-Griffiths, P.E.; Grammatikos, S.; Tzounis, L. Additive manufacturing of multifunctional polylactic acid (PLA)—Multiwalled carbon nanotubes (MWCNTs) nanocomposites. Nanocomposites 2021, 7, 184–199. [Google Scholar] [CrossRef]

- Tzounis, L.; Petousis, M.; Grammatikos, S.; Vidakis, N. 3D Printed Thermoelectric Polyurethane/Multiwalled Carbon Nanotube Nanocomposites: A Novel Approach towards the Fabrication of Flexible and Stretchable Organic Thermoelectrics. Materials 2020, 13, 2879. [Google Scholar] [CrossRef]

- Cantrell, J.T.; Rohde, S.; Damiani, D.; Gurnani, R.; DiSandro, L.; Anton, J.; Young, A.; Jerez, A.; Steinbach, D.; Kroese, C.; et al. Experimental characterization of the mechanical properties of 3D-printed ABS and polycarbonate parts. Rapid Prototyp. J. 2017, 23, 811–824. [Google Scholar] [CrossRef]

- Fang, L.; Yan, Y.; Agarwal, O.; Seppala, J.E.; Hemker, K.J.; Kang, S.H. Processing-structure-property relationships of bisphenol-A-polycarbonate samples prepared by fused filament fabrication. Addit. Manuf. 2020, 35, 101285. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Kechagias, J.D. A comprehensive investigation of the 3D printing parameters’ effects on the mechanical response of polycarbonate in fused filament fabrication. Prog. Addit. Manuf. 2022, 7, 713–722. [Google Scholar] [CrossRef]

- Koker, B.; Ruckdashel, R.; Abajorga, H.; Curcuru, N.; Pugatch, M.; Dunn, R.; Kazmer, D.O.; Wetzel, E.D.; Park, J.H. Enhanced Interlayer Strength and Thermal Stability via Dual Material Filament for Material Extrusion Additive Manufacturing. Addit. Manuf. 2022, 55, 102807. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Korlos, A.; Velidakis, E.; Mountakis, N.; Charou, C.; Myftari, A. Strain Rate Sensitivity of Polycarbonate and Thermoplastic Polyurethane for Various 3D Printing Temperatures and Layer Heights. Polymers 2021, 13, 2752. [Google Scholar] [CrossRef] [PubMed]

- Kattinger, J.; Ebinger, T.; Kurz, R.; Bonten, C. Numerical simulation of the complex flow during material extrusion in fused filament fabrication. Addit. Manuf. 2022, 49, 102476. [Google Scholar] [CrossRef]

- Puttonen, T.; Salmi, M.; Partanen, J. Mechanical properties and fracture characterization of additive manufacturing polyamide 12 after accelerated weathering. Polym. Test. 2021, 104, 107376. [Google Scholar] [CrossRef]

- Gupta, A.; Hasanov, S.; Fidan, I. Thermal characterization of short carbon fiber reinforced high temperature polymer material produced using the fused filament fabrication process. J. Manuf. Process. 2022, 80, 515–528. [Google Scholar] [CrossRef]

- Arai, T.; Kawaji, M. Thermal performance and flow characteristics in additive manufactured polycarbonate pulsating heat pipes with Novec 7000. Appl. Therm. Eng. 2021, 197, 117273. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Grammatikos, S.; Papadakis, V.; Korlos, A.; Mountakis, N. High Performance Polycarbonate Nanocomposites Mechanically Boosted with Titanium Carbide in Material Extrusion Additive Manufacturing. Nanomaterials 2022, 12, 1068. [Google Scholar] [CrossRef]

- Pandey, R.; Bux, S.; Shrivastava, A.; Choubey, A.; Singh, S. A process optimization of additive layer manufacturing processes for the production of polymer composite-based components. Mater. Today Proc. 2022, 60, 1565–1569. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Spiridaki, M.; Kechagias, J.D. Mechanical performance of fused filament fabricated and 3d-printed polycarbonate polymer and polycarbonate/ cellulose nanofiber nanocomposites. Fibers 2021, 9, 74. [Google Scholar] [CrossRef]

- Farcas, M.T.; Stefaniak, A.B.; Knepp, A.K.; Bowers, L.; Mandler, W.K.; Kashon, M.; Jackson, S.R.; Stueckle, T.A.; Sisler, J.D.; Friend, S.A.; et al. Acrylonitrile butadiene styrene (ABS) and polycarbonate (PC) filaments three-dimensional (3-D) printer emissions-induced cell toxicity. Toxicol. Lett. 2019, 317, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Hua, W.; Shi, W.; Mitchell, K.; Raymond, L.; Hua, W.; Shi, W.; Mitchell, K.; Raymond, L.; Coulter, R. 3D Printing of Biodegradable Polymer Vascular Stents: A Review. Chin. J. Mech. Eng. Addit. Manuf. Front. 2022, 1, 100020. [Google Scholar] [CrossRef]

- Brognara, L.; Fantini, M.; Morellato, K.; Graziani, G.; Baldini, N.; Cauli, O. Foot Orthosis and Sensorized House Slipper by 3D Printing. Materials 2022, 15, 4064. [Google Scholar] [CrossRef]

- Błaszczyk, M.; Gabor, J.; Flak, T.; Wróbel, Z.; Swinarew, A.S. Surgery Training System Supported by Organic Materials. Materials 2022, 15, 4162. [Google Scholar] [CrossRef]

- Liu, Z.; Zhan, J.; Fard, M.; Davy, J.L. Acoustic properties of a porous polycarbonate material produced by additive manufacturing. Mater. Lett. 2016, 181, 296–299. [Google Scholar] [CrossRef]

- Park, S.J.; Lee, J.E.; Lee, H.B.; Park, J.; Lee, N.K.; Son, Y.; Park, S.H. 3D printing of bio-based polycarbonate and its potential applications in ecofriendly indoor manufacturing. Addit. Manuf. 2020, 31, 100974. [Google Scholar] [CrossRef]

- Katoh, Y.; Snead, L.L. Silicon carbide and its composites for nuclear applications—Historical overview. J. Nucl. Mater. 2019, 526, 151849. [Google Scholar] [CrossRef]

- Saddow, S.E. Silicon Carbide Technology for Advanced Human Healthcare Applications. Micromachines 2022, 13, 346. [Google Scholar] [CrossRef]

- Willander, M.; Friesel, M.; Wahab, Q.U.; Straumal, B. Silicon carbide and diamond for high temperature device applications. J. Mater. Sci. Mater. Electron. 2006, 17, 1–25. [Google Scholar] [CrossRef]

- Yan, W.; Qin, X.; Zhang, Z.; Zhang, C.; Gao, T. Evolution of Microstructure during Rapid Solidification of SiC under High Pressure. Adv. Condens. Matter Phys. 2022, 2022, 7823211. [Google Scholar] [CrossRef]

- Koyanagi, T.; Terrani, K.; Harrison, S.; Liu, J.; Katoh, Y. Additive manufacturing of silicon carbide for nuclear applications. J. Nucl. Mater. 2021, 543, 152577. [Google Scholar] [CrossRef]

- Fatima, A.; Majid, A.; Haider, S.; Akhtar, M.S.; Alkhedher, M. First principles study of layered silicon carbide as anode in lithium ion battery. Int. J. Quantum Chem. 2022, 122, e26895. [Google Scholar] [CrossRef]

- Dai, Z.; Zhou, S.; Yang, T.; Zou, L. Nanofabrication of Silicon Carbide and Optical Processing and Inspection of Noncurved Mirrors. Adv. Mater. Sci. Eng. 2022, 2022, 3496494. [Google Scholar] [CrossRef]

- Jalluri, T.D.P.V.; Rao, B.V.; Rudraswamy, B.; Venkateswaran, R.; Sriram, K.V. Optical polishing and characterization of chemical vapour deposited silicon carbide mirrors for space applications. J. Opt. 2022, 1–15. [Google Scholar] [CrossRef]

- Majety, S.; Strohauer, S.; Saha, P.; Wietschorke, F.; Finley, J.J.; Müller, K.; Radulaski, M. Triangular Quantum Photonic Devices with Integrated Detectors in Silicon Carbide. arXiv 2022. [Google Scholar] [CrossRef]

- Castelletto, S.; Boretti, A. Silicon carbide color centers for quantum applications. J. Phys Photonics. 2020, 2, 022001. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, Z.; Si, Y.; Liu, Y.; Wang, M.; Lei, Q. A Comprehensive Short-Circuit Protection Scheme for Series-Connected SiC MOSFETs. IEEE Open J. Power Electron. 2022, 3, 115–130. [Google Scholar] [CrossRef]

- She, X.; Huang, A.Q.; Lucia, O.; Ozpineci, B. Review of Silicon Carbide Power Devices and Their Applications. IEEE Trans. Ind. Electron. 2017, 64, 8193–8205. [Google Scholar] [CrossRef]

- Wang, F.; Zhang, Z. Overview of Silicon Carbide Technology: Device, converter, system, and application. CPSS Trans. Power Electron. Appl. 2016, 1, 13–32. [Google Scholar] [CrossRef]

- Ariffin, I.A.; Kamdi, Z. Review on Wear Behavior of Nickel-Silicon Carbide Electrodeposition Coating. Res. Prog. Mech. Manuf. Eng. 2022, 3, 377–383. [Google Scholar]

- He, R.; Zhou, N.; Zhang, K.; Zhang, X.; Zhang, L.; Wang, W.; Fang, D. Progress and challenges towards additive manufacturing of SiC ceramic. J. Adv. Ceram. 2021, 10, 637–674. [Google Scholar] [CrossRef]

- Liu, G.; Ma, D.; Liu, H.; Zhang, Z.; Fan, C. Enhanced Effect of SiC Nanoparticles Combined with Nanohydroxyapatite Material to Stimulate Bone Regenerations in Femoral Fractures Treatment. J. Clust. Sci. 2022, 1–8. [Google Scholar] [CrossRef]

- Ahmed, H.; Abduljalil, H.M.; Hashim, A. Analysis of Structural, Optical and Electronic Properties of Polymeric Nanocomposites/Silicon Carbide for Humidity Sensors. Trans. Electr. Electron. Mater. 2019, 20, 206–217. [Google Scholar] [CrossRef]

- Guo, Z.; Kim, T.Y.; Lei, K.; Pereira, T.; Sugar, J.G.; Hahn, H.T. Strengthening and thermal stabilization of polyurethane nanocomposites with silicon carbide nanoparticles by a surface-initiated-polymerization approach. Compos. Sci. Technol. 2008, 68, 164–170. [Google Scholar] [CrossRef]

- Sternitzke, M.; Derby, B.; Brook, R.J. Alumina/silicon carbide nanocomposites by hybrid polymer/powder processing: Microstructures and mechanical properties. J. Am. Ceram. Soc. 1998, 81, 41–48. [Google Scholar] [CrossRef]

- Han, Y.; Shi, X.; Yang, X.; Guo, Y.; Zhang, J.; Kong, J.; Gu, J. Enhanced thermal conductivities of epoxy nanocomposites via incorporating in-situ fabricated hetero-structured SiC-BNNS fillers. Compos. Sci. Technol. 2020, 187, 107944. [Google Scholar] [CrossRef]

- Thooyavan, Y.; Kumaraswamidhas, L.A.; Raj, R.D.E.; Binoj, J.S.; Mansingh, B.B. Effect of combined micro and nano silicon carbide particles addition on mechanical, wear and moisture absorption features of basalt bidirectional mat/vinyl ester composites. Polym. Compos. 2022, 43, 2574–2583. [Google Scholar] [CrossRef]

- Pelanconi, M.; Colombo, P.; Ortona, A. Additive manufacturing of silicon carbide by selective laser sintering of PA12 powders and polymer infiltration and pyrolysis. J. Eur. Ceram. Soc. 2021, 41, 5056–5065. [Google Scholar] [CrossRef]

- Grossin, D.; Montón, A.; Navarrete-Segado, P.; Özmen, E.; Urruth, G.; Maury, F.; Maury, D.; Frances, C.; Tourbin, M.; Lenormand, P.; et al. A review of additive manufacturing of ceramics by powder bed selective laser processing (sintering/melting): Calcium phosphate, silicon carbide, zirconia, alumina, and their composites. Open Ceram. 2021, 5, 100073. [Google Scholar] [CrossRef]

- Sreenivasan, R.; Goel, A.; Bourell, D.L. Sustainability issues in laser-based additive manufacturing. Phys. Procedia 2010, 5, 81–90. [Google Scholar] [CrossRef]

- Xu, T.-T.; Cheng, S.; Jin, L.; Zhang, K.; Zeng, T. High-temperature flexural strength of SiC ceramics prepared by additive manufacturing. Int. J. Appl. Ceram. Technol. 2019, 17, 438–448. [Google Scholar] [CrossRef]

- Polozov, I.; Razumov, N.; Masaylo, D.; Silin, A.; Lebedeva, Y.; Popovich, A. Fabrication of Silicon Carbide Fiber-Reinforced Silicon Carbide Matrix Composites Using Binder. Materials 2020, 13, 1766. [Google Scholar] [CrossRef]

- Du, W.; Singh, M.; Singh, D. Binder jetting additive manufacturing of silicon carbide ceramics: Development of bimodal powder feedstocks by modeling and experimental methods. Ceram. Int. 2020, 46, 19701–19707. [Google Scholar] [CrossRef]

- Raman, V.; Bhatia, G.; Bhardwaj, S.; Srivastva, A.K.; Sood, K.N. Synthesis of silicon carbide nanofibers by sol-gel and polymer blend techniques. J. Mater. Sci. 2005, 40, 1521–1527. [Google Scholar] [CrossRef]

- Alhusaiki-Alghamdi, H.M. Effect of Silicon Carbide (SiC) Nanoparticles on the Spectroscopic Properties and Performance of PMMA/PC Polymer Blend. J. Mod. Phys. 2019, 10, 487–499. [Google Scholar] [CrossRef]

- Lule, Z.C.; Kim, J. Compatibilization effect of silanized SiC particles on polybutylene adipate terephthalate/polycarbonate blends. Mater. Chem. Phys. 2021, 258, 123879. [Google Scholar] [CrossRef]

- Böhning, M.; Goering, H.; Hao, N.; Mach, R.; Schönhals, A. Polycarbonate/SiC nanocomposites—Influence of nanoparticle dispersion on molecular mobility and gas transport. Polym. Adv. Technol. 2005, 16, 262–268. [Google Scholar] [CrossRef]

- Stuart, B.H. Temperature studies of polycarbonate using Fourier transform Raman spectroscopy. Polym. Bull. 1996, 36, 341–346. [Google Scholar] [CrossRef]

- Zimmerer, C.; Matulaitiene, I.; Niaura, G.; Reuter, U.; Janke, A.; Boldt, R.; Sablinskas, V.; Steiner, G. Nondestructive characterization of the polycarbonate-octadecylamine interface by surface enhanced Raman spectroscopy. Polym. Test. 2019, 73, 152–158. [Google Scholar] [CrossRef]

- Resta, V.; Quarta, G.; Lomascolo, M.; Maruccio, L.; Calcagnile, L. Raman and Photoluminescence spectroscopy of polycarbonate matrices irradiated with different energy 28Si+ ions. Vacuum 2015, 116, 82–89. [Google Scholar] [CrossRef]

- Makarem, M.; Lee, C.M.; Kafle, K.; Huang, S.; Chae, I.; Yang, H.; Kubicki, J.D.; Kim, S.H. Probing cellulose structures with vibrational spectroscopy. Cellulose 2019, 26, 35–79. [Google Scholar] [CrossRef]

- Giordano, D.; Russell, J.K.; González-García, D.; Bersani, D.; Dingwell, D.B.; del Negro, C. Raman spectroscopy from laboratory and proximal to remote sensing: A tool for the volcanological sciences. Remote Sens. 2020, 12, 805. [Google Scholar] [CrossRef]

- Spivak, A.V.; Litvin, Y.A.; Shushkanova, A.V.; Litvin, V.Y.; Shiryaev, A.A. Diamond formation in carbonate-silicate-sulfide-carbon melts: Raman- and IR-microspectroscopy. Eur. J. Mineral. 2008, 20, 341–347. [Google Scholar] [CrossRef]

| Wavenumber (cm−1) | Assignment | Change |

|---|---|---|

| 781 | Si–O stretching | Increase of peak for SiC 6% sample [75] |

| 966 | Antisymmetric stretching of Si–O | Increase of peak for SiC samples [75] |

| 1003 | C–H bending | Increase of peak for SiC samples [73] |

| 1175 | C–O–C stretching | Increase of peak for SiC samples [73] |

| 1344 | Si–C | Increase of peak for SiC 6% sample [76] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petousis, M.; Vidakis, N.; Mountakis, N.; Grammatikos, S.; Papadakis, V.; David, C.N.; Moutsopoulou, A.; Das, S.C. Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate. Polymers 2022, 14, 3492. https://doi.org/10.3390/polym14173492

Petousis M, Vidakis N, Mountakis N, Grammatikos S, Papadakis V, David CN, Moutsopoulou A, Das SC. Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate. Polymers. 2022; 14(17):3492. https://doi.org/10.3390/polym14173492

Chicago/Turabian StylePetousis, Markos, Nectarios Vidakis, Nikolaos Mountakis, Sotirios Grammatikos, Vassilis Papadakis, Constantine N. David, Amalia Moutsopoulou, and Subrata C. Das. 2022. "Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate" Polymers 14, no. 17: 3492. https://doi.org/10.3390/polym14173492

APA StylePetousis, M., Vidakis, N., Mountakis, N., Grammatikos, S., Papadakis, V., David, C. N., Moutsopoulou, A., & Das, S. C. (2022). Silicon Carbide Nanoparticles as a Mechanical Boosting Agent in Material Extrusion 3D-Printed Polycarbonate. Polymers, 14(17), 3492. https://doi.org/10.3390/polym14173492