Relationships between Size Distribution, Morphological Characteristics, and Viscosity of Cellulose Nanofibril Dispersions

Abstract

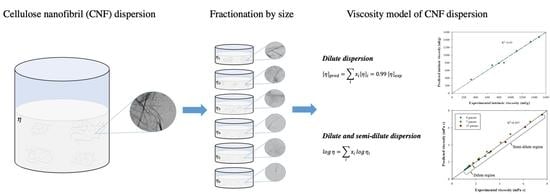

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of CNF Dispersions

2.3. Size Distribution of CNF Dispersions

2.4. Morphological Characteristics

2.5. Shear Viscosity Measurement

2.6. Critical Concentration

2.7. Data Analysis

3. Results and Discussion

3.1. Morphological Characteristics of CNFs

3.2. Size Distribution

3.3. Dilute and Semi-Dilute Regions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Iwamoto, S.; Lee, S.H.; Endo, T. Relationship between aspect ratio and suspension viscosity of wood cellulose nanofibers. Polym. J. 2014, 46, 73–76. [Google Scholar] [CrossRef]

- ISO/TS 20477:2017; Nanotechnologies—Standard Terms and Their Definition for Cellulose Nanomaterial. ISO: Geneva, Switzerland, 2017.

- Ishii, D.; Saito, T.; Isogai, A. Viscoelastic evaluation of average length of cellulose nanofibers prepared by TEMPO-mediated oxidation. Biomacromolecules 2011, 12, 548–550. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O.; Belgacem, M.N.; Pignon, F. Current progress in rheology of cellulose nanofibril suspensions. Biomacromolecules 2016, 17, 2311–2320. [Google Scholar] [CrossRef] [PubMed]

- Naderi, A.; Lindström, T. Rheological measurements on nanofibrillated cellulose systems: A science in progress. In Cellulose and Cellulose Derivatives: Synthesis, Modification and Applications; Nova Science Publishers: New York, NY, USA, 2015; pp. 187–204. [Google Scholar]

- Lavoine, N.; Desloges, I.; Dufresne, A.; Bras, J. Microfibrillated cellulose–Its barrier properties and applications in cellulosic materials: A review. Carbohydr. Polym. 2012, 90, 735–764. [Google Scholar] [CrossRef] [PubMed]

- Chinga-Carrasco, G. Cellulose fibres, nanofibrils and microfibrils: The morphological sequence of MFC components from a plant physiology and fibre technology point of view. Nanoscale Res. Lett. 2011, 6, 417. [Google Scholar] [CrossRef]

- Rizal, S.; Saharudin, N.I.; Olaiya, N.G.; Khalil, H.P.S.A.; Haafiz, M.K.M.; Ikramullah, I.; Muksin, U.; Olaiya, F.G.; Abdullah, C.K.; Yahya, E.B. Functional Properties and Molecular Degradation of Schizostachyum Brachycladum Bamboo Cellulose Nanofibre in PLA-Chitosan Bionanocomposites. Molecules 2021, 26, 2008. [Google Scholar] [CrossRef]

- Zhan, C.; Sharma, P.R.; Geng, L.; Sharma, S.K.; Wang, R.; Joshi, R.; Hsiao, B.S. Structural characterization of carboxyl cellulose nanofibers extracted from underutilized sources. Sci. China Technol. Sci. 2019, 62, 971–981. [Google Scholar] [CrossRef]

- Mansfield, M.L.; Douglas, J.F. Transport properties of wormlike chains with applications to double helical DNA and carbon nanotubes. Macromolecules 2008, 41, 5412–5421. [Google Scholar] [CrossRef]

- Tanaka, R.; Saito, T.; Hondo, H.; Isogai, A. Influence of flexibility and dimensions of nanocelluloses on the flow properties of their aqueous dispersions. Biomacromolecules 2015, 16, 2127–2131. [Google Scholar] [CrossRef]

- Albornoz-Palma, G.; Betancourt, F.; Mendonça, R.T.; Chinga-Carrasco, G.; Pereira, M. Relationship between rheological and morphological characteristics of cellulose nanofibrils in dilute dispersions. Carbohydr. Polym. 2020, 230, 115588. [Google Scholar] [CrossRef]

- Varanasi, S.; He, R.; Batchelor, W. Estimation of cellulose nanofibre aspect ratio from measurements of fibre suspension gel point. Cellulose 2013, 20, 1885–1896. [Google Scholar] [CrossRef]

- Krishnan, J.M. Rheology of Complex Fluids, 1st ed.; Springer: New York, NY, USA, 2010. [Google Scholar] [CrossRef]

- Pääkkö, M.; Ankerfors, M.; Kosonen, H.; Nykänen, A.; Ahola, S.; Österberg, M.; Lindström, T. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscale cellulose fibrils and strong gels. Biomacromolecules 2017, 8, 1934–1941. [Google Scholar] [CrossRef] [PubMed]

- Nechyporchuk, O. Cellulose Nanofibers for the Production of Bionanocomposites. Ph.D. Thesis, Université Grenoble Alpes, Grenoble, France, 2015. [Google Scholar]

- Nazari, B.; Kumar, V.; Bousfield, D.W.; Toivakka, M. Rheology of cellulose nanofibers suspensions: Boundary driven flow. J. Rheol. 2016, 60, 1151–1159. [Google Scholar] [CrossRef]

- Larson, R.G.; Wei, Y. A review of thixotropy and its rheological modeling. J. Rheol. 2019, 63, 477–501. [Google Scholar] [CrossRef]

- Dullaert, K.; Mewis, J. Stress jumps on weakly flocculated dispersions: Steady state and transient results. J. Colloid Interface Sci. 2005, 287, 542–551. [Google Scholar] [CrossRef]

- Saarinen, T.; Lille, M.; Seppälä, J. Technical aspects on rheological characterization of microfibrillar cellulose water suspensions. Annu. Trans. Nord. Rheol. Soc. 2009, 17, 121–128. [Google Scholar]

- Ilyin, S.O.; Makarova, V.V.; Polyakova, M.Y.; Kulichikhin, V.G. Phase behavior and rheology of miscible and immiscible blends of linear and hyperbranched siloxane macromolecules. Mater. Today Commun. 2020, 22, 100833. [Google Scholar] [CrossRef]

- Taheri, H.; Samyn, P. Effect of homogenization (microfluidization) process parameters in mechanical production of micro-and nanofibrillated cellulose on its rheological and morphological properties. Cellulose 2016, 23, 1221–1238. [Google Scholar] [CrossRef]

- Haridevan, H.; Chaleat, C.; Pooley, L.; Evans, D.A.; Halley, P.J.; Martin, D.J.; Annamalai, P.K. Processing and rheological properties of polyol/cellulose nanofibre dispersions for polyurethanes. Polymer 2022, 255, 125130. [Google Scholar] [CrossRef]

- Lee, D.; Oh, Y.; Yoo, J.K.; Yi, J.W.; Um, M.K.; Park, T. Rheological study of cellulose nanofiber disintegrated by a controlled high-intensity ultrasonication for a delicate nano-fibrillation. Cellulose 2020, 27, 9257–9269. [Google Scholar] [CrossRef]

- Saddique, A.; Cheong, I.W. Recent advances in three-dimensional bioprinted nanocellulose-based hydrogel scaffolds for biomedical applications. Korean J. Chem. Eng. 2021, 38, 2171–2194. [Google Scholar] [CrossRef]

- Postek, M.T.; Moon, R.J.; Rudie, A.W.; Bilodeau, M.A. Production and Applications of Cellulose; Tappi Press: Peachtree Corners, GA, USA, 2013. [Google Scholar]

- Rezaei, A.; Nasirpour, A.; Fathi, M. Application of cellulosic nanofibers in food science using electrospinning and its potential risk. Compr. Rev. Food Sci. Food Saf. 2015, 14, 269–284. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.; Wu, Q.; Lee, S.; Qing, Y.; Wu, Y. Cellulose Nanofibers as a Modifier for Rheology, Curing and Mechanical Performance of Oil Well Cement. Sci. Rep. 2016, 6, 31654. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Li, K.; Copenhaver, K.; Mackay, S.; Lamm, M.E.; Zhao, X.; Dixon, B.; Wang, J.; Han, Y.; Neivandt, D.; et al. Review on Nonconventional Fibrillation Methods of Producing Cellulose Nanofibrils and Their Applications. Biomacromolecules 2021, 22, 4037–4059. [Google Scholar] [CrossRef]

- Hinestroza, J.; Netravali, A.N. Cellulose Based Composites: New Green Nanomaterials, 1st ed.; John Wiley & Sons: Weinheim, Germany, 2014; p. 16. [Google Scholar]

- Hu, R.; Zhang, M.; Adhikari, B.; Liu, Y. Effect of homogenization and ultrasonication on the physical properties of insoluble wheat bran fibres. Int. Agrophysics 2015, 29, 423–432. [Google Scholar] [CrossRef]

- Hua, X.; Xu, S.; Wang, M.; Chen, Y.; Yang, H.; Yang, R. Effects of high-speed homogenization and high-pressure homogenization on structure of tomato residue fibers. Food Chem. 2017, 232, 443–449. [Google Scholar] [CrossRef]

- Morris, E.R.; Cutler, A.N.; Ross-Murphy, S.B.; Rees, D.A.; Price, J. Concentration and shear rate dependence of viscosity in random coil polysaccharide solutions. Carbohydr. Polym. 1981, 1, 5–21. [Google Scholar] [CrossRef]

- Jones, R.G. International Union of Pure and Applied Chemistry Polymer Division. In Compendium of Polymer Terminology and Nomenclature: IUPAC Recommendations 2008; Wilks, E.S., Ed.; RSC Pub: Piccadilly, UK, 2009; p. 443. [Google Scholar]

- Dubin, P.L. Aqueous Size-Exclusion Chromatography; Elsevier: Amsterdam, The Netherlands, 1998; Volume 40. [Google Scholar] [CrossRef]

- Larson, R.G. The rheology of dilute solutions of flexible polymers: Progress and problems. J. Rheol. 2005, 49, 1–70. [Google Scholar] [CrossRef]

- Fertah, M. Isolation and characterization of alginate from seaweed. In Seaweed Polysaccharides; Elsevier: Amsterdam, The Netherlands, 2017; pp. 11–26. [Google Scholar] [CrossRef]

- Pal, P.; Pandey, J.P.; Sen, G. Synthesis and Application as Programmable Water Soluble Adhesive of Polyacrylamide Grafted Gum Tragacanth (GT-g-PAM). In Biopolymer Grafting; Elsevier: Amsterdam, The Netherlands, 2018; pp. 153–203. [Google Scholar] [CrossRef]

- Rubinstein, M.; Colby, R.H. Polymer Physics; Oxford University Press: New York, NY, USA, 2003; Volume 23. [Google Scholar]

- Wu, C.S. Handbook of Size Exclusion Chromatography and Related Techniques: Revised and Expanded; CRC Press: Boca Raton, FL, USA, 2003; Volume 91. [Google Scholar] [CrossRef]

- Costa, J.M. Diccionario de Química Física; Ediciones Díaz de Santos: Madrid, Spain, 2005. [Google Scholar]

- Everett, D.H. Manual of symbols and terminology for physicochemical quantities and units, appendix II: Definitions, terminology and symbols in colloid and surface chemistry. Pure Appl. Chem. 1972, 31, 577–638. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Maloney, T.; Gane, P. Effect of fibril length, aspect ratio and surface charge on ultralow shear-induced structuring in micro and nanofibrillated cellulose aqueous suspensions. Cellulose 2018, 25, 117–136. [Google Scholar] [CrossRef]

- Mansfield, M.L.; Douglas, J.F. Transport properties of rodlike particles. Macromolecules 2008, 41, 5422–5432. [Google Scholar] [CrossRef]

- Grüneberger, F.; Künniger, T.; Zimmermann, T.; Arnold, M. Rheology of nanofibrillated cellulose/acrylate systems for coating applications. Cellulose 2014, 21, 1313–1326. [Google Scholar] [CrossRef]

- Mewis, J.; Wagner, N.J. Colloidal Suspension Rheology; Cambridge University Press: Cambridge, UK, 2012. [Google Scholar]

- Silveira, M.T.; Ferreira, A.G.; Lobo, L.Q. The viscosity of aqueous suspensions of cellulose fibers: Part 1. Influence of consistency and fiber length. Silva Lusit. 2002, 10, 171–178. [Google Scholar]

- Rosen, S.L. Fundamental Principles of Polymeric Materials, 3rd ed.; John Wiley & Sons: Weinheim, Germany, 2012. [Google Scholar]

- Wang, Y.; Yu, L.; Sun, Q.; Xie, F. Hydroxypropyl methylcellulose and hydroxypropyl starch: Rheological and gelation effects on the phase structure of their mixed hydrocolloid system. Food Hydrocoll. 2021, 115, 106598. [Google Scholar] [CrossRef]

- Song, Y.; Mathias, P.M.; Tremblay, D.; Chen, C.C. Liquid viscosity model for polymer solutions and mixtures. Ind. Eng. Chem. Res. 2003, 42, 2415–2422. [Google Scholar] [CrossRef]

| No. | Average Width (a) (nm) | S.D. of the Sample (a,b) (nm) (Coefficient of Variation (a) (%)) | Average Length (a) (μm) | S.D. of the Sample (a) (μm) (Coefficient of Variation (a) (%)) | Radius of Gyration (μm) | Aspect Ratio (a) | Intrinsic Viscosity (a) (mL/g) |

|---|---|---|---|---|---|---|---|

| 0P | 121.4 ± 1.0 | 68.1 (56) | 17.7 ± 0.4 | 15.9 (90) | 3.87 | 145.5 | 323.2 |

| 1P | 42.6 ± 0.4 | 22.3 (51) | 8.9 ± 0.4 | 6.3 (71) | 2.01 | 210.1 | 684.4 |

| 2P | 31.6 ± 0.2 | 13.0 (41) | 7.7 ± 0.4 | 5.3 (70) | 1.73 | 243.8 | 801.6 |

| 4P | 28.2 ± 0.2 | 10.6 (38) | 7.5 ± 0.2 | 5.3 (70) | 1.68 | 264.8 | 885.2 |

| 7P | 18.2 ± 0.2 | 6.3 (35) | 5.9 ± 0.3 | 3.7 (63) | 1.32 | 325.4 | 1481.6 |

| 10P | 18.1 ± 0.3 | 6.0 (34) | 5.0 ± 0.4 | 3.5 (69) | 1.13 | 278.7 | 1102.5 |

| 15P | 14.6 ± 0.1 | 4.0 (28) | 4.4 ± 0.8 | 3.3 (75) | 0.99 | 304.6 | 1339.8 |

| Mesh (Width) | 0 Passes | 1 Pass | 2 Passes | 4 Passes | 7 Passes | 10 Passes | 15 Passes |

|---|---|---|---|---|---|---|---|

| 45 (180.1 nm) | 36.6% | 2.3% | - | - | - | - | - |

| 60 (100.8 nm) | 37.0% | 4.3% | 0.6% | - | - | - | - |

| 100 (84.3 nm) | 7.0% | 6.1% | 2.1% | 0.7% | 0.1% | - | - |

| 200 (56.1 nm) | 6.4% | 8.7% | 5.2% | 2.1% | 0.4% | 0.4% | 0.2% |

| 400 (44.9 nm) | 3.4% | 18.0% | 14.2% | 11.3% | 12.0% | 11.3% | 1.9% |

| Under 400 | 9.6% | 60.6% | 77.9% | 85.9% | 87.5% | 88.3% | 97.9% |

| Mesh | Average Width (nm) | S.D. of the Sample (a)\nm (Coefficient of Variation (%)) | Average Length (μm) | S.D. of the Sample (μm) (Coefficient of Variation (%)) | Aspect Ratio | Critical Concentration (mg/mL) | Intrinsic Viscosity (mL/g) | Power Index (c) |

|---|---|---|---|---|---|---|---|---|

| 45 | 180.1 ± 0.5 | 64.6 (36) | 16.9 ± 0.4 | 10.2 (60) | 93.6 | 7.6 (b) | 134.0 | - |

| 60 | 100.8 ± 0.5 | 47.7 (47) | 15.9 ± 0.5 | 9.5 (60) | 158.0 | 2.3 | 356.9 | 1.38 |

| 100 | 84.3 ± 0.4 | 30.8 (37) | 15.8 ± 0.1 | 8.6 (54) | 187.9 | 2.1 | 502.2 | 1.40 |

| 200 | 56.1 ± 0.3 | 26.2 (47) | 12.1 ± 0.7 | 7.2 (59) | 214.9 | 1.6 | 596.0 | 1.48 |

| 400 | 44.9 ± 0.3 | 19.6 (44) | 10.4 ± 0.5 | 5.1 (49) | 230.8 | 1.1 | 786.6 | 1.51 |

| Under 400, 0 passes | 28.3 ± 0.2 | 12.7 (45) | 6.7 ± 0.1 | 3.4 (51) | 237.2 | 1.0 | 807.7 | 1.57 |

| Under 400, 7 passes | 16.1 ± 0.3 | 7.2 (45) | 5.2 ± 0.3 | 2.3 (44) | 323.7 | 0.57 | 1567.9 | 1.63 |

| Under 400, 15 passes | 13.1 ± 0.2 | 3.4 (26) | 4.0 ± 0.3 | 2.0 (50) | 306.2 | 0.62 | 1361.5 | 1.70 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albornoz-Palma, G.; Ching, D.; Andrade, A.; Henríquez-Gallegos, S.; Teixeira Mendonça, R.; Pereira, M. Relationships between Size Distribution, Morphological Characteristics, and Viscosity of Cellulose Nanofibril Dispersions. Polymers 2022, 14, 3843. https://doi.org/10.3390/polym14183843

Albornoz-Palma G, Ching D, Andrade A, Henríquez-Gallegos S, Teixeira Mendonça R, Pereira M. Relationships between Size Distribution, Morphological Characteristics, and Viscosity of Cellulose Nanofibril Dispersions. Polymers. 2022; 14(18):3843. https://doi.org/10.3390/polym14183843

Chicago/Turabian StyleAlbornoz-Palma, Gregory, Daniel Ching, Andrea Andrade, Sergio Henríquez-Gallegos, Regis Teixeira Mendonça, and Miguel Pereira. 2022. "Relationships between Size Distribution, Morphological Characteristics, and Viscosity of Cellulose Nanofibril Dispersions" Polymers 14, no. 18: 3843. https://doi.org/10.3390/polym14183843

APA StyleAlbornoz-Palma, G., Ching, D., Andrade, A., Henríquez-Gallegos, S., Teixeira Mendonça, R., & Pereira, M. (2022). Relationships between Size Distribution, Morphological Characteristics, and Viscosity of Cellulose Nanofibril Dispersions. Polymers, 14(18), 3843. https://doi.org/10.3390/polym14183843