Significant Shear Failure Difference among Additively Manufactured Polymers Using Different Techniques

Abstract

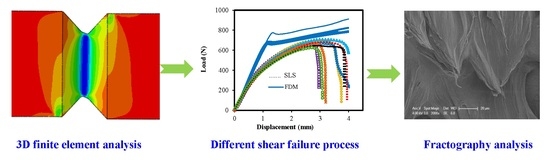

:1. Introduction

2. Materials and Methods

2.1. New Necking-Shaped Shear Test

2.2. Specimen Manufacture Using FDM and SLS

2.3. Pure Shear Experiment

2.4. Three-Dimensional Finite Element Analysis (FEA)

3. Results and Discussion

3.1. Stress Distribution of the Necking-Shaped Shear Specimen

3.2. Significant Difference in Shear Failure Processes for Two Kinds of PA Specimens

3.3. Shear Failure Mechanism Analysis Using Interface Mechanics and SEM

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, M.; Sanjayan, J.G. Methods of enhancing strength of geopolymer produced from powder-based 3D printing process. Mater. Lett. 2018, 227, 281–283. [Google Scholar] [CrossRef]

- Awasthi, P.; Banerjee, S.S. Fused deposition modeling of thermoplastic elastomeric materials: Challenges and opportunities. Addit. Manuf. 2021, 46, 102177. [Google Scholar] [CrossRef]

- Gang, F.; Ma, C.; Guo, C.; Shi, R.; Xiao, Y. Integrated rapid-prototyping and strength-increasing all-in-one 3D printing of chitosan hydrogels. Mater. Lett. 2022, 323, 132542. [Google Scholar] [CrossRef]

- Han, R.; Yang, Q.; Wang, Z.; Cao, D.; Li, G.; Zheng, L.; Peng, B.; Gao, X.; Chen, G. 3D printing-enabled self-assembling β-nucleating agent alignment: Structural evolution and mechanical performances. Polymer 2022, 246, 124736. [Google Scholar] [CrossRef]

- Krishnan, A.; Xu, L.R. Effect of the interfacial stress distribution on the material interfacial shear strength measurement. Exp. Mech. 2010, 50, 283–288. [Google Scholar] [CrossRef]

- Isaac, J.P.; Dondeti, S.; Tippur, H.V. Fracture behavior of additively printed ABS: Effects of print architecture and loading rate. Int. J. Solids Struct. 2021, 212, 80–95. [Google Scholar] [CrossRef]

- Zhang, G.; Wang, Q.; Ni, Y.; Liu, P.; Liu, F.; Leguillon, D.; Xu, L.R. A systematic investigation on the minimum tensile strengths and size effects of 3D printing polymers. 2022; paper under review. [Google Scholar]

- Wang, Q.; Zhang, G.; Zheng, X.; Liu, Y.; Xu, L.R. Efficient characterization on the interlayer shear strengths of 3D printing polymers. 2022; paper under review. [Google Scholar]

- Hutchinson, J.W.; Suo, Z. Mixed-mode cracking in layered materials. Adv. Appl. Mech. 1991, 29, 63–191. [Google Scholar]

- Xu, L.R. Rosakis, A.J. Impact failure characteristics in sandwich structures: Part I: Basic failure mode selection. Int. J. Solids Struct. 2002, 39, 4215–4235. [Google Scholar] [CrossRef]

- Garcia, R.; Prabhakar, P. Bond interface design for single lap joints using polymeric additive manufacturing. Compos. Struct. 2017, 176, 547–555. [Google Scholar] [CrossRef]

- Lammens, N.; Kersemans, M.; de Baere, I.; van Paepegem, W. On the visco-elasto-plastic response of additively manufactured polyamide-12 (PA-12) through selective laser sintering. Polym. Test. 2017, 57, 149–155. [Google Scholar] [CrossRef]

- Striemann, P.; Gerdes, L.; Huelsbusch, D.; Niedermeier, M.; Walther, F. Interlayer bonding capability of additively manufactured polymer structures under high strain rate tensile and shear loading. Polymers 2021, 13, 1301. [Google Scholar] [CrossRef] [PubMed]

| Manufacturing Technique | Strength (MPa) | Specimen Number | Remarks |

|---|---|---|---|

| FDM | 27.69 ± 1.53 (yielding) | 10 | Ultimate strength > 32 MPa |

| SLS | 24.24 ± 1.17 | 8 | Pure shear failure |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, L.R.; Wang, Q.; Ni, Y.; Zhang, G.; Liu, F.; Zheng, X.; Liu, Y. Significant Shear Failure Difference among Additively Manufactured Polymers Using Different Techniques. Polymers 2022, 14, 4028. https://doi.org/10.3390/polym14194028

Xu LR, Wang Q, Ni Y, Zhang G, Liu F, Zheng X, Liu Y. Significant Shear Failure Difference among Additively Manufactured Polymers Using Different Techniques. Polymers. 2022; 14(19):4028. https://doi.org/10.3390/polym14194028

Chicago/Turabian StyleXu, Luoyu Roy, Qinglin Wang, Yinxu Ni, Gonghe Zhang, Fenghua Liu, Xiaodong Zheng, and Yang Liu. 2022. "Significant Shear Failure Difference among Additively Manufactured Polymers Using Different Techniques" Polymers 14, no. 19: 4028. https://doi.org/10.3390/polym14194028

APA StyleXu, L. R., Wang, Q., Ni, Y., Zhang, G., Liu, F., Zheng, X., & Liu, Y. (2022). Significant Shear Failure Difference among Additively Manufactured Polymers Using Different Techniques. Polymers, 14(19), 4028. https://doi.org/10.3390/polym14194028