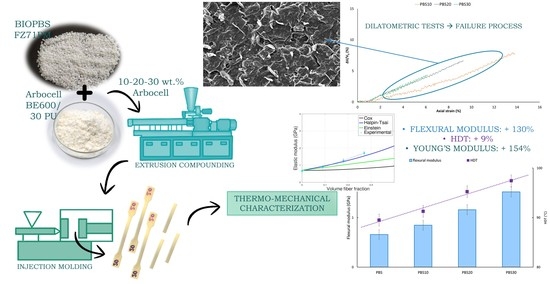

Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Composites Preparation

2.3. Specimens Preparation by Injection Molding

2.4. Mechanichal Tests

2.5. Morphological Characterization

2.6. Thermal Characterization

3. Theoretical Analysis

3.1. Elastic Modulus

3.2. Interfacial Adhesion

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Abrha, H.; Cabrera, J.; Dai, Y.; Irfan, M.; Toma, A.; Jiao, S.; Liu, X. Bio-Based Plastics Production, Impact and End of Life: A Literature Review and Content Analysis. Sustainability 2022, 14, 4855. [Google Scholar] [CrossRef]

- Gupta, A.; Chudasama, B.; Chang, B.P.; Mekonnen, T. Robust and Sustainable PBAT—Hemp Residue Biocomposites: Reactive Extrusion Compatibilization and Fabrication. Compos. Sci. Technol. 2021, 215, 109014. [Google Scholar] [CrossRef]

- Momeni, S.; Safder, M.; Khondoker, M.A.H.; Elias, A.L. Valorization of Hemp Hurds as Bio-Sourced Additives in Pla-Based Biocomposites. Polymers 2021, 13, 3786. [Google Scholar] [CrossRef] [PubMed]

- Sergi, C.; Sbardella, F.; Lilli, M.; Tirillò, J.; Calzolari, A.; Sarasini, F. Hybrid Cellulose–Basalt Polypropylene Composites with Enhanced Compatibility: The Role of Coupling Agent. Molecules 2020, 25, 4384. [Google Scholar] [CrossRef] [PubMed]

- Wang, Q.; Ji, C.; Sun, J.; Zhu, Q.; Liu, J. Structure and Properties of Polylactic Acid Biocomposite Films Reinforced with Cellulose Nanofibrils. Molecules 2020, 25, 3306. [Google Scholar] [CrossRef]

- Liang, Z.; Wu, H.; Liu, R.; Wu, C. Preparation of Long Sisal Fiber-Reinforced Polylactic Acid Biocomposites with Highly Improved Mechanical Performance. Polymers 2021, 13, 1124. [Google Scholar] [CrossRef]

- Zuccarello, B.; Marannano, G. Random Short Sisal Fiber Biocomposites: Optimal Manufacturing Process and Reliable Theoretical Models. Mater. Des. 2018, 149, 87–100. [Google Scholar] [CrossRef]

- Sánchez, M.L.; Patiño, W.; Cárdenas, J. Physical-Mechanical Properties of Bamboo Fibers-Reinforced Biocomposites: Influence of Surface Treatment of Fibers. J. Build. Eng. 2020, 28, 101058. [Google Scholar] [CrossRef]

- Wu, Y.; Fei, M.; Chen, T.; Qiu, R.; Liu, W. Biocomposites from Bamboo Fibers and Palm Oil-Based Thermosets: Effects of Natural Phenolic Cross-Linkers. Compos. Commun. 2020, 22, 100489. [Google Scholar] [CrossRef]

- Pivsa-Art, S.; Pivsa-Art, W. Eco-Friendly Bamboo Fiber-Reinforced Poly(Butylene Succinate) Biocomposites. Polym. Compos. 2021, 42, 1752–1759. [Google Scholar] [CrossRef]

- Bos, H.L.; Müssig, J.; van den Oever, M.J.A. Mechanical Properties of Short-Flax-Fibre Reinforced Compounds. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1591–1604. [Google Scholar] [CrossRef]

- Botta, L.; Fiore, V.; Scalici, T.; Valenza, A.; Scaffaro, R. New Polylactic Acid Composites Reinforced with Artichoke Fibers. Materials 2015, 8, 7770–7779. [Google Scholar] [CrossRef] [Green Version]

- De Rosa, I.M.; Kenny, J.M.; Puglia, D.; Santulli, C.; Sarasini, F. Morphological, Thermal and Mechanical Characterization of Okra (Abelmoschus esculentus) Fibres as Potential Reinforcement in Polymer Composites. Compos. Sci. Technol. 2010, 70, 116–122. [Google Scholar] [CrossRef]

- Sarikanat, M.; Seki, Y.; Sever, K.; Durmuşkahya, C. Determination of Properties of Althaea officinalis L. (Marshmallow) Fibres as a Potential Plant Fibre in Polymeric Composite Materials. Compos. B Eng. 2014, 57, 180–186. [Google Scholar] [CrossRef]

- Komal, U.K.; Lila, M.K.; Singh, I. PLA/Banana Fiber Based Sustainable Biocomposites: A Manufacturing Perspective. Compos. B Eng. 2020, 180, 107535. [Google Scholar] [CrossRef]

- Oksman, K.; Wallström, L.; Berglund, L.A.; Toledo Filho, R.D. Morphology and Mechanical Properties of Unidirectional Sisal-Epoxy Composites. J. Appl. Polym. Sci. 2002, 84, 2358–2365. [Google Scholar] [CrossRef]

- Oksman, K.; Skrifvars, M.; Selin, J.F. Natural Fibres as Reinforcement in Polylactic Acid (PLA) Composites. Compos. Sci. Technol. 2003, 63, 1317–1324. [Google Scholar] [CrossRef]

- Valadez-Gonzalez, A.; Cervantes-Uc, J.M.; Olayo, R.; Herrera-Franco, P.J. Effect of Fiber Surface Treatment on the Fiber-Matrix Bond Strength of Natural Fiber Reinforced Composites. Compos. B Eng. 1999, 30, 309–320. [Google Scholar] [CrossRef]

- Huda, M.S.; Drzal, L.T.; Mohanty, A.K.; Misra, M. The Effect of Silane Treated-and Untreated-Talc on the Mechanical and Physico-Mechanical Properties of Poly (Lactic Acid)/Newspaper Fibers/Talc Hybrid Composites. Compos. B Eng. 2007, 38, 367–379. [Google Scholar] [CrossRef]

- Cho, D.; Seo, J.M.; Lee, H.S.; Cho, C.W.; Han, S.O.; Park, W.H. Property Improvement of Natural Fiber-Reinforced Green Composites by Water Treatment. Adv. Compos. Mater. 2007, 16, 299–314. [Google Scholar] [CrossRef]

- Fiore, V.; Scalici, T.; Nicoletti, F.; Vitale, G.; Prestipino, M.; Valenza, A. A New Eco-Friendly Chemical Treatment of Natural Fibres: Effect of Sodium Bicarbonate on Properties of Sisal Fibre and Its Epoxy Composites. Compos. B Eng. 2016, 85, 150–160. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Jaszkiewicz, A.; Urbaniak, M.; Stankowska-Walczak, D. Biocomposites in the Past and in the Future. Fibres Text. East. Eur. 2012, 96, 15–22. [Google Scholar]

- Morreale, M.; Mistretta, M.C.; Fiore, V. Creep Behavior of Poly(Lactic Acid) Based Biocomposites. Materials 2017, 10, 395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Manu, T.; Nazmi, A.R.; Shahri, B.; Emerson, N.; Huber, T. Biocomposites: A Review of Materials and Perception. Mater. Today Commun. 2022, 31, 103308. [Google Scholar] [CrossRef]

- Gigante, V.; Aliotta, L.; Phuong, V.T.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Effects of Waviness on Fiber-Length Distribution and Interfacial Shear Strength of Natural Fibers Reinforced Composites. Compos. Sci. Technol. 2017, 152, 129–138. [Google Scholar] [CrossRef]

- Thirumalai, R.; Prabhakaran, D.; Lilholt, H.; Aviles, F.; Løgstrup Andersen, T.; Knudsen, H. Fibre Waviness and Misalignment Measurement of Unidirectional Glass/LPET Commingled Composites—Effect on Mechanical Properties. Risoe International Symposium on Materials Science. Proceedings 2013, 34, 349–363. [Google Scholar]

- Mohanty, A.K.; Misra, M.; Hinrichsen, G. Biofibres, Biodegradable Polymers and Biocomposites: An Overview. Macromol. Mater. Eng. 2000, 276–277, 1–24. [Google Scholar] [CrossRef]

- Shih, Y.F.; Chen, L.S.; Jeng, R.J. Preparation and Properties of Biodegradable PBS/Multi-Walled Carbon Nanotube Nanocomposites. Polym. (Guildf.) 2008, 49, 4602–4611. [Google Scholar] [CrossRef]

- Rafiqah, S.A.; Khalina, A.; Harmaen, A.S.; Tawakkal, I.A.; Zaman, K.; Asim, M.; Nurrazi, M.N.; Lee, C.H. A Review on Properties and Application of Bio-Based Poly(Butylene Succinate). Polymers 2021, 13, 1436. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Morreale, M. Green Composites: A Brief Review. Compos. Part A Appl. Sci. Manuf. 2011, 42, 579–588. [Google Scholar] [CrossRef]

- Renner, K.; Kenyó, C.; Móczó, J.; Pukánszky, B. Micromechanical Deformation Processes in PP/Wood Composites: Particle Characteristics, Adhesion, Mechanisms. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1653–1661. [Google Scholar] [CrossRef]

- Kain, S.; Ecker, J.V.; Haider, A.; Musso, M.; Petutschnigg, A. Effects of the Infill Pattern on Mechanical Properties of Fused Layer Modeling (FLM) 3D Printed Wood/Polylactic Acid (PLA) Composites. Eur. J. Wood Wood Prod. 2020, 78, 65–74. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Cinelli, P.; Coltelli, M.-B.; Lazzeri, A. Effect of a Bio-Based Dispersing Aid (Einar® 101) on PLA-Arbocel® Biocomposites: Evaluation of the Interfacial Shear Stress on the Final Mechanical Properties. Biomolecules 2020, 10, 1549. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.B.; Cinelli, P.; Lazzeri, A. Evaluation of Mechanical and Interfacial Properties of Bio-Composites Based on Poly (Lactic Acid) with Natural Cellulose Fibers. Int. J. Mol. Sci. 2019, 20, 960. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aliotta, L.; Gigante, V.; Coltelli, M.-B.; Lazzeri, A. Volume Change during Creep and Micromechanical Deformation Processes in PLA–PBSA Binary Blends. Polymers 2021, 13, 2379. [Google Scholar] [CrossRef]

- Aliotta, L.; Lazzeri, A. A Proposal to Modify the Kelly-Tyson Equation to Calculate the Interfacial Shear Strength (IFSS) of Composites with Low Aspect Ratio Fibers. Compos. Sci. Technol. 2020, 186, 107920. [Google Scholar] [CrossRef]

- Aliotta, L.; Cinelli, P.; Beatrice Coltelli, M.; Lazzeri, A. Rigid Filler Toughening in PLA-Calcium Carbonate Composites: Effect of Particle Surface Treatment and Matrix Plasticization. Eur. Polym. J. 2018, 113, 78–88. [Google Scholar] [CrossRef]

- Abderrahim, B.; Abderrahman, E.; Mohamed, A.; Fatima, T.; Abdesselam, T.; Krim, O. Kinetic Thermal Degradation of Cellulose, Polybutylene Succinate and a Green Composite: Comparative Study. World J. Environ. Eng. 2015, 3, 95–110. [Google Scholar] [CrossRef]

- Kim, H.G.; Kwac, L.K. Evaluation of Elastic Modulus for Unidirectionally Aligned Short Fiber Composites. J. Mech. Sci. Technol. 2009, 23, 54–63. [Google Scholar] [CrossRef]

- Bourkas, G.; Prassianakis, I.; Kytopoulos, V.; Sideridis, E.; Younis, C. Estimation of Elastic Moduli of Particulate Composites by New Models and Comparison with Moduli Measured by Tension, Dynamic, and Ultrasonic Tests. Adv. Mater. Sci. Eng. 2010, 2010, 891824. [Google Scholar] [CrossRef] [Green Version]

- Cox, H.L. The Elasticity and Strength of Paper and Other Fibrous Materials. Br. J. Appl. Phys. 1952, 3, 72–79. [Google Scholar] [CrossRef]

- Ahmed, S.; Jones, F.R. A Review of Particulate Reinforcing Theories for Polymer Composites. J. Mater. Sci. 1990, 25, 4933–4942. [Google Scholar] [CrossRef]

- Halpin, J.C.; Kardos, J.L. The Halpin-Tsai Equations: A Review. Polym. Eng. Sci. 1976, 16, 344–352. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of Particle Size, Particle/Matrix Interface Adhesion and Particle Loading on Mechanical Properties of Particulate-Polymer Composites. Compos. B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Adusumali, R.B.; Reifferscheid, M.; Weber, H.; Roeder, T.; Sixta, H.; Gindl, W. Mechanical Properties of Regenerated Cellulose Fibres for Composites. Macromol. Symp. 2006, 244, 119–125. [Google Scholar] [CrossRef]

- Luo, J.J.; Daniel, I.M. Characterization and Modeling of Mechanical Behavior of Polymer/Clay Nanocomposites. Compos. Sci. Technol. 2003, 63, 1607–1616. [Google Scholar] [CrossRef]

- Huang, Y.; Kinloch, A.J. Modelling of the Toughening Mechanisms in Rubber-Modified Epoxy Polymers—Part I Finite Element Analysis Studies. J. Mater. Sci. 1992, 27, 2753–2762. [Google Scholar] [CrossRef]

- Qi, D.; Hinkley, J.; He, G. Molecular Dynamics Simulation of Thermal and Mechanical Properties of Polyimide-Carbon-Nanotube Composites. Model Simul. Mat. Sci. Eng. 2005, 13, 493–507. [Google Scholar] [CrossRef] [Green Version]

- Bartos, A.; Kócs, J.; Anggono, J.; Móczó, J.; Pukánszky, B. Effect of Fiber Attrition, Particle Characteristics and Interfacial Adhesion on the Properties of PP/Sugarcane Bagasse Fiber Composites. Polym. Test. 2021, 98, 107189. [Google Scholar] [CrossRef]

- Facca, A.G.; Kortschot, M.T.; Yan, N. Predicting the Elastic Modulus of Natural Fibre Reinforced Thermoplastics. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1660–1671. [Google Scholar] [CrossRef]

- Shibata, S.; Cao, Y.; Fukumoto, I. Press Forming of Short Natural Fiber-Reinforced Biodegradable Resin: Effects of Fiber Volume and Length on Flexural Properties. Polym. Test. 2005, 24, 1005–1011. [Google Scholar] [CrossRef]

- Serrano, A.; Espinach, F.X.; Tresserras, J.; del Rey, R.; Pellicer, N.; Mutje, P. Macro and Micromechanics Analysis of Short Fiber Composites Stiffness: The Case of Old Newspaper Fibers-Polypropylene Composites. Mater. Des. 2014, 55, 319–324. [Google Scholar] [CrossRef]

- Aliotta, L.; Gigante, V.; Coltelli, M.; Cinelli, P.; Lazzeri, A.; Seggiani, M. Thermo-Mechanical Properties of PLA/Short Flax Fiber Biocomposites. Appl. Sci. 2019, 9, 3797. [Google Scholar] [CrossRef] [Green Version]

- George, G.; Tomlal Jose, E.; Åkesson, D.; Skrifvars, M.; Nagarajan, E.R.; Joseph, K. Viscoelastic Behaviour of Novel Commingled Biocomposites Based on Polypropylene/Jute Yarns. Compos. Part A Appl. Sci. Manuf. 2012, 43, 893–902. [Google Scholar] [CrossRef]

- Abhilash, R.M.; Venkatesh, G.S.; Chauhan, S.S. Micromechanical Modeling of Bamboo Short Fiber Reinforced Polypropylene Composites. Multiscale Multidiscip. Model. Exp. Des. 2021, 4, 25–40. [Google Scholar] [CrossRef]

- Aliotta, L.; Sciara, L.M.; Cinelli, P.; Canesi, I.; Lazzeri, A. Improvement of the PLA Crystallinity and Heat Distortion Temperature Optimizing the Content of Nucleating Agents and the Injection Molding Cycle Time. Polymers 2022, 14, 977. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Injection-Molded Short Hemp Fiber/Glass Fiber-Reinforced Polypropylene Hybrid Composites—Mechanical, Water Absorption and Thermal Properties. J. Appl. Polym. Sci. 2007, 103, 2432–2441. [Google Scholar] [CrossRef]

- Picard, M.C.; Rodriguez-Uribe, A.; Thimmanagari, M.; Misra, M.; Mohanty, A.K. Sustainable Biocomposites from Poly(Butylene Succinate) and Apple Pomace: A Study on Compatibilization Performance. Waste Biomass Valorization 2020, 11, 3775–3787. [Google Scholar] [CrossRef]

- Nanda, M.R.; Misra, M.; Mohanty, A.K. Performance Evaluation of Biofibers and Their Hybrids as Reinforcements in Bioplastic Composites. Macromol. Mater. Eng. 2013, 298, 779–788. [Google Scholar] [CrossRef]

- Lee, S.-H.; Wang, S. Biodegradable Polymers/Bamboo Fiber Biocomposite with Bio-Based Coupling Agent. Compos. Part A Appl. Sci. Manuf. 2006, 37, 80–91. [Google Scholar] [CrossRef]

- Faludi, G.; Dora, G.; Imre, B.; Renner, K.; Móczó, J.; Pukánszky, B. PLA/Lignocellulosic Fiber Composites: Particle Characteristics, Interfacial Adhesion, and Failure Mechanism. J. Appl. Polym. Sci. 2014, 131, 39902. [Google Scholar] [CrossRef] [Green Version]

- Lazzeri, A.; Thio, Y.S.; Cohen, R.E. Volume Strain Measurements on CACO3/Polypropylene Particulate Composites: The Effect of Particle Size. J. Appl. Polym. Sci. 2004, 91, 925–935. [Google Scholar] [CrossRef]

- Faludi, G.; Link, Z.; Renner, K.; Móczó, J.; Pukánszky, B. Factors Determining the Performance of Thermoplastic Polymer/Wood Composites; the Limiting Role of Fiber Fracture. Mater. Des. 2014, 61, 203–210. [Google Scholar] [CrossRef] [Green Version]

- Várdai, R.; Lummerstorfer, T.; Pretschuh, C.; Jerabek, M.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Reinforcement of PP with Polymer Fibers: Effect of Matrix Characteristics, Fiber Type and Interfacial Adhesion. Polym. (Guildf.) 2020, 190, 122203. [Google Scholar] [CrossRef]

| BIOPBS FZ71PM |

|

| Arbocel BE600/30 PU |

|

| Name | PBS wt.% | Arbocel wt.% |

|---|---|---|

| PBS | 100 | - |

| PBS10 | 90 | 10 |

| PBS20 | 80 | 20 |

| PBS30 | 70 | 30 |

| PBS | PBS10 | PBS20 | PBS30 | |||

|---|---|---|---|---|---|---|

| TEMPERATURES (°C) | T1 | 140 | 140 | 140 | 140 |

| T2 | 150 | 150 | 150 | 150 | ||

| T3 | 140 | 140 | 140 | 140 | ||

| T4 | 140 | 140 | 140 | 140 | ||

| Mold | 50 | 50 | 50 | 50 | ||

| INJECTION | Injection pressure (bar) | 55 | 65 | 75 | 75 | |

| Injection filling speed (%) | 80 | 80 | 80 | 80 | ||

| MAINTAINING | Maintaining pressure (bar) | 50 | 60 | 70 | 70 | |

| Maintaining time (s) | 10 | 10 | 10 | 10 | ||

| Cooling time (s) | 15 | 15 | 15 | 15 |

| Model | Ecomposite | Parameters Used |

|---|---|---|

| Einstein | ||

| Cox | ||

| Halpin-Tsai |

| Name | Symbol | Value | Source |

|---|---|---|---|

| Fiber modulus | Em | 23.4 (GPa) | [45] |

| Fiber aspect ratio | ar | 3 | From Technical data sheet |

| Matrix Poisson ration | υ | 0.35 | [46,47,48] |

| Name | Tg (°C) | Tm (°C) | ΔHm (J/g) | Xc (%) |

|---|---|---|---|---|

| PBS | −34.0 | 115.1 | 57.5 | 52.1 |

| PBS10 | −34.1 | 115.1 | 52.4 | 52.8 |

| PBS20 | −34.1 | 116.0 | 45.7 | 51.8 |

| PBS30 | −34.0 | 116.7 | 40.5 | 52.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aliotta, L.; Gasenge, M.; Gigante, V.; Lazzeri, A. Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications. Polymers 2022, 14, 4499. https://doi.org/10.3390/polym14214499

Aliotta L, Gasenge M, Gigante V, Lazzeri A. Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications. Polymers. 2022; 14(21):4499. https://doi.org/10.3390/polym14214499

Chicago/Turabian StyleAliotta, Laura, Mattia Gasenge, Vito Gigante, and Andrea Lazzeri. 2022. "Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications" Polymers 14, no. 21: 4499. https://doi.org/10.3390/polym14214499

APA StyleAliotta, L., Gasenge, M., Gigante, V., & Lazzeri, A. (2022). Micromechanical Deformation Processes and Failure of PBS Based Composites Containing Ultra-Short Cellulosic Fibers for Injection Molding Applications. Polymers, 14(21), 4499. https://doi.org/10.3390/polym14214499