Influence of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates

Abstract

:1. Introduction

- ―

- After the introduction of the VACNT interleave, will the thickness of laminate plies or laminate be affected?

- ―

- Will the void content or void distribution change?

- ―

- Will the orientations of fibers change inside plies? Closer to the interfaces?

2. Materials

2.1. Nanostitch

2.2. Laminates and Test Samples

- ―

- Increase pressure from vacuum at 0.07 MPa to 0.6–0.7 MPa and hold throughout the cure cycle. Vent the vacuum when the pressure inside chamber reaches 0.14 MPa.

- ―

- Increase temperature at a steady rate of not more than 5 °C/min until reaching 90 °C.

- ―

- Dwell: Hold the temperature at 90 °C (195 F) for 30 min.

- ―

- Increase the temperature at a steady rate of not more than 5 °C/min until 120–130 °C and hold for 60 min.

- ―

- Decrease the temperature at a rate below 3 °C/min; release the pressure to 0 MPa when the temperature reaches 65 °C.

2.3. Synchrotron Radiation Computed Tomography

- Cropping: The images were cropped to dimensions ~1550 × 1400 × (2159) pix3 so that they did not contain air surrounding the sample. The exact XY dimensions varied from image to image. The resulting files were ~9 MB size.

- Density scaling: The actual grey scale range of the images is shorter than the full range from black to white. Therefore, the range was rescaled so that black (0) corresponds to the lowest grey scale value, and white (255) corresponds to the highest grey scale value of the image.

- Filtering: The Gaussian filter with kernel size 3 and standard deviation 2.0 pix was applied to the images. This operation eliminated high frequency noise and is recommended before analyzing the image anisotropy and directionality.

3. Fibrous Microstructure of Laminates

- ―

- thickness of plies and of the inter-ply interfaces (and, thereby, of the laminate);

- ―

- presence of voids;

- ―

- (mis) orientation of fibers deep inside the plies and closer to their interfaces.

3.1. Thickness of Plies and Interfaces

3.1.1. Measurement Method

3.1.2. Results

- ―

- Variability: The individual ply thicknesses vary, as can be observed in Figure 3. These variations (standard deviation) are ~6% for BSL, ~10% for N1, and ~8% for N2. The nanostitch seems to increase ply thickness variability, but the difference in variance between BSL and Nx corresponds to statistical significance of only ~0.8. Ply thickness may be expected to be affected, in principle, by the ply position in a laminate. This was not, however, the case.

- ―

- Nominal ply thickness: The averaged value of 121 µm for the BSL ply thickness differs from the nominal value of 129 µm.

- ―

- Gap: The average interface gap in Nx laminates (as interleave thickness) equals 5.2 µm for N1 and 3.3 µm for N2, i.e., is comparable to the fiber diameter.

- ―

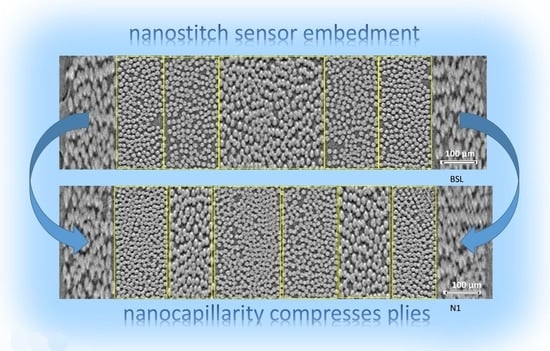

- Difference between BSL and Nx: The mean ply thickness of the Nx laminates is lower than for BSL by 3–5 µm, which is approximately the interleave thickness in the Nx laminates. In the result, the embedment of the nanostitch interleaves at every interface between plies does not cause a change in the laminate thickness on average. It seems that the nanostitch due to its nano-capillarity provides additional pressure that compresses fibrous plies, maintaining an overall unchanged laminate thickness (more accurately, the difference in means does not pass a statistical test for significance because of a high variance). We observe no significant difference in this effect between N1 and N2 laminates, suggesting that the direction of the nano-capillarity channels does not play a significant role.

- ―

- Fiber volume fraction inside the plies: VF = 62.0% for BSL and 64.6% for Nx, serving again as an indication of the additional ply compression introduced by the nanostitch.

3.2. Voids

3.3. Fiber Orientation

3.3.1. Measurement Method

- ―

- degree of anisotropy β ∈ [0, 1], where β = 0 corresponds to the isotropic image structure (pictured by black color) and β = 1 corresponds to the transversely isotropic material (pictured by white color);

- ―

- principal direction of anisotropy p, which for voxels corresponding to the fiber reinforced regions was identified with the fiber direction;

- ―

- average grey scale of the voxel.

- ―

- ply in-plane misorientation <φ> −φnom, where <…> designates the averaging of the fiber orientations over the ROI;

- ―

- ply out-of-plane misorientation <θ> −90°;

- ―

- fiber in-plane misalignment Δφ = std (φ), where std () is standard deviation over the ROI;

- ―

- fiber out-of-plane misalignment Δθ = std(θ), where std () is standard deviation over the ROI.

3.3.2. Results

- ―

- Data quality: The data are consistent and repeatable in four images for all three laminate variants.

- ―

- Misalignment deep inside plies: Average in-plane/out-of-plane misalignment in plies does not exceed 3°/4°, respectively; when averaged over all of the plies, it is on the level of 2°/3°, respectively.

- ―

- Misalignment at interfaces: Normally higher than inside the neighboring plies by about 1° both for the in- and out-of-plane angles. The fiber misalignment is illustrated in Figure 9, which shows in-plane slices in 0° and 45° plies and at their interface. In-plane misalignment at interfaces with 45° difference of plies orientations (interfaces 0/45°) is about 1° larger than at the interfaces of plies with orthogonal orientations (interfaces 0°/90° and +45°/−45°). For the out-of-plane misalignment at the interfaces, this difference is not observed.

- ―

- Difference between the baseline and nanostitched laminates: The features, stated above, are seen in both the BSL and Nx laminates. No systematic difference is observed between the misalignment angles in three laminates, neither for in-plane nor for out-of-plane angles.

4. Conclusions

- After the nanostitch embedment, the laminate preserves its thickness, with resin/CNT-rich gaps of ~5 µm created at plies’ interfaces and corresponding to a decrease in individual ply thicknesses. We argue that the latter effect is related to the effective pressure created by the nanostitch nano-capillarity.

- There are no voids with sizes over 1–2 µm observed, both in the baseline and in the nanostitched laminates.

- The misorientation of plies (as the difference of the average fiber direction in a ply and the nominal ply angle) is under 2°.

- The in-plane and out-of-plane misalignment (standard deviation of fiber orientation) inside the plies is in the range of 1.5°–3° and 2°–4°, respectively; the misalignment closer to the plies interfaces is increased in comparison with the misalignment within plies by ~1°.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Lee, J.; Stein, I.Y.; Kessler, S.S.; Wardle, B.L. Aligned carbon nanotube film enables thermally induced state transformations in layered polymeric materials. ACS Appl. Mater. Interfaces 2015, 7, 8900–8905. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, J.; Ni, X.; Daso, F.; Xiao, X.; King, D.; Gómez, J.S.; Varela, T.B.; Kessler, S.S.; Wardle, B.L. Advanced carbon fiber composite out-of-autoclave laminate manufacture via nanostructured out-of-oven conductive curing. Compos. Sci. Technol. 2018, 166, 150–159. [Google Scholar] [CrossRef]

- Lee, J.; Wardle, B. Nanoengineered In Situ Cure Status Monitoring Technique Based on Carbon Nanotube Network. In Proceedings of the AIAA Conference, Portland, ME, USA, 11–15 August 2019. [Google Scholar]

- Lee, J.; Kessler, S.S.; Wardle, B.L. Void-free layered polymeric architectures via capillary-action of nanoporous films. Adv. Mater. Interfaces 2020, 7, 1901427. [Google Scholar] [CrossRef]

- Blanco, J.; Garcia, E.J.; de Villoria, R.G.; Wardle, B.L. Limiting Mechanisms of Mode I Interlaminar Toughening of Composites Reinforced with Aligned Carbon Nanotubes. J. Compos. Mater. 2009, 43, 825–841. [Google Scholar] [CrossRef]

- Garcia, E.J.; Wardle, B.L.; Hart, A.J. Joining prepreg composite interfaces with aligned carbon nanotubes. Compos. Part A-Appl. Sci. Manuf. 2008, 39, 1065–1070. [Google Scholar] [CrossRef]

- Mecklenburg, M.; Mizushima, D.; Ohtake, N.; Bauhofer, W.; Fiedler, B.; Schulte, K. On the manufacturing and electrical and mechanical properties of ultra-high wt.% fraction aligned MWCNT and randomly oriented CNT epoxy composites. Carbon 2015, 91, 275–290. [Google Scholar] [CrossRef]

- de Villoria, R.; Hallander, P.; Ydrefors, L.; Nordin, P.; Wardle, B.L. In-plane strength enhancement of laminated composites via aligned carbon nanotube interlaminar reinforcement. Compos. Sci. Technol. 2016, 133 (Suppl. C), 33–39. [Google Scholar] [CrossRef]

- Stahl, J.J.; Bogdanovich, A.E.; Bradford, P.D. Carbon nanotube shear-pressed sheet interleaves for Mode I interlaminar fracture toughness enhancement. Compos. Part A 2016, 80, 127–137. [Google Scholar] [CrossRef] [Green Version]

- Kalfon-Cohen, E.; Kopp, R.; Furtado, C.; Ni, X.; Arteiro, A.; Borstnar, G.; Mavrogordato, M.N.; Sinclair, I.; Spearing, S.M.; Camanho, P.P.; et al. Synergetic effects of thin plies and aligned carbon nanotube interlaminar reinforcement in composite laminates. Compos. Sci. Technol. 2018, 166, 160–168. [Google Scholar] [CrossRef] [Green Version]

- Fritz, N.K.; Kopp, R.; Nason, A.K.; Ni, X.; Lee, J.; Stein, I.Y.; Kalfon-Cohen, E.; Sinclair, I.; Spearing, S.M.; Camanho, P.P.; et al. New interlaminar features and void distributions in advanced aerospace-grade composites revealed via automated algorithms using micro-computed tomography. Compos. Sci. Technol. 2020, 193, 108132. [Google Scholar] [CrossRef]

- Ni, X.; Acauan, L.H.; Wardle, B.L. Coherent nanofiber array buckling-enabled synthesis of hierarchical layered composites with enhanced strength. Extrem. Mech. Lett. 2020, 39, 100773. [Google Scholar] [CrossRef]

- Ni, X.C.; Kopp, R.; Kalfon-Cohen, E.; Furtado, C.; Lee, J.; Arteiro, A.; Borstnar, G.; Mavrogordato, M.N.; Helfen, L.; Sinclair, I.; et al. In situ synchrotron computed tomography study of nanoscale interlaminar reinforcement and thin-ply effects on damage progression in composite laminates. Compos. Part B-Eng. 2021, 217, 108623. [Google Scholar] [CrossRef]

- Furtado, C.; Kalfon-Cohen, E.; Lee, J.; Patel, P.B.; Kopp, R.; Hank, T.J.; Kessler, S.; Wardle, B.L. Effective Interlaminar Reinforcement of High Glass Transition Temperature Laminated Composites via Vertically Aligned Carbon Nanotubes. In AIAA SCITECH 2022 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2021. [Google Scholar]

- Patel, P.; Furtado, C.; Cooper, M.; Acuan, L.; Lomov, S.V.; Akhatov, I.; Abaimov, S.; Lee, J.; Wardle, B.L. Nanoengineered glass fiber reinforced composite laminates with integrated multifunctionality. In Proceedings of the 36th ASC Technical VIRTUAL Conference (ASC 2021), Online, 19–22 September 2021; pp. 2078–2090. [Google Scholar]

- Patel, P.B.; Furtado, C.; Lee, J.; Cooper, M.F.; Acauan, L.H.; Lomov, S.V.; Akhatov, I.S.; Abaimov, S.G.; Wardle, B.L. Building life-cycle enhancement multifunctionality into glass fiber reinforced composite laminates via hierarchical assemblies of aligned carbon nanotubes. In Proceedings of the AIAA SciTech Forum, San Diego, CA, USA; 2021. [Google Scholar]

- Sabuncuoglu, B.; Tanabi, H.; Soete, J.; Lomov, S.V. Micro-CT analysis of deviations in fiber orientation and composite stiffness near the microvascular channels embedded in glass-fiber reinforced composites. Compos. Struct. 2020, 237, 111896. [Google Scholar] [CrossRef]

- Aravand, M.A.; Shishkina, O.; Straumit, I.; Liotta, A.H.; Wicks, S.S.; Wardle, B.L.; Lomov, S.V.; Gorbatikh, L. Effect of “fuzzy” fiber morphology on the internal geometry of textile composites characterized by micro-computed tomography. Compos. Part A 2016, 88, 295–304. [Google Scholar] [CrossRef]

- Mehdikhani, M.; Gorbatikh, L.; Verpoest, I.; Lomov, S.V. Voids in fiber-reinforced polymer composites: A review on their formation, characteristics, and effects on mechanical performance. J. Compos. Mater. 2019, 53, 1579–1669. [Google Scholar] [CrossRef]

- Malgioglio, F.; Pimenta, S.; Matveeva, A.; Farkas, L.; Desmet, W.; Lomov, S.V.; Swolfs, Y. Microscale material variability and its effect on longitudinal tensile failure of unidirectional carbon fibre composites. Compos. Struct. 2021, 261, 113300. [Google Scholar] [CrossRef]

- Gomarasca, S.; Peeters, D.M.J.; Atli-Veltin, B.; Dransfeld, C. Characterising microstructural organisation in unidirectional composites. Compos. Sci. Technol. 2021, 215, 109030. [Google Scholar] [CrossRef]

- Liu, J.L.; Tay, T.E.; Ng, S.W.; Tan, V.B.C. Effects of inter-ply mismatch angle on interlaminar properties and their influence in numerical simulations. Compos. Part A-Appl. Sci. Manuf. 2022, 154, 106795. [Google Scholar] [CrossRef]

- Patel, P.; Furtado, C.; Cooper, M.; Lee, J.; Ball, K.; Lee, Y.; Arteiro, A.; Majkut, M.; Helfen, L.; Acauan, L.; et al. Synchrotron radiation 3D computed tomography study on insitu mechanical damage progression of nanoengineered glass fiber reinforced composite laminates with integrated multifunctionality. In Proceedings of the 20th European Conference on Composite Materials (ECCM-20), Lausanne, Switzerland, 26–30 June 2022; p. 62376. [Google Scholar]

- Straumit, I.; Lomov, S.V.; Wevers, M. Quantification of the internal structure and automatic generation of voxel models of textile composites from X-ray computed tomography data. Compos. Part A 2015, 69, 150–158. [Google Scholar] [CrossRef]

- Nguyen, N.; Mehdikhani, M.; Straumit, I.; Gorbatikh, L.; Lessard, L.; Lomov, S.V. Micro-CT measurement of fibre misalignment: Application to carbon/epoxy laminates manufactured in autoclave and by vacuum assisted resin transfer moulding. Compos. Part A 2018, 104, 14–23. [Google Scholar] [CrossRef]

- Kopp, R.; Ni, X.; Furtado, C.; Lee, J.; Kalfon-Cohen, E.; Uesugi, K.; Kinsella, M.; Mavrogordato, M.N.; Sinclair, I.; Spearing, S.M.; et al. Synchrotron X-ray microtomography of progressive damage in canted notched cross-ply composites with interlaminar nanoreinforcement. In AIAA SCITECH 2022 Forum; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2021. [Google Scholar]

- Vo, N.T.; Atwood, R.C.; Drakopoulos, M. Radial lens distortion correction with sub-pixel accuracy for X-ray micro-tomography. Opt. Express 2015, 23, 32859–32868. [Google Scholar] [CrossRef] [PubMed]

- Nikishkov, Y.; Airoldi, L.; Makeev, A. Measurement of voids in composites by X-ray Computed Tomography. Compos. Sci. Technol. 2013, 89, 89–97. [Google Scholar] [CrossRef]

- Auenhammer, R.M.; Jeppesen, N.; Mikkelsen, L.P.; Dahl, V.A.; Blinzler, B.J.; Asp, L.E. Robust numerical analysis of fibrous composites from X-ray computed tomography image data enabling low resolutions. Compos. Sci. Technol. 2022, 224, 109458. [Google Scholar] [CrossRef]

- Auenhammer, R.M.; Jeppesen, N.; Dahl, V.A.; Mikkelsen, L.P. X-ray computed tomography data structure tensor orientation mapping for finite element models–STXAE. Softw. Impacts 2022, 11, 100216. [Google Scholar] [CrossRef]

| Plies 0° | Plies 45° | Plies −45° | All Plies | Gap | |

|---|---|---|---|---|---|

| BSL | 120 ± 10 | 121 ± 4 | 122 ± 4 | 121 ± 7 | n/a |

| N1 | 117 ± 12 | 112 ± 9 | 119 ± 12 | 116 ± 11 | 5.2 ± 0.6 |

| N2 | 114 ± 9 | 120 ± 6 | 118 ± 11 | 117 ± 9 | 3.3 ± 0.9 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lomov, S.V.; Abaimov, S.G. Influence of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates. Polymers 2022, 14, 4644. https://doi.org/10.3390/polym14214644

Lomov SV, Abaimov SG. Influence of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates. Polymers. 2022; 14(21):4644. https://doi.org/10.3390/polym14214644

Chicago/Turabian StyleLomov, Stepan V., and Sergey G. Abaimov. 2022. "Influence of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates" Polymers 14, no. 21: 4644. https://doi.org/10.3390/polym14214644

APA StyleLomov, S. V., & Abaimov, S. G. (2022). Influence of the Nanostitch Sensor Embedment on the Fibrous Microstructure of Glass Fiber Prepreg Laminates. Polymers, 14(21), 4644. https://doi.org/10.3390/polym14214644