Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets

Abstract

:1. Introduction

2. Materials and Methods

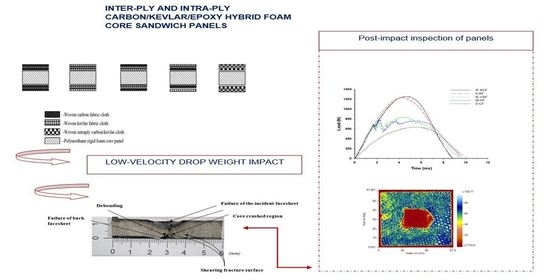

2.1. Panel Fabrication

2.2. Low-Velocity Impact Tests

2.3. Impact Depth Measurement

2.4. Damage Evaluation by Immersion Ultrasonic Testing

2.5. Microscopic Scan of Fractured Surface

3. Numerical Modelling

4. Results and Discussion

4.1. Contact Load with Time History of Combinations of Hybrid Face Sheet Specimens

4.2. Comparison of Peak Loads of Different Combinations of Foam Core Sandwich Panels

4.3. Post-Impact Inspection of Panels

5. Conclusions

- The low-velocity impact-resistant properties of the carbon fiber face sheet sandwich composites are improved with the addition of the intra-ply and inter-play hybrid Kevlar face sheets. The addition of a Kevlar layer to the face sheet improves the peak load carrying capacity of foam core sandwich panels. The inter-ply carbon/Kevlar sandwich panel shows a considerable increase of peak load when the Kevlar-ply is placed as the outer lamina in the incident face sheet. The visual inspection of the drop weight impacted specimens demonstrates the diverse damage patterns.

- The load curve for the sandwich specimens demonstrates a peak load with sudden fluctuations in the load, which denotes the failure of the incident face sheet; this is followed by a plateau region which represents the time required for the crushing of the core. The secondary peak in the load-time curve illustrates the failure of the secondary face sheet, which completes the perforation of the sandwich panel.

- The inter-ply Kevlar/carbon foam core sandwich with the Kevlar layer towards the other surface displayed a reduced length of the surface damage out of the non-perforated panels.

- The results reveal that at 30 J impact energy the intra-ply carbon/Kevlar sandwich panel displayed a peak load capacity increase of 34.10% when compared with monolithic carbon face sheet foam core sandwich panel, and at 40 J impact energy, the peak load carrying capacity of intra-ply hybrid foam core sandwich panel with Kevlar towards the outer surface of the panel is 31.57% higher when compared with the sandwich panel with carbon towards the outer surface.

- The maximum load predicted by numerical models is very close to that measured experimentally. Within a 10% margin of error, the maximum load carrying capacity of various panels was predicted.

- By visual inspection and the SEM scan, the primary damage mechanisms of the sandwich panels have been identified as fiber breakage, matrix failure, debonding of the core and the face sheet and core crushing. A small increase in the dented area is evident, but the dent depth has a significant decrease for the inter-ply hybrid sandwich panels. The water immersion C-Scan revealed the discontinuity produced by the low-velocity impact on the face sheets and the interface between the face sheet laminas. The intra-ply hybrid panels have greater load carrying capacity than the monolithic sandwich panels when subjected to low-velocity impact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Carlsson, L.A.; Sendlein, L.S.; Merry, S.L. Characterization of Face Sheet/Core Shear Fracture of Composite Sandwich Beams. J. Compos. Mater. 1991, 25, 101–116. [Google Scholar] [CrossRef]

- Caprino, G.; Teti, R. Impact and Post-Impact Behavior of Foam Core Sandwich Structures. Compos. Struct. 1994, 29, 47–55. [Google Scholar] [CrossRef]

- Zhang, S.; Dulieu-Barton, J.M.; Thomsen, O.T. The Effect of Temperature on the Failure Modes of Polymer Foam Cored Sandwich Structures. Compos. Struct. 2015, 121, 104–113. [Google Scholar] [CrossRef] [Green Version]

- Castanie, B.; Bouvet, C.; Ginot, M. Review of Composite Sandwich Structure in Aeronautic Applications. Compos. Part C Open Access 2020, 1, 100004. [Google Scholar] [CrossRef]

- Zhuang, W.; Yang, C.; Wu, Z. Mechanical Stability of Hybrid Corrugated Sandwich Plates under Fluid-Structure-Thermal Coupling for Novel Thermal Protection Systems. Appl. Sci. 2020, 10, 2790. [Google Scholar] [CrossRef] [Green Version]

- Tarlochan, F. Sandwich Structures for Energy Absorption Applications: A Review. Materials 2021, 14, 4731. [Google Scholar] [CrossRef] [PubMed]

- Eyvazian, A.; Taghizadeh, S.A.; Hamouda, A.M.; Tarlochan, F.; Moeinifard, M.; Gobbi, M. Buckling and crushing behavior of foam-core hybrid composite sandwich columns under quasi-static edgewise compression. J. Sandw. Struct. Mater. 2021, 23, 2643–2670. [Google Scholar] [CrossRef]

- Waddar, S.; Pitchaimani, J.; Doddamani, M.; Barbero, E. Buckling and Vibration Behaviour of Syntactic Foam Core Sandwich Beam with Natural Fiber Composite Facings under Axial Compressive Loads. Compos. Part B Eng. 2019, 175, 107133. [Google Scholar] [CrossRef]

- Galatas, A.; Hassanin, H.; Zweiri, Y.; Seneviratne, L. Additive Manufactured Sandwich Composite/ABS Parts for Unmanned Aerial Vehicle Applications. Polymers 2018, 10, 1262. [Google Scholar] [CrossRef] [Green Version]

- Wu, Y.; Wan, Y. The Low-Velocity Impact and Compression after Impact (CAI) Behavior of Foam Core Sandwich Panels with Shape Memory Alloy Hybrid Face-Sheets. Sci. Eng. Compos. Mater. 2019, 26, 517–530. [Google Scholar] [CrossRef]

- Wang, J.; Li, J.; GangaRao, H.; Liang, R.; Chen, J. Low-Velocity Impact Responses and CAI Properties of Synthetic Foam Sandwiches. Compos. Struct. 2019, 220, 412–422. [Google Scholar] [CrossRef] [Green Version]

- Schubel, P.M.; Luo, J.-J.; Daniel, I.M. Low Velocity Impact Behavior of Composite Sandwich Panels. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1389–1396. [Google Scholar] [CrossRef]

- Abo Sabah, S.H.; Kueh, A.B.H.; Bunnori, N.M. Failure Mode Maps of Bio-Inspired Sandwich Beams under Repeated Low-Velocity Impact. Compos. Sci. Technol. 2019, 182, 107785. [Google Scholar] [CrossRef]

- Wang, Z.; Meng, G.; Wang, L.; Tian, L.; Chen, S.; Wu, G.; Kong, B.; Cheng, Y. Simultaneously enhanced dielectric properties and through-plane thermal conductivity of epoxy composites with alumina and boron nitride nanosheets. Sci. Rep. 2021, 11, 2495. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Wang, X.; Wang, S.; He, J.; Zhang, T.; Wang, J.; Wu, G. Simultaneously Enhanced Thermal Conductivity and Dielectric Breakdown Strength in Sandwich AlN/Epoxy Composites. Nanomaterials 2021, 11, 1898. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhao, N.; He, J.; Wang, S.; Wu, G.; Cheng, Y. The desirable dielectric properties and high thermal conductivity of epoxy composites with the cobweb-structured SiCnw–SiO2–NH2 hybrids. J. Mater. Sci. Mater. Electron. 2021, 32, 20973–20984. [Google Scholar] [CrossRef]

- Zhu, Y.; Sun, Y. Low-Velocity Impact Response of Multilayer Foam Core Sandwich Panels with Composite Face Sheets. Int. J. Mech. Sci. 2021, 209, 106704. [Google Scholar] [CrossRef]

- Foo, C.C.; Seah, L.K.; Chai, G.B. Low-Velocity Impact Failure of Aluminium Honeycomb Sandwich Panels. Compos. Struct. 2008, 85, 20–28. [Google Scholar] [CrossRef]

- Fatima, N.S.; Dhaliwal, G.S.; Newaz, G. Influence of Interfacial Adhesive on Impact and Post-Impact Behaviors of CFRP/End-Grain Balsawood Sandwich Composites. Compos. Part B Eng. 2021, 212, 108718. [Google Scholar] [CrossRef]

- Wang, M.; Pan, Z.; Wu, Z.; Ying, Z. Effect of Carbon/Kevlar Asymmetric Hybridization Ratio on the Low-Velocity Impact Response of Plain-Woven Laminates. Compos. Struct. 2021, 276, 114574. [Google Scholar] [CrossRef]

- Vasudevan, A.; Senthil Kumaran, S.; Naresh, K.; Velmurugan, R. Layer-wise damage prediction in carbon/Kevlar/S-glass/E-glass fibre reinforced epoxy hybrid composites under low-velocity impact loading using advanced 3D computed tomography. Int. J. Crashworthiness 2020, 25, 9–23. [Google Scholar] [CrossRef]

- Bandaru, A.K.; Patel, S.; Ahmad, S.; Bhatnagar, N. An experimental and numerical investigation on the low velocity impact response of thermoplastic hybrid composites. J. Compos. Mater. 2018, 52, 877–889. [Google Scholar] [CrossRef]

- Priyanka, P.; Dixit, A.; Mali, H.S. High-Strength Hybrid Textile Composites with Carbon, Kevlar, and E-Glass Fibers for Impact-Resistant Structures. A Review. Mech Compos. Mater. 2017, 53, 685–704. [Google Scholar] [CrossRef]

- Sy, B.L.; Oguamanam, D.; Bougherara, H. Impact Response of a New Kevlar/Flax/Epoxy Hybrid Composite Using Infrared Thermography and High-Speed Imaging. Compos. Struct. 2022, 280, 114885. [Google Scholar] [CrossRef]

- Wang, C.; Su, D.; Xie, Z.; Zhang, K.; Wu, N.; Han, M.; Zhou, M. Low-Velocity Impact Response of 3D Woven Hybrid Epoxy Composites with Carbon and Heterocyclic Aramid Fibres. Polym. Test. 2021, 101, 107314. [Google Scholar] [CrossRef]

- Sarasini, F.; Tirillò, J.; D’Altilia, S.; Valente, T.; Santulli, C.; Touchard, F.; Chocinski-Arnault, L.; Mellier, D.; Lampani, L.; Gaudenzi, P. Damage Tolerance of Carbon/Flax Hybrid Composites Subjected to Low Velocity Impact. Compos. Part B Eng. 2016, 91, 144–153. [Google Scholar] [CrossRef]

- Sarwar, A.; Mahboob, Z.; Zdero, R.; Bougherara, H. Mechanical Characterization of a New Kevlar/Flax/Epoxy Hybrid Composite in a Sandwich Structure. Polym. Test. 2020, 90, 106680. [Google Scholar] [CrossRef]

- Xia, F.; Wu, X. Work on Low-velocity Impact Properties of Foam Sandwich Composites with Various Face Sheets. J. Reinf. Plast. Compos. 2010, 29, 1045–1054. [Google Scholar] [CrossRef]

- Jhou, S.-Y.; Hsu, C.-C.; Yeh, J.-C. The Dynamic Impact Response of 3D-Printed Polymeric Sandwich Structures with Lattice Cores: Numerical and Experimental Investigation. Polymers 2021, 13, 4032. [Google Scholar] [CrossRef]

- Xia, F.; Qing, X. Work on Impact Properties of Foam Sandwich Composites with Different Structure. J. Sandw. Struct. Mater. 2010, 12, 47–62. [Google Scholar] [CrossRef]

- Pinho, A.C.; Piedade, A.P. Sandwich Multi-Material 3D-Printed Polymers: Influence of Aging on the Impact and Flexure Resistances. Polymers 2021, 13, 4030. [Google Scholar] [CrossRef] [PubMed]

- Sharif, U.; Sun, B.; Hussain, S.; Ibrahim, D.S.; Adewale, O.O.; Ashraf, S.; Bashir, F. Dynamic Behavior of Sandwich Structures with Magnetorheological Elastomer: A Review. Materials 2021, 14, 7025. [Google Scholar] [CrossRef] [PubMed]

- Farokhi Nejad, A.; Rahimian Koloor, S.S.; Syed Hamzah, S.M.S.A.; Yahya, M.Y. Mechanical Behaviour of Pin-Reinforced Foam Core Sandwich Panels Subjected to Low Impact Loading. Polymers 2021, 13, 3627. [Google Scholar] [CrossRef] [PubMed]

- Quadrini, F.; Bellisario, D.; Iorio, L.; Santo, L.; Pappas, P.; Koutroumanis, N.; Anagnostopoulos, G.; Galiotis, C. Shape Memory Composite Sandwich Structures with Self-Healing Properties. Polymers 2021, 13, 3056. [Google Scholar] [CrossRef]

- Dogan, A. Low-velocity impact, bending, and compression response of carbon fiber/epoxy-based sandwich composites with different types of core materials. J. Sandw. Struct. Mater. 2021, 23, 1956–1971. [Google Scholar] [CrossRef]

- Mouritz, A.P. Review of Z-Pinned Laminates and Sandwich Composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106128. [Google Scholar] [CrossRef]

- Santhanakrishnan, R.; Samlal, S.; Stanley, A.J.; Jayalatha, J. Impact study on sandwich panels with and without stitching. Adv. Compos. Mater. 2018, 27, 163–182. [Google Scholar] [CrossRef]

- Palazotto, A.N.; Gummadi, L.N.B.; Vaidya, U.K.; Herup, E.J. Low Velocity Impact Damage Characteristics of Z-Fiber Reinforced Sandwich Panels—An Experimental Study. Compos. Struct. 1998, 43, 275–288. [Google Scholar] [CrossRef]

- Mostafa, A.; Shankar, K.; Morozov, E.V. Effect of Shear Keys Diameter on the Shear Performance of Composite Sandwich Panel with PVC and PU Foam Core: FE Study. Compos. Struct. 2013, 102, 90–100. [Google Scholar] [CrossRef]

- Hartley, J.W.; Kratz, J.; Ward, C.; Partridge, I.K. Effect of Tufting Density and Loop Length on the Crushing Behaviour of Tufted Sandwich Specimens. Compos. Part B Eng. 2017, 112, 49–56. [Google Scholar] [CrossRef] [Green Version]

- Balıkoğlu, F.; Demircioğlu, T.K.; İnal, O.; Arslan, N.; Ataş, A. Compression after Low Velocity Impact Tests of Marine Sandwich Composites: Effect of Intermediate Wooden Layers. Compos. Struct. 2018, 183, 636–642. [Google Scholar] [CrossRef]

- Gustin, J.; Joneson, A.; Mahinfalah, M.; Stone, J. Low Velocity Impact of Combination Kevlar/Carbon Fiber Sandwich Composites. Compos. Struct. 2005, 69, 396–406. [Google Scholar] [CrossRef]

- Mohmmed, R.; Zhang, F.; Sun, B.; Gu, B. Static and low-velocity impact on mechanical behaviors of foam sandwiched composites with different ply angles face sheets. J. Compos. Mater. 2014, 48, 1173–1188. [Google Scholar] [CrossRef]

- Dehkordi, M.T.; Nosraty, H.; Shokrieh, M.M.; Minak, G.; Ghelli, D. Low Velocity Impact Properties of Intra-Ply Hybrid Composites Based on Basalt and Nylon Woven Fabrics. Mater. Des. 2010, 31, 3835–3844. [Google Scholar] [CrossRef]

- Jayaram, R.; Nagarajan, V.; Kumar, K.V. Low velocity impact and compression after impact behaviour of polyester pin-reinforced foam filled honeycomb sandwich panels. J. Sandw. Struct. Mater. 2022, 24, 157–173. [Google Scholar] [CrossRef]

- Zangana, S.; Epaarachchi, J.; Ferdous, W.; Leng, J.; Schubel, P. Behaviour of Continuous Fibre Composite Sandwich Core under Low-Velocity Impact. Thin-Walled Struct. 2021, 158, 107157. [Google Scholar] [CrossRef]

- Feng, D.; Aymerich, F. Effect of Core Density on the Low-Velocity Impact Response of Foam-Based Sandwich Composites. Compos. Struct. 2020, 239, 112040. [Google Scholar] [CrossRef]

- Mohammadkhani, P.; Jalali, S.S.; Safarabadi, M. Experimental and Numerical Investigation of Low-Velocity Impact on Steel Wire Reinforced Foam Core/Composite Skin Sandwich Panels. Compos. Struct. 2021, 256, 112992. [Google Scholar] [CrossRef]

- Divinycell-H Home Page. Available online: https://www.diabgroup.com/products/divinycell-pvc/divinycell-h/ (accessed on 1 December 2021).

- Fiberglast Home Page. Available online: https://www.fibreglast.com/category/Composite-Fabrics (accessed on 1 December 2021).

- Araldite® GY 257 Home Page. Available online: https://www.ulprospector.com/en/asia/Adhesives/Detail/21260/564569/Araldite-GY-257 (accessed on 1 December 2021).

- ASTM D5628-18; Standard Test Method for Impact Resistance of Flat, Rigid Plastic Specimens by Means of a Falling Dart (Tup or Falling Mass); ASTM International Standards Organization: West Conshohocken, PA, USA, 2018; (revised 14 June 2018).

- Sartip, Z.; Jayantha, E.; Wahid, F.; Jinsong, L. A novel hybridised composite sandwich core with Glass, Kevlar and Zylon fibres—Investigation under low-velocity impact. Int. J. Impact Eng. 2020, 137, 103430. [Google Scholar] [CrossRef]

- Bao, J.W.; Wang, Y.W.; An, R.; Cheng, H.W.; Wang, F.C. Investigation of the mechanical and ballistic properties of hybrid carbon/aramid woven laminates. Def. Technol. 2021, in press. [Google Scholar] [CrossRef]

- Nunes, S.G.; Scazzosi, R.; Manes, A.; Amico, S.C.; de Amorim Júnior, W.F.; Giglio, M. Influence of projectile and thickness on the ballistic behavior of aramid composites: Experimental and numerical study. Int. J. Impact Eng. 2019, 132, 103307. [Google Scholar] [CrossRef]

- Feraboli, P.; Wade, B.; Deleo, F.; Rassaian, M.; Higgins, M.; Byar, A. LS-DYNA MAT54 modeling of the axial crushing of a composite tape sinusoidal specimen. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1809–1825. [Google Scholar] [CrossRef]

- Rajaneesh, A.; Sridhar, I.; Rajendran, S. Relative performance of metal and polymeric foam sandwich plates under low velocity impact. Int. J. Impact Eng. 2014, 65, 126–136. [Google Scholar] [CrossRef]

| Property | Value |

|---|---|

| Density (kg/m3) | 80 |

| Compressive Strength (Mpa) | 1.28 |

| Compressive Modulus (Mpa) | 85 |

| Tensile Strength (Mpa) | 2.4 |

| Tensile Modulus (Mpa) | 80 |

| Shear Strength (Mpa) | 1.05 |

| Shear Modulus (Mpa) | 25 |

| Shear Strain (%) | 30 |

| Property | Cabron | Kevlar | Intra-Ply Hybrid |

|---|---|---|---|

| Weave pattern | 2 × 2 Twill weave | Plain weave | 2 × 2 Twill weave |

| Area density (g/m3) | 193 | 170 | 186 |

| Thickness (mm) | 0.305 | 0.298 | 0.305 |

| Rows per inch | 12.5 × 12.5 | 15 × 15 | 12.5 × 12.5 |

| Property | Value |

|---|---|

| Appearance | Clear |

| Epoxy value (eq/Kg) | 5.15–5.45 |

| Weight per epoxide (g/eq) | 185–195 |

| Viscosity at 25 °C (mPa.s) | 525–725 |

| Density at 25 °C (g/mm3) | 1.15 × 10−6 |

| Flash point | ≥140 °C |

| Specimen Notation | Hybrid Structure | Layer Sequence | Average Thickness (mm) | Diagram |

|---|---|---|---|---|

| S-CF | Carbon-foam core sandwich | [C2/Foam core/C2] | 12.40 |  |

| S-KF | Kevlar-foam core sandwich | [K2/Foam core/K2] | 12.30 |  |

| IE-CKF | Inter-hybrid carbon/Kevlar sandwich | [C/K/Foam core/K/C] | 12.36 |  |

| IE-KCF | Inter-hybrid carbon/Kevlar sandwich | [K/C/Foam core/C/K] | 12.35 |  |

| IA-HF | Intra-hybrid carbon/Kevlar sandwich | [H2/Foam core/H2] | 12.37 |  |

-Carbon woven fabric;

-Carbon woven fabric;  -Kevlar woven fabric;

-Kevlar woven fabric;  -Intra-hybrid carbon/Kevlar;

-Intra-hybrid carbon/Kevlar;  -Foam core.

-Foam core.| Sandwich Panel Code | Sandwich Structure | Energy Level (J) | Length of the Surface Damage (Incident Face Sheet) d1 (mm) | Length of the Surface Damage (Incident Face Sheet) d2 (mm) | Average Length of the Surface Damage (Incident Face Sheet) d (mm) |

|---|---|---|---|---|---|

| S-CF | Carbon-foam core sandwich | 5 | 17.00 | 17.04 | 17.02 |

| 10 | 24.21 | 19.06 | 21.64 1 | ||

| 20 | 22.42 | 21.91 | 22.17 2 | ||

| 30 | 24.09 | 20.90 | 22.50 2 | ||

| 40 | 24.36 | 20.98 | 22.67 2 | ||

| S-KF | Kevlar-foam core sandwich | 5 | 20.43 | 20.01 | 20.22 |

| 10 | 22.39 | 21.90 | 22.15 | ||

| 20 | 28.47 | 26.42 | 27.44 | ||

| 30 | 28.44 | 27.00 | 27.72 | ||

| 40 | 37.16 | 34.46 | 35.81 | ||

| IE-CKF | Inter-ply Carbon/Kevlar foam core sandwich | 5 | 12.04 | 11.20 | 11.62 |

| 10 | 20.04 | 19.02 | 19.53 | ||

| 20 | 25.22 | 22.98 | 24.10 | ||

| 30 | 34.83 | 22.95 | 28.89 | ||

| 40 | 34.30 | 31.04 | 32.67 | ||

| IE-KCF | Inter-ply Kevlar/carbon foam core sandwich | 5 | 10.10 | 8.95 | 9.53 |

| 10 | 17.24 | 14.51 | 15.87 | ||

| 20 | 22.40 | 22.60 | 22.50 | ||

| 30 | 26.13 | 26.52 | 26.33 | ||

| 40 | 30.28 | 30.96 | 30.62 | ||

| IA-HF | Intra-ply carbon/Kevlar foam core sandwich | 5 | 14.92 | 13.92 | 14.42 |

| 10 | 23.98 | 21.98 | 22.98 | ||

| 20 | 22.32 | 23.91 | 23.11 1 | ||

| 30 | 22.43 | 24.80 | 23.61 2 | ||

| 40 | 24.40 | 24.97 | 24.68 2 |

| Sandwich Panel Code | Energy Level (J) | Experimental Maximum Load (N) | Numerical Maximum Load (N) | % Deviation |

|---|---|---|---|---|

| S-CF | 5 | 636.5 | 658.3 | 3.42 |

| 10 | 962.3 | 1008.3 | 4.79 | |

| 20 | 1082.9 | 1180.2 | 8.99 | |

| 30 | 1112.3 | 1222.6 | 9.92 | |

| 40 | 1368.2 | 1470.4 | 7.47 | |

| S-KF | 5 | 802.6 | 862.3 | 7.44 |

| 10 | 1922.0 | 2110.8 | 9.82 | |

| 20 | 2593.2 | 2682.9 | 3.46 | |

| 30 | 3111.4 | 3283.6 | 5.53 | |

| 40 | 3491.1 | 3828.4 | 9.66 | |

| IE-CKF | 5 | 847.0 | 924.3 | 9.12 |

| 10 | 1402.5 | 1536.6 | 9.56 | |

| 20 | 2026.2 | 2184.8 | 7.83 | |

| 30 | 2286.3 | 2492.8 | 9.03 | |

| 40 | 2829.7 | 2968.6 | 4.91 | |

| IE-KCF | 5 | 1225.7 | 1328.6 | 8.39 |

| 10 | 2512.4 | 2758.1 | 9.78 | |

| 20 | 2744.5 | 3018.3 | 9.98 | |

| 30 | 3182.5 | 3488.6 | 9.62 | |

| 40 | 3723.9 | 3883.2 | 4.28 | |

| IA-HF | 5 | 802.6 | 872.3 | 8.69 |

| 10 | 1032.8 | 1127.5 | 9.16 | |

| 20 | 1198.6 | 1302.5 | 8.67 | |

| 30 | 1491.6 | 1634.3 | 9.57 | |

| 40 | 1548.3 | 1690.2 | 9.16 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samlal, S.; Santhanakrishnan, R. Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets. Polymers 2022, 14, 1060. https://doi.org/10.3390/polym14051060

Samlal S, Santhanakrishnan R. Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets. Polymers. 2022; 14(5):1060. https://doi.org/10.3390/polym14051060

Chicago/Turabian StyleSamlal, Stanley, and R. Santhanakrishnan. 2022. "Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets" Polymers 14, no. 5: 1060. https://doi.org/10.3390/polym14051060

APA StyleSamlal, S., & Santhanakrishnan, R. (2022). Low-Velocity Impact Behavior of Foam Core Sandwich Panels with Inter-Ply and Intra-Ply Carbon/Kevlar/Epoxy Hybrid Face Sheets. Polymers, 14(5), 1060. https://doi.org/10.3390/polym14051060