On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders

Abstract

:1. Introduction

2. Theoretical Background

2.1. Light Interaction with Matter

2.2. Assessment of the Mixing Level with RTD Curves

3. Materials and Methods

3.1. Materials

3.2. Experimental Set-Up

- (i)

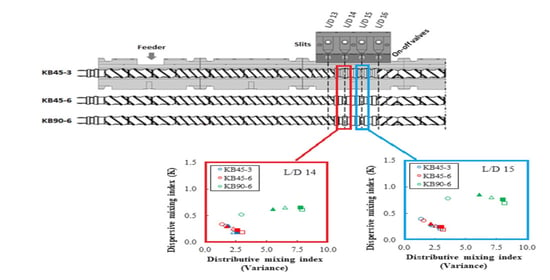

- The three screws have the same configuration up to L/D = 13, consisting of conveying elements with decreasing pitch downstream.

- (ii)

- The three screws have the same configuration from L/D = 16 onwards, starting with two left-handed (LH) elements (each 15 mm long), in order to ensure that they worked fully filled upstream, at least at L/D = 16, so that a material sample could be collected for an optical measurement.

- (iii)

- Between L/D = 13 and L/D = 16, three distinct mixing zones were assembled: (1) four kneading blocks with positive 45° stagger, each containing five 3 mm thick disks (KB45-3); (2) two kneading blocks with 45° positive stagger, each containing five 6 mm thick disks (KB45-6); (3) two kneading blocks with neutral 90° stagger, each containing five 6 mm thick disks (KB90-6).

3.3. Experimental Procedure

4. Results and Discussion

4.1. Flow along the Mixing Zone

4.2. Assessing Mixing

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Manas-Zloczower, I. Mixing and Compounding of Polymers: Theory and Practice, 2nd ed.; Carl Hanser Verlag GmbH & Co.: Munich, Germany, 2009. [Google Scholar]

- Tadmor, Z.; Gogos, C.G. Principles of Polymer Processing, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2006. [Google Scholar]

- Domingues, N.; Gaspar-Cunha, A.; Covas, J.A. A quantitative approach to assess the mixing ability of single-screw extruders for polymer extrusion. J. Polym. Eng. 2012, 32, 81–93. [Google Scholar] [CrossRef]

- Sarhangi Fard, A.; Hulsen, M.A.; Meijer, H.E.H.; Famili, N.M.H.; Anderson, P.D. Tools to simulate distributive mixing in twin-screw extruders. Macromol. Theory Simul. 2012, 21, 217–240. [Google Scholar] [CrossRef]

- Wang, W.; Manas-Zloczower, I.; Kaufman, M. Entropic characterization of distributive mixing in polymer processing equipment. AIChE J. 2003, 49, 1637–1644. [Google Scholar] [CrossRef]

- Puaux, J.P.; Bozga, G.; Ainser, A. Residence time distribution in a corotating twin-screw extruder. Chem. Eng. Sci. 2000, 55, 1641–1651. [Google Scholar] [CrossRef]

- Lawal, A.; Kalyon, D.M. Mechanisms of mixing in single and co-rotating twin screw extruders. Polym. Eng. Sci. 1995, 35, 1325–1338. [Google Scholar] [CrossRef]

- Alsteens, B.; Legat, V.; Avalosse, T. Parametric study of the mixing efficiency in a kneading block section of a twin-screw extruder. Int. Polym. Process. 2004, 19, 207–217. [Google Scholar] [CrossRef] [Green Version]

- Kim, N.; Kim, H.; Lee, J. Numerical analysis of internal flow and mixing performance in polymer extruder II: Twin screw element. Korea Aust. Rheol. J. 2006, 18, 153–160. [Google Scholar]

- Wesholowski, J.; Berghaus, A.; Thommes, M. Investigations concerning the residence time distribution of twin-screw-extrusion processes as indicator for inherent mixing. Pharmaceutics 2018, 10, 207. [Google Scholar] [CrossRef] [Green Version]

- Kao, S.V.; Allison, G.R. Residence time distribution in a twin screw extruder. Polym. Eng. Sci. 1984, 24, 645–651. [Google Scholar] [CrossRef]

- Gao, J.; Walsh, G.C.; Bigio, D.; Briber, R.M.; Wetzel, M.D. Mean residence time analysis for twin screw extruders. Polym. Eng. Sci. 2000, 40, 227–237. [Google Scholar] [CrossRef]

- Oberlehner, J.; Cassagnau, P.; Michel, A. Local residence time distribution in a twin screw extruder. Chem. Eng. Sci. 1994, 49, 3897–3907. [Google Scholar] [CrossRef]

- Lee, S.M.; Park, J.C.; Lee, S.M.; Ahn, Y.J.; Lee, J.W. In-line measurement of residence time distribution in twin-screw extruder using non-destructive ultrasound. Korea Aust. Rheol. J. 2005, 17, 87–95. [Google Scholar]

- Ziegler, G.R.; Aguilar, C.A. Residence time distribution in a co-rotating, twin-screw continuous mixer by the step change method. J. Food Eng. 2003, 59, 161–167. [Google Scholar] [CrossRef]

- Poulesquen, A.; Vergnes, B. A study of residence time distribution in co-rotating twin-screw extruders. Part I: Theoretical modeling. Polym. Eng. Sci. 2003, 43, 1841–1848. [Google Scholar] [CrossRef]

- Poulesquen, A.; Vergnes, B.; Cassagnau, P.; Michel, A.; Carneiro, O.S.; Covas, J.A. A study of residence time distribution in co-rotating twin-screw extruders. Part II: Experimental validation. Polym. Eng. Sci. 2003, 43, 1849–1862. [Google Scholar] [CrossRef]

- Lepschi, A.; Gerstorfer, G.; Miethlinger, J. Determining the residence time distribution of various screw elements in a co-rotating twin-screw extruder by means of fluorescence spectroscopy. AIP Conf. Proc. 2015, 1664, 1–5. [Google Scholar] [CrossRef]

- Emin, M.A.; Schuchmann, H.P. Analysis of the dispersive mixing efficiency in a twin-screw extrusion processing of starch based matrix. J. Food Eng. 2013, 115, 132–143. [Google Scholar] [CrossRef]

- Scurati, A.; Feke, D.L.; Manas-Zloczower, I. Analysis of the kinetics of agglomerate erosion in simple shear flows. Chem. Eng. Sci. 2005, 60, 6564–6573. [Google Scholar] [CrossRef]

- Valette, R.; Coupez, T.; David, C.; Vergnes, B. A direct 3D numerical simulation code for extrusion and mixing processes. Int. Polym. Process. 2009, 24, 141–147. [Google Scholar] [CrossRef]

- Pandey, V.; Chen, T.; Guo, M.; Maia, J.M. Simple and immediate quantitative evaluation of dispersive mixing. Polym. Test. 2020, 88, 106587. [Google Scholar] [CrossRef]

- Prezenszky, A.C.; Ambrósio, J.D.; Pessan, L.A.; Hage Jr., E. Correlation between processing, morphology and impact resistance of PBT/ABS blends. Mater. Res. 2017, 20, 452–457. [Google Scholar] [CrossRef] [Green Version]

- Yao, C.-H.; Manas-Zloczower, I. Influence of design on mixing efficiency in a variable intermeshing clearance mixer. Int. Polym. Process. 1997, 12, 92–103. [Google Scholar] [CrossRef]

- Ishikawa, T.; Amano, T.; Kihara, S.-I.; Funatsu, K. Flow patterns and mixing mechanisms in the screw mixing element of a co-rotating twin-screw extruder. Polym. Eng. Sci. 2002, 42, 925–939. [Google Scholar] [CrossRef]

- Wei, J.; Liang, X.L.; Chen, D.B.; Yang, Y.L.; Zhou, D.M. Evaluation of the mixing performance for one novel twin screw kneader with particle tracking. Polym. Eng. Sci. 2014, 54, 2407–2419. [Google Scholar] [CrossRef]

- Carson, S.O.; Maia, J.M.; Covas, J.A. A new extensional mixing element for improved dispersive mixing in twin-screw extrusion, Part 2: Experimental validation for immiscible polymer blends. Adv. Polym. Technol. 2018, 37, 167–175. [Google Scholar] [CrossRef]

- Chen, H.; Pandey, V.; Carson, S.; Maia, J.M. Enhanced dispersive mixing in twin-screw extrusion via extension-dominated static mixing elements of varying contraction ratios. Int. Polym. Process. 2020, 35, 37–49. [Google Scholar] [CrossRef]

- Alemaskin, K.; Manas–Zloczower, I.; Kaufman, M. Index for simultaneous dispersive and distributive mixing characterization in processing equipment. Int. Polym. Process. 2004, 19, 327–334. [Google Scholar] [CrossRef]

- Teixeira, E.C.; do Nascimento Siqueira, R. Performance assessment of hydraulic efficiency indexes. J. Environ. Eng. 2008, 134, 851–859. [Google Scholar] [CrossRef]

- Saerens, L.; Vervaet, C.; Remon, J.P.; De Beer, T. Process monitoring and visualization solutions for hot-melt extrusion: A review. J. Pharm. Pharmacol. 2014, 66, 180–203. [Google Scholar] [CrossRef] [Green Version]

- Aime, S.; Ramos, L.; Fromental, J.M.; Prévot, G.; Jelinek, R.; Cipelletti, L. A stress-controlled shear cell for small-angle light scattering and microscopy. Rev. Sci. Instrum. 2016, 87, 123907. [Google Scholar] [CrossRef] [Green Version]

- Schlatter, G.; Serra, C.; Bouquey, M.; Muller, R.; Terrisse, J. Online light scattering measurements: A method to assess morphology development of polymer blends in a twin-screw extruder. Polym. Eng. Sci. 2002, 42, 1965–1975. [Google Scholar] [CrossRef]

- Jourdainne, L.; Boumbimba, R.M.; Triki, B.; Bouquey, M.; Muller, R.; Hébraud, P.; Pfeiffer, P. Compact and flexible optical sensor designed for on-line monitoring. Int. J. Mater. Form. 2012, 5, 1–9. [Google Scholar] [CrossRef]

- Lakshmanan, M.; Kanna, T.; Radhakrishnan, R. Shape-changing collisions of coupled bright solitons in birefringent optical fibers. Rep. Math. Phys. 2000, 46, 143–156. [Google Scholar] [CrossRef] [Green Version]

- Bernardo, F.O.C.; Silva, J.M.; Canevarolo, S.V. Dispersed particle size characterization by in-line turbidimetry during polymer extrusion. Polym. Test. 2018, 70, 449–457. [Google Scholar] [CrossRef]

- Becker, W.; Guschin, V.; Mikonsaari, I.; Teipel, U.; Kölle, S.; Weiss, P. Turbidimetric method for the determination of particle sizes in polypropylene/clay-composites during extrusion. Anal. Bioanal. Chem. 2017, 409, 741–751. [Google Scholar] [CrossRef] [PubMed]

- Bicalho, L.A.; Covas, J.A.; Canevarolo, S.V. Online optical monitoring of polymer melting in a twin-screw extruder. Polym. Eng. Sci. 2020, 60, 2163–2175. [Google Scholar] [CrossRef]

- Bohren, C.F.; Huffman, D.R. Absorption and Scattering of Light by Small Particles, 1st ed.; John Wiley & Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Søndergaard, K.; Lyngaae-Jørgensen, J. Rheo-Physics of Multiphase Polymer Systems: Characterization by Rheo-optical Techniques, 1st ed.; Technomic Pub. Co.: Lancaster, PA, USA, 1995. [Google Scholar]

- Santos, A.M.C.; Cáceres, C.A.; Calixto, L.S.; Zborowski, L.; Canevarolo, S.V. In-line optical techniques to characterize the polymer extrusion. Polym. Eng. Sci. 2014, 54, 386–395. [Google Scholar] [CrossRef]

- Van de Hulst, H.C. Light Scattering by Small Particles, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 1983. [Google Scholar]

- Zborowski, L.; Canevarolo, S.V. In-line turbidity monitoring of the second phase droplets deformation during extrusion. Polym. Eng. Sci. 2013, 53, 2422–2428. [Google Scholar] [CrossRef]

- Meeten, G.H. Optical Properties of Polymers, 1st ed.; Elsevier Science Publishing: Amsterdam, The Netherlands, 1986. [Google Scholar]

- Folkes, M.J.; Keller, A. The birefringence and mechanical properties of a ‘single crystal’ from a three-block copolymer. Polymer 1971, 12, 222–236. [Google Scholar] [CrossRef]

- Folkes, M.J.; Keller, A.; Odell, J.A. Optical and swelling properties of macroscopic “single crystals” of an S–B–S copolymer. II. Samples possessing a cylindrical morphology. J. Polym. Sci. Polym. Phys. Ed. 1976, 14, 847–859. [Google Scholar] [CrossRef]

- Danckwerts, P.V. Continuous flow systems. Chem. Eng. Sci. 1953, 2, 1–13. [Google Scholar] [CrossRef]

- Sebastian Escotet-Espinoza, M.; Moghtadernejad, S.; Oka, S.; Wang, Y.; Roman-Ospino, A.; Schäfer, E.; Cappuyns, P.; Van Assche, I.; Futran, M.; Ierapetritou, M.; et al. Effect of tracer material properties on the residence time distribution (RTD) of continuous powder blending operations. Part I of II: Experimental evaluation. Powder Technol. 2019, 342, 744–763. [Google Scholar] [CrossRef]

- Canevarolo, S.V.; Mélo, T.J.A.; Covas, J.A.; Carneiro, O.S. Direct method for deconvoluting two residence time distribution curves. Int. Polym. Proc. 2001, 16, 334–340. [Google Scholar] [CrossRef]

- Fozilov, M.M.; Chistyakova, T.B.; Polosin, A.N. Computer system of vibration analysis for evaluating extrusion equipament operability at productions of multi-assortment polymeric films. J. Phys. Conf. Ser. 2021, 1902, 12–44. [Google Scholar] [CrossRef]

- Kohlgrüber, K. Co-Rotating Twin-Screw Extruders: Fundamentals, Technology and Applications, 1st ed.; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2007. [Google Scholar]

- Teixeira, C.; Gaspar-Cunha, A.; Covas, J.A. Flow and heat transfer along the length of a co-rotating twin screw extruder. Polym. Plast. Technol. Eng. 2012, 51, 1567–1577. [Google Scholar] [CrossRef]

- Domenech, T.; Peuvrel-Disdier, E.; Vergnes, B. The importance of specific mechanical energy during twin screw extrusion of organoclay based polypropylene nanocomposites. Compos. Sci. Technol. 2013, 75, 7–14. [Google Scholar] [CrossRef] [Green Version]

- Fang, Y.; Zhang, B.; Wei, Y. Effects of the specific mechanical energy on the physicochemical properties of texturized soy protein during high-moisture extrusion cooking. J. Food Eng. 2014, 121, 32–38. [Google Scholar] [CrossRef]

- Kolter, K.; Karl, M.; Gryckze, A. Hot-Melt Extrusion with BASF Pharma Polymers, 2nd ed.; BASF SE: Ludwigshafen, Germany, 2012. [Google Scholar]

- Fayose, F.T.; Huan, Z. Specific mechanical energy requirement of a locally developed extruder for selected starchy crops. Food Sci. Technol. Res. 2014, 20, 793–798. [Google Scholar] [CrossRef] [Green Version]

- Carneiro, O.S.; Covas, J.A.; Ferreira, J.A.; Cerqueira, M.F. On-line monitoring of the residence time distribution along a kneading block of a twin-screw extruder. Polym. Test. 2004, 23, 925–937. [Google Scholar] [CrossRef]

- Zhang, X.-M.; Feng, L.-F.; Chen, W.-X.; Hu, G.-H. Numerical simulation and experimental validation of mixing performance of kneading discs in a twin screw extruder. Polym. Eng. Sci. 2009, 49, 1772–1783. [Google Scholar] [CrossRef]

- Teixeira, P.F.; Covas, J.A.; Hilliou, L. In-Line rheo-optical investigation of the dispersion of organoclay in a polymer matrix during twin-screw compounding. Polymers 2021, 13, 2128. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bernardo, F.; Covas, J.A.; Canevarolo, S.V. On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders. Polymers 2022, 14, 1152. https://doi.org/10.3390/polym14061152

Bernardo F, Covas JA, Canevarolo SV. On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders. Polymers. 2022; 14(6):1152. https://doi.org/10.3390/polym14061152

Chicago/Turabian StyleBernardo, Felipe, José A. Covas, and Sebastião V. Canevarolo. 2022. "On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders" Polymers 14, no. 6: 1152. https://doi.org/10.3390/polym14061152

APA StyleBernardo, F., Covas, J. A., & Canevarolo, S. V. (2022). On-Line Optical Monitoring of the Mixing Performance in Co-Rotating Twin-Screw Extruders. Polymers, 14(6), 1152. https://doi.org/10.3390/polym14061152