Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer

Abstract

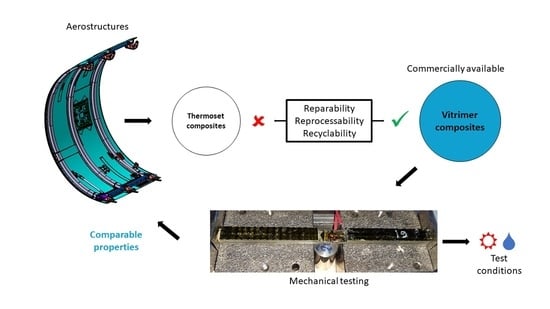

:1. Introduction

2. Experimental

2.1. Materials

2.2. Manufacturing Procedure

2.3. Tests and Equipments

2.4. Baseline Properties

3. Results and Discussion

3.1. Tg

3.2. Neat Vitrimer Tension

3.3. Neat Vitrimer Flexion

3.4. Tension

3.5. Compression

3.6. Interlaminar Shear Strength

3.7. In-Plane Shear

3.8. Open-Hole Tension, Compression and Filled-Hole Compression

3.8.1. Open-Hole Tension

3.8.2. Open-Hole Compression

3.8.3. Filled-Hole Compression

3.9. Interlaminar Fracture Toughness

4. Conclusions and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yang, Y.; Xu, Y.; Ji, Y.; Wei, Y. Functional epoxy vitrimers and composites. Prog. Mater. Sci. 2021, 120, 100710. [Google Scholar] [CrossRef]

- Liu, H.; Zhang, H.; Wang, H.; Huang, X.; Huang, G.; Wu, J. Weldable, malleable and programmable epoxy vitrimers with high mechanical properties and water insensitivity. Chem. Eng. J. 2019, 368, 61–70. [Google Scholar] [CrossRef]

- Denissen, W.; Winne, J.M.; Du Prez, F.E. Vitrimers: Permanent organic networks with glass-like fluidity. Chem. Sci. 2016, 7, 30–38. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dorigato, A. Recycling of thermosetting composites for wind blade application. Adv. Ind. Eng. Polym. Res. 2021, 4, 116–132. [Google Scholar] [CrossRef]

- Witik, R.A.; Teuscher, R.; Michaud, V.; Ludwig, C.; Månson, J.-A.E. Carbon fibre reinforced composite waste: An environmental assessment of recycling, energy recovery and landfilling. Compos. Part A Appl. Sci. Manuf. 2013, 49, 89–99. [Google Scholar] [CrossRef]

- Yuan, Y.; Sun, Y.; Yan, S.; Zhao, J.; Liu, S.; Zhang, M.; Zheng, X.; Jia, L. Multiply fully recyclable carbon fibre reinforced heat-resistant covalent thermosetting advanced composites. Nat. Commun. 2017, 8, 14657. [Google Scholar] [CrossRef]

- Azcune, I.; Odriozola, I. Aromatic disulfide crosslinks in polymer systems: Self-healing, reprocessability, recyclability and more. Eur. Polym. J. 2016, 84, 147–160. [Google Scholar] [CrossRef]

- Montarnal, D.; Capelot, M.; Tournilhac, F.; Leibler, L. Silica-Like Malleable Materials from Permanent Organic Networks. Science 2011, 334, 965–968. [Google Scholar] [CrossRef]

- Ruiz de Luzuriaga, A.; Martin, R.; Markaide, N.; Rekondo, A.; Cabañero, G.; Rodríguez, J.; Odriozola, I. Epoxy resin with exchangeable disulfide crosslinks to obtain reprocessable, repairable and recyclable fiber-reinforced thermoset composites. Mater. Horiz. 2016, 3, 241–247. [Google Scholar] [CrossRef]

- Si, H.; Zhou, L.; Wu, Y.; Song, L.; Kang, M.; Zhao, X.; Chen, M. Rapidly reprocessable, degradable epoxy vitrimer and recyclable carbon fiber reinforced thermoset composites relied on high contents of exchangeable aromatic disulfide crosslinks. Compos. Part B Eng. 2020, 199, 108278. [Google Scholar] [CrossRef]

- Kissounko, D.A.; Taynton, P.; Kaffer, C. New material: Vitrimers promise to impact composites. Reinf. Plast. 2018, 62, 162–166. [Google Scholar] [CrossRef]

- Yang, Y.; Peng, G.; Wu, S.; Hao, W. A repairable anhydride-epoxy system with high mechanical properties inspired by vitrimers. Polymer 2018, 159, 162–168. [Google Scholar] [CrossRef]

- Yu, Q.; Peng, X.; Wang, Y.; Geng, H.; Xu, A.; Zhang, X.; Xu, W.; Ye, D. Vanillin-based degradable epoxy vitrimers: Reprocessability and mechanical properties study. Eur. Polym. J. 2019, 117, 55–63. [Google Scholar] [CrossRef]

- Ji, F.; Liu, X.; Sheng, D.; Yang, Y. Epoxy-vitrimer composites based on exchangeable aromatic disulfide bonds: Reprocessibility, adhesive, multi-shape memory effect. Polymers 2020, 197, 122514. [Google Scholar] [CrossRef]

- Feng, X.; Li, G. Catalyst-free β-hydroxy phosphate ester exchange for robust fire-proof vitrimers. Chem. Eng. J. 2021, 417, 129132. [Google Scholar] [CrossRef]

- Krishnakumar, B.; Sanka, R.V.S.P.; Binder, W.H.; Park, C.; Jung, J.; Parthasarthy, V.; Rana, S.; Yun, G.J. Catalyst free self-healable vitrimer/graphene oxide nanocomposites. Compos. Part B Eng. 2020, 184, 107647. [Google Scholar] [CrossRef]

- Han, J.; Liu, T.; Hao, C.; Zhang, S.; Guo, B.; Zhang, J. A Catalyst-Free Epoxy Vitrimer System Based on Multifunctional Hyperbranched Polymer. Macromolecules 2018, 51, 6789–6799. [Google Scholar] [CrossRef]

- Zhao, W.; An, L.; Wang, S. Recyclable High-Performance Epoxy-Anhydride Resins with DMP-30 as the Catalyst of Transesterification Reactions. Polymers 2021, 13, 296. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, B.; Ma, S.; Yu, T.; Xu, X.; Li, Q.; Wang, S.; Han, Y.; Yu, Z.; Zhu, J. Catalyst-free malleable, degradable, bio-based epoxy thermosets and its application in recyclable carbon fiber composites. Compos. Part B Eng. 2021, 211, 108654. [Google Scholar] [CrossRef]

- Memon, H.; Wei, Y.; Zhang, L.; Jiang, Q.; Liu, W. An imine-containing epoxy vitrimer with versatile recyclability and its application in fully recyclable carbon fiber reinforced composites. Compos. Sci. Technol. 2020, 199, 108314. [Google Scholar] [CrossRef]

- Zhu, Y.; Gao, F.; Zhong, J.; Shen, L.; Lin, Y. Renewable castor oil and DL-limonene derived fully bio-based vinylogous urethane vitrimers. Eur. Polym. J. 2020, 135, 109865. [Google Scholar] [CrossRef]

- Alabiso, W.; Schlögl, S. The Impact of Vitrimers on the Industry of the Future: Chemistry, Properties and Sustainable Forward-Looking Applications. Polymer 2020, 12, 1660. [Google Scholar] [CrossRef]

- Wang, S.; Ma, S.; Li, Q.; Xu, X.; Wang, B.; Yuan, W.; Zhou, S.; You, S.; Zhu, J. Facile in situ preparation of high-performance epoxy vitrimer from renewable resources and its application in nondestructive recyclable carbon fiber composite. Green Chem. 2019, 21, 1484–1497. [Google Scholar] [CrossRef]

- Chabert, E.; Vial, J.; Cauchois, J.-P.; Mihaluta, M.; Tournilhac, F. Multiple welding of long fiber epoxy vitrimer composites. Soft Matter 2016, 12, 4838–4845. [Google Scholar] [CrossRef]

- Denissen, W.; De Baere, I.; Van Paepegem, W.; Leibler, L.; Winne, J.; Du Prez, F.E. Vinylogous Urea Vitrimers and Their Application in Fiber Reinforced Composites. Macromolecules 2018, 51, 2054–2064. [Google Scholar] [CrossRef] [Green Version]

- De Baere, I.; Denissen, W.; Van Paepegem, W.; Winne, J.; Du Prez, F. Assessement of urea based vitrimers as a new matrix material for fibre reinforced polymers. In Proceedings of the ECCM18—18th European Conference on Composite, Athens, Greece, 24–28 June 2018; Available online: http://hdl.handle.net/1854/LU-8569138 (accessed on 16 September 2021).

- Bangash, M.K.; Ruiz de Luzuriaga, A.; Aurrekoetxea, J.; Markaide, N.; Grande, H.-J.; Ferraris, M. Development and characterisation of dynamic bi-phase (epoxy/PU) composites for enhanced impact resistance. Compos. Part B Eng. 2018, 155, 122–131. [Google Scholar] [CrossRef]

- Taynton, P.; Ni, H.; Zhu, C.; Yu, K.; Loob, S.; Jin, Y.; Qi, H.J.; Zhang, W. Repairable Woven Carbon Fiber Composites with Full Recyclability Enabled by Malleable Polyimine Networks. Adv. Mater. 2016, 28, 2904–2909. [Google Scholar] [CrossRef] [PubMed]

- MALLINDA. Vitrimer Matrix Composites for the Circular Economy. Available online: https://www.mallinda.com/ (accessed on 9 September 2021).

- Taynton, P.; Yu, K.; Shoemaker, R.; Jin, Y.; Qi, H.J.; Zhang, W. Heat- or Water-Driven Malleability in a Highly Recyclable Covalent Network Polymer. Adv. Mater. 2014, 26, 3938–3942. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Xing, X.; Zhang, X.; Wang, X.; Jing, X. Room-temperature fully recyclable carbon fibre reinforced phenolic composites through dynamic covalent boronic ester bonds. J. Mater. Chem. A 2018, 6, 10868–10878. [Google Scholar] [CrossRef]

- Liu, X.; Li, Y.; Xing, X.; Zhang, G.; Jing, X. Fully recyclable and high performance phenolic resin based on dynamic urethane bonds and its application in self-repairable composites. Polymers 2021, 229, 124022. [Google Scholar] [CrossRef]

- Liu, T.; Hao, C.; Shao, L.; Kuang, W.; Cosimbescu, L.; Simmons, K.L.; Zhang, J. Carbon Fiber Reinforced Epoxy Vitrimer: Robust Mechanical Performance and Facile Hydrothermal Decomposition in Pure Water. Macromol. Rapid Commun. 2021, 42, e2000458. [Google Scholar] [CrossRef]

- Wang, H.; Liu, H.-C.; Zhang, Y.; Xu, H.; Jin, B.-Q.; Cao, Z.-X.; Wu, H.-T.; Huang, G.-S.; Wu, J.-R. A Triple Crosslinking Design toward Epoxy Vitrimers and Carbon Fiber Composites of High Performance and Multi-shape Memory. Chin. J. Polym. Sci. 2021, 39, 736–744. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; He, J.; Li, Y.-D.; Zhao, X.-L.; Zeng, J.-B. Biobased epoxy vitrimer from epoxidized soybean oil for reprocessable and recyclable carbon fiber reinforced composite. Compos. Commun. 2020, 22, 100445. [Google Scholar] [CrossRef]

- Liu, Y.-Y.; Liu, G.-L.; Li, Y.-D.; Weng, Y.; Zeng, J.-B. Biobased High-Performance Epoxy Vitrimer with UV Shielding for Recyclable Carbon Fiber Reinforced Composites. ACS Sustain. Chem. Eng. 2021, 9, 4638–4647. [Google Scholar] [CrossRef]

- Xu, Y.; Dai, S.; Bi, L.; Jiang, J.; Zhang, H.; Chen, Y. Catalyst-free self-healing bio-based vitrimer for a recyclable, reprocessable, and self-adhered carbon fiber reinforced composite. Chem. Eng. J. 2021, 429, 132518. [Google Scholar] [CrossRef]

- Hexcel Corporation. HexPly® 8552. 2020. Available online: https://www.hexcel.com/user_area/content_media/raw/ (accessed on 7 September 2021).

- Hexion. EPIKOTETM Resin 475 and EPIKURETM Curing Agent 375 and HELOXYTM Additive 575. 2021. Available online: https://www.hexion.com/CustomServices/PDFDownloader.aspx?type=tds&pid=77f8c63d-5814-6fe3-ae8a-ff0300fcd525 (accessed on 7 September 2021).

- Beier, U.; Fischer, F.; Sandler, J.K.; Altstädt, V.; Weimer, C.; Buchs, W. Mechanical performance of carbon fibre-reinforced composites based on stitched preforms. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1655–1663. [Google Scholar] [CrossRef]

- AIRPOXY. Thermoformable, Repairable & Bondable Smart Epoxy-Based Composites for Aero Structures. Available online: https://www.airpoxy.eu/ (accessed on 7 July 2021).

- European Commision. Thermoformable, Repairable and Bondable Smart Epoxy Based Composites for Aero Structures. 2018. Available online: https://cordis.europa.eu/project/id/769274 (accessed on 7 July 2021).

- Odriozola, I.; Ruiz de Luzuriaga, A.; Rekondo, A.; Martin, R.; Markaide, N.; Cabañero, G.; Grande, H.J. Thermomechanically Reprocessable Epoxy Composites and Processes for Their Manufacturing. US Patent US20170166717A1, 3 December 2015. [Google Scholar]

- Odriozola, I.; Ruiz de Luzuriaga, A.; Rekondo, A.; Martin, R.; Markaide, N.; Cabañero, G.; Grande, H.J. Composites de Epoxi Reprocesables Termomecánicamente y Procedimientos para su Fabricación. ES Patent ES2682954T3, 24 September 2018. [Google Scholar]

- Cidetec. 3R Leading Technology Reprocessable, Repairable and Recyclable: Materials with an Endless Lifespan. Available online: https://www.cidetec.es/en/top-achievements/3r-leading-technology (accessed on 7 July 2021).

- Chomarat. C-WEAVETM 280SA5 T800HB 6K. Available online: https://composites.chomarat.com/en/product/c-weave-280sa5-t800hb-6k/ (accessed on 7 July 2021).

- De Fontgallant, A.; Calderón, D. AIRPOXY Deliverable 1.3: Report on the Preliminary Analysis and Definition of Specifications for the Raw Materials. 2019. Available online: https://www.airpoxy.eu/wp-content/uploads/AIRPOXY-D1.3-Preliminary-specifications-for-the-raw-materials_R1.0.pdf (accessed on 7 July 2021).

- Calderón, D.; González, R.; De Fontgallant, A. AIRPOXY Deliverable 1.1: Report on the Preliminary Specifications for Demonstrators. 2019. Available online: https://www.airpoxy.eu/wp-content/uploads/AIRPOXY-D1.1-Preliminary-specifications-for-demonstrators_R1.0.pdf (accessed on 7 July 2021).

- Simacek, P.; Eksik, Ö.; Heider, D.; Gillespie, J.W.; Advani, S. Experimental validation of post-filling flow in vacuum assisted resin transfer molding processes. Compos. Part A Appl. Sci. Manuf. 2012, 43, 370–380. [Google Scholar] [CrossRef]

- Olivero, K.A.; Barraza, H.J.; O’Rear, E.A.; Altan, M.C. Effect of Injection Rate and Post-Fill Cure Pressure on Properties of Resin Transfer Molded Disks. J. Compos. Mater. 2002, 36, 2011–2028. [Google Scholar] [CrossRef] [Green Version]

- ISO Standard. Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; ISO 527-2:2012; International Organization for Standardization: Geneva, Switzerland, 2012. [Google Scholar]

- ISO Standard. Plastics—Determination of Flexural Properties; ISO 178:2019; International Organization for Standardization: Geneva, Switzerland, 2019. [Google Scholar]

- ISO Standard. Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites; ISO 527-4:1997; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO Standard. Fibre-Reinforced Plastic Composites—Determination of Compressive Properties in the In-Plane Direction; ISO 14126:1999; International Organization for Standardization: Geneva, Switzerland, 1999. [Google Scholar]

- ASTM Standard. Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials; ASTM D3410/D3410M; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ISO Standard. Fibre-Reinforced Plastic Composites Determination of Apparent Interlaminar Shear Strength by Short-Beam Method; ISO 14130:1997; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- ISO Standard. Fibre-Reinforced Plastic Composites—Determination of the Stress/Shear Strain Response, Including the In-Plane Shear Modulus and Strength by the ±45° Tension Test Method; ISO 14129:1997; International Organization for Standardization: Geneva, Switzerland, 1997. [Google Scholar]

- ASTM Standard. Standard Test Method for Open-Hole Tensile Strength of Polymer Matrix Composite Laminates; ASTM D5766/D5766M-11; ASTM International: West Conshohocken, PA, USA, 2008. [Google Scholar]

- ASTM Standard. Standard Test Method for Open-Hole Compressive Strength of Polymer Matrix; ASTM D6484/D6484M-20; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM International. Standard Practice for Filled-Hole Tension and Compression Testing of Polymer Matrix Composite Laminates; ASTM D6742/D6742M-17; ASTM International: West Conshohocken, PA, USA, 2017. [Google Scholar]

- UNE Standard. Aerospace Series—Carbon Fibre Reinforced Plastics—Test Method—Determination of Interlaminar Fracture Toughness Energy—Mode I—GIC; UNE-EN 6033:2015; Spanish Association for Standardization (UNE): Madrid, Spain, 2015. [Google Scholar]

- UNE Standard. Aerospace Series—Carbon Fibre Reinforced Plastics—Test Method—Determination of Interlaminar Fracture Toughness Energy—Mode II—GIIC (Endorsed by AENOR in January of 2016); UNE-EN 6034:2015; Spanish Association for Standardization (UNE): Madrid, Spain, 2015. [Google Scholar]

- ISO Standard. Plastics—Differential Scanning Calorimetry (DSC)—Part 2: Determination of Glass Transition Temperature and Step Height; ISO 11357-2:2020; International Organization for Standardization: Geneva, Switzerland, 2020. [Google Scholar]

- Hexcel Corporation. HexFlow® RTM6. 2018. Available online: https://www.hexcel.com/user_area/content_media/raw/RTM6_DataSheetPDF.pdf (accessed on 3 August 2021).

- Matsuhisa, Y.; Bunsell, A. Tensile failure of carbon fibers. In Handbook of Tensile Properties of Textile and Technical Fibres; Elsevier: Amsterdam, The Netherlands, 2009; pp. 574–602. [Google Scholar]

- Jeon, Y.-P.; Alway-Cooper, R.; Morales, M.; Ogale, A.A. Carbon Fibers. In Handbook of Advanced Ceramics; Elsevier: Amsterdam, The Netherlands, 2013; pp. 143–154. [Google Scholar]

- Composite Materials Database 900GPa. Product Datashhet: HEXCEL HexForce® G0926 D 1304 TCT. Available online: https://www.900gpa.com/es/product/fabric/WovenCombo_00A23AD07F?u=metric (accessed on 12 January 2021).

- Teijin. Tenax Filament Yarn. Available online: https://www.teijincarbon.com/fileadmin/PDF/Datenblätter_en/Product_Data_Sheet_TSG01en__EU_Filament_.pdf (accessed on 12 January 2021).

- Delasi, R.; Whiteside, J. Effect of Moisture on Epoxy Resins and Composites. In Advanced Composite Materials—Environmental Effects; ASTM International: West Conshohocken, PA, USA, 2009; p. 2. [Google Scholar]

- Cauich-Cupul, J.I.; Pérez-Pacheco, E.; Valadez-Gonzalez, A.; Herrera-Franco, P.J. Effect of moisture absorption on the micromechanical behavior of carbon fiber/epoxy matrix composites. J. Mater. Sci. 2011, 46, 6664–6672. [Google Scholar] [CrossRef]

- Liu, T.; Peng, J.; Liu, J.; Hao, X.; Guo, C.; Ou, R.; Liu, Z.; Wang, Q. Fully recyclable, flame-retardant and high-performance carbon fiber composites based on vanillin-terminated cyclophosphazene polyimine thermosets. Compos. Part B Eng. 2021, 224, 109188. [Google Scholar] [CrossRef]

- Aranberri, I.; Landa, M.; Elorza, E.; Salaberria, A.M.; Rekondo, A. Thermoformable and recyclable CFRP pultruded profile manufactured from an epoxy vitrimer. Polym. Test. 2021, 93, 106931. [Google Scholar] [CrossRef]

- Hamada, H.; Oya, N.; Yamashita, K.; Maekawa, Z.-I. Tensile Strength and its Scatter of Unidirectional Carbon Fibre Reinforced Composites. J. Reinf. Plast. Compos. 1997, 16, 119–130. [Google Scholar] [CrossRef]

- Maurin, R.; Davies, P.; Baral, N.; Baley, C. Transverse Properties of Carbon Fibres by Nano-Indentation and Micro-mechanics. Appl. Compos. Mater. 2008, 15, 61–73. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Effect of polyamide-6,6 (PA 66) nonwoven veils on the mechanical performance of carbon fiber/epoxy composites. Compos. Struct. 2018, 194, 21–35. [Google Scholar] [CrossRef]

- Beylergil, B.; Tanoğlu, M.; Aktaş, E. Enhancement of interlaminar fracture toughness of carbon fiber-epoxy composites using polyamide-6,6 electrospun nanofibers. J. Appl. Polym. Sci. 2017, 134, 1–12. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivankovic, A.; Murphy, N. Interlaminar fracture toughness of aerospace-grade carbon fibre reinforced plastics interleaved with thermoplastic veils. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105642. [Google Scholar] [CrossRef]

- García-Rodríguez, S.; Costa, J.; Rankin, K.; Boardman, R.; Singery, V.; Mayugo, J. Interleaving light veils to minimise the trade-off between mode-I interlaminar fracture toughness and in-plane properties. Compos. Part A Appl. Sci. Manuf. 2020, 128, 105659. [Google Scholar] [CrossRef]

- Quan, D.; Bologna, F.; Scarselli, G.; Ivanković, A.; Murphy, N. Mode-II fracture behaviour of aerospace-grade carbon fibre/epoxy composites interleaved with thermoplastic veils. Compos. Sci. Technol. 2020, 191, 108065. [Google Scholar] [CrossRef]

- Monteserín, C.; Blanco, M.; Murillo, N.; Pérez-Márquez, A.; Maudes, J.; Gayoso, J.; Laza, J.M.; Aranzabe, E.; Vilas, J.L. Effect of Different Types of Electrospun Polyamide 6 Nanofibres on the Mechanical Properties of Carbon Fibre/Epoxy Composites. Polymers 2018, 10, 1190. [Google Scholar] [CrossRef] [Green Version]

- Quan, D.; Alderliesten, R.; Dransfeld, C.; Murphy, N.; Ivanković, A.; Benedictus, R. Enhancing the fracture toughness of carbon fibre/epoxy composites by interleaving hybrid meltable/non-meltable thermoplastic veils. Compos. Struct. 2020, 252, 112699. [Google Scholar] [CrossRef]

- Quan, D.; Deegan, B.; Alderliesten, R.; Dransfeld, C.; Murphy, N.; Ivanković, A.; Benedictus, R. The influence of interlayer/epoxy adhesion on the mode-I and mode-II fracture response of carbon fibre/epoxy composites interleaved with thermoplastic veils. Mater. Des. 2020, 192, 108781. [Google Scholar] [CrossRef]

- Cheng, C.; Chen, Z.; Huang, Z.; Zhang, C.; Tusiime, R.; Zhou, J.; Sun, Z.; Liu, Y.; Yu, M.; Zhang, H. Simultaneously improving mode I and mode II fracture toughness of the carbon fiber/epoxy composite laminates via interleaved with uniformly aligned PES fiber webs. Compos. Part A Appl. Sci. Manuf. 2020, 129, 105696. [Google Scholar] [CrossRef]

- Daelemans, L.; van der Heijden, S.; De Baere, I.; Rahier, H.; Van Paepegem, W.; De Clerck, K. Nanofibre bridging as a toughening mechanism in carbon/epoxy composite laminates interleaved with electrospun polyamide nanofibrous veils. Compos. Sci. Technol. 2015, 117, 244–256. [Google Scholar] [CrossRef]

- Ramirez, V.A.; Hogg, P.J.; Sampson, W. The influence of the nonwoven veil architectures on interlaminar fracture toughness of interleaved composites. Compos. Sci. Technol. 2015, 110, 103–110. [Google Scholar] [CrossRef]

- Zhu, L. Investigations on damage resistance of carbon fiber composite panels toughened using veils. Chin. J. Aeronaut. 2013, 26, 807–813. [Google Scholar] [CrossRef] [Green Version]

- García-Rodríguez, S.; Costa, J.; Singery, V.; Boada, I.; Mayugo, J.A. The effect interleaving has on thin-ply non-crimp fabric laminate impact response: X-ray tomography investigation. Compos. Part A Appl. Sci. Manuf. 2018, 107, 409–420. [Google Scholar] [CrossRef] [Green Version]

- Wu, Z.; Yi, X.-S.; Wilkinson, A. Interlaminar fracture toughness of carbon fibre/RTM6-2 composites toughened with thermoplastic-coated fabric reinforcement. Compos. Part B Eng. 2017, 130, 192–199. [Google Scholar] [CrossRef] [Green Version]

- Beckermann, G.W.; Pickering, K. Mode I and Mode II interlaminar fracture toughness of composite laminates interleaved with electrospun nanofibre veils. Compos. Part A Appl. Sci. Manuf. 2015, 72, 11–21. [Google Scholar] [CrossRef]

- Kuwata, M.; Hogg, P. Interlaminar toughness of interleaved CFRP using non-woven veils: Part Mode-II testing. Compos. Part A Appl. Sci. Manuf. 2011, 42, 1560–1570. [Google Scholar] [CrossRef]

| Reference | Fiber/Fabric | Resin/Monomer | Dynamic System/Hardener | Tensile Modulus [GPa] | Tensile Strength [MPa] | Compression Strength [MPa] | Flexural Modulus [GPa] | Flexural Strength [MPa] | ILSS [MPa] | Impact Strength [kJ/m2] | Tg [°C] |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Ruiz, A. et al. [9] | Glass | Diglycidyl ether of bisphenol A | 4-aminophenyl disulfide | - | - | 292 ± 16 | - | 595 ± 39 | 37 ± 3 | 194 ± 18 | 130 |

| Denissen, W. et al. [25,26] | Glass—plain weave (hot-pressed) | Vinylogous urethane | Amine | 33.2 | 336 | - | - | - | - | - | - |

| Liu, X. et al. [32] | Glass cloth (180 g/m2) | Phenol formaldehyde | Urethane | - | - | - | - | 184.1 | 12.93 | - | 157 |

| Si, H. et al. [10] | Carbon | Bis(4-glycidyloxyphenyl)disulfide | 4-aminophenyl disul-fide | 10.5 | 334.5 ± 87.7 | - | - | - | - | - | 147 |

| Yuan, Y. et al. [6] | Carbon woven T300-1000 (119 g/m2) | Poly(hexahydrotriazine) | 2,2-bis[4-(4-aminophenoxy)phenyl]propane | 68.3 | 741.2 | 351.5 | 54.8 | 829.7 | 75.5 | - | 198.2 |

| Carbon UD HS (200 g/m2) | 141.7 | 1806.6 | 343.3 | 127.4 | 1241.2 | 69.1 | - | 199.5 | |||

| Taynton, P. et al. [28] | Carbon—twill weave | Diamine | Polyimine | 14.2 ± 1.1 | 399 ± 85 | - | 32.4 ± 3.7 | 255 ± 56 | - | - | 145 |

| Wang, S. et al. [31] | Carbon | Phenol formaldehyde | Boronic ester | - | - | - | 24.2 ± 0.3 | 411.6 ± 5.3 | 48 ± 2.5 | - | 153 |

| Liu, Y. et al. [19] | Carbon | Itaconic acid-based epoxy | Maleic acid + glycerin | 31.3 | 417 | - | - | - | 45 | - | 54 |

| Wang, S. et al. [23] | Carbon—plain weave | Vanillin epoxy | Diamine 4,4′-methyl- enebiscyclohexanamine | 35.3 ± 2.4 | 763 ± 71 | - | - | - | - | - | 172 |

| Liu, Y.Y. et al. [35] | Carbon | Bio epoxidized soybean oil | Vanillin + 4-aminophenol | 1.18 ± 0.14 | 145.4 ± 17.13 | - | - | - | - | - | 27.6 |

| Liu, Y.Y. et al. [36] | Carbon—plain weave | Glycerol triglycidyl ether | Vanillin + A4-aminophenol | 12.9 | 449 | - | - | - | - | - | 70 |

| Memom, H. et al. [20] | Carbon | Trifunctional epoxy | Vanillin + methylcyclohexanediamine | - | - | - | 56 | 1028 | 52 | - | 131 |

| Liu, T. et al. [33] | Carbon | Bisphenol A + Ethylenediamine | Glutaric anhydride | 17.1 ± 2.5 | 356 ± 28.7 | - | - | - | - | - | 95 |

| Wang, H. et al. [34] | Carbon (low wt%) | Diglycidyl ether of bisphenol F | 4-Aminophenyl disulfide + γ-Aminopropyltriethoxysilane + Poly(propylene glycol) bis(2-aminopropyl ether) | 10.18 | 320 | - | - | - | - | - | 97.4 |

| Xu, Y. et al. [37] | Carbon (braided 60% FVF) | Epoxidized menthane dia- mine | Adipic acid | - | 465 | - | - | - | - | - | 86.4 |

| Aeronautic standard reference [6] | Carbon–5 h satin (prepreg) | Hexply 914 | - | 70 | 631 | - | 61 | 912 | 64 | - | 190 |

| Aeronautic standard reference [38] | Carbon 8H satin 6K (prepreg) | Hexply 8552 | - | 86 | 1014 | - | - | - | 90 | - | 200 |

| Aeronautic standard reference [39] | Carbon UD (prepreg) | Epikote 475 | - | - | - | - | 60 | 1020 | 65 | - | 190 |

| Aeronautic standard reference (approximated results) [40] | Carbon–5H satin (370 g/m2) | RTM6 | - | 69 | 1180 | 950 | - | - | 67.5 | - | - |

| Material | Specification | Unit | Value | |||||

| Neat resin | Glass transition temperature | °C | >170 | |||||

| Tensile modulus | GPa | 3 | ||||||

| Tensile strength | MPa | 75 | ||||||

| Flexural modulus | GPa | 3.3 | ||||||

| Flexural strength | MPa | 132 | ||||||

| Material | Specification | Unit | Fabric configuration and test conditioning | |||||

| CP | UD | |||||||

| RT | HW70 | HW120 | RT | HW70 | HW120 | |||

| Ply properties | Tensile modulus—warp direction | GPa | >70 | >155 | ||||

| Tensile modulus—weft direction | GPa | >70 | >8.5 | |||||

| Tensile strength—warp direction | MPa | >980 | >2325 | |||||

| Tensile strength—weft direction | MPa | >980 | >47.6 | |||||

| Compression modulus—warp direction | GPa | >68 | >140 | |||||

| Compression modulus—weft direction | GPa | >68 | >8.5 | |||||

| Compression strength—warp direction | MPa | >646 | >1386 | |||||

| Compression strength—weft direction | MPa | >646 | >255 | |||||

| Interlaminar shear strength | MPa | >60 | >42 | >30 | >70 | >42 | >30 | |

| In-plane shear modulus | GPa | >4.5 | >3.6 | >2.3 | >4.4 | >3.5 | >2.2 | |

| In-plane shear strength | MPa | >86 | >73 | >49 | >82 | >65 | >41 | |

| Material | Specification | Unit | Quasi-isotropic laminate | |||||

| RT | HW70 | HW120 | ||||||

| Laminate properties | Fracture toughness GIC * | J/m2 | >700 | |||||

| OHT strength | MPa | >490 | >380 | >360 | ||||

| OHC strength | MPa | >340 | >250 | >180 | ||||

| FCH strength | MPa | >430 | >300 | >275 | ||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Builes Cárdenas, C.; Gayraud, V.; Rodriguez, M.E.; Costa, J.; Salaberria, A.M.; Ruiz de Luzuriaga, A.; Markaide, N.; Dasan Keeryadath, P.; Calderón Zapatería, D. Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer. Polymers 2022, 14, 1223. https://doi.org/10.3390/polym14061223

Builes Cárdenas C, Gayraud V, Rodriguez ME, Costa J, Salaberria AM, Ruiz de Luzuriaga A, Markaide N, Dasan Keeryadath P, Calderón Zapatería D. Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer. Polymers. 2022; 14(6):1223. https://doi.org/10.3390/polym14061223

Chicago/Turabian StyleBuiles Cárdenas, Cristian, Vincent Gayraud, Maria Eugenia Rodriguez, Josep Costa, Asier M. Salaberria, Alaitz Ruiz de Luzuriaga, Nerea Markaide, Priya Dasan Keeryadath, and Diego Calderón Zapatería. 2022. "Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer" Polymers 14, no. 6: 1223. https://doi.org/10.3390/polym14061223

APA StyleBuiles Cárdenas, C., Gayraud, V., Rodriguez, M. E., Costa, J., Salaberria, A. M., Ruiz de Luzuriaga, A., Markaide, N., Dasan Keeryadath, P., & Calderón Zapatería, D. (2022). Study into the Mechanical Properties of a New Aeronautic-Grade Epoxy-Based Carbon-Fiber-Reinforced Vitrimer. Polymers, 14(6), 1223. https://doi.org/10.3390/polym14061223