Surface Response Analysis for the Optimization of Mechanical and Thermal Properties of Polypropylene Composite Drawn Fibers with Talc and Carbon Nanotubes

Abstract

:1. Introduction

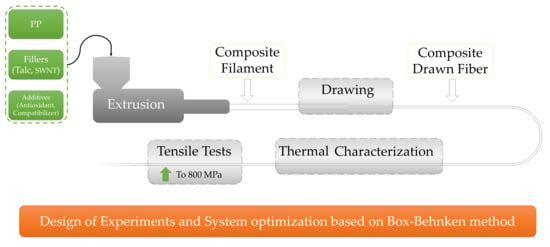

2. Experimental

2.1. Materials

2.2. Experimental Apparatus and Procedure

2.3. Characterization

3. Design of Experiments

4. Results and Discussion

4.1. Composites with Talc (DoE 1)

4.1.1. Single Design Variable Effect on Response Variables for Composites with Talc

4.1.2. Combined Effect of Design Variables on Response Variables for Composites with Talc

4.1.3. Optimization Runs for Composites with Talc

4.1.4. Verification—Comparison with Literature

4.2. Composites with SWCNTs (DoE 2)

4.2.1. Single Design Variable Effect on Response Variables for Composites with SWCNTs

4.2.2. Combined Effect of Design Variables on Response Variables for Composites with SWCNTs

4.2.3. Optimization Runs for Composites with SWCNTs

4.2.4. Verification—Comparison with Literature

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qinglong, J.; Luna, L. COVID-19: From Crude Oil to Medical Mask. ES Mater. Manuf. 2020, 7, 1–3. [Google Scholar]

- Hamza, A.; Belal, A.; Sokkar, T.; El-Bakary, M.; Yassien, K. Interferometric detection of structure deformation due to cold drawing of polypropylene fibres at high draw ratios. J. Opt. A Pure Appl. Opt. 2007, 9, 820–827. [Google Scholar] [CrossRef]

- Chen, J.; Si, X.; Hu, S.; Wang, Y.; Wang, Y. The preparation and study on ultrahigh molecular weight polypropylene gel-spun fibers. J. Macromol. Sci. Phys. 2008, 47, 192–200. [Google Scholar] [CrossRef]

- El-Dessouky, H.M.; Mahmoudi, M.R.; Lawrence, C.A.; Yassien, K.M.; Sokkar, T.Z.N.; Hamza, A.A. On the physical behavior of isotactic polypropylene fibers extruded at different draw-down ratios I. Optical properties and cold drawing. Polym. Eng. Sci. 2009, 49, 2116–2124. [Google Scholar] [CrossRef]

- Larin, B.; Lyashenko, T.; Harel, H.; Marom, G. Flow induced orientated morphology and properties of nanocomposites of polypropylene/vapor grown carbon fibers. Compos. Sci. Technol. 2011, 71, 177–182. [Google Scholar] [CrossRef]

- Tambe, P.B.; Bhattacharyya, A.R.; Kamath, S.S.; Kulkarni, A.R.; Sreekumar, T.V.; Srivastav, A.; Bhasker Rao, K.U.; Liu, Y.; Kumar, S. Structure–Property Relationship Studies in Amine Functionalized Multiwall Carbon Nanotubes Filled Polypropylene Composite Fiber. Polym. Eng. Sci. 2011, 52, 1183–1194. [Google Scholar] [CrossRef]

- Li, Y.; Wang, X.; Mu, X.; Zhang, S. The performance of barium sulfate nanoparticles/polypropylene hybrid multifilament. Int. J. Nanosci. 2012, 11, 1240039. [Google Scholar] [CrossRef]

- Avci, H.; Kotek, R.; Yoon, J. Developing an ecologically friendly isothermal bath to obtain a new class high-tenacity and high-modulus polypropylene fibers. J. Mater. Sci. 2013, 48, 7791–7804. [Google Scholar] [CrossRef]

- Yin, S.; Tuladhar, R.; Shanks, R.A.; Collister, T.; Combe, M.; Jacob, M.; Tian, M.; Sivakugan, N. Fiber preparation and mechanical properties of recycled polypropylene for reinforcing concrete. J. Appl. Polym. Sci. 2015, 132, 41866. [Google Scholar] [CrossRef]

- Butola, B.S.; Joshi, M.; Kumar, S. Hybrid organic-inorganic POSS (polyhedral oligomeric silsesquioxane)/polypropylene nanocomposite filaments. Fibers Polym. 2010, 11, 1137–1145. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Leontiadis, K.; Messaritakis, S.; Terzaki, A.; Xidas, P.; Mystikos, K.; Tzimpilis, E.; Tsivintzelis, I. Experimental investigation of polypropylene composite drawn fibers with talc, wollastonite, attapulgite and single wall carbon nanotubes. Polymers 2022, 14, 260. [Google Scholar] [CrossRef] [PubMed]

- Leontiadis, K.; Tsioptsias, C.; Messaritakis, S.; Terzaki, A.; Xidas, P.; Mystikos, K.; Tzimpilis, E.; Tsivintzelis, I. Optimization of Thermal and Mechanical Properties of Polypropylene-Wollastonite Composite Drawn Fibers Based on Surface Response Analysis. Polymers 2022, 14, 924. [Google Scholar] [CrossRef] [PubMed]

- Deng, H.; Bilotti, E.; Zhang, R.; Peijs, T. Effective reinforcement of carbon nanotubes in polypropylene matrices. J. Appl. Polym. Sci. 2010, 118, 30–41. [Google Scholar] [CrossRef]

- Polec, I.; Hine, P.J.; Bonner, M.J.; Ward, I.M.; Barton, D.C. Die drawn wood polymer composites. II. Micromechanical modelling of tensile modulus. Compos. Sci. Technol. 2010, 70, 53–60. [Google Scholar] [CrossRef]

- Joshi, M.; Shaw, M.; Butola, B.S. Studies on Composite Filaments from Nanoclay Reinforced Polypropylene. Fibers Polym. 2004, 5, 59–67. [Google Scholar] [CrossRef]

- Dondero, W.E.; Gorga, R.E. Morphological and mechanical properties of carbon nanotube/polymer composites via melt compounding. J. Polym. Sci. Part B Polym. Phys. 2006, 44, 864–878. [Google Scholar] [CrossRef] [Green Version]

- Mohan, T.P.; Kanny, K. Preparation and characteristics of polypropylene-clay nanocomposite fibers. J. Polym. Eng. 2015, 35, 773–784. [Google Scholar] [CrossRef]

- Lee, B.; Cho, J.; Kim, K. Crystallization, orientation, and mechanical properties of laser-heated photothermally drawn polypropylene/multi-walled carbon nanotube fibers. Eur. Polym. J. 2017, 91, 70–80. [Google Scholar] [CrossRef]

- Skrifvars, M.; Soroudi, A. Melt Spinning of Carbon Nanotube Modified Polypropylene for Electrically Conducting Nanocomposite Fibres. Solid State Phenom. 2009, 151, 43–47. [Google Scholar] [CrossRef]

- Nilsson, E.; Oxfall, H.; Wandelt, W.; Rychwalski, R.; Hagstrom, B. Melt Spinning of Conductive Textile Fibers with Hybridized Graphite Nanoplatelets and Carbon Black Filler. J. Appl. Polym. Sci. 2013, 130, 2579–2587. [Google Scholar] [CrossRef]

- Cao, L.; Su, D.; Su, Z.; Chen, X. Fabrication of Multiwalled Carbon Nanotube/Polypropylene Conductive Fibrous Membranes by Melt Electrospinning. Ind. Eng. Chem. Res. 2014, 53, 2308–2317. [Google Scholar] [CrossRef]

- Tsioptsias, C.; Leontiadis, K.; Tzimpilis, E.; Tsivintzelis, I. Polypropylene nanocomposite fibers: A review of current trends and new developments. J. Plast. Film Sheeting 2021, 37, 283–311. [Google Scholar] [CrossRef]

- Joshi, M.; Viswanathan, V. High-Performance Filaments from Compatibilized Polypropylene/Clay Nanocomposites. J. Appl. Polym. Sci. 2006, 102, 2164–2174. [Google Scholar] [CrossRef]

- Lorenzi, D.; Sartori, G.; Ferrara, G.; Fambri, L. Spinnability of Nanofilled Polypropylene. Macromol. Symp. 2011, 301, 73–81. [Google Scholar] [CrossRef]

- Borsig, E.; Ujhelyiova, A.; Mlynarcikova, Z.; Kaemfer, D.; Mulhaupt, R.; Marcincin, A.; Berek, D. DSC study of syndiotactic polypropylene/organoclay nanocomposite fibers: Crystallization and melting behavior. Int. J. Polym. Mater. 2007, 56, 771–788. [Google Scholar] [CrossRef]

- Fambri, L.; Dabrowska, I.; Ceccato, R.; Pegoretti, A. Effects of fumed silica and draw ratio on nanocomposite polypropylene fibers. Polymers 2017, 9, 41. [Google Scholar] [CrossRef] [Green Version]

- Liang, J.-Z. Impact and Flexural Properties of PP/CaSiO3 Composites. Polym. Compos. 2018, 39, 398–404. [Google Scholar] [CrossRef]

- Ding, Q.; Zhang, Z.; Dai, X.; Li, M.; Mai, K. Crystalline Morphology and Mechanical Properties of Isotactic Polypropylene Composites Filled by Wollastonite With β-Nucleating Surface. Polym. Compos. 2014, 35, 1445–1452. [Google Scholar] [CrossRef]

- Salas-Papayanopolos, H.; Morales, A.; Lozano, T.; Laria, J.; Sanchez, S.; Rodriguez, F.; Martinez, G.; Cerino, F. Improvement of Toughness Properties of Polypropylene/Wollastonite Composites Using an Interface Modifier. Polym. Compos. 2014, 35, 1184–1192. [Google Scholar] [CrossRef]

- McIntosh, D.; Khabashesku, V.N.; Barrera, E.V. Nanocomposite Fiber Systems Processed from Fluorinated Single-Walled Carbon Nanotubes and a Polypropylene Matrix. Chem. Mater. 2006, 18, 4561–4569. [Google Scholar] [CrossRef]

- McInerney, L.F.; Kao, N.; Bhattacharya, N. Melt Strength and Extensibility of Talc-Filled Polypropylene. Polym. Eng. Sci. 2003, 43, 1821–1829. [Google Scholar] [CrossRef]

- Youssefi, M.; Safaie, B. Effect of Multi Walled Carbon Nanotube on the Crystalline Structure of Polypropylene Fibers. Fibers Polym. 2013, 14, 1602–1607. [Google Scholar] [CrossRef]

- Youssefi, M.; Safaie, B. The Study on the Mechanical Properties of Multi-walled Carbon Nanotube/Polypropylene Fibers. J. Inst. Eng. 2018, 99, 37–42. [Google Scholar] [CrossRef]

- Zhang, F.; Liu, X.; Zheng, G.; Guo, Z.; Liu, C.; Shen, C. Facile route to improve the crystalline memory effect: Electrospun composite fiber and annealing. Macromol. Chem. Phys. 2018, 219, 1800236. [Google Scholar] [CrossRef]

- Acierno, S.; Barretta, R.; Luciano, R.; Marotti de Sciarra, F.; Russo, P. Experimental evaluations and modeling of the tensile behavior of polypropylene/single-walled carbon nanotubes fibers. Compos. Struct. 2017, 174, 12–18. [Google Scholar] [CrossRef]

- Fabia, J.; Janicki, J.; Slusarczyk, C.; Rom, M.; Graczyk, T.; Gawlowski, A. Study of structure of polypropylene microfibres modified with multi-walled carbon nanotubes. Fibres Text. East. Eur. 2015, 23, 38–44. [Google Scholar] [CrossRef]

- O’Haire, T.; Rigout, M.; Russell, S.J.; Carr, C.M. Influence of nanotube dispersion and spinning conditions on nanofiber nanocomposites of polypropylene and multi-walled carbon nanotubes produced through ForcespinningTM. J. Thermoplast. Compos. Mater. 2015, 27, 205–214. [Google Scholar] [CrossRef]

- Nohut, S.; Tascan, M. Determination of the minimum sample size for a reliable strength measurement of talc-filled polypropylene fibers. J. Appl. Polym. Sci. 2020, 133, 44083. [Google Scholar] [CrossRef]

- Tascan, M.; Nohut, S. Melt-spun talc-filled polypropylene fibers and yarns with higher thermal shock resistance. Text. Res. J. 2017, 87, 31–45. [Google Scholar] [CrossRef]

- Bakhtiari, A.; Ghasemi, F.A.; Naderi, G.; Nakhaei, M.R. An approach to the optimization of mechanical properties of polypropylene/nitrile butadiene rubber/halloysite nanotybe/polypropylene-g-maleic anhydride nanocomposites using response surface methodology. Polym. Compos. 2020, 41, 2330–2340. [Google Scholar] [CrossRef]

- Sukriti; Sharma, J.; Pruthi, V.; Anand, P.; Chaddha, A.P.S.; Bhatia, J.; Kaith, B.S. Surface response methodology-central composite design screening for the fabrication of a Gx-psy-g-polyacrylicacid adsorbent and sequestration of auramine-O dye from a textile effluent. RSC Adv. 2016, 6, 74300–74313. [Google Scholar] [CrossRef]

| Material | Abbreviation | Characteristics 1,2,3,4 | Supplier |

|---|---|---|---|

| Isotactic PP (ECOLEN HZ42Q) | PP | MFI = 18 g/10 min, TS = 33 MPa, Tm = 168–171 °C | Hellenic Petroleum S.A., Thessaloniki, Greece |

| Masterbatch with compatibilizer (Bondyram 1001) | MA | PP grafted with maleic anhydride (PP-g-MA). MA content 1%, MFI = 100 g/10 min, Tm = 160 °C | Polyram Plastic Industries LTD, Gilboa, Israel |

| Masterbatch with antioxidant (KRITILEN® AO PP9216) | AO | PP with 20.5% wt. antioxidant (combination of phosphite and phenolic types) | Plastika Kritis S.A., Heraklion, Greece |

| Masterbatch with ultra-fine talc (KRITILEN® D05-00046) | UT | PP with 30% wt. ultra-fine (D50 = 0.7 μm) MFI 5 = 25 g/10 min | Plastika Kritis S.A., Heraklion, Greece |

| Masterbatch with SWCNT (KRITILEN® D05-00067) | SWCNT | PP with 5% wt. SWCNT MFI 5 = 25 g/10 min | Plastika Kritis S.A., Heraklion, Greece |

| ID | Talc Content (% wt.) | Compatibilizer Content a (% wt.) | Drawing Ratio, λ |

|---|---|---|---|

| 1 | 0 | 0 | 8 |

| 2 | 4 | 0 | 8 |

| 3 | 0 | 7.5 | 8 |

| 4 | 4 | 7.5 | 8 |

| 5 | 0 | 3.75 | 7 |

| 6 | 4 | 3.75 | 7 |

| 7 | 0 | 3.75 | 9 |

| 8 | 4 | 3.75 | 9 |

| 9 | 2 | 0 | 7 |

| 10 | 2 | 7.5 | 7 |

| 11 | 2 | 0 | 9 |

| 12 | 2 | 7.5 | 9 |

| 13 | 2 | 3.75 | 8 |

| 14 | 2 | 3.75 | 8 |

| 15 | 2 | 3.75 | 8 |

| ID | SWCNT Content (% wt.) | Antioxidant Content a (% wt.) | Drawing Ratio, λ |

|---|---|---|---|

| 1 | 0 | 0 | 14 |

| 2 | 1 | 0 | 14 |

| 3 | 0 | 8 | 14 |

| 4 | 1 | 8 | 14 |

| 5 | 0 | 4 | 7 |

| 6 | 1 | 4 | 7 |

| 7 | 0 | 4 | 21 |

| 8 | 1 | 4 | 21 |

| 9 | 0.5 | 0 | 7 |

| 10 | 0.5 | 8 | 7 |

| 11 | 0.5 | 0 | 21 |

| 12 | 0.5 | 8 | 21 |

| 13 | 0.5 | 4 | 14 |

| 14 | 0.5 | 4 | 14 |

| 15 | 0.5 | 4 | 14 |

| ID | Talc Content (% wt.) | Compatibilizer Content a (% wt.) | Drawing Ratio, λ | TS (ΜΡa) | Tdec (°C) | ΔH (J g−1) | Tm (°C) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0.00 | 8 | 451 ± 56 | 303 | 104.8 | 163 |

| 2 | 4 | 0.00 | 8 | 419 ± 45 | 316 | 101.6 | 164 |

| 3 | 0 | 7.50 | 8 | 481 ± 67 | 308 | 100.1 | 163 |

| 4 | 4 | 7.50 | 8 | 425 ± 69 | 301 | 103.5 | 165 |

| 5 | 0 | 3.75 | 7 | 414 ± 90 | 291 | 96.5 | 163 |

| 6 | 4 | 3.75 | 7 | 376 ± 44 | 291 | 96.2 | 164 |

| 7 | 0 | 3.75 | 9 | 744 ± 43 | 298 | 107.2 | 166 |

| 8 | 4 | 3.75 | 9 | 438 ± 68 | 304 | 98.1 | 161 |

| 9 | 2 | 0.00 | 7 | 363 ± 26 | 311 | 99.3 | 163 |

| 10 | 2 | 7.50 | 7 | 272 ± 79 | 305 | 99.7 | 163 |

| 11 | 2 | 0.00 | 9 | 454 ± 30 | 301 | 98.9 | 163 |

| 12 | 2 | 7.50 | 9 | 439 ± 57 | 302 | 98.6 | 167 |

| 13 | 2 | 3.75 | 8 | 442 ± 37 | 301 | 101.9 | 165 |

| 14 | 2 | 3.75 | 8 | 478 ± 145 | 297 | 100.6 | 165 |

| 15 | 2 | 3.75 | 8 | 433 ± 42 | 301 | 100.2 | 165 |

| ID | SWCNT Content (% wt.) | Antioxidant Content a (% wt.) | Drawing Ratio, λ | TS (ΜΡa) | Tdec (°C) | ΔH (J g−1) | Tm (°C) |

|---|---|---|---|---|---|---|---|

| 1 | 0 | 0 | 14 | 521 ± 51 | 268 | 98.2 | 171 |

| 2 | 1 | 0 | 14 | 536 ± 77 | 260 | 106.0 | 169 |

| 3 | 0 | 8 | 14 | 806 ± 70 | 308 | 107.3 | 171 |

| 4 | 1 | 8 | 14 | 623 ± 89 | 305 | 107.9 | 169 |

| 5 | 0 | 4 | 7 | 402 ± 21 | 308 | 85.1 | 167 |

| 6 | 1 | 4 | 7 | 345 ± 11 | 308 | 86.6 | 167 |

| 7 | 0 | 4 | 21 | 598 ± 169 | 302 | 111.3 | 169 |

| 8 | 1 | 4 | 21 | 802 ± 227 | 302 | 94.3 | 166 |

| 9 | 0.5 | 0 | 7 | 406 ± 37 | 283 | 86.6 | 165 |

| 10 | 0.5 | 8 | 7 | 357 ± 36 | 311 | 84.2 | 166 |

| 11 | 0.5 | 0 | 21 | 673 ± 74 | 273 | 97.9 | 168 |

| 12 | 0.5 | 8 | 21 | 706 ± 56 | 310 | 107.1 | 167 |

| 13 | 0.5 | 4 | 14 | 596 ± 29 | 299 | 91.1 | 169 |

| 14 | 0.5 | 4 | 14 | 643 ± 45 | 298 | 100.5 | 170 |

| 15 | 0.5 | 4 | 14 | 702 ± 88 | 304 | 100.9 | 170 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leontiadis, K.; Tsioptsias, C.; Messaritakis, S.; Terzaki, A.; Xidas, P.; Mystikos, K.; Tzimpilis, E.; Tsivintzelis, I. Surface Response Analysis for the Optimization of Mechanical and Thermal Properties of Polypropylene Composite Drawn Fibers with Talc and Carbon Nanotubes. Polymers 2022, 14, 1329. https://doi.org/10.3390/polym14071329

Leontiadis K, Tsioptsias C, Messaritakis S, Terzaki A, Xidas P, Mystikos K, Tzimpilis E, Tsivintzelis I. Surface Response Analysis for the Optimization of Mechanical and Thermal Properties of Polypropylene Composite Drawn Fibers with Talc and Carbon Nanotubes. Polymers. 2022; 14(7):1329. https://doi.org/10.3390/polym14071329

Chicago/Turabian StyleLeontiadis, Konstantinos, Costas Tsioptsias, Stavros Messaritakis, Aikaterini Terzaki, Panagiotis Xidas, Kyriakos Mystikos, Evangelos Tzimpilis, and Ioannis Tsivintzelis. 2022. "Surface Response Analysis for the Optimization of Mechanical and Thermal Properties of Polypropylene Composite Drawn Fibers with Talc and Carbon Nanotubes" Polymers 14, no. 7: 1329. https://doi.org/10.3390/polym14071329

APA StyleLeontiadis, K., Tsioptsias, C., Messaritakis, S., Terzaki, A., Xidas, P., Mystikos, K., Tzimpilis, E., & Tsivintzelis, I. (2022). Surface Response Analysis for the Optimization of Mechanical and Thermal Properties of Polypropylene Composite Drawn Fibers with Talc and Carbon Nanotubes. Polymers, 14(7), 1329. https://doi.org/10.3390/polym14071329