Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of CF for Functionalization with GO

2.2. Preparation of Epoxy-Curaua Fiber Composites

2.3. Izod Impact Test

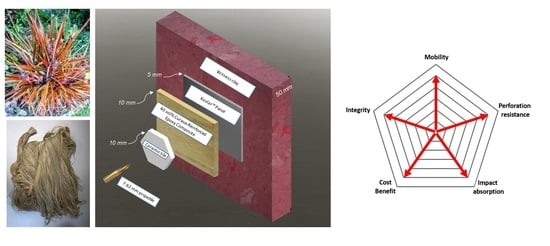

2.4. Multilayer Armor Sistem Assembly

2.5. Ballistic Tests

2.6. Zeta Potential Analysis

2.7. Transmission Electron Microscopy

2.8. Field Emission-Scanning Electron Microscopy (FE-SEM) Analysis

2.9. Electron Energy-Loss Spectroscopy

3. Results and Discussions

3.1. Izod Impact Test

3.2. Ballistic Impact Results

3.3. Cost-Effectiveness Analysis

3.4. The Zeta Potential of GO Dispersion

3.5. Electron Microscopy Analysis of GO

3.6. Electron Energy Loss Spectroscopy (EELS) Analysis of GO

3.7. Ballistic Fracture Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, P.; Strano, M.S. Toward ambient armor: Can new materials change longstanding concepts of projectile protection? Adv. Funct. Mater. 2016, 26, 943–954. [Google Scholar] [CrossRef]

- Akella, K.; Naik, N.K. Composite armour—A review. J. Indian Inst. Sci. 2015, 95, 297–312. [Google Scholar]

- Chagas, N.P.S.; Aguiar, V.O.; Garcia Filho, F.C.; Figueiredo, A.B.-H.S.; Monteiro, S.N.; Huaman, N.R.C.; Marques, M.F.V. Ballistic performance of boron carbide nanoparticles reinforced ultra-high molecular weight polyethylene (UHMWPE). J. Mater. Res. Technol. 2022, 17, 1799–1811. [Google Scholar] [CrossRef]

- Nascimento, R.F.; Silva, A.O.; Weber, R.P.; Monteiro, S.N. Influence of UV radiation and moisten associated with natural weathering on the ballistic performance of aramid fabric armor. J. Mater. Res. Technol. 2020, 9, 10334–10345. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lima, E.P.; Louro, L.H.L.; Silva, L.C.; Drelich, J.W. Unlocking function of aramid fibers in multilayered ballistic armor. Metall. Mater. Trans. A 2015, 46, 37–40. [Google Scholar] [CrossRef]

- Lee, Y.S.; Wetzel, E.D.; Wagner, N. The ballistic impact characteristics of Kevlar® woven fabrics impregnated with a colloidal shear thickening fluid. J. Mater. Sci. 2003, 38, 2825–2833. [Google Scholar] [CrossRef]

- Morye, S.S.; Hine, P.I.; Duckett, R.A.; Carr, D.I.; Ward, I.M. modelling of the energy absorption by polymer composites upon ballistic impact. Compos. Sci. Technol. 2000, 60, 2631–2642. [Google Scholar] [CrossRef]

- Nurazzi, N.; Asyraf, M.; Khalina, A.; Abdullah, N.; Aisyah, H.; Rafiqah, S.; Sabaruddin, F.; Kamarudin, S.; Norrrahim, M.; Ilyas, R.; et al. A review on natural fiber reinforced polymer composite for bullet proof and ballistic applications. Polymers 2021, 13, 646. [Google Scholar] [CrossRef]

- Nayak, S.Y.; Sultan, M.T.H.; Shenoy, S.B.; Kini, C.R.; Samant, R.; Shah, A.U.; Amuthakkannan, P. Potential of natural fibers in composites for ballistic applications–A review. J. Natural Fibers 2020, 1–11. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Oliveira, M.S.; Pereira, A.C.; Nascimento, L.F.C.; Matheus, J.R.G.; Monteiro, S.N. Ballistic behavior of epoxy matrix composites reinforced with piassava fiber against high energy ammunition. J. Mater. Res. Technol. 2020, 9, 1734–1741. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Drelich, J.W.; Lopera, H.A.; Nascimento, L.F.; da Luz, F.S.; da Silva, L.C.; dos Santos, J.L.; da Costa Garcia Filho, F.; de Assis, F.S.; Lima, P.E.; et al. Natural fibers reinforced polymer composites applied in ballistic multilayered armor for personal protection—An overview. In Green Materials Engineering, 1st ed.; Ikhmayies, S., Li, J., Vieira, C., Margem, J., de Oliveira Braga, F., Eds.; Springer: Cham, Switzerland, 2019; pp. 33–47. [Google Scholar] [CrossRef]

- Benzait, Z.; Trabzon, L. A review of recent research on materials used in polymer–matrix composites for body armor application. J. Compos. Mater. 2018, 52, 3241–3263. [Google Scholar] [CrossRef]

- Naveen, J.; Jayakrishna, K.; Hameed Sultan, M.T.B.; Amir, S.M.M. Ballistic Performance Of Natural Fiber Based Soft And Hard Body Armour- A Mini Review. Front. Mater. 2020, 7, 608139. [Google Scholar] [CrossRef]

- Luz, F.S.; Monteiro, S.N.; Lima, E.S.; Lima, E.P. Ballistic application of coir fiber reinforced epoxy composite in multilayered armor. Mater. Res. 2017, 20, 23–28. [Google Scholar] [CrossRef]

- Braga, F.O.; Bolzan, L.T.; Luz, F.S.; Lopes, P.H.L.M.; Lima, E.P.; Monteiro, S.N. High energy ballistic and fracture comparison between multilayered armor systems using non-woven curaua fabric composites and aramid laminates. J. Mater. Res. Technol. 2017, 6, 417–422. [Google Scholar] [CrossRef]

- Luz, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Nascimento, L.F.C.; Monteiro, S.N. Composites with natural fibers and conventional materials applied in a hard armor: A comparison. Polymers 2020, 12, 1920. [Google Scholar] [CrossRef]

- Reis, R.H.M.; Nunes, L.F.; Luz, F.S.; Candido, V.S.; Silva, A.C.S.; Monteiro, S.N. Ballistic performance of guaruman fiber composites in multilayered armor system and as single target. Polymers 2021, 13, 1203. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Luz, F.S.; Oliveira, M.S.; Bezerra, W.B.A.; Barbosa, J.D.V.; Monteiro, S.N. Influence of rigid brazilian natural fiber arrangements in polymer composites: Energy absorption and ballistic efficiency. J. Compos. Sci. 2021, 5, 201. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Garcia Filho, F.O.; Pereira, A.C.S.; Nunes, L.F.; Luz, F.S.; Braga, F.O.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance and statistical evaluation of multilayered armor with epoxy-fique fabric composites using the weibull analysis. J. Mater. Res. Technol. 2019, 8, 5899–5908. [Google Scholar] [CrossRef]

- Pereira, A.C.S.; Assis, F.S.; Garcia Filho, F.C.; Oliveira, M.S.; Demosthenes, L.C.C.; Lopera, H.A.C.; Monteiro, S.N. Ballistic performance of multilayered armor with intermediate polyester composite reinforced with fique natural fabric and fibers. J. Mater. Res. Technol. 2019, 8, 4221–4226. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Monteiro, S.N. Piassava fiber as an epoxy matrix composite reinforcement for ballistic armor applications. JOM 2019, 71, 801–808. [Google Scholar] [CrossRef]

- Odesanya, K.; Ahmad, R.; Jawaid, M.; Bingol, S.; Adebayo, G.O.; Wong, Y.H. Natural Fibre-Reinforced Composite For Ballistic Applications: A Review. J. Polym. Environ. 2021, 29, 3795–3812. [Google Scholar] [CrossRef]

- Faruk, O.; Bledzki, A.K.; Fink, H.-P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Kalia, S.; Kaith, B.S.; Kaur, I. Pretreatments of natural fibers and their application as reinforcing material in polymer composites-a review. Polym. Eng. Sci. 2009, 49, 1253–1272. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Zafeiropoulos, N.; Panayiotou, C. Development of biodegradable composites with treated and compatibilized lignocellulosic fibers. J. Appl. Polym. Sci. 2006, 100, 4703–4710. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Reihmane, S.; Gassan, J. Properties and modification methods for vegetable fibers for natural fiber composites. J. Appl. Polym. Sci. 1996, 59, 1329–1336. [Google Scholar] [CrossRef]

- Ali, A.; Shaker, K.; Nawab, Y.; Jabbar, M.; Hussain, T.; Militky, J.; Baheti, V. Hydrophobic treatment of natural fibers and their composites—A review. J. Industr. Text. 2016, 47, 2153–2183. [Google Scholar] [CrossRef]

- Luz, F.S.; Garcia Filho, F.C.; del-Río, M.T.G.; Nascimento, L.F.C.; Pinheiro, W.A.; Monteiro, S.N. Graphene-incorporated natural fiber polymer composites: A first overview. Polymers 2020, 12, 1601. [Google Scholar] [CrossRef]

- Sarker, F.; Karim, N.; Afroj, S.; Koncherry, V.; Novoselov, K.S.; Potluri, P. High-performance graphene-based natural fiber composites. ACS Appl. Mater. Interf. 2018, 10, 34502–34512. [Google Scholar] [CrossRef]

- Silveira, P.H.P.M.; Ribeiro, M.P.; Silva, T.T.; Lima, A.M.; Lemos, M.F.; Oliveira, A.G.B.A.M.; Nascimento, L.F.C.; Gomes, A.V.; Monteiro, S.N. Effect of alkaline treatment and graphene oxide coating on thermal and chemical properties of hemp (Cannabis sativa) fibers. J. Nat. Fiber 2022, 1–14. [Google Scholar] [CrossRef]

- Pereira, A.C.; Lima, A.M.; Demosthenes, L.C.C.; Oliveira, M.S.; Costa, U.O.; Bezerra, W.B.A.; Monteiro, S.N.; Rodriguez, R.J.S.; Deus, J.F.; Pinheiro, W.A. Ballistic performance of ramie fabric reinforcing graphene oxide-incorporated epoxy matrix composite. Polymers 2020, 12, 2711. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Luz, F.S.; Oliveira, M.S.; Pereira, A.C.; Costa, U.O.; Monteiro, S.N. Thermal behavior of graphene oxide-coated piassava fiber and their epoxy composites. J. Mater. Res. Technol. 2020, 9, 5343–5351. [Google Scholar] [CrossRef]

- Chen, J.; Huang, Z.; Lv, W.; Wang, C. Graphene oxide decorated sisal fiber/MAPP modified PP composites: Toward high-performance biocomposites. Polym. Compos. 2017, 39, E113–E121. [Google Scholar] [CrossRef]

- Tebeta, R.T.; Fattahi, A.M.; Ahmed, N.A. Experimental and numerical study on HDPE/SWCNT nanocomposite elastic properties considering the processing techniques effect. Microsyst. Technol. 2020, 26, 2423–2441. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Louro, L.H.L.; Trindade, W.; Elias, C.N.; Ferreira, C.L.; Lima, E.S.; Weber, R.P.; Suarez, J.C.M.; Figueiredo, A.B.-H.S.; Pinheiro, W.A.; et al. Natural curaua fiber-reinforced composites in multilayered ballistic armor. Metall. Mater. Trans. A 2015, 46, 4567–4577. [Google Scholar] [CrossRef]

- Panda, P.K.; Dash, P.; Yang, J.M.; Chang, Y.H. Development of chitosan, graphene oxide, and cerium oxide composite blended films: Structural, physical, and functional properties. Cellulose 2020, 29, 2399–2411. [Google Scholar] [CrossRef]

- Mittal, G.; Dhand, V.; Rhee, K.Y.; Park, S.J.; Lee, W.R. A review on carbon nanotubes and graphene as fillers in reinforced polymer nanocomposites. J. Ind. Eng. Chem. 2015, 21, 11–25. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Barbosa, A.P.; Bevitori, A.B.; Silva, I.L.A.D.; Costa, L.L.D. Natural lignocellulosic fibers as engineering materials—an overview. Metall. Mater. Trans. A 2011, 42, 2963–2974. [Google Scholar] [CrossRef] [Green Version]

- Costa, U.O.; Nascimento, L.F.C.; Bezerra, W.B.A.; Aguiar, V.O.; Pereira, A.C.; Monteiro, S.N.; Pinheiro, W.A. Dynamic mechanical behavior of graphene oxide functionalized curaua fiber-reinforced epoxy composites: A brief report. Polymers 2021, 13, 1897. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Garcia Filho, F.C.; Luz, F.S.; Pinheiro, W.A.; Monteiro, S.N. Mechanical properties of composites with graphene oxide functionalization of either epoxy matrix or curaua fiber reinforcement. J. Mater. Res. Technol. 2020, 9, 13390–13401. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Monteiro, S.N.; Luz, F.S.; Pinheiro, W.A.; Garcia Filho, F.C. Effect of graphene oxide coating on natural fiber composite for multilayered ballistic armor. Polymers 2019, 11, 1356. [Google Scholar] [CrossRef] [Green Version]

- Rourke, J.P.; Pandey, P.A.; Moore, J.J.; Bates, M.; Kinloch, I.A.; Young, R.J.; Wilson, N.R. The real graphene oxide revealed: Stripping the oxidative debris from the graphene-like sheets. Angew. Chem. Internat. Ed. 2011, 50, 3173–3177. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ASTM International. Test Methods for Determining the Izod Pendulum Impact Resistance of Plastics; ASTM D256-10; ASTM International: West Conshohocken, PA, USA, 2018. [Google Scholar] [CrossRef]

- U.S. Department of Justice-National Institute of Justice. NIJ Standard-0101.04; Ballistic Resistance of Personal Body Armor. U.S. Department of Justice-National Institute of Justice: Rockville, MD, USA, 2000.

- Krishnamoorthy, K.; Veerapandian, M.; Yun, K.; Kim, S.J. The chemical and structural analysis of graphene oxide with different degrees of oxidation. Carbon 2013, 53, 38–49. [Google Scholar] [CrossRef]

- Mindivan, F. The synthesis and charecterization of graphene oxide (GO) and reduced graphene oxide (RGO). In XIII International Scientific Congress Machines Technologies Materials; Scientific Proceedings of The Scientific Technical Union of Mechanical Engineering: Borovets, Bulgaria, 2016; pp. 51–54. [Google Scholar]

- Hu, X.; Yu, Y.; Hou, W.; Zhou, J.; Song, L. Effects of particle size and PH value on the hydrophilicity of graphene oxide. Appl. Surf. Sci. 2013, 273, 118–121. [Google Scholar] [CrossRef]

- ASTM International. Zeta Potential Colloids in Water and Waste Water; ASTM D4187-82; ASTM International: West Conshohocken, PA, USA, 1982. [Google Scholar]

- Liu, Y.; Hamon, A.; Fan, B.; He, D.; Haghi-Ashtiani, P.; Reiss, T.; Bai, J. Intensive EELS study of epoxy composites reinforced by graphene-based nanofillers. J. Appl. Polym. Sci. 2018, 135, 46748. [Google Scholar] [CrossRef]

- Berger, S.D.; McKenzie, D.R.; Martin, P.J. EELS analysis of vacuum arc-deposited diamond-like films. Philos. Mag. Lett. 1988, 57, 285–290. [Google Scholar] [CrossRef]

- Bernier, N.; Bocquet, F.; Allouche, A.; Saikaly, W.; Brosset, C.; Thibault, J.; Charaï, A. A methodology to optimize the quantification of sp2 carbon fraction from K edge EELS spectra. J. Elect. Spectr. Relat. Phenom. 2008, 164, 34–43. [Google Scholar] [CrossRef]

- Leyva-Porras, C.; Ornelas-Gutiérrez, C.; Miki-Yoshida, M.; Avila-Vega, Y.I.; Macossay, J.; Bonilla-Cruz, J. EELS analysis of Nylon 6 nanofibers reinforced with nitroxide-functionalized graphene oxide. Carbon 2014, 70, 164–172. [Google Scholar] [CrossRef] [Green Version]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef]

- Garcia Filho, F.C.; Luz, F.S.; Nascimento, L.F.C.; Satyanarayana, K.G.; Drelich, J.W.; Monteiro, S.N. Mechanical properties of Boehmeria nivea natural fabric reinforced epoxy matrix composite prepared by vacuum-assisted resin infusion molding. Polymers 2020, 12, 1311. [Google Scholar] [CrossRef]

- Costa, U.O.; Nascimento, L.F.C.; Garcia, J.M.; Bezerra, W.B.A.; Monteiro, S.N. Evaluation of Izod Impact and bend properties of epoxy composites reinforced with mallow fibers. J. Mater. Res. Technol. 2020, 9, 373–382. [Google Scholar] [CrossRef]

- Oliveira, M.S.; Luz, F.S.; Souza, A.T.; Demosthenes, L.C.C.; Pereira, A.C.; Garcia Filho, F.C.; Braga, F.O.; Figueiredo, A.B.-H.S.; Monteiro, S.N. Tucum fiber from amazon Astrocaryum vulgare palm tree: Novel reinforcement for polymer composites. Polymers 2020, 12, 2259. [Google Scholar] [CrossRef] [PubMed]

- Neuba, L.M.; Pereira Junio, R.F.; Ribeiro, M.P.; Souza, A.T.; Lima, E.D.S.; Garcia Filho, F.C.; Figueiredo, A.B.-H.S.; Braga, F.O.; Azevedo, A.R.G.D.; Monteiro, S.N. Promising mechanical, thermal, and ballistic properties of novel epoxy composites reinforced with Cyperus malaccensis sedge fiber. Polymers 2020, 12, 1776. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, M.S.; Garcia Filho, F.C.; Luz, F.S.; Pereira, A.C.; Demosthenes, L.C.C.; Nascimento, L.F.C.; Lopera, H.A.C.; Monteiro, S.N. Statistical analysis of notch toughness of epoxy matrix composites reinforced with fique fabric. J. Mater. Res. Technol. 2019, 8, 6051–6057. [Google Scholar] [CrossRef]

- Simonassi, N.T.; Pereira, A.C.; Monteiro, S.N.; Margem, F.M.; Rodríguez, R.J.S.; Deus, J.F.; Vieira, C.M.F.; Drelich, J. Reinforcement of polyester with renewable ramie fibers. Mater. Res. 2017, 20, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Braga, F.O.; Simonassi, N.T.; Cabral, A.C.; Monteiro, S.N.; Assis, F.S. Tensile and impact properties of two fiber configurations for curaua reinforced composites. In Proceedings of the 3rd Pan American Materials Congress; Springer: Cham, Switzerland, 2017; pp. 429–436. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Margem, F.M.; Assis, F.S.; Loiola, R.L.; Oliveira, M.P. Izod impact tests in polyester matrix composites reinforced with banana fibers. Mater. Sci. Forum 2014, 775–776, 261–265. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Lopes, F.P.D.; Nascimento, D.C.O.; Ferreira, A.D.S.; Satyanarayana, K.G. Processing and properties of continuous and aligned curaua fibers incorporated polyester composites. J. Mater. Res. Technol. 2013, 2, 2–9. [Google Scholar] [CrossRef] [Green Version]

- Mishra, V.; Biswas, S. Physical and mechanical properties of bi-directional jute fiber epoxy composites. Procedia Eng. 2013, 51, 561–566. [Google Scholar] [CrossRef] [Green Version]

- Pereira, A.C.; Monteiro, S.N.; Simonassi, N.T.; Vieira, C.M.F.; Lima, A.M.; Costa, U.O.; Pinheiro, W.A.; Oliveira, M.S.; Figueiredo, A.B.-H.S. Enhancement of impact toughness using graphene oxide in epoxy composite reinforced with ramie fabric. Compos. Struct. 2022, 282, 115023. [Google Scholar] [CrossRef]

- Ashori, A.; Fallah, A.; Ghiyasi, M.; Rabiee, M. Reinforcing effects of functionalized graphene oxide on glass fiber/epoxy composites. Polym. Compos. 2017, 39, E2324–E2333. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Braga, F.O.; Lima, E.P.; Louro, L.H.L.; Drelich, J.W. Promising curaua fiber-reinforced polyester composite for high-impact ballistic multilayered armor. Polym. Eng. Sci. 2016, 57, 947–954. [Google Scholar] [CrossRef]

- Assis, F.S.; Pereira, A.C.; Garcia Filho, F.C.; Lima, E.P.; Monteiro, S.N.; Weber, R.P. Performance of jute non-woven mat reinforced polyester matrix composite in multilayered armor. J. Mater. Res. Technol. 2018, 7, 535–540. [Google Scholar] [CrossRef]

- Luz, F.S.; Ramos, F.J.H.T.V.; Nascimento, L.F.C.; Figueiredo, A.B.-H.S.; Monteiro, S.N. Critical length and interfacial strength of palf and coir fiber incorporated in epoxy resin matrix. J. Mater. Res. Technol. 2018, 7, 528–534. [Google Scholar] [CrossRef]

- Braga, F.O.; Bolzan, L.T.; Ramos, F.J.H.T.V.; Monteiro, S.N.; Lima, E.P.; Silva, L.C. Ballistic efficiency of multilayered armor systems with sisal fiber polyester composites. Mater. Res. 2018, 20, 767–774. [Google Scholar] [CrossRef]

- Cruz, R.B.; Lima, E.P.; Monteiro, S.N.; Louro, L.H.L. Giant bamboo fiber reinforced epoxy composite in multilayered ballistic armor. Mater. Res. 2015, 18, 70–75. [Google Scholar] [CrossRef] [Green Version]

- Monteiro, S.N.; Candido, V.S.; Braga, F.O.; Bolzan, L.T.; Weber, R.P.; Drelich, J.W. Sugarcane bagasse waste in composites for multilayered armor. Eur. Polym. J. 2016, 78, 173–185. [Google Scholar] [CrossRef]

- Monteiro, S.N.; Milanezi, T.L.; Louro, L.H.L.; Lima, E.P.; Braga, F.O.; Gomes, A.V.; Drelich, J.W. Novel ballistic ramie fabric composite competing with Kevlar™ fabric in multilayered armor. Mater. Desig. 2016, 96, 263–269. [Google Scholar] [CrossRef]

- Wilson, N.; Pandey, P.; Beanland, R.; Young, R.; Kinloch, I.; Gong, L.; Liu, Z.; Suenaga, K.; Rourke, J.; York, S.; et al. Graphene oxide: Structural analysis and application as a highly transparent support for electron microscopy. ACS Nano 2009, 3, 2547–2556. [Google Scholar] [CrossRef]

- Meyer, J.; Geim, A.; Katsnelson, M.; Novoselov, K.; Obergfell, D.; Roth, S.; Girit, C.; Zettl, A. On the roughness of single- and bi-layer graphene membranes. Solid State Commun. 2007, 143, 101–109. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Hamon, A.; Haghi-Ashtiani, P.; Reiss, T.; Fan, B.; He, D.; Bai, J. Quantitative study of interface/interphase in epoxy/graphene-based nanocomposites by combining STEM and EELS. ACS Appl. Mater. Interf. 2016, 8, 34151–34158. [Google Scholar] [CrossRef]

- Luz, F.S.; Lima, E.P.; Louro, L.H.L.; Monteiro, S.N. Ballistic test of multilayered armor with intermediate epoxy composite reinforced with jute fabric. Mater. Res. 2015, 18, 170–177. [Google Scholar] [CrossRef]

- Trindade, W.; Silva, M.H.P.; Gomes, A.V.; Campos, J.B.; Louro, L.H.L. Processing and properties of niobia-doped alumina sintered at 1400 °C. Mater. Sci. Forum 2014, 798–799, 665–670. [Google Scholar] [CrossRef]

| Fiber/Matrix | Amount of Fiber | Izod Impact- Absorbed Energy (J/m) | Reference |

|---|---|---|---|

| Curaua/Epoxy | 40 | 620 | PW |

| GO-functionalized Curaua/Epoxy | 40 | 813 | PW |

| Ramie/Epoxy | 30 | 567 | [52] |

| Mallow/Epoxy | 30 | 499 | [53] |

| Tucum/Epoxy | 40 | 216 | [54] |

| Sedge/Epoxy | 30 | 63 | [55] |

| Fique/Epoxy | 40 | 222 | [56] |

| Ramie/Polyester | 30 | 594 | [57] |

| Curaua non-woven/Epoxy | 30 | 433 | [58] |

| Banana Fiber/Polyester | 30 | 265 | [59] |

| Curaua/Polyester | 30 | 190 | [60] |

| Jute/Epoxy | 30 | 426 | [61] |

| GO Ramie/Epoxy | 30 | 60 | [62] |

| GO Glass Fiber/Epoxy | 40 | 290 | [63] |

| Material in Ballistic Armor for Protection against Level III Ammunition | Backface Signature (mm) | Reference |

|---|---|---|

| 40 vol% curaua fiber/epoxy composite | 24.8 | PW |

| 40 vol% GO-functionalized curaua fiber/epoxy composite | 24.8 | PW |

| 30 vol% Guaruman fiber/epoxy composite | 27.5 | [17] |

| 30 vol% pineapple leaf fiber (PALF)/epoxy composite | 26.6 | [16] |

| 30 vol% curaua fiber/epoxy composite | 24.3 | [35] |

| 30 vol% curaua fiber/polyester composite | 22.2 | [66] |

| 30 vol% jute mat/polyester composite | 24.7 | [67] |

| 30 vol% coir fiber/epoxy composite | 31.6 | [68] |

| 30 vol% sisal fiber/ Polyester composite | 22.3 | [69] |

| 30 vol% bamboo fiber/epoxy composite | 18.2 | [70] |

| 30 vol% sugarcane bagasse/epoxy composite | 39.8 | [71] |

| 10 mm Kevlar™ as the MAS second layer | 21.3 | [72] |

| 25 mm Dyneema™ plate (complete MAS) | 41.5 | [16] |

| Armor Component | Volume (cm3) | Density (g/cm³) | Weight (kg) | Price per kg (US Dollars) | Component Cost (US Dollars) |

|---|---|---|---|---|---|

| Al2O3-ceramic tile | 225 | 3.89 | 0.74 | 2.60 | 1.94 |

| 30CF/EM | 225 | 1.05 | 0.24 | 25.91 | 6.22 |

| 40CF/EM | 225 | 1.03 | 0.23 | 25.91 | 5.96 |

| GO | - | - | 0.000083 | 31.240 a–174,000 b | 2.59–14.44 |

| 40GOCF/EM | 225 | 1.03 | 0.23 | 28.50–40.35 | 6.56–9.28 |

| Kevlar™ | 168.75 | 1.09 | 0.18 | 72.50 | 13.05 |

| Total MAS weght with 30CF/EM | 1.23 | Total cost with 30CF/EM composite (US dollars) | 21.21 | ||

| Total MAS weight with 40CF/EM composite (kg) | 1.22 | Total cost with 40CF/EM composite (US dollars) | 20.95 | ||

| Total MAS weight with 40GOCF/EM nanocomposite (kg) | 1.22 | Total cost with 40GOCF/EM composite (US dollars) | 21.55–24.27 | ||

| Decrease in weight (%) 30CF/E compared to 40CF/EM | 0.81 | Decrease in cost (%) 30CF/E compared to 40CF/EM | 1.24 | ||

| Decrease in weight (%) 40CF/E compared to 40GOCF/EM | 0.00 | Increase in cost (%) 40CF/E compared to 40GOCF/EM | 2.86–15.85 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, U.O.; Nascimento, L.F.C.; Bezerra, W.B.A.; Neves, P.P.; Huaman, N.R.C.; Monteiro, S.N.; Pinheiro, W.A. Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites. Polymers 2022, 14, 1859. https://doi.org/10.3390/polym14091859

Costa UO, Nascimento LFC, Bezerra WBA, Neves PP, Huaman NRC, Monteiro SN, Pinheiro WA. Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites. Polymers. 2022; 14(9):1859. https://doi.org/10.3390/polym14091859

Chicago/Turabian StyleCosta, Ulisses Oliveira, Lucio Fabio Cassiano Nascimento, Wendell Bruno Almeida Bezerra, Pamela Pinto Neves, Noemi Raquel Checca Huaman, Sergio Neves Monteiro, and Wagner Anacleto Pinheiro. 2022. "Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites" Polymers 14, no. 9: 1859. https://doi.org/10.3390/polym14091859

APA StyleCosta, U. O., Nascimento, L. F. C., Bezerra, W. B. A., Neves, P. P., Huaman, N. R. C., Monteiro, S. N., & Pinheiro, W. A. (2022). Dynamic and Ballistic Performance of Graphene Oxide Functionalized Curaua Fiber-Reinforced Epoxy Nanocomposites. Polymers, 14(9), 1859. https://doi.org/10.3390/polym14091859