Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures

Abstract

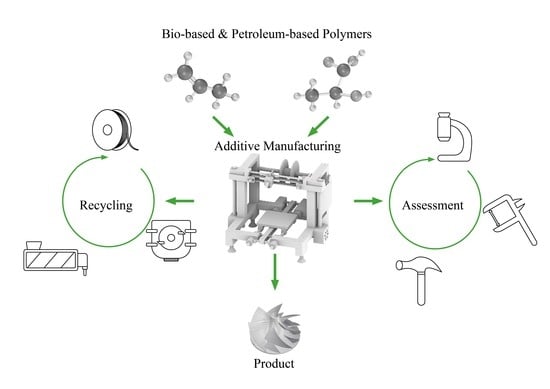

:1. Introduction

2. Materials and Methods

3. Results

3.1. Fabrication and Recycling Process

3.2. Morphology

3.3. Filament and Material Characterization

| MFR Values [g/10 min; 2.16 kg; 230 °C] | ||||||

|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec | PP 0rec | PP 1rec | PP Sup 0rec | PP Sup 1rec | |

| MAX | 37 | 56 | 14 | 9 | 11 | 11 |

| MIN | 23 | 54 | 8 | 7 | 10 | 10 |

| MEAN | 30 | 55 | 9 | 8 | 10 | 10 |

| STDV | 3.6 | 1.0 | 1.6 | 0.7 | 0.2 | 0.1 |

| Filament Diameter Values [mm] | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec_1extr | PLA 1rec_2extr | PP 0rec | PP 1rec_1extr | PP 1rec_2extr | PP Sup 0rec | PP Sup 1rec_1extr | PP Sup 1rec_2extr | |

| MAX | 1.78 | 1.94 | 2.11 | 1.76 | 2.04 | 1.81 | 1.75 | 2.50 | 1.79 |

| MIN | 1.75 | 1.54 | 1.39 | 1.68 | 0.24 | 1.63 | 1.72 | 1.30 | 1.60 |

| MEAN | 1.76 | 1.72 | 1.71 | 1.72 | 1.65 | 1.69 | 1.73 | 1.69 | 1.67 |

| STDV | 0.01 | 0.06 | 0.12 | 0.01 | 0.22 | 0.03 | 0.01 | 0.13 | 0.03 |

3.4. Mechanical Testing

3.5. Surface Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Schmitt, P.; Zorn, S.; Gericke, K. Additive Manufacturing research landscape. A literature review. In Proceedings of the International Conference on Engineering Design (ICED21), Gothenburg, Sweden, 16–20 August 2021. [Google Scholar]

- Ngo, T.; Kashani, A.; Imbalzano, G.; Nguyen, K.; Hui, D. Additive Manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Maguire, A.; Pottackal, N.; Saadi, M.; Rahman, M.; Ajayan, P. Additive Manufacturing of polymer-based structures by extrusion technologies. Oxf. Open Mater. Sci. 2021, 1, itaa004. [Google Scholar] [CrossRef]

- Bourell, D.; Kruth, J.; Leu, M.; Levy, G.; Rosen, D.; Beese, A.; Clare, A. Materials for Additive Manufacturing. CIRP Ann. 2017, 66, 659–681. [Google Scholar] [CrossRef]

- Rashid, A.; Koç, M. Fused Filament Fabrication Process: A review of numerical simulation techniques. Polymers 2021, 13, 3534. [Google Scholar] [CrossRef] [PubMed]

- Tofail, S.; Koumoulos, E.; Badyopadhyay, A.; Bose, S.; O’Donoghue, L.; Charitidis, C. Additiv Manufacturing: Scientific and technological challenges, market uptake and opportunities. Mater. Today 2018, 21, 22–37. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Ford, S.; Despeisse, M. Additive Manufacturing and sustainability: An exploratory of the advantages and challenges. J. Clean. Prod. 2016, 137, 1573–1587. [Google Scholar] [CrossRef]

- Peng, T.; Kellens, K.; Tang, R.; Chen, C.; Chen, G. Sustainability of Additive Manufacturing: An overview on its energy demand and environmental impact. Addit. Manuf. 2018, 21, 694–704. [Google Scholar] [CrossRef]

- Colorado, H.A.; Velásquez, E.I.G.; Monteiro, S.N. Sustainability of Additive Manufacturing: The Circular Economy of materials and environmental perspective. J. Mater. Res. Technol. 2020, 9, 8221–8234. [Google Scholar] [CrossRef]

- Kellens, K.; Baumers, M.; Gutowski, T.; Flanagan, W.; Lifset, R.; Duflou, J. Environmental dimensions of AM: Mapping application domains and their environmental implications. J. Ind. Ecol. 2017, 21, 49–68. [Google Scholar] [CrossRef]

- Streenhuis, H.-J.; Pretorius, L. Additive Manufacturing or 3D printing and its adoption. In IAMOT 2015 Conference Proceedings; University of Pretoria: Pretoria, South Africa, 2015. [Google Scholar]

- Oropallo, W.; Piegl, L. Ten challenges in 3D printing. Eng. Comput. 2016, 32, 135–148. [Google Scholar] [CrossRef]

- Geyer, R.; Jambeck, J.; Law, K. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Hahladakis, J.; Iacovidou, E. Closing the loop on plastic packaging materials: What is quality and how does it affect their circularity? Sci. Total Environ. 2018, 630, 1394–1400. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Liu, P.; Gu, Z.; Cheng, H.; Li, X. A scientometric review of resource recycling industry. Int. J. Environ. Res. Public Health 2019, 16, 4654. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of the art review and future applications. Compos. Part B 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Grigore, M. Methods of recycling, properties and applications of recycled thermoplastic polymers. Recycling 2017, 2, 24. [Google Scholar] [CrossRef]

- Kazemi, M.; Kabir, S.; Fini, E. State of art in recycling waste thermoplastics and thermosets and their applications in construction. Resour. Conserv. Recycl. 2021, 174, 105776. [Google Scholar] [CrossRef]

- Vogt, B.; Stokes, K.; Kumar, S. Why is recycling of postconsumer plastics so challenging? ACS Appl. Polym. Mater. 2021, 3, 4325–4346. [Google Scholar] [CrossRef]

- Ragaert, K.; Delva, L.; Van Geem, K. Mechanical and chemical recycling of solid plastic waste. Waste Manag. 2017, 69, 24–58. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.M.; Laurent, C.; Fontaine, L.; Montembault, V. Mechanical recycling: Compatibilization of mixed thermoplastic wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Hopewell, J.; Dvorak, R.; Kosior, E. Plastic recycling: Challenges and opportunities. Philos. Trans. R. Soc. B Biol. Sci. 2009, 365, 2115–2126. [Google Scholar] [CrossRef] [PubMed]

- Cimpan, C.; Maul, A.; Jansen, M.; Pretz, T.; Wenzel, H. Central sorting and recovery of MSW recyclable materials: A review of technological state-of-the-art, cases, practice and implications for materials recycling. Environ. Manag. 2015, 156, 181–199. [Google Scholar] [CrossRef] [PubMed]

- Calero, M.; Martin-Lara, M.; Godoy, V.; Quesada, L.; Martinez, D.; Peula, F.; Soto, J. Characterization of plastic materials present in municipal solid waste: Preliminary study for their mechanical recycling. Multidiscip. J. Waste Resour. Residues 2018, 2018, 104. [Google Scholar] [CrossRef]

- Pandey, J.; Reddy, R.; Kumar, P.; Singh, R.P. An overview on the degradability of polymer nanoncomposites. Polym. Degrad. Stab. 2005, 88, 234–250. [Google Scholar] [CrossRef]

- Capone, C.; Di Landro, L.; Inzoli, F.; Penco, M.; Sartore, L. Thermal and mechanical degradation during polymer extrusion processing. Polym. Eng. Sci. 2007, 47, 1813–1819. [Google Scholar] [CrossRef]

- Lambert, S.; Sinclair, C.; Boxall, A. Occurrence, degradation, and effect of polymer-based materials in the environment. Rev. Environ. Contam. Toxicol. 2014, 227, 1–53. [Google Scholar]

- He, Y.; Li, H.; Xiao, X.; Zhao, X. Polymer degredation: Category, mechanism and development prospect. In E3S Web Conferences ICGEC21; EDP Sciences: Paris, France, 2021. [Google Scholar]

- Harris, M.; Potgieter, J.; Archer, R.; Arif, K. Effect of material and process specific factors on the strength of printed parts in Fused Filament Fabrication: A review on recent developments. Materials 2019, 12, 1664. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Iñiguez-Franco, F.; Samsudin, H.; Fang, X.; Auras, R. Poly(lactic acid)–Mass production, processing, industrial applications, and End of Life. Adv. Drug Deliv. Rev. 2016, 107, 333–366. [Google Scholar] [CrossRef]

- Murariu, M.; Dubois, P. PLA composites: From production to properties. Adv. Drug Deliv. Rev. 2016, 107, 17–46. [Google Scholar] [CrossRef]

- Nampoothiri, K.; Nair, N.; John, R. An overview of the recent developments in polylactide (PLA) research. Bioresour. Technol. 2010, 101, 8493–8501. [Google Scholar] [CrossRef]

- Jamshidian, M.; Tehrany, E.; Imran, M.; Jacquot, M.; Desobry, S. Polylactid acid: Production, applications, nanocomposites, and release studies. Compr. Rev. Food Sci. Food Saf. 2010, 9, 552–571. [Google Scholar] [CrossRef] [PubMed]

- Chacón, J.; Caminero, M.; García-Plaza, E.; Núnez, P.J. Additive Manufacturing of PLA structures using Fused Deposition Modelling: Effect of process parameters on mechanical properties and their optimal selection. Mater. Des. 2017, 124, 143–157. [Google Scholar] [CrossRef]

- Ilyas, R.; Sapuan, S.; Harussani, M.; Hakimi, M.; Haziq, M.; Atika, M.; Asyraf, M.; Ishak, M.; Razman, M.; Nurazzi, N.; et al. Asrofi, Polylactic Acid (PLA) Biocomposite: Processing, Additive Manufacturing and advanced applications. Polymers 2021, 13, 1326. [Google Scholar] [CrossRef] [PubMed]

- Sato, H.; Ogawa, H. Review on development of Polypropylene manufacturing process. Materials 2009, 10–18. [Google Scholar]

- Maddah, H. Polypropylene as a promising plastic: A review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Dabbak, S.; Illias, H.; Ang, B.C.; Latiff, N.; Makmud, M. Electrical properties of Polyethylene/Polypropylene compounds of high voltage insulation. Energies 2017, 11, 1448. [Google Scholar] [CrossRef]

- Patil, A.; Patel, A.; Purohit, R. An overview of polymeric materials for automotive applications. Mater. Today Proc. 2017, 4, 3807–3815. [Google Scholar] [CrossRef]

- Antosik, A.; Kowalska, U.; Stobińska, M.; Dziecol, P.; Pieczykolan, M.; Kozlowska, K.; Bartkowiak, A. Develepoment and characterization of bioactive Polypropylene films for food packaging applications. Polymers 2021, 13, 3478. [Google Scholar] [CrossRef]

- Genis, A. Analysis of the global and Russian markets for Polypropylene and of its main consumption areas. Russ. J. Gen. Chem. 2015, 87, 2137–2150. [Google Scholar] [CrossRef]

- Jin, M.; Neuber, C.; Schmidt, H.W. Tailoring polypropylene for extrusion-based Additive Manufacturing. Addit. Manuf. 2020, 33, 101101. [Google Scholar] [CrossRef]

- Carneiro, O.; Silva, A.; Gomes, R. Fused Deposition Modelling with Polypropylene. Mater. Des. 2015, 83, 768–776. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Velidakis, E.; Tzounis, L.; Mountakis, N.; Kechagias, J.; Grammatikos, S. Optimization of the filler concentration on Fused Filament Fabrication 3D printe polypropylene with titanium oxide nanocomposites. Materials 2021, 14, 3076. [Google Scholar] [CrossRef]

- Kechagias, J.; Chaidas, D.; Vidakis, N.; Salonitis, K.; Vaxevanidis, N. Key parameters controlling surface quality and dimensional accuracy: A critical review of FFF process. Mater. Manuf. Process. 2022, 37, 963–984. [Google Scholar] [CrossRef]

- Kechagias, J.; Vidakis, N.; Petousis, M.; Mountakis, N. A multi-parametric process evaluation of the mechanical response of PLA in FFF 3D printing. Mater. Manuf. Process. 2022, 38, 941–953. [Google Scholar] [CrossRef]

- Das, A.; Riet, J.; Bortner, M.; McIlroy, C. Rheology, crystallization, and process conditions: The effect on interlayer properties in three-dimensional printing. Phys. Fluids 2022, 34, 123108. [Google Scholar] [CrossRef]

- Romani, A.; Rognoli, V.; Levi, M. Design, materials, and extrusion-based Additive Manufacturing in Circular Economy contexts: From waste to new products. Sustainability 2021, 13, 7269. [Google Scholar] [CrossRef]

- Despeisse, M.; Baumers, M.; Brown, P.; Charnley, F.; Ford, S.J.; Garmulewicz, A.; Knowles, S.; Minshall, T.H.W.; Mortara, L.; Reed-Tsochas, F.P.; et al. Unlocking value for a Circular Economy through 3D printing: A research agenda. Technol. Forecast. Soc. Chang. 2016, 115, 75–84. [Google Scholar] [CrossRef]

- Shanmugam, V.; Das, O.; Neisiany, E.; Babu, K.; Singh, S.; Hednqvist, M.; Berto, F.; Ramakrishna, S. Polymer recycling in Additive Manufacturing an opportunity for the Circular Economy. Mater. Circ. Econ. 2020, 2, 11. [Google Scholar] [CrossRef]

- Sanchez, F.C.; Boudaoud, H.; Carmago, M.; Pearce, J. Plastic recycling and Additive Manufacturing: A systematic literature review and opportunities for the Circular Economy. J. Clean. Prod. 2020, 264, 121602. [Google Scholar] [CrossRef]

- Fico, D.; Rizzo, D.; Casciaro, R.; Corcione, C.E. A review of polymer-based materials for Fused Filament Fabrication (FFF): Focus on sustainability and recycled materials. Polymers 2022, 14, 465. [Google Scholar] [CrossRef]

- Lanzotti, A.; Martorelli, M.; Maietta, S.; Gerbino, S.; Penta, F.; Gloria, A. A comparison between mechanical properties of specimen 3D printed with virgin and recycled PLA. In Proceedings of the 12th CIRP Conference on Intelligent Computation and Manufacturing Engineering (ICME18), Naples, Italy, 18–20 July 2018. [Google Scholar]

- Sanchez, F.C.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer recycling in an open-source Additive Manufacturing context: Mechanical issues. Addit. Manuf. 2017, 17, 87–105. [Google Scholar] [CrossRef]

- Tanney, D.; Meisel, N.; Moore, J. Investigating material degradation through the recycling of PLA in additively manufactured parts. In Proceedings of the Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 7–9 August 2017. [Google Scholar]

- Beltrán, F.; Arrieta, M.; Moreno, E.; Gaspar, G.; Muneta, L.; Carrasco-Gallego, R.; Yáñez, S.; Hidalgo-Carvajal, D.; de la Orden, M.; Urreaga, J.M. Evaluation of the technical viability of distributed mechanical recycling of PLA 3D printing wastes. Polymers 2021, 13, 1247. [Google Scholar] [CrossRef] [PubMed]

- Sasse, J.; Pelzer, L.; Schön, M.; Ghaddar, T.; Hopmann, C. Investigation of recycled and coextruded PLA filament for Additive Manufacturing. Polymers 2022, 14, 2407. [Google Scholar] [CrossRef]

- Spoerk, M.; Arbeiter, F.; Raguz, I.; Holzer, C.; Gonzalez-Gutierrez, J. Mechanical recycability of Polypropylene composites produced by material extrusion-based Additive Manufacturing. Polymers 2019, 11, 1318. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Papageorgiou, D.; Liebscher, M.; Mechtcherine, V. Sustainable Additive Manufacturing: Mechanical response of Polypropylene over multiple recycling processes. Sustainability 2020, 13, 159. [Google Scholar] [CrossRef]

- Dobránsky, J.; Pollák, M.; Behálek, L.; Svetlik, J. Implementation of a recycled Polypropylene homopolymer material for use in Additive Manufacturing. Sustainability 2021, 13, 4990. [Google Scholar] [CrossRef]

- Pickering, K.L.; Stoof, D. Sustainable composite Fused Deposition Modelling filament using post-consumer recycled Polypropylene. J. Compos. Sci. 2017, 1, 17. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Maniadi, A. Sustainable Additive Manufacturing: Mechanical response of high-density polyethylene over multiple recycling processes. Recycling 2021, 6, 4. [Google Scholar] [CrossRef]

- Momanyi, J.; Herzog, M.; Muchiri, P. Analysis of thermomechanical properties of selected class of recycled thermoplastic materials based on their applications. Recycling 2019, 4, 33. [Google Scholar] [CrossRef]

- Jubinville, D.; Esmizadeh, E.; Saikrishnan, S.; Tzoganakis, C.; Mekonnen, T. A comprehensive review of global production and recycling methods of polyolefin (PO) based products and their post-recycling applications. Sustain. Mater. Technol. 2020, 25, e00188. [Google Scholar] [CrossRef]

- Saikrishnan, S.; Jubinville, D.; Tzoganakis, C.; Mekonnen, T. Thermomechanical degradation of polypropylene (PP) and low-density polyethylene (LDPE) blends exposed to simulated recycling. Polym. Degrad. Stab. 2020, 182, 109390. [Google Scholar] [CrossRef]

- Gudadhe, A.; Bachar, N.; Kumar, A.; Andrade, P.; Kumaraswamy, G. Three-Dimensional Printing with waste High-Density Polyethylene. ACS Appl. Polym. Mater. 2019, 1, 3157–3164. [Google Scholar] [CrossRef]

- Zander, N.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled polypropylene blends as novel 3D printing materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Badia, J.D.; Amparo, R. Mechanical recycling of Polylactide, upgrading trends and combination of valorisation techniques. Eur. Polym. J. 2016, 84, 22–39. [Google Scholar] [CrossRef]

- Villaplana, F.; Karlsson, S. Quality concepts for the improved use of recycled polymetric materials: A review. Macromol. Mater. Eng. 2009, 293, 274–297. [Google Scholar] [CrossRef]

- Strömberg, E.; Karlsson, S. The design of a test protocol to model the degradation of polyolefins during recycling and service life. J. Appl. Polym. Sci. 2009, 12, 1835–1844. [Google Scholar] [CrossRef]

- ASTM F1980–16th Edition: 15.09.2016; Standard guide for accelerated aging of sterile barrier systems for medical devices. ASTM International: West Conshohocken, PA, USA, 2016.

- Garlotta, D. A Literature Review of Poly(Lactic Acid). J. Polym. Environ. 2001, 9, 63–84. [Google Scholar] [CrossRef]

- Lanyi, F.; Wenzke, N.; Kaschta, J.; Schubert, D. On the determination of the enthalpy of fusion of α-crystalline isotactic polypropylene using differential scanning calorimetry, x-ray diffraction, and Fourier-Transform Infrared Spectroscopy: An old story revisited. Adv. Eng. Mater. 2020, 22, 1900796. [Google Scholar] [CrossRef]

- Reyes-Labarta, J.; Olaya, M.; Marcilla, A. DSC and TGA study of the transitions involved in the thermal treatment of binary mixtures PE and EVA copolymer with a crosslinking agent. Polymer 2006, 47, 8194–8202. [Google Scholar] [CrossRef]

- Cullis, C.; Hirschler, M. The Combustion of Organic Polymers; Cleandon Press: Oxford, UK, 1981. [Google Scholar]

- León-Cabezas, M.; Martínez-Garcia, A.; Varela-Gandia, F.J. Innovative functionalized monofilaments for 3D printing using Fused Deposition Modelling for the toy industry. Procedia Manuf. 2017, 13, 738–745. [Google Scholar] [CrossRef]

- Cardona, C.; Curdes, A.; Isaacs, A. Effects of filament diameter tolerances in Fused Filament Fabrication. IU J. Undergrad. Res. 2016, 2, 44–47. [Google Scholar] [CrossRef]

- Spoerk, M.; Svandaiah, C.; Arbeiter, F.; Sapkota, J.; Holzer, C. Optimization of mechanical properties of glass-spheres-filled Polypropylene composites for extrusion-based Additive Manufacturing. Polym. Compos. 2019, 40, 638–651. [Google Scholar] [CrossRef]

- Menyhárd, A. Direct correlation between modulus and the crystalline structure in isotactic polypropylene. Express Polym. Lett. 2015, 9, 308–320. [Google Scholar] [CrossRef]

- El-Hadi, A.; Schnabel, R.; Straube, E.; Müller, G.; Henning, S. Correlation between degree of crystallinity, morphology, glass temperature, mechanical properties and biodegradation of poly(2-hydroxalkonate) PHAs and their blends. Polym. Test. 2002, 21, 665–674. [Google Scholar] [CrossRef]

- Meijer, H.; Govaert, L. Mechanical performance of polymer systems. The relation between structure and properties. Prog. Polym. Sci. 2005, 30, 915–938. [Google Scholar] [CrossRef]

- Shetty, S.; Shetty, N. Investigation of mechanical properties and applications of polylactic acids—A review. Mater. Res. Express 2019, 6, 112002. [Google Scholar] [CrossRef]

- Yu, H.; Huang, N.; Wang, C.; Tang, Z. Modeling of poly(L-lactide) thermal degradation: Theoretical prediction of molecular weight and polydispersity index. J. Appl. Polym. Sci. 2003, 88, 2557–2562. [Google Scholar] [CrossRef]

- Das, A.; Marnot, A.; Fallon, J.; Martin, S.; Joseph, E.; Bortner, M. Material extrusion-based Additive Manufacturing with blends of polypropylene and hydrocarbon resins. ACS Appl. Polym. Mater. 2020, 2, 911–921. [Google Scholar] [CrossRef]

- Bhushan, B. Modern Tribology Handbook, Two Volume Set; CRC Press: Boca Raton, FL, USA, 2000. [Google Scholar]

- Alsoufi, M.; Elsayed, E. How surface roughness performance of printed parts manufactured by desktop FDM 3D printer with PLA is influenced by measuring direction. Am. J. Mech. Eng. 2017, 5, 211–222. [Google Scholar]

- Chaidas, D.; Kitsakis, K.; Kechagias, J.; Maropoulos, S. The impact of temperature changing on surface roughness of FFF process. IOP Conf. Ser. Mater. Sci. Eng. 2016, 161, 012033. [Google Scholar] [CrossRef]

| Parameters | Cuboid | Impeller | Square Tube |

|---|---|---|---|

| Nozzle temperature [°C] | 210 | 210 | 210 |

| Bed temperature [°C] | 20 (first layer 70) | 20 (first layer 70) | 20 (first layer 70) |

| Layer height [mm] | 0.2 | 0.2 | 0.2 |

| Layer width [mm] | 0.4 | 0.4 | 0.4 |

| Top solid layers | 3 | 5 | 1 |

| Bottom solid layers | 3 | 5 | 1 |

| Infill density [%] | 50 | 25 | 50 |

| Support infill density [%] | 25 | ||

| Material flow [%] | 100 | 100 | 100 |

| Travel speed [mm/s] | 20 | 20 | 20 |

| Adhesion structure | Skirt | Raft | Skirt |

| Material | ΔHm [J/g] | XC [%] | |

|---|---|---|---|

| PLA 0rec | 2 | 93.7 [73] | 2.1 |

| PLA 1rec | 4 | 4.3 | |

| PP 0rec | 59 | 171 [74] | 34.5 |

| PP 1rec | 57 | 33.3 | |

| PP Sup 0rec | 11 | - | - |

| PP Sup 1rec | 12 | - |

| Filament Ovality Values | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec_1extr | PLA 1rec_2extr | PP 0rec | PP 1rec_1extr | PP 1rec_2extr | PP Sup 0rec | PP Sup 1rec_1extr | PP Sup 1rec_2extr | |

| MAX | 0.019 | 0.024 | 0.031 | 0.055 | 0.562 | 0.044 | 0.02 | 0.035 | 0.033 |

| MIN | 0.002 | 0.001 | 0.000 | 0.015 | 0.011 | 0.007 | 0.003 | 0.003 | 0.004 |

| MEAN | 0.009 | 0.008 | 0.007 | 0.033 | 0.097 | 0.015 | 0.011 | 0.014 | 0.017 |

| STDV | 0.003 | 0.004 | 0.005 | 0.005 | 0.129 | 0.004 | 0.003 | 0.004 | 0.004 |

| 90° E-Modulus Values [MPa] | ||||||

|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec | PP 0rec | PP 1rec | PP Sup 0rec | PP Sup 1rec | |

| MAX | 3177 | 2673 | 467 | 485 | 809 | 800 |

| MIN | 2029 | 2048 | 377 | 354 | 684 | 709 |

| MEAN | 2724 | 2404 | 410 | 424 | 743 | 756 |

| STDV | 391 | 214 | 27 | 66 | 54 | 34 |

| 90° Tensile Strain at Break Values [%] | ||||||

|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec | PP 0rec | PP 1rec | PP Sup 0rec | PP Sup 1rec | |

| MAX | 2.3 | 1.8 | 742 | 632 | 24 | 20 |

| MIN | 1.2 | 1.3 | 574 | 602 | 17 | 11 |

| MEAN | 1.9 | 1.6 | 659 | 614 | 20 | 15 |

| STDV | 0.4 | 0.1 | 55 | 16 | 2.6 | 3.7 |

| 90° Tensile Yield Strength Values [MPa] | ||||||

|---|---|---|---|---|---|---|

| PLA 0rec | PLA 1rec | PP 0rec | PP 1rec | PP Sup 0rec | PP Sup 1rec | |

| MAX | 44 | 36 | 14 | 16 | 17 | 16 |

| MIN | 28 | 27 | 12 | 15 | 15 | 15 |

| MEAN | 40 | 33 | 13 | 15 | 16 | 15 |

| STDV | 5.5 | 3.1 | 0.5 | 0.6 | 0.5 | 0.5 |

| Roughness [μm] | ||||

|---|---|---|---|---|

| PLA 0rec | PLA 1rec | PP 0rec | PP 1rec | |

| Ra | 13.1 | 17.7 | 11.6 | 11.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nagengast, N.; Bay, C.; Döpper, F.; Schmidt, H.-W.; Neuber, C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers 2023, 15, 2291. https://doi.org/10.3390/polym15102291

Nagengast N, Bay C, Döpper F, Schmidt H-W, Neuber C. Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers. 2023; 15(10):2291. https://doi.org/10.3390/polym15102291

Chicago/Turabian StyleNagengast, Niko, Christian Bay, Frank Döpper, Hans-Werner Schmidt, and Christian Neuber. 2023. "Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures" Polymers 15, no. 10: 2291. https://doi.org/10.3390/polym15102291

APA StyleNagengast, N., Bay, C., Döpper, F., Schmidt, H. -W., & Neuber, C. (2023). Thermo-Mechanical Recyclability of Additively Manufactured Polypropylene and Polylactic Acid Parts and Polypropylene Support Structures. Polymers, 15(10), 2291. https://doi.org/10.3390/polym15102291