A Green Approach for Recycling Compact Discs

Abstract

:1. Introduction

2. Materials and Methods

3. Results

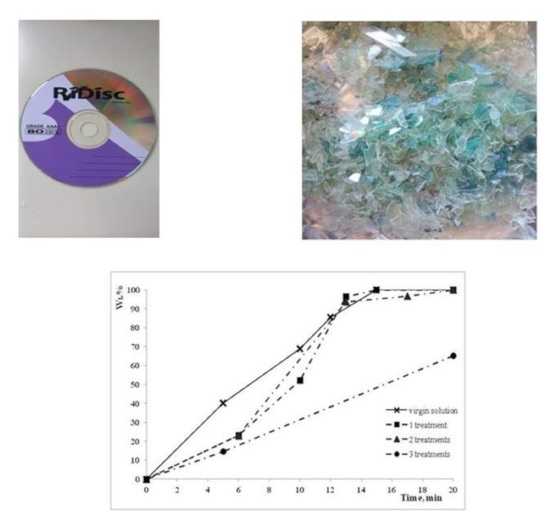

3.1. Cleaning of the Compact Discs

3.2. Reprocessing of the Polycarbonate

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Giovanella, J.; Janczkowski, R.; Soares, G.C.; Serafim, C.; Ramos, T.O.B.; Silva, C.; Molinari, E.J.; Conti, D.S. Reciclagem de materiais: Estudo das propriedades mecânicas de policarbonato reciclado de discos compactos. Mater. Sci. 2008, 13, 643–649. [Google Scholar] [CrossRef] [Green Version]

- Pedreño-Rojas, M.A.; Morales-Conde, M.J.; Pérez-Gálvez, F.; Rubio-de-Hita, P. Reuse of CD and DVD Wastes as Reinforcement in Gypsum Plaster Plates. Materials 2020, 13, 989. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ibrahim, S.; Abdelfattah, I.; Soliman, O. Environmental recycling of compact disc using industrial wastewater. Pharm. Lett. 2016, 8, 207–214. [Google Scholar]

- Office Europeen Des Brevets. Treatment of Compact Discs. European Patent Office—EP 0601719 A1, 3 September 1997.

- Achilias, D.S.; Antonakou, E.V.; Koutsokosta, E.; Lappas, A.A. Chemical recycling of polymers from Waste Electric and Electronic Equipment. J. Appl. Polym. Sci. 2009, 14, 212–221. [Google Scholar] [CrossRef]

- Ahmed, S.J. Effect of Particle Size on Mechanical Properties of the Recycling Compact Disks Reinforced Epoxy. Eng. Technol. J. 2018, 36, 641–645. [Google Scholar] [CrossRef]

- Boudreau, K.A. An Evaluation of the Properties of Recovered Polycarbonate from Mechanically Recycled Compact DiscsMS. Ph.D. Thesis, University of Massachusetts Lowell, Lowell, MA, USA, 1992. [Google Scholar]

- Leone, C.; Genna, S.; Caggiano, A. Resource efficient low power laser cleaning of compact discs for material reuse by polycarbonate recovery. CIRP J. Manuf. Sci. Technol. 2015, 9, 39–50. [Google Scholar] [CrossRef]

- Gioia, C.; Vannini, M.; Celli, A.; Colonna, M.; Minesso, A. Chemical recycling of post-consumer compact discs towards novel polymers for powder coating applications. RSC Adv. 2016, 6, 31462–31469. [Google Scholar] [CrossRef]

- Praharaj Bhatnagar, M. Reclaiming Polycarbonate from Compact Discs and its Use in Synthesizing Hollow Micro Spheres by Electrospraying. ChemRxiv, 2022; preprint. [Google Scholar] [CrossRef]

- La Mantia, F.P.; Conte, F. Recycling of extrusion and injection moulding grade polycarbonate. Macplas Int. 1997, 31–34. [Google Scholar]

- La Mantia, F.P.; Correnti, A. Effect of Processing Conditions on the Degradation and on the Recycling of Polycarbonate. Prog. Rubber Plast. Recycl. Technol. 2003, 19, 135–142. [Google Scholar] [CrossRef]

- Feller, J.F.; Bourmaud, A. Rheological and calorimetric properties of recycled bisphenol A poly(carbonate). Polym. Deg. Stab. 2003, 82, 99–104. [Google Scholar] [CrossRef]

- Antonakou, E.V.; Achilias, D.S. Recent Advances in Polycarbonate Recycling: A Review of Degradation Methods and Their Mechanisms. Waste Biomass-Valorization 2013, 4, 9–21. [Google Scholar] [CrossRef]

- Elmaghor, F.; Zhang, L.; Fan, R.; Li, H. Recycling of polycarbonate by blending with maleic anhydride grafted ABS. Polymer 2004, 45, 6719–6724. [Google Scholar] [CrossRef]

- De la Colina Martíneza, A.L.; Martínez Barrera, G.; Barrera Díaz, C.E.; Ávila Córdoba, L.I.; UreñaNúñez, F.; Delgado Hernández, D.J. Recycled polycarbonate from electronic waste and its use in concrete: Effect of irradiation. Constr. Build. Mater. 2019, 201, 778–785. [Google Scholar] [CrossRef]

- Gamze Karsli, N.; Yilmaz, T. From polymeric waste to potential industrial product: Modification of recycled polycarbonate. J. Elastomers Plast. 2022, 54, 857–876. [Google Scholar] [CrossRef]

| Solution | pH |

|---|---|

| Distilled water, 0% | 7 |

| Ammonia 0.25% | 11.7 |

| Ammonia 0.5% | 11.9 |

| Ammonia 0.75% | 12.1 |

| Solution | pH |

|---|---|

| Virgin, 0.75% | 12.1 |

| After 1 treatment | 11.21 |

| After 2 treatments | 10.41 |

| After 3 treatments | 9.06 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

La Mantia, F.P.; Liarda, D.; Ceraulo, M.; Mistretta, M.C. A Green Approach for Recycling Compact Discs. Polymers 2023, 15, 491. https://doi.org/10.3390/polym15030491

La Mantia FP, Liarda D, Ceraulo M, Mistretta MC. A Green Approach for Recycling Compact Discs. Polymers. 2023; 15(3):491. https://doi.org/10.3390/polym15030491

Chicago/Turabian StyleLa Mantia, Francesco Paolo, Domenico Liarda, Manuela Ceraulo, and Maria Chiara Mistretta. 2023. "A Green Approach for Recycling Compact Discs" Polymers 15, no. 3: 491. https://doi.org/10.3390/polym15030491

APA StyleLa Mantia, F. P., Liarda, D., Ceraulo, M., & Mistretta, M. C. (2023). A Green Approach for Recycling Compact Discs. Polymers, 15(3), 491. https://doi.org/10.3390/polym15030491