Luminescent Polymer Composites for Optical Fiber Sensors

Abstract

:1. Introduction

2. Materials and Methods

- (a)

- Weigh the phosphors and place them in a beaker;

- (b)

- Pour the base materials of the PDMS elastomer (silicone oil) and the chloroform (CHCl3) into the beaker (1 g/1.5 mL of PDMS/CHCl3 ratio);

- (c)

- Place the beaker in a combined hot-plate/magnetic-stirrer device for 60 min at 80 rpm and 90 °C to obtain a homogenous mix and to evaporate the chloroform;

- (d)

- Remove the beaker from the hot plate/magnetic stirrer and leave it to rest until reaching room temperature (approximately 10 min). Then, add the PDMS curing agent (10:1 ratio) and mix manually for 1 min;

- (e)

- Place the mixture in a vacuum chamber for degassing for 60 min;

- (f)

- Pour the PDMS-phosphor mixture in the desired substrate (either molds or glass slides (see below)) to obtain membranes;

- (g)

- Finally, place the substrate with the PDMS-phosphor composite in an oven at 80 °C for 4 h for solidification.

3. Polymer Composite Membrane Characterization

3.1. PDMS-YbEr Composite

3.2. PDMS-GOS:Eu Composites

4. Applications and Discussion

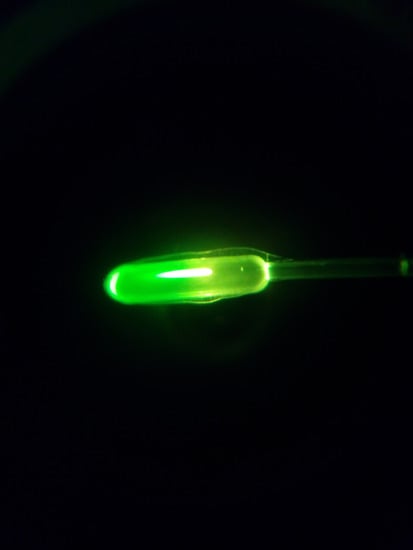

4.1. Optical Fiber Temperature Sensors with PDMS-YbEr Composites

4.2. Devices with PDMS-UKL Composites

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shin, Y.-H.; Gutierrez-Wing, M.T.; Choi, J.-W. Review—Recent Progress in Portable Fluorescence Sensors. J. Electrochem. Soc. 2021, 168, 017502. [Google Scholar] [CrossRef]

- Pfeiffer, S.A.; Nagl, S. Microfluidic Platforms Employing Integrated Fluorescent or Luminescent Chemical Sensors: A Review of Methods, Scope and Applications. Methods Appl. Fluoresc. 2015, 3, 034003. [Google Scholar] [CrossRef] [PubMed]

- Basabe-Desmonts, L.; Reinhoudt, D.N.; Crego-Calama, M. Design of Fluorescent Materials for Chemical Sensing. Chem. Soc. Rev. 2007, 36, 993–1017. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ahumada, G.; Borkowska, M. Fluorescent Polymers Conspectus. Polymers 2022, 14, 1118. [Google Scholar] [CrossRef]

- Melnikov, P.; Bobrov, A.; Marfin, Y. On the Use of Polymer-Based Composites for the Creation of Optical Sensors: A Review. Polymers 2022, 14, 4448. [Google Scholar] [CrossRef]

- Demchenko, A.P. Nanoparticles and Nanocomposites for Fluorescence Sensing and Imaging. Methods Appl. Fluoresc. 2013, 1, 022001. [Google Scholar] [CrossRef]

- Wang, X.-D.; Wolfbeis, O.S. Fiber-Optic Chemical Sensors and Biosensors (2008–2012). Anal. Chem. 2013, 85, 487–508. [Google Scholar] [CrossRef]

- Rivero, P.J.; Goicoechea, J.; Arregui, F.J. Optical Fiber Sensors Based on Polymeric Sensitive Coatings. Polymers 2018, 10, 280. [Google Scholar] [CrossRef] [Green Version]

- Epstein, J.R.; Walt, D.R. Fluorescence-Based Fibre Optic Arrays: A Universal Platform for Sensing. Chem. Soc. Rev. 2003, 32, 203–214. [Google Scholar] [CrossRef]

- Kamaljith, V.; Tanner, M.G.; Tanner, M.G.; Wood, H.A.C.; Harrington, K.; Choudhury, D.; Bradley, M.; Thomson, R.R.; Thomson, R.R. Ultrafast-Laser-Ablation-Assisted Spatially Selective Attachment of Fluorescent Sensors onto Optical Fibers. Opt. Lett. OL 2020, 45, 2716–2719. [Google Scholar] [CrossRef]

- Ochoa, M.; Algorri, J.F.; Roldán-Varona, P.; Rodríguez-Cobo, L.; López-Higuera, J.M. Recent Advances in Biomedical Photonic Sensors: A Focus on Optical-Fibre-Based Sensing. Sensors 2021, 21, 6469. [Google Scholar] [CrossRef] [PubMed]

- Seethapathy, S.; Górecki, T. Applications of Polydimethylsiloxane in Analytical Chemistry: A Review. Anal Chim Acta 2012, 750, 48–62. [Google Scholar] [CrossRef]

- Wolf, M.P.; Salieb-Beugelaar, G.B.; Hunziker, P. PDMS with Designer Functionalities—Properties, Modifications Strategies, and Applications. Progress in Polymer Science 2018, 83, 97–134. [Google Scholar] [CrossRef]

- Pérez-Calixto, D.; Zamarrón-Hernández, D.; Cruz-Ramírez, A.; Hautefeuille, M.; Hérnandez-Cordero, J.; Velázquez, V.; Grether, M. Fabrication of Large All-PDMS Micropatterned Waveguides for Lab on Chip Integration Using a Rapid Prototyping Technique. Opt. Mater. Express OME 2017, 7, 1343–1350. [Google Scholar] [CrossRef]

- Sarabi, M.R.; Jiang, N.; Ozturk, E.; Yetisen, A.K.; Tasoglu, S. Biomedical Optical Fibers. Lab Chip 2021, 21, 627–640. [Google Scholar] [CrossRef] [PubMed]

- Sánchez-Escobar, S.; Hernández-Cordero, J. Fiber Optic Fluorescence Temperature Sensors Using Up-Conversion from Rare-Earth Polymer Composites. Opt. Lett. OL 2019, 44, 1194–1197. [Google Scholar] [CrossRef] [PubMed]

- Hernández-Arenas, A.; Pimentel-Domínguez, R.; Rodrigo Vélez-Cordero, J.; Hernández-Cordero, J. Fiber Optic Probe with Functional Polymer Composites for Hyperthermia. Biomed. Opt. Express 2021, 12, 4730–4744. [Google Scholar] [CrossRef]

- Pimentel-Domínguez, R.; Velázquez-Benítez, A.M.; Vélez-Cordero, J.R.; Hautefeuille, M.; Sánchez-Arévalo, F.; Hernández-Cordero, J. Photothermal Effects and Applications of Polydimethylsiloxane Membranes with Carbon Nanoparticles. Polymers 2016, 8, 84. [Google Scholar] [CrossRef]

- Chakradhar, R.P.S.; Basu, B.J.; Lakshmi, R.V. Effect of Particle Size and Dopant Concentration on Photophysical Properties of Eu3+-Doped Rare Earth Oxysulphide Phosphor Coatings. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2011, 78, 783–787. [Google Scholar] [CrossRef]

- Carrillo-Betancourt, R.A.; Islas-Sánchez, S.R.; Matatagui, D.; Gutierrez-Herrera, E. Responsivity Evaluation of Fluorescent Thin Films for Sensitizing a CMOS Sensor in the UV Range for Cellular Proliferation Imaging. In Proceedings of the Nanoengineering: Fabrication, Properties, Optics, Thin Films, and Devices XVI, San Diego, CA, USA, 3 September 2019; International Society for Optics and Photonics—SPIE: Bellingham, WA, USA, 2019; Volume 11089, p. 1108924. [Google Scholar]

- Carrillo-Betancourt, R.A.; Hernández-Cordero, J. Polymer Coatings with Rare-Earth Activated Phosphors for Optical Fiber Fluorosensors. In Proceedings of the Nanoengineering: Fabrication, Properties, Optics, Thin Films, and Devices XIX, San Diego, CA, USA, 3 October 2022; International Society for Optics and Photonics—SPIE: Bellingham, WA, USA, 2022; Volume 12202, pp. 65–73. [Google Scholar]

- González-Martínez, F.; González-Cortez, O.; Pimentel-Domínguez, R.; Hernández-Cordero, J.; Aguilar, G. Composite Polymer Membranes for Laser-Induced Fluorescence Thermometry. Opt. Mater. Express OME 2018, 8, 3072–3081. [Google Scholar] [CrossRef]

- Bao, R.; Yu, L.; Ye, L.; Zhang, X.; Wang, L.-G. Compact and Sensitive Er3+/Yb3+ Co-Doped YAG Single Crystal Optical Fiber Thermometry Based on up-Conversion Luminescence. Sens. Actuators A Phys. 2018, 269, 182–187. [Google Scholar] [CrossRef]

- Tran, N.T.; You, J.P.; Shi, F.G. Effect of Phosphor Particle Size on Luminous Efficacy of Phosphor-Converted White LED. J. Light. Technol. 2009, 27, 5145–5150. [Google Scholar] [CrossRef]

- Tyona, M.D. A Theoritical Study on Spin Coating Technique. AMR 2013, 2, 195. [Google Scholar] [CrossRef] [Green Version]

- Hall, D.B.; Underhill, P.; Torkelson, J.M. Spin Coating of Thin and Ultrathin Polymer Films. Polym. Eng. Sci. 1998, 38, 2039–2045. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Q.; Bu, Y.; Liu, C.-S.; Liu, T.; Yan, X. Optical Temperature Sensing of Rare-Earth Ion Doped Phosphors. RSC Adv. 2015, 5, 86219–86236. [Google Scholar] [CrossRef]

- Zhang, B.; Guo, X.; Zhang, Z.; Fu, Z.; Zheng, H. Luminescence Thermometry with Rare Earth Doped Nanoparticles: Status and Challenges. J. Lumin. 2022, 250, 119110. [Google Scholar] [CrossRef]

- Wegh, R.T.; Donker, H.; Oskam, K.D.; Meijerink, A. Visible Quantum Cutting in LiGdF4:Eu3+ Through Downconversion. Science 1999, 283, 663–666. [Google Scholar] [CrossRef]

- Liu, B.; Chen, Y.; Shi, C.; Tang, H.; Tao, Y. Visible Quantum Cutting in BaF2:Gd, Eu via Downconversion. J. Lumin. 2003, 101, 155–159. [Google Scholar] [CrossRef]

- Zmojda, J.; Kochanowicz, M.; Miluski, P.; Dorosz, D. Side-Detecting Optical Fiber Doped with Tb3+ for Ultraviolet Sensor Application. Fibers 2014, 2, 150–157. [Google Scholar] [CrossRef] [Green Version]

- Liu, Y.; Zhang, J.; Zhang, C.; Jiang, J.; Jiang, H. High Efficiency Green Phosphor Ba9Lu2Si6O24:Tb3+: Visible Quantum Cutting via Cross-Relaxation Energy Transfers. J. Phys. Chem. C 2016, 120, 2362–2370. [Google Scholar] [CrossRef]

- Chorvatova, A.; Chorvat, D. Tissue Fluorophores and Their Spectroscopic Characteristics; CRC Press: Boca Raton, FL, USA, 2014; pp. 47–84. ISBN 978-0-429-19375-0. [Google Scholar]

- Cano-Velázquez, M.S.; Hernández-Cordero, J.A. Controlled Fabrication of Polymer End-Capped Fiber Optic Sensors. IEEE Sens. J. 2021, 21, 9203–9209. [Google Scholar] [CrossRef]

| Sample | d = 150 μm | d = 300 μm |

|---|---|---|

| C = 1.5% | ST = −5.2 × 10−3, R2 = 0.996 | ST = −5.0 × 10−3, R2 = 0.995 |

| C = 2.0% | ST = −4.8 × 10−3, R2 = 0.995 | ST = −4.4 × 10−3, R2 = 0.991 |

| C = 2.5% | ST = −4.8 × 10−3, R2 = 0.991 | ST = −3.9 × 10−3, R2 = 0.998 |

| Concentration (% wt./wt.) | Density (g/cm3) |

|---|---|

| 0.1 | 1.103 |

| 0.5 | 1.106 |

| 2.5 | 1.123 |

| 12.5 | 1.207 |

| 62.5 | 1.595 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrillo-Betancourt, R.A.; López-Camero, A.D.; Hernández-Cordero, J. Luminescent Polymer Composites for Optical Fiber Sensors. Polymers 2023, 15, 505. https://doi.org/10.3390/polym15030505

Carrillo-Betancourt RA, López-Camero AD, Hernández-Cordero J. Luminescent Polymer Composites for Optical Fiber Sensors. Polymers. 2023; 15(3):505. https://doi.org/10.3390/polym15030505

Chicago/Turabian StyleCarrillo-Betancourt, Rodolfo A., A. Darío López-Camero, and Juan Hernández-Cordero. 2023. "Luminescent Polymer Composites for Optical Fiber Sensors" Polymers 15, no. 3: 505. https://doi.org/10.3390/polym15030505

APA StyleCarrillo-Betancourt, R. A., López-Camero, A. D., & Hernández-Cordero, J. (2023). Luminescent Polymer Composites for Optical Fiber Sensors. Polymers, 15(3), 505. https://doi.org/10.3390/polym15030505