Influence of Electrospinning Setup Parameters on Properties of Polymer-Perovskite Nanofibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Electrospinning Solution

2.3. Fabrication of Electrospun Nanofibers

2.4. Fabrication of Spin-Coated Layers

2.5. Cleaning Substrates

2.6. External Structure of Nanofibers

2.7. Perovskite Crystallinity

2.8. Optical Properties

2.9. Thermal Behavior

2.10. Measuring the Shrinkage Ratio after Annealing

2.11. Mechanical Properties

3. Results

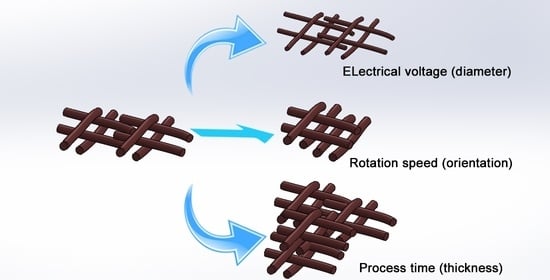

3.1. Electrospinning Setup Parameters and Nanofibers Structure

3.2. Electrospinning Setup Parameters and Perovskite Crystallinity

3.3. Electrospinning Setup Parameters and Optical Properties

3.4. Electrospinning Setup Parameters and the Thermal Behavior

- -

- DSC requires a specific preparation process for the samples to be placed in the crucible, which can potentially alter the structure of the tested nanofibers and affect the accuracy of the results. In contrast, XRD, light absorption, and PL methods do not require special preparation of the samples or even handling them. They are tested directly on the substrate. Therefore, the structure of the nanofibers is well preserved. So, DSC will be more useful for detecting changes in the perovskite crystallinity when the content of polymer or perovskite is altered;

- -

- It should also be noted that the crystallinity of perovskite can be affected by various factors such as the conditions under which it is annealed (temperature, time, atmosphere N2 (as in DSC) or air (usual annealing) and the annealing program (200 °C for 5 min (usual annealing) or a gradual increase in the temperature from room temperature (as in DSC technique)) [8,32,33,34,45]. These parameters can also play a role in increasing the crystallinity of perovskite in conjunction with changes in electrical voltage. Therefore, researchers in the field of perovskite-polymer composites prefer to evaluate the crystallinity of perovskite by XRD, light absorption, and PL methods, while DSC is usually used to characterize the thermal behavior of polymers.

| PVP Powder | 1–20 kV | 2–23 kV | 3-Planar Collector | 4-Rotary 250 rpm | 5-Rotary 500 rpm | 6-Rotary 750 rpm | ||

|---|---|---|---|---|---|---|---|---|

| Transition, full evaporation, or/and reorganization | Temperature, °C (midpoint) | - | 129.1 ± 2.8 | 129.4 ± 1.1 | 128.8 ± 3.3 | 129.1 ± 0.6 | 128.9 ± 0.3 | 127.1 ± 1.3 |

| ΔH, J/g | - | 4.82 ± 0.27 | 4.85 ± 0.06 | 4.65 ± 0.21 | 4.7 ± 0.04 | 4.33 ± 0.16 | 3.82 ± 0.11 | |

| α-CsPbI3 formation | Temperature, °C (peak center) | - | 322.3 ± 0.5 | 322.5 ± 0.3 | 323.5 ± 0.1 | 323.9 ± 0.5 | 323.9 ± 1.2 | 324.4 ± 0.2 |

| ΔH, J/g | - | 16.42 ± 0.02 | 16.64 ± 0.11 | 16.47 ± 0.13 | 16.45 ± 0.13 | 16.47 ± 0.08 | 16.46 ± 0.15 | |

| * Crystallinity, % | - | 83.94 ± 0.11 | 85.07 ± 0.54 | 84.20 ± 0.65 | 84.10 ± 0.65 | 84.2 ± 0.4 | 84.15 ± 0.76 | |

| Polymer glass transition (Tg) | Temperature, °C (midpoint) | 179.95 | 174.33 ± 0.24 | 174.04 ± 0.14 | 174.53 ± 0.11 | 174.32 ± 0.26 | 173.2 ± 0.26 | 172.1 ± 0.97 |

3.5. Electrospinning Setup Parameters and Mechanical Properties

3.6. Long-Term Stability and an Applied Electrical Voltage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Ding, B.; Yu, J. Electrospun Nanofibers for Energy and Environmental Applications; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar] [CrossRef]

- He, J.-H.; Liu, Y.; Mo, L.-F.; Wan, Y.-Q.; Xu, L. Electrospun Nanofibres and Their Applications; ISmithers: Shawbury, UK, 2008. [Google Scholar]

- Ahmadian, A.; Shafiee, A.; Aliahmad, N.; Agarwal, M. Overview of nano-fiber mats fabrication via electrospinning and morphology analysis. Textiles 2021, 1, 206–226. [Google Scholar] [CrossRef]

- Wang, Y.; Yokota, T.; Someya, T. Electrospun nanofiber-based soft electronics. NPG Asia Mater. 2021, 13, 1–22. [Google Scholar] [CrossRef]

- Sarac, A.S. Nanofibers of Conjugated Polymers; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Bohr, C.; Le, K.; Fischer, T.; Mathur, S. Triaxial perovskite composite fibers spinning the way to flexible solar cells. Adv. Eng. Mater. 2022, 24, 2100773. [Google Scholar] [CrossRef]

- Ko, F.K.; Yang, H. Functional nanofibre: Enabling material for the next generations smart textiles. JFBI 2008, 1, 81–92. [Google Scholar] [CrossRef]

- Bkkar, M.; Olekhnovich, R.O.; Uspenskaya, M.V. Obtaining nanofibers based on perovskite-polymer composites for applying in solar cells. Int. Multidiscip. Sci. GeoConference Surv. Geol. Min. Ecol. Manag. SGEM 2020, 20, 129–136. [Google Scholar] [CrossRef]

- Zhang, Y. Electrospun Nanofibers with Tunable Electrical Conductivity. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2013. [Google Scholar]

- Li, X.; Zhou, J.; Quan, Z.; Wang, L.; Li, F.; Qin, X.; Yu, J. Light scattering tunability of nanofiber membrane for enhancing color yield. Dyes Pigm. 2021, 193, 109462. [Google Scholar] [CrossRef]

- Isaac, B.; Taylor, R.M.; Reifsnider, K. Mechanical and dielectric properties of aligned electrospun fibers. Fibers 2021, 9, 4. [Google Scholar] [CrossRef]

- Kim, W.-T.; Park, D.-C.; Yang, W.-H.; Cho, C.-H.; Choi, W.-Y. Effects of electrospinning parameters on the microstructure of PVP/TiO2 nanofibers. Nanomaterials 2021, 11, 1616. [Google Scholar] [CrossRef]

- Selatile, K.; Ray, S.S.; Ojijo, V.; Sadiku, R.E. Morphological, Thermal, and Mechanical Properties of Electrospun Recycled Poly (ethylene terephthalate)/Graphene Oxide Composite Nanofiber Membranes. ACS Omega 2021, 6, 21005–21015. [Google Scholar] [CrossRef]

- Stafiej, P.; K¨ung, F.; Kruse, F.; Schubert, D.; Fuchsluger, T. Mechanical and optical properties of PCL nanofiber reinforced alginate hydrogels for application in corneal wound healing. Biomater. Med. Appl. 2018, 2, 1–9. [Google Scholar] [CrossRef]

- Conte, A.A.; Sun, K.; Hu, X.; Beachley, V.Z. Effects of fiber density and strain rate on the mechanical properties of electrospun polycaprolactone nanofiber mats. Front. Chem. 2020, 8, 610. [Google Scholar] [CrossRef]

- Doustgani, A.; Vasheghani-Farahani, E.; Soleimani, M.; Hashemi-Najafabadi, S. Optimizing the mechanical properties of electrospun polycaprolactone and nanohydroxyapatite composite nanofibers. Compos. B. Eng. 2012, 43, 1830–1836. [Google Scholar] [CrossRef]

- Kuchi, C.; Harish, G.; Reddy, P.S. Effect of polymer concentration, needle diameter and annealing temperature on TiO2-PVP composite nanofibers synthesized by electrospinning technique. Ceram. Int. 2018, 44, 5266–5272. [Google Scholar] [CrossRef]

- Borrotti, M.; Lanzarone, E.; Manganini, F.; Ortelli, S.; Pievatolo, A.; Tonetti, C. Defect minimization and feature control in electrospinning through design of experiments. J. Appl. Polym. Sci. 2017, 134, 1–10. [Google Scholar] [CrossRef]

- Haider, A.; Haider, S.; Kang, I.-K. A comprehensive review summarizing the effect of electrospinning parameters and potential applications of nanofibers in biomedical and biotechnology. Arab. J. Chem. 2018, 11, 1165–1188. [Google Scholar] [CrossRef]

- Zhang, Q.; Deng, X.; Tan, C.; Zhou, Y.; Chen, X.; Bai, X.; Li, J.; Tang, B.; Li, S.; Lin, H. Gamma-phase CsPbBr3 perovskite nanocrystals/polymethyl methacrylate electrospun nanofibrous membranes with superior photo-catalytic property. J. Chem. Phys. 2020, 153, 024703. [Google Scholar] [CrossRef]

- Chen, T.; Huang, M.; Ye, Z.; Hua, J.; Lin, S.; Wei, L.; Xiao, L. Blinking CsPbBr3 perovskite nanocrystals for the nanoscopic imaging of electrospun nanofibers. Nano Res. 2021, 14, 1397–1404. [Google Scholar] [CrossRef]

- Shao, Y.; Zhang, C.; Zhou, C.; Wang, T.; Chen, J.; Liu, X.; Lin, J.; Chen, X. Designable and highly stable emissive CsPbI3 perovskite quantum dots/polyvinylidene fluoride nanofiber composites. Opt. Mater. Express 2022, 12, 109–118. [Google Scholar] [CrossRef]

- Bohr, C.; Pfeiffer, M.; Oz, S.; von Toperczer, F.; Lepcha, A.; Fischer, T.; Schutz, M.; Lindfors, K.; Mathur, S. Electrospun hybrid perovskite fibers—Flexible networks of one-dimensional semiconductors for light-harvesting applications. ACS Appl. Mater. Interfaces 2019, 11, 25163–25169. [Google Scholar] [CrossRef]

- Chen, D.; Zhu, Y. Electrospun perovskite nanofibers. Nanoscale Res. Lett. 2017, 12, 114. [Google Scholar] [CrossRef] [Green Version]

- Li, G.; Jiang, Z.; Wang, W.; Chu, Z.; Zhang, Y.; Wang, C. Electrospun PAN/MAPbI3 composite fibers for flexible and broadband photodetectors. Nanomaterials 2019, 9, 50. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, H.-J.; Oh, H.; Kim, T.; Kim, D.; Park, M. Stretchable photodetectors based on electrospun polymer/perovskite composite nanofibers. ACS Appl. Nano Mater. 2022, 5, 1308–1316. [Google Scholar] [CrossRef]

- Ning, L.; Gu, N.; Wang, T.; Liu, W.; Du, P.; Chen, W.-H.; Song, L.; Siddique, S.H.; Xiong, J. Flexible hybrid perovskite nanofiber for all-inorganic perovskite solar cells. Mater. Res. Bull. 2022, 149, 111747. [Google Scholar] [CrossRef]

- Chao, L.-M.; Tai, T.-Y.; Chen, Y.-Y.; Lin, P.-Y.; Fu, Y.-S. Fabrication of CH3NH3PbI3/PVP composite fibers via electrospinning and deposition. Materials 2015, 8, 5467–5478. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tsai, P.-C.; Chen, J.-Y.; Ercan, E.; Chueh, C.-C.; Tung, S.-H.; Chen, W.-C. Uniform luminous perovskite nanofibers with color-tunability and improved stability prepared by one-step core/shell electrospinning. Small 2018, 14, 1704379. [Google Scholar] [CrossRef]

- Lu, X.; Hu, Y.; Guo, J.; Wang, C.-F.; Chen, S. Fiber-spinning-chemistry method toward in situ generation of highly stable halide perovskite nanocrystals. Adv.Sci. 2019, 6, 1901694. [Google Scholar] [CrossRef] [Green Version]

- Ercan, E.; Tsai, P.-C.; Chen, J.-Y.; Lam, J.-Y.; Hsu, L.-C.; Chueh, C.-C.; Chen, W.-C. Stretchable and ambient stable perovskite/polymer luminous hybrid Nanofibers of multicolor fiber mats and their white LED applications. ACS Appl. Mater. Interfaces 2019, 11, 23605–23615. [Google Scholar] [CrossRef]

- Bkkar, M.A.; Olekhnovich, R.O.; Kremleva, A.V.; Kovach, Y.N.; Kalanchina, V.; Uspenskaya, M.V. Fabrication of electrospun polymer nanofibers modified with all-inorganic perovskite nanocrystals for flexible optoelectronic devices. Appl. Nanosci. 2022, 12, 2961–2977. [Google Scholar] [CrossRef]

- Li, B.; Zhang, Y.; Fu, L.; Yu, T.; Zhou, S.; Zhang, L.; Yin, L. Surface passivation engineering strategy to fully-inorganic cubic CsPbI3 perovskites for high-performance solar cells. Nat. Commun. 2018, 9, 1076. [Google Scholar] [CrossRef] [Green Version]

- Bkkar, M.A.; Olekhnovich, R.O.; Uspenskaya, M.V. Perovskite nanocomposite layers engineering for efficient and stable solar cells. J. Nano Res. 2022, 71, 71–109. [Google Scholar] [CrossRef]

- Romiluyi, O.; Eatmon, Y.; Ni, R.; Rand, B.P.; Clancy, P. The efficacy of Lewis affinity scale metrics to represent solvent interactions with reagent salts in all-inorganic metal halide perovskite solutions. J. Mater. Chem. A 2021, 9, 13087–13099. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, J. Electrospinning of perovskite crystals with strong emission and improved electrical conductivity. In Proceedings of the 2020 International Conference on Artificial Intelligence and Electromechanical Automation (AIEA), Tianjin, China, 26–28 June 2020. [Google Scholar] [CrossRef]

- Chen, L.; Chuang, Y.; Yang, W.-D.; Tsai, K.-C.; Chen, C.-W.; Dong, C.-D. All inorganic perovskite CsPbX3 electrospun nanofibers with color-tunable photoluminescence and high performance optoelectronic applications. J. Alloys Compd. 2021, 856, 157426. [Google Scholar] [CrossRef]

- Kirakosyan, A.; Kim, Y.; Sihn, M.R.; Jeon, M.-G.; Jeong, J.-R.; Choi, J. Solubility-controlled room-temperature synthesis of cesium lead halide perovskite nanocrystals. Chem. Nano Mat. 2020, 6, 1863–1869. [Google Scholar] [CrossRef]

- Meng, X.; Li, Y.; Qu, Y.; Chen, H.; Jiang, N.; Li, M.; Xue, D.-J.; Hu, J.-S.; Huang, H.; Yang, S. Crystallization kinetics modulation of FASnI3 films with pre-nucleation clusters for efficient lead-free perovskite solar cells. Angew. Chem. Int. Ed. 2021, 60, 3693–3698. [Google Scholar] [CrossRef]

- Ura, D.P.; Stachewicz, U. The Significance of electrical polarity in electrospinning: A nanoscale approach for the enhancement of the polymer fibers’ properties. Macromol. Mater. Eng. 2022, 307, 2100843. [Google Scholar] [CrossRef]

- Ura, D.P.; Rosell-Llompart, J.; Zaszczy’nska, A.; Vasilyev, G.; Gradys, A.; Szewczyk, P.K.; Knapczyk-Korczak, J.; Avrahami, R.; Šišková, A.O.; Arinstein, A.; et al. The role of electrical polarity in electrospinning and on the mechanical and structural properties of as-spun fibers. Materials 2020, 13, 4169. [Google Scholar] [CrossRef]

- Li, Q.-F.; Wang, J.-T.; Tian, B.; Kong, S.; Wang, T.; Wang, Z. Hybridization of CsPbBr3 perovskite nanocrystals with polymer nanofiber to improve their luminescence stability. Eur. J. Inorg. Chem. 2018, 2018, 4215–4220. [Google Scholar] [CrossRef]

- Yang, M.; Yu, J.; Jiang, S.; Zhang, C.; Sun, Q.; Wang, M.; Zhou, H.; Li, C.; Man, B.; Lei, F. High stability luminophores: Fluorescent CsPbX3 (X= Cl, Br and I) nanofiber prepared by one-step electrospinning method. Opt. Express 2018, 26, 20649–20660. [Google Scholar] [CrossRef]

- Du, S.; Yang, J.; Qu, S.; Lan, Z.; Sun, T.; Dong, Y.; Shang, Z.; Liu, D.; Yang, Y.; Yan, L.; et al. Impact of precursor concentration on perovskite crystallization for efficient wide-bandgap solar cells. Materials 2022, 15, 3185. [Google Scholar] [CrossRef]

- Ye, T.; Zhou, B.; Zhan, F.; Yuan, F.; Ramakrishna, S.; Golberg, D.; Wang, X. Below 200 °C Fabrication strategy of black-phase CsPbI3 film for ambient-air-stable solar cells. Sol. RRL 2020, 4, 2000014. [Google Scholar] [CrossRef]

- Wang, B.; Navrotsky, A. Thermodynamics of cesium lead halide (CsPbX3, x= I, Br, Cl) perovskites. Thermochim. Acta 2021, 695, 178813. [Google Scholar] [CrossRef]

- Wang, B.; Navrotsky, A. Thermodynamic studies of bromide incorporation into cesium lead iodide (CsPbI3). J. Phys. Chem. C 2020, 124, 8639–8642. [Google Scholar] [CrossRef]

- Dastidar, S.; Hawley, C.J.; DeVries Dillon, A.; Gutierrez-Perez, A.D.; Spanier, J.E.; Fafarman, A.T. Quantitative phase-change thermodynamics and metastability of perovskite-phase cesium lead iodide. J. Phys. Chem. Lett. 2017, 8, 1278–1282. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Novendra, N.; Navrotsky, A. Energetics, Structures, and phase transitions of cubic and orthorhombic cesium lead iodide (CsPbI3) polymorphs. J. Am. Chem. Soc. 2019, 141, 14501–14504. [Google Scholar] [CrossRef]

- Nagabhushana, G.P.; Shivaramaiah, R.; Navrotsky, A. Direct calorimetric verification of thermodynamic instability of lead halide hybrid perovskites. PNAS 2016, 113, 7717–7721. [Google Scholar] [CrossRef] [Green Version]

- Dualeh, A.; Gao, P.; Seok, S., II; Nazeeruddin, M.K.; Grätzel, M. Thermal behavior of methylammonium lead-trihalide perovskite photovoltaic light harvesters. Chem. Mater. 2014, 26, 6160–6164. [Google Scholar] [CrossRef]

- Navrotsky, A. Thermochemistry of Complex Perovskites. In Proceedings of the AIP Conference. Am. Inst. Phys. 2000, 535, 288–296. [Google Scholar] [CrossRef]

- Navrotsky, A. Energetics and crystal chemical systematics among ilmenite, lithium niobate, and perovskite structures. Chem. Mater. 1998, 10, 2787–2793. [Google Scholar] [CrossRef]

- Wang, B.; Wang, D.; Zhao, S.; Huang, X.; Zhang, J.; Lv, Y.; Liu, X.; Lv, G.; Ma, X. Evaluate the ability of PVP to inhibit crystallization of amorphous solid dispersions by density functional theory and experimental verify. Eur. J. Pharm. Sci. 2017, 96, 45–52. [Google Scholar] [CrossRef]

- Turner, D.T.; Schwartz, A. The glass transition temperature of poly(/Vvinylpyrrolidone) by differential scanning calorimetry. Polymer 1985, 26, 757–762. [Google Scholar] [CrossRef]

- Del Pilar Buera, M.; Levi, G.; Karel, M. Glass transition in poly(vinylpyrro1idone): Effect of molecular weight and diluents. Biotechnol. PrW. 1992, 8, 144–148. [Google Scholar] [CrossRef]

- Heczko, D.; Hachuła, B.; Maksym, P.; Kamiński, K.; Zieba, A.; Orszulak, L.; Paluch, M.; Kamińska, E. The effect of various poly (N-vinylpyrrolidone) (PVP) polymers on the crystallization of flutamide. Pharmaceuticals 2022, 15, 971. [Google Scholar] [CrossRef]

- Elishav, O.; Beilin, V.; Rozent, O.; Shter, G.E.; Grader, G.S. Thermal shrinkage of electrospun PVP nanofibers. J. Polym. Sci. Part B Polym. Phys. 2018, 56, 248–254. [Google Scholar] [CrossRef]

- Liu, L.; Li, T.; Sun, M.; Jia, W.; Jiao, K.; Wang, S.; Liu, Y.; Jiang, K.; Yang, Y.; Dai, Z.; et al. Preparation of temperature-controlled shrinkage PTMC/PVP core-shell nanofibrous membrane with spindle-knotted structure for accelerating wound closure. Mater. Lett. 2022, 324, 132601. [Google Scholar] [CrossRef]

- Fang, F.; Wang, H.; Wang, H.; Huang, W.M.; Chen, Y.; Cai, N.; Chen, X.; Chen, X. Stimulus-responsive shrinkage in electrospun membranes: Fundamentals and control. Micromachines 2021, 12, 920. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, N.; Dai, Q.; Li, C.; Hou, D.; Luo, X.; Xue, Y.; Yu, F. Effect of thermal annealing on mechanical properties of polyelectrolyte complex nanofiber membranes. Fibers Polym 2014, 15, 1406–1413. [Google Scholar] [CrossRef]

- Dodero, A.; Brunengo, E.; Castellano, M.; Vicini, S. Investigation of the mechanical and dynamic-mechanical properties of electrospun polyvinylpyrrolidone membranes: A design of experiment approach. Polymers 2020, 12, 1524. [Google Scholar] [CrossRef]

- Huang, S.; Zhou, L.; Li, M.-C.; Wu, Q.; Kojima, Y.; Zhou, D. Preparation and properties of electrospun poly (vinyl pyrrolidone)/cellulose nanocrystal/silver nanoparticle composite fibers. Materials 2016, 9, 523. [Google Scholar] [CrossRef]

- Ghelich, R.; Jahannama, M.R.; Abdizadeh, H.; Torknik, F.S.; Vaezi, M.R. Effects of hafnium and boron on antibacterial and mechanical properties of polyvinylpyrrolidone-based nanofibrous composites. Polym. Bull. 2022, 79, 5885–5899. [Google Scholar] [CrossRef]

- Hashmi, M.; Ullah, S.; Ullah, A.; Saito, Y.; Haider, K.; Bie, X.; Wada, K.; Kim, I. Carboxymethyl Cellulose (CMC) Based Electrospun Composite Nanofiber Mats for Food Packaging. Polymers 2021, 13, 302. [Google Scholar] [CrossRef]

- Rahmani, F.; Ziyadi, H.; Baghali, M.; Luo, H.; Ramakrishna, S. Electrospun PVP/PVA nanofiber mat as a novel potential transdermal drug-delivery system for buprenorphine: A solution needed for pain management. Appl. Sci. 2021, 11, 2779. [Google Scholar] [CrossRef]

- Bansode, U.; Rahman, A.; Ogale, S. Low-temperature processing of optimally polymer-wrapped a-CsPbI3 for self-powered flexible photo-detector application. J. Mater. Chem. C 2019, 7, 6986–6996. [Google Scholar] [CrossRef]

| Sample Number | Perovskites:Solvent, mmol | Electrospinning Parameters | Average Diameter, nm | |

|---|---|---|---|---|

| Sample 1 | (CsI:PbI2:DMF)- (1:1:16.15 mmol) | Voltage: 20 kV, distance: 150 mm, Needle diameter: 0.42 mm, feed rate: 0.1 mL/h. | 329 ± 70 | |

| Sample 2 | 23 kV, 150 mm, 0.42 mm, 0.1 mL/h. | 268 ± 48 | ||

| - | 23 kV, 120 mm, 0.42 mm, 0.1 mL/h. | 271 ± 55 | ||

| - | 23 kV, 150 mm, 0.42 mm, 0.3 mL/h. | 279 ± 51 | ||

| - | 23 kV, 150 mm, 0.72 mm, 0.1 mL/h. | 287 ± 92 | ||

| Sample 3 | 20 kV, 150 mm, 0.72 mm, 0.3 mL/h, planar collector | 360.7 ± 85 | ||

| Sample 4 | 20 kV, 150 mm, 0.72 mm, 0.3 mL/h, rotary collector | 250 rpm | 358.4 ± 74 | |

| Sample 5 | 500 rpm | 347.6 ± 70 | ||

| Sample 6 | 750 rpm | 345.5 ± 62 | ||

| 1–20 kV | 2–23 kV | 3-Planar Collector | 4-Rotary 250 rpm | 5-Rotary 500 rpm | 6-Rotary 750 rpm | PVP Powder | |

|---|---|---|---|---|---|---|---|

| Extrapolated onset temperature, °C | 402.4 | 409.7 | 403.5 | 407.9 | 407.8 | 406.3 | 396.4 |

| Weight loss, % | 94.8 | 93.8 | 94.3 | 94 | 96.2 | 96.3 | 90.5 |

| 200 °C | |||||||

| Weight loss, % | 98.05 | 98.20 | 98.11 | 98.67 | 98.99 | 98.99 | 94.68 |

| Sample | 3-planar collector, 20 kV | 4-rotary 250 rpm, 20 kV | 5-rotary 500 rpm, 20 kV | 6-rotary 750 rpm, 20 kV | 7- rotary 750 rpm, 23 kV | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Sample direction | LD | TD | LD | TD | LD | TD | LD | TD | LD | TD |

| Shrinkage ration, % | 13.11 | - | 13.21 | 8.79 | 13.39 | 14.3 | 14.73 | 13.79 | 13.04 | 14.51 |

| ± | 1.45 | - | 0.4 | 2.47 | 0.31 | 0.45 | 0.49 | 0.61 | 0.8 | 1 |

| Sample | LD/TD | Strain at Break, % | Tensile Strength, MPa | Young’s Modulus, MPa |

|---|---|---|---|---|

| 3-planar collector, 20 kV | LD | 1.59 ± 0.55 | 1.28 ± 0.34 | 93.71 ± 26.83 |

| TD | - | - | - | |

| 4-rotary 250 rpm, 20 kV | LD | 1.67 ± 0.45 | 1.42 ± 0.33 | 106.42 ± 36.46 |

| TD | 1.03 ± 0.47 | 1.42 ± 0.27 | 173.25 ± 48.76 | |

| 5-rotary 500 rpm, 20 kV | LD | 3.49 ± 0.98 | 1.93 ± 0.42 | 112.29 ± 14.59 |

| TD | 2.47 ± 0.08 | 1.42 ± 0.42 | 79.17 ± 25.44 | |

| 6-rotary 750 rpm, 20 kV | LD | 3.2 ± 0.99 | 2.12 ± 0.33 | 116.30 ± 4.97 |

| TD | 2.15 ± 1.30 | 1.05 ± 0.24 | 72.87 ± 15.39 | |

| 7-rotary 750 rpm, 23 kV | LD | 1.19 ± 0.43 | 1.04 ± 0.22 | 105.71 ± 19.11 |

| TD | 0.77 ± 0.22 | 0.63 ± 0.22 | 90.44 ± 10.98 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bkkar, M.; Olekhnovich, R.; Kremleva, A.; Sitnikova, V.; Kovach, Y.; Zverkov, N.; Uspenskaya, M. Influence of Electrospinning Setup Parameters on Properties of Polymer-Perovskite Nanofibers. Polymers 2023, 15, 731. https://doi.org/10.3390/polym15030731

Bkkar M, Olekhnovich R, Kremleva A, Sitnikova V, Kovach Y, Zverkov N, Uspenskaya M. Influence of Electrospinning Setup Parameters on Properties of Polymer-Perovskite Nanofibers. Polymers. 2023; 15(3):731. https://doi.org/10.3390/polym15030731

Chicago/Turabian StyleBkkar, Muhammad, Roman Olekhnovich, Arina Kremleva, Vera Sitnikova, Yakov Kovach, Nikolai Zverkov, and Mayya Uspenskaya. 2023. "Influence of Electrospinning Setup Parameters on Properties of Polymer-Perovskite Nanofibers" Polymers 15, no. 3: 731. https://doi.org/10.3390/polym15030731

APA StyleBkkar, M., Olekhnovich, R., Kremleva, A., Sitnikova, V., Kovach, Y., Zverkov, N., & Uspenskaya, M. (2023). Influence of Electrospinning Setup Parameters on Properties of Polymer-Perovskite Nanofibers. Polymers, 15(3), 731. https://doi.org/10.3390/polym15030731