Formulation and Performance of NBR/CR-Based High-Damping Rubber Composites for Soundproof Using Orthogonal Test

Abstract

:1. Introduction

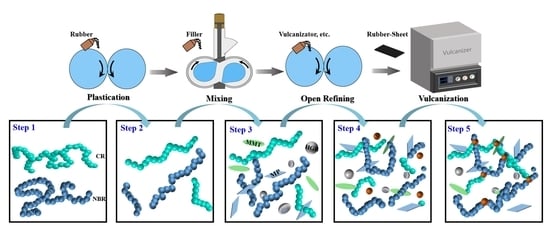

2. Raw Materials and Methodologies

2.1. Raw Materials

2.2. Orthogonal Test Design

2.3. Characterization

2.3.1. Mechanical Properties

2.3.2. Damping Properties

2.3.3. Sound Insulation Properties

3. Test Results and Analysis of Orthogonal Experiment

3.1. Orthogonal Test Results

3.2. Analysis of Orthogonal Test Results

3.2.1. Range and Variance Analysis

3.2.2. The Mechanical Properties Robustness Analysis

3.2.3. The Sound Insulation Properties Robustness Analysis

3.2.4. The Damping Properties Robustness Analysis

3.3. Weight Matrix Analysis

4. Multiscale Synergy of Acoustic Composites

5. Conclusions

- (1)

- Both the blending ratio of NBR/CR and the content of different fillers have important influence on the mechanical properties, damping properties, and sound insulation properties. The tensile strength of NBR/CR composites increased with adding self-reinforcing CR in the matrix, and the tensile strength of composites was improved by adding various fillers compared to the nonfiller composite; however, the excessive addition of filler might induce the crack propagation of rubber matrix and lead to the rapid reduction of tensile strength.

- (2)

- For sound insulation, both the lamellar structures of mica powder (MP) and montmorillonite (MMT), and the spherical shell surfaces of hollow glass beads (HGB), enhanced the reflection and scattering of acoustic waves, expanded the distance of acoustic wave propagation, and greatly increased the dissipation rate of acoustic energy in the composites. In addition, HGB can also improve the sound absorption ability of the composites through the multiple microwave reflections and resonances in the cell room because of its hollow microcavities.

- (3)

- For the damping properties, the existence of the polar group (-Cl) of CR restricted the motility of molecular chain segments, leading to a decrease of damping, and the lamellar structures in MP and MMT fillers increased the friction among molecular chains owing to the high specific surface area to improve damping; however, the smooth spherical surfaces in HGB filler might increase the risk of molecular chain slippage, which was unfavorable for damping performance.

- (4)

- From the range analysis and variance analysis, it can be concluded that the impact order of each factor on tensile strength was content of MP > content of MMT > content of HGB > NBR/CR blending ratio; the impact order of each factor on sound insulation was content of HGB > content of MP > content of MMT > NBR/CR blending ratio; and the impact order of each factor on damping properties was NBR/CR blending ratio > content of HGB > content of MP > content of MMT.

- (5)

- The weight of the factors (A–D) on each indicator was given quantitatively by the weight matrix analysis method, obtaining the preferred combination of high-damping acoustic composites to be NBR/CR blending ratio of 70/30, MP of 10 phr, HGB of 4 phr, and MMT of 10 phr.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| phr | per hundred rubber |

| tanδ | damping factor |

| tanδmax | damping peak |

| E″ | loss modulus, N/mm |

| E′ | storage modulus, N/mm |

| R | sound transmission loss, dB |

| TLavg | average transmission loss, dB |

| τ | transmission coefficient |

| Ri | range |

| Kij | average of all the results indicator related to the level j |

| SSf | sum of square of each factor |

| SSe | sum of square of error |

| df | degrees of freedom |

| MSf | mean square of each factor |

| MSe | mean square of error |

| F | F-value |

| M | indicator layer matrix |

| T | factor layer matrix |

| S | the level layer matrix |

| ω | weight matrix |

References

- Kausar, A. Rubber toughened epoxy-based nanocomposite: A promising pathway toward advanced materials. J. Macromol. Sci. Part A 2020, 57, 499–511. [Google Scholar] [CrossRef]

- Collins, I.; Hossain, M.; Dettmer, W.; Masters, I. Flexible membrane structures for wave energy harvesting: A review of the developments, materials and computational modelling approaches. Renew. Sustain. Energy Rev. 2021, 151, 111478. [Google Scholar] [CrossRef]

- Sattayanurak, S.; Sahakaro, K.; Kaewsakul, W.; Dierkes, W.K.; Reuvekamp, L.A.E.M.; Blume, A.; Noordermeer, J.W.M. Synergistic effect by high specific surface area carbon black as secondary filler in silica reinforced natural rubber tire tread compounds. Polym. Test. 2020, 81, 106173. [Google Scholar] [CrossRef]

- Long, X.-H.; Ma, Y.-T.; Yue, R.; Fan, J. Experimental study on impact behaviors of rubber shock absorbers. Constr. Build. Mater. 2018, 173, 718–729. [Google Scholar] [CrossRef]

- Smirnova, O.M.; Menéndez Pidal de Navascués, I.; Mikhailevskii, V.R.; Kolosov, O.I.; Skolota, N.S. Sound-Absorbing Composites with Rubber Crumb from Used Tires. Appl. Sci. 2021, 11, 7347. [Google Scholar] [CrossRef]

- Kumari, P.; Unnikrishnan, G. Thermal properties of compatibilized and filled natural rubber/acrylonitrile butadiene rubber blends. J. Therm. Anal. Calorim. 2013, 114, 67–75. [Google Scholar] [CrossRef]

- Satyanarayana, M.S.; Bhowmick, A.K.; Kumar, K.D. Preferentially fixing nanoclays in the phases of incompatible carboxylated nitrile rubber (XNBR)-natural rubber (NR) blend using thermodynamic approach and its effect on physico mechanical properties. Polymer 2016, 99, 21–43. [Google Scholar] [CrossRef]

- Tang, K.; Wang, J. Chlorinated butyl rubber/two-step modified montmorillonite nanocomposites: Mechanical and damping properties. Chin. J. Chem. Eng. 2022, 42, 437–449. [Google Scholar] [CrossRef]

- Chen, S.; Wang, Q.; Wang, T. Damping, thermal, and mechanical properties of montmorillonite modified castor oil-based polyurethane/epoxy graft IPN composites. Mater. Chem. Phys. 2011, 130, 680–684. [Google Scholar] [CrossRef]

- Kaliyathan, A.V.; Rane, A.V.; Huskic, M.; Kunaver, M.; Kalarikkal, N.; Rouxel, D.; Thomas, S. Carbon black distribution in natural rubber/butadiene rubber blend composites: Distribution driven by morphology. Compos. Sci. Technol. 2020, 200, 108484. [Google Scholar] [CrossRef]

- Qu, L.; Huang, G.; Zhang, P.; Nie, Y.; Weng, G.; Wu, J. Synergistic reinforcement of nanoclay and carbon black in natural rubber. Polym. Int. 2010, 59, 1397–1402. [Google Scholar] [CrossRef]

- Akçakale, N.; Bülbül, Ş. The Effect of Mica Powder and Wollastonite Fillings on the Mechanical Properties of NR/SBR Type Elastomer Compounds. J. Rubber Res. 2017, 20, 157–167. [Google Scholar] [CrossRef]

- Su, J.; Zhang, J. Improvement of mechanical and dielectrical properties of ethylene propylene diene monomer (EPDM)/barium titanate (BaTiO3) by layered mica and graphite flakes. Compos. Part B Eng. 2017, 112, 148–157. [Google Scholar] [CrossRef]

- Guo, Y.; Cao, Z.; Wang, D.; Liu, S. Improving the friction and abrasion properties of nitrile rubber hybrid with hollow glass beads. Tribol. Int. 2016, 101, 122–130. [Google Scholar] [CrossRef]

- Quan, X.; Han, R.; Shao, Y.; Niu, K. Effect of hollow glass beads on density and mechanical properties of silicone rubber composites. J. Appl. Polym. Sci. 2021, 138, 49865. [Google Scholar] [CrossRef]

- Ghofrani, M.; Ashori, A.; Rezvani, M.H.; Ghamsari, F.A. Acoustical properties of plywood/waste tire rubber composite panels. Measurement 2016, 94, 382–387. [Google Scholar] [CrossRef]

- Liu, C.; Fan, J.; Chen, Y. Design of regulable chlorobutyl rubber damping materials with high-damping value for a wide temperature range. Polym. Test. 2019, 79, 106003. [Google Scholar] [CrossRef]

- Pongsopha, P.; Sukontasukkul, P.; Zhang, H.; Limkatanyu, S. Thermal and acoustic properties of sustainable structural lightweight aggregate rubberized concrete. Results Eng. 2022, 13, 100333. [Google Scholar] [CrossRef]

- Sukontasukkul, P.; Tontiwattanakul, K.; Puttiwongrak, A.; Zhang, H.; Parichatprecha, R.; Suksiripattanapong, C.; Phoo-ngernkham, T.; Imjai, T.; Chindaprasirt, P. Use of viscoelastic polymer sheet as an acoustic control treatment in ceramic tiles to improve sound insertion loss. Results Eng. 2023, 17, 100897. [Google Scholar] [CrossRef]

- Najib, N.N.; Ariff, Z.M.; Bakar, A.A.; Sipaut, C.S. Correlation between the acoustic and dynamic mechanical properties of natural rubber foam: Effect of foaming temperature. Mater. Des. 2011, 32, 505–511. [Google Scholar] [CrossRef]

- Yan, J.; Kim, M.-S.; Kang, K.-M.; Joo, K.-H.; Kang, Y.-J.; Ahn, S.-H. Evaluation of Pp/Clay Composites as Soundproofing Material. Polym. Polym. Compos. 2014, 22, 65–72. [Google Scholar] [CrossRef]

- Shi, X.; Wu, J.; Wang, X.; Zhou, X.; Xie, X.; Xue, Z. Novel sound insulation materials based on epoxy/hollow silica nanotubes composites. Compos. Part B Eng. 2017, 131, 125–133. [Google Scholar] [CrossRef]

- Xia, L.; Wu, H.; Guo, S.; Sun, X.; Liang, W. Enhanced sound insulation and mechanical properties of LDPE/mica composites through multilayered distribution and orientation of the mica. Compos. Part Appl. Sci. Manuf. 2016, 81, 225–233. [Google Scholar] [CrossRef]

- Wang, X.; You, F.; Zhang, F.S.; Li, J.; Guo, S. Experimental and theoretic studies on sound transmission loss of laminated mica-filled poly(vinyl chloride) composites. J. Appl. Polym. Sci. 2011, 122, 1427–1433. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, H.; Li, R.; Gao, S.; Wang, Q.; Wang, G.; Ouyang, X.; Wei, H. High-damping polyurethane/hollow glass microspheres sound insulation materials: Preparation and characterization. J. Appl. Polym. Sci. 2021, 138, 49970. [Google Scholar] [CrossRef]

- Zeng, X.; Li, G.; Zhu, J.; Sain, M.; Jian, R. NBR/CR-Based High-Damping Rubber Composites Containing Multiscale Structures for Tailoring Sound Insulation. Macromol. Mater. Eng. 2023, 308, 2200464. [Google Scholar] [CrossRef]

- Wan, Y.; Soh, A.; Shao, Y.; Cui, X.; Tang, Y.; Chua, K.J. Numerical study and correlations for heat and mass transfer coefficients in indirect evaporative coolers with condensation based on orthogonal test and CFD approach. Int. J. Heat Mass Transf. 2020, 153, 119580. [Google Scholar] [CrossRef]

- Sun, H.; Wang, S.; Huang, S.; Peng, L.; Wang, Q.; Zhao, W.; Zou, J. 3D focusing acoustic lens optimization method using multi-factor and multi-level orthogonal test designing theory. Appl. Acoust. 2020, 170, 107538. [Google Scholar] [CrossRef]

- Xia, S.; Lin, R.; Cui, X.; Shan, J. The application of orthogonal test method in the parameters optimization of PEMFC under steady working condition. Int. J. Hydrogen Energy 2016, 41, 11380–11390. [Google Scholar] [CrossRef]

- Liu, H.; Li, W.; Luo, G.; Liu, S.; Lyu, X. Mechanical Properties and Fracture Behavior of Crumb Rubber Basalt Fiber Concrete Based on Acoustic Emission Technology. Sensors 2020, 20, 3513. [Google Scholar] [CrossRef]

- Abrahamsen, E.B.; Milazzo, M.F.; Selvik, J.T.; Asche, F.; Abrahamsen, H.B. Prioritising investments in safety measures in the chemical industry by using the Analytic Hierarchy Process. Reliab. Eng. Syst. Saf. 2020, 198, 106811. [Google Scholar] [CrossRef]

- Song, Q.; Jiang, P.; Zheng, S. The application of cloud model combined with nonlinear fuzzy analytic hierarchy process for the safety assessment of chemical plant production process. Process Saf. Environ. Prot. 2021, 145, 12–22. [Google Scholar] [CrossRef]

- Yao, Z.; Liu, J.; Qiu, Z.; Pan, W.; Wu, Z. Numerical investigation of 700 °C boiler flue gas thermal deviation based on orthogonal experiment. Fuel 2021, 295, 120510. [Google Scholar] [CrossRef]

| Experimental Factor | Factor | Level | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | ||

| NBR/CR | A | 100/0 | 70/30 | 50/50 | 30/70 | 0/100 |

| MP (phr) * | B | 0 | 5 | 10 | 15 | 20 |

| HGB (phr) | C | 0 | 4 | 8 | 12 | 16 |

| MMT (phr) | D | 0 | 5 | 10 | 15 | 20 |

| No. | Factor Level | Test Result | |||||

|---|---|---|---|---|---|---|---|

| NBR/CR | MP | HGB | MMT | Tensile Strength/MPa | tanδmax | TLavg/dB | |

| 1 | 100/0 | 0 | 0 | 0 | 11.30 | 0.62 | 21.00 |

| 2 | 100/0 | 5 | 4 | 5 | 13.88 | 0.65 | 24.40 |

| 3 | 100/0 | 10 | 8 | 10 | 13.45 | 0.64 | 30.90 |

| 4 | 100/0 | 15 | 12 | 15 | 11.18 | 0.61 | 30.02 |

| 5 | 100/0 | 20 | 16 | 20 | 9.24 | 0.53 | 26.20 |

| 6 | 70/30 | 0 | 4 | 10 | 14.25 | 0.61 | 26.53 |

| 7 | 70/30 | 5 | 8 | 15 | 14.43 | 0.59 | 27.98 |

| 8 | 70/30 | 10 | 12 | 20 | 11.61 | 0.58 | 30.40 |

| 9 | 70/30 | 15 | 16 | 0 | 12.36 | 0.56 | 28.64 |

| 10 | 70/30 | 20 | 0 | 5 | 13.81 | 0.59 | 26.43 |

| 11 | 50/50 | 0 | 8 | 20 | 11.67 | 0.53 | 25.38 |

| 12 | 50/50 | 5 | 12 | 0 | 12.91 | 0.55 | 26.91 |

| 13 | 50/50 | 10 | 16 | 5 | 13.13 | 0.57 | 29.09 |

| 14 | 50/50 | 15 | 0 | 10 | 13.62 | 0.63 | 29.68 |

| 15 | 50/50 | 20 | 4 | 15 | 11.75 | 0.53 | 28.75 |

| 16 | 30/70 | 0 | 12 | 5 | 13.58 | 0.55 | 26.41 |

| 17 | 30/70 | 5 | 16 | 10 | 12.91 | 0.55 | 26.64 |

| 18 | 30/70 | 10 | 0 | 15 | 13.22 | 0.60 | 25.32 |

| 19 | 30/70 | 15 | 4 | 20 | 13.53 | 0.54 | 27.34 |

| 20 | 30/70 | 20 | 8 | 0 | 10.20 | 0.51 | 26.14 |

| 21 | 0/100 | 0 | 16 | 15 | 11.35 | 0.51 | 27.06 |

| 22 | 0/100 | 5 | 0 | 20 | 12.17 | 0.55 | 24.79 |

| 23 | 0/100 | 10 | 4 | 0 | 15.25 | 0.54 | 26.17 |

| 24 | 0/100 | 15 | 8 | 5 | 14.03 | 0.54 | 26.69 |

| 25 | 0/100 | 20 | 12 | 10 | 11.38 | 0.53 | 30.06 |

| Factor | df | SSf | MSf | F-Value | p-Value |

|---|---|---|---|---|---|

| NBR/CR | 4 | 5.775 | 1.4437 | 1.94 | 0.197 |

| MP | 4 | 14.300 | 3.5749 | 4.81 | 0.028 |

| HGB | 4 | 11.032 | 2.7581 | 3.71 | 0.054 |

| MMT | 4 | 12.192 | 3.0479 | 4.10 | 0.043 |

| error | 8 | 5.947 | 0.7434 | - | - |

| Factor | df | SSf | MSf | F-Value | p-Value |

|---|---|---|---|---|---|

| NBR/CR | 4 | 12.19 | 3.049 | 2.25 | 0.153 |

| MP | 4 | 39.57 | 9.892 | 7.29 | 0.009 |

| HGB | 4 | 29.89 | 7.472 | 5.51 | 0.02 |

| MMT | 4 | 26.80 | 6.700 | 4.94 | 0.027 |

| error | 8 | 10.86 | 1.357 | - | - |

| Factor | df | SSf | MSf | F-Value | p-Value |

|---|---|---|---|---|---|

| NBR/CR | 4 | 0.018016 | 0.004504 | 47.91 | 0.00001 |

| MP | 4 | 0.007016 | 0.001754 | 18.66 | 0.00041 |

| HGB | 4 | 0.007816 | 0.001954 | 20.79 | 0.00028 |

| MMT | 4 | 0.006736 | 0.001684 | 17.91 | 0.00047 |

| error | 8 | 0.000752 | 0.000094 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, X.; Zhu, J.; Li, G.; Miao, Q.; Sain, M.; Jian, R. Formulation and Performance of NBR/CR-Based High-Damping Rubber Composites for Soundproof Using Orthogonal Test. Polymers 2023, 15, 2208. https://doi.org/10.3390/polym15092208

Zeng X, Zhu J, Li G, Miao Q, Sain M, Jian R. Formulation and Performance of NBR/CR-Based High-Damping Rubber Composites for Soundproof Using Orthogonal Test. Polymers. 2023; 15(9):2208. https://doi.org/10.3390/polym15092208

Chicago/Turabian StyleZeng, Xiankui, Jinmei Zhu, Gaowei Li, Qing Miao, Mohini Sain, and Ranran Jian. 2023. "Formulation and Performance of NBR/CR-Based High-Damping Rubber Composites for Soundproof Using Orthogonal Test" Polymers 15, no. 9: 2208. https://doi.org/10.3390/polym15092208

APA StyleZeng, X., Zhu, J., Li, G., Miao, Q., Sain, M., & Jian, R. (2023). Formulation and Performance of NBR/CR-Based High-Damping Rubber Composites for Soundproof Using Orthogonal Test. Polymers, 15(9), 2208. https://doi.org/10.3390/polym15092208