Processing-Induced Inhomogeneity of Yield Stress in Polycarbonate Product and Its Influence on the Impact Behavior

Abstract

:1. Introduction

2. The Predictive Model of Processing-Induced Yield Stress of PC

3. Izod Impact Experiment

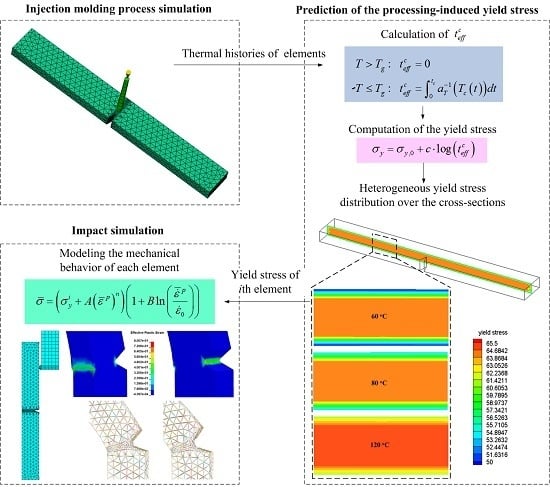

4. Integrative Simulation

4.1. Prediction of Yield Stresses Based on the Injection Molding Simulation

4.2. Impact Simulation

4.3. Simulation Results and Comparison with Experimental Data

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gunnarsson, C.; Ziemski, B.; Weerasooriya, T.; Moy, P. Deformation and failure of polycarbonate during impact as a function of thickness. In Proceedings of the SEM Annual Conference, Albuquerque, NM, USA, 1 June 2009.

- Qasim, H.S.; Yousif, A.A. Effect of distance from the support on the penetration mechanism of clamped circular polycarbonate armor plates. Int. J. Impact Eng. 2008, 35, 1244–1250. [Google Scholar]

- Ball, A.; McKenzie, H.W. On the low velocity impact behaviour of glass plates. In Proceedings of the International Conference on Mechanical and Physical Behaviour of Materials under Dynamic Loading, Oxford, UK, 26–30 Sepetmber 1994.

- Wright, S.C.; Fleck, N.A.; Stronge, W.J. Ballistic impact of polycarbonate-an experimental investigation. Int. J. Impact Eng. 1993, 13, 1–20. [Google Scholar] [CrossRef]

- Li, K.; Goldsmith, W. Perforation of steel and polycarbonate plates by tumbling projectiles. Int. J. Solids Struct. 1997, 34, 4581–4596. [Google Scholar] [CrossRef]

- Fraser, R.A.W.; Ward, I.M. The impact fracture behaviour of notched specimens of polycarbonate. J. Mater. Sci. 1977, 12, 459–468. [Google Scholar] [CrossRef]

- Cheng, C.; Hiltner, A.; Baer, E.; Soskey, P.; Mylonakis, S. Deformation of rubber toughened polycarbonate: Macroscale analysis of the damage zone. J. Appl. Polym. Sci. 1994, 52, 177–193. [Google Scholar] [CrossRef]

- Lombardo, B.; Keskkula, H.; Paul, D. Influence of ABS type on morphology and mechanical properties of PC/ABS blends. J. Appl. Polym. Sci. 1994, 54, 1697–1720. [Google Scholar] [CrossRef]

- Inberg, J.P.F.; Gaymens, R.J. Polycarbonate and co-continuous polycarbonate/abs blends: Influence of notch radius. Polymer 2002, 40, 4197–4205. [Google Scholar] [CrossRef]

- Dorogoy, A.; Rittel, D.; Brill, A. Experimentation and modeling of inclined ballistic impact in thick polycarbonate plates. Int. J. Impact Eng. 2011, 38, 804–814. [Google Scholar] [CrossRef]

- Dorogoy, A.; Rittel, D. Effect of confinement on thick polycarbonate plates impacted by long and AP projectiles. Int. J. Impact Eng. 2015, 76, 38–48. [Google Scholar] [CrossRef]

- Qasim, H.S. Impact resistance of a rectangular polycarbonate armor plate subjected to single and multiple impacts. Int. J. Impact Eng. 2009, 36, 1128–1135. [Google Scholar]

- Hu, W.K.; Wang, Y.N.; Yu, J.; Yen, C.F.; Bobaru, F. Impact damage on a thin glass plate with a thin polycarbonate backing. Int. J. Impact Eng. 2013, 62, 152–165. [Google Scholar] [CrossRef]

- Tvergaard, V.; Needleman, A. An analysis of thickness effects in the Izod test. Int. J. Solids Struct. 2008, 45, 3951–3966. [Google Scholar] [CrossRef]

- Xu, Y.J.; Zhang, Q.W.; Zhang, W.H.; Zhang, P. Optimization of injection molding process parameters to improve the mechanical performance of polymer product against impact. Int. J. Adv. Manuf. Technol. 2015, 76, 2199–2208. [Google Scholar] [CrossRef]

- Nagato, K. Injection compression molding of replica molds for nanoimprint lithography. Polymers 2014, 6, 604–612. [Google Scholar] [CrossRef]

- Govaert, L.E.; Engels, T.A.P.; Klompen, E.T.J.; Peters, G.W.M.; Meijer, H.E.H. Processing-induced properties in glassy polymers. Int. Polym. Proc. 2005, 20, 170–177. [Google Scholar] [CrossRef]

- Engels, T.A.P.; Govaert, L.E.; Meijer, H.E.H. Quantitative prediction of mechanical performance of polymer products directly from processing conditions. In Proceedings of the XV International Congress on Rheology: The Society of Rheology 80th Annual Meeting, Monterey, CA, USA, 3–8 August 2008.

- Engels, T.A.P.; van Breemen, L.C.A.; Govaert, L.E.; Meijer, H.E.H. Predicting the long-term mechanical performance of polycarbonate from thermal history during injection molding. Macromol. Mater. Eng. 2009, 294, 829–838. [Google Scholar] [CrossRef]

- Verbeeten, W.M.H.; Kanters, M.J.W.; Engels, T.A.P.; Govaert, L.E. Yield stress distribution in injection-moulded glassy polymers. Polym. Int. 2015, 64, 1527–1536. [Google Scholar] [CrossRef]

- Engels, T.A.P.; van Breemen, L.C.A.; Govaert, L.E.; Meijer, H.E.H. Criteria to predict the embrittlement of polycarbonate. Polymer 2011, 52, 1811–1819. [Google Scholar] [CrossRef]

- Xu, Y.J.; Lu, H.; Gao, T.L.; Zhang, W.H. Predicting the low-velocity impact behavior of polycarbonate: Influence of thermal history during injection molding. Int. J. Impact Eng. 2015, 86, 265–273. [Google Scholar] [CrossRef]

| Mold temperature (°C) | Method | 60 | 80 | 120 |

|---|---|---|---|---|

| Fracture energy (kJ/m2) | Presented method | 79.81 | 84.66 | 88.30 |

| Average method | 77.53 | 82.38 | 86.94 | |

| Experimental | 85.74 | 90.18 | 95.63 |

© 2016 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, Y.; Lu, H.; Gao, T.; Zhang, W. Processing-Induced Inhomogeneity of Yield Stress in Polycarbonate Product and Its Influence on the Impact Behavior. Polymers 2016, 8, 72. https://doi.org/10.3390/polym8030072

Xu Y, Lu H, Gao T, Zhang W. Processing-Induced Inhomogeneity of Yield Stress in Polycarbonate Product and Its Influence on the Impact Behavior. Polymers. 2016; 8(3):72. https://doi.org/10.3390/polym8030072

Chicago/Turabian StyleXu, Yingjie, Huan Lu, Tenglong Gao, and Weihong Zhang. 2016. "Processing-Induced Inhomogeneity of Yield Stress in Polycarbonate Product and Its Influence on the Impact Behavior" Polymers 8, no. 3: 72. https://doi.org/10.3390/polym8030072

APA StyleXu, Y., Lu, H., Gao, T., & Zhang, W. (2016). Processing-Induced Inhomogeneity of Yield Stress in Polycarbonate Product and Its Influence on the Impact Behavior. Polymers, 8(3), 72. https://doi.org/10.3390/polym8030072