Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

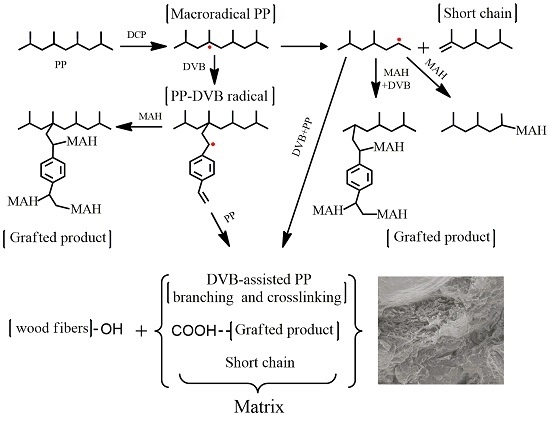

2.2.1. Modification of Matrix

2.2.2. Preparation of Composites

2.3. Characterization

2.3.1. Fourier-Transform Infrared (FTIR) Spectroscopy Analysis

2.3.2. Determination of Melt Flow Index and MAH Grafting Level of the Modified Matrix

2.3.3. Determination of Strength Properties

2.3.4. Dynamic Mechanical Analysis

2.3.5. Morphological Analysis

3. Results and Discussion

3.1. Characterization of Chemically Grafted Polypropylene

3.2. Characteristics of the Composites

3.2.1. Mechanical Properties of the Composites

3.2.2. Dynamic Mechanical Analysis

3.2.3. Fracture Morphology Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Rivera-Gómez, C.; Galán-Marín, C.; Bradley, F. Analysis of the influence of the fiber type in polymer matrix/fiber bond using natural organic polymer stabilizer. Polymers 2014, 6, 977–994. [Google Scholar] [CrossRef] [Green Version]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Biocomposites reinforced with natural fibers: 2000–2010. Prog. Polym. Sci. 2012, 37, 1552–1596. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef] [Green Version]

- Cheung, H.Y.; Lau, K.T.; Lau, K.T.; Hui, D. A critical review on polymer-based bio-engineered materials for scaffold development. Compos. Part B Eng. 2007, 38, 291–300. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibers and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–15. [Google Scholar] [CrossRef]

- Gupta, M.K.; Srivastava, R.K. Mechanical Properties of Hybrid Fibers-Reinforced Polymer Composite: A Review. Polym. Plast. Technol. Eng. 2016, 55, 626–642. [Google Scholar] [CrossRef]

- Cui, Y.H.; Lee, S.; Noruziaan, B.; Cheung, M.; Tao, J. Fabrication and interfacial modification of wood/recycled plastic composite materials. Compos. Part A Appl. Sci. Manuf. 2008, 39, 655–661. [Google Scholar] [CrossRef]

- Yan, Z.L.; Wang, H.; Lau, K.T.; Pather, S.; Zhang, J.C.; Lin, G.; Ding, Y. Reinforcement of polypropylene with hemp fibres. Compos. Part B Eng. 2013, 46, 221–226. [Google Scholar] [CrossRef]

- Del Rey, R.; Serrat, R.; Alba, J.; Perez, I.; Mutje, P.; Espinach, F.X. Effect of Sodium Hydroxide Treatments on the Tensile Strength and the Interphase Quality of Hemp Core Fiber-Reinforced Polypropylene Composites. Polymers 2017, 9, 377. [Google Scholar] [CrossRef]

- Flores-Hernández, C.; Colín-Cruz, A.; Velasco-Santos, C.; Castaño, V.; Rivera-Armenta, J.; Almendarez-Camarillo, A.; García-Casillas, P.; Martínez-Hernández, A. All green composites from fully renewable biopolymers: Chitosan-starch reinforced with keratin from feathers. Polymers 2014, 6, 686–705. [Google Scholar] [CrossRef]

- Naghmouchi, I.; Espinach, F.X.; Mutjc, P.; Boufi, S. Polypropylene composites based on lignocellulosic fillers: How the filler morphology affects the composite properties. Mater. Des. 2015, 65, 454–461. [Google Scholar] [CrossRef]

- Zhang, H.L. Effect of a novel coupling agent, alkyl ketene dimer, on the mechanical properties of wood-plastic composites. Mater. Des. 2014, 59, 130–134. [Google Scholar] [CrossRef]

- Ou, R.X.; Zhao, H.; Sui, S.J.; Song, Y.M.; Wang, Q.W. Reinforcing effects of Kevlar fiber on the mechanical properties of wood-flour/high-density-polyethylene composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1272–1278. [Google Scholar] [CrossRef]

- Karmarkar, A.; Chauhan, S.S.; Modak, J.M.; Chanda, M. Mechanical properties of wood-fiber reinforced polypropylene composites: Effect of a novel compatibilizer with isocyanate functional group. Compos. Part A 2007, 38, 227–233. [Google Scholar] [CrossRef]

- Notta-Cuvier, D.; Lauro, F.; Bennani, B.; Nciri, M. Impact of natural variability of flax fibres properties on mechanical behaviour of short-flax-fibre-reinforced polypropylene. J. Mater. Sci. 2016, 51, 2911–2925. [Google Scholar] [CrossRef]

- Xie, Y.J.; Hill, C.A.S.; Xiao, Z.F.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- EI-Sabbagh, A. Effect of coupling Agent on natural fibre in natural fibre/polypropylene composites on mechanical and thermal behaviour. Compos. Part B Eng. 2014, 57, 126–135. [Google Scholar] [CrossRef]

- Aggarwal, P.K.; Raghu, N.; Karmarkar, A.; Chuahan, S. Jute-polypropylene composites using m-TMI-grafted-polypropylene as a coupling agent. Mater. Des. 2013, 43, 112–117. [Google Scholar] [CrossRef]

- Cantero, G.; Arbelaiz, A.; Mugika, F.; Valea, A.; Mondragon, I. Mechanical behavior of wood/polypropylene composites: Effects of fiber treatments and ageing processes. J. Reinf. Plast. Compos. 2003, 22, 37–50. [Google Scholar] [CrossRef]

- Xie, Y.J.; Xiao, Z.F.; Timo, G.; Militz, H.; Hill, C.A.S.; Leif, S.; Carsten, M. Effects of chemical modification of wood particles with glutaraldehyde and 1,3-dimethylol-4,5-dihydroxyethyleneurea on properties of the resulting polypropylene composites. Compos. Sci. Technol. 2010, 70, 2003–2011. [Google Scholar] [CrossRef]

- Arbelaiz, A.; Fernandez, B.; Cantero, G.; Llano-Ponte, R.; Valea, A.; Mondragon, I. Mechanical properties of flax fiber/polypropylene composites. Influence of fibre/matrix modification and glass fiber hybridization. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1637–1644. [Google Scholar] [CrossRef]

- Pracella, M.; Chionna, D.; Anguillesi, I.; Kulinski, Z.; Piorkowska, E. Functionalization, compatibilization and properties of polypropylene composites with Hemp fibers. Compos. Sci. Technol. 2006, 66, 2218–2230. [Google Scholar] [CrossRef]

- Gonzalez-Sanchez, C.; Martinez-Aguirre, A.; Perez-Garcia, B.; Acosta, J.; Fonseca-Valero, C.; de la Orden, M.U.; Sánchez, C.; Urreaga, J.M. Enhancement of mechanical properties of waste-sourced biocomposites through peroxide induced crosslinking. Compos. Part A Appl. Sci. Manuf. 2016, 80, 285–291. [Google Scholar] [CrossRef]

- Gao, H.; Xie, Y.J.; Ou, R.X.; Wang, Q.W. Grafting effects of polypropylene/polyethylene blends with maleic anhydride on the properties of the resulting wood–plastic composites. Compos. Part A Appl. Sci. Manuf. 2012, 43, 150–157. [Google Scholar] [CrossRef]

- Li, Y.; Xie, X.M.; Guo, B.H. Study on styrene-assisted melt free-radical grafting of maleic anhydride onto polypropylene. Polymer 2001, 42, 3419–3425. [Google Scholar] [CrossRef]

- Zhang, Z.J.; Wan, D.; Xing, H.P.; Zhang, Z.J.; Tan, H.Y.; Wang, L.; Zheng, J.; An, Y.J.; Tang, T. A new grafting monomer for synthesizing long chain branched polypropylene through melt radical reaction. Polymer 2012, 53, 121–129. [Google Scholar] [CrossRef]

- Shi, D.A.; Yang, J.H.; Yao, Z.H.; Wang, Y.; Huang, H.L.; Jing, W.; Yin, J.H.; Costa, G. Functionalization of isotactic polypropylene with maleic anhydride by reactive extrusion: Mechanism of melt grafting. Polymer 2001, 42, 5549–5557. [Google Scholar] [CrossRef]

- Al-Malaika, S.; Eddiyanto, E. Reactive processing of polymers: Effect of bifunctional and tri-functional comonomers on melt grafting of glycidyl methacrylate onto polypropylene. Polym. Degrad. Stab. 2010, 95, 353–362. [Google Scholar] [CrossRef]

- Passaglia, E.; Coilai, S.; Augier, S. Control of macromolecular architecture during the reactive functionalization in the melt of olefin polymers. Prog. Polym. Sci. 2009, 34, 911–947. [Google Scholar] [CrossRef]

- Etaati, A.; Pather, S.; Fang, Z.P.; Wang, H. The study of fibre/matrix bond strength in short hemp polypropylene composites from dynamic mechanical analysis. Compos. Part B Eng. 2014, 62, 19–28. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Alothman, O.Y.; Paridah, M.T. A review on dynamic mechanical properties of natural fibre reinforced polymer composites. Constr. Build. Mater. 2016, 106, 149–159. [Google Scholar] [CrossRef]

- John, M.J.; Anandjiwala, R.D. Chemical modification of flax reinforced polypropylene composites. Compos. Part A Appl. Sci. Manuf. 2009, 40, 442–448. [Google Scholar] [CrossRef]

- Chauhan, S.; Karmarkar, A.; Aggarwal, P. Damping Behavior of wood filled polypropylene composites. J. Appl. Polym. Sci. 2009, 114, 2421–2426. [Google Scholar] [CrossRef]

- Jawaid, M.; Khalil, H.P.S.; Hassan, A.; Dungani, R.; Hadiyane, A. Effect of jute fibre loading on tensile and dynamic mechanical properties of oil palm epoxy composites. Compos. Part B Eng. 2013, 45, 619–624. [Google Scholar] [CrossRef]

- Liu, H.; Wu, Q.; Han, G.; Yao, F.; Kojima, Y.; Suzuki, S. Compatibilizing and toughening bamboo flour-filled HDPE composites: Mechanical properties and morphologies. Compos. Part A Appl. Sci. Manuf. 2009, 39, 1891–1900. [Google Scholar] [CrossRef]

- Huang, X.H.; Zhang, J.J. Effect of Filler–Filler and Polymer–Filler Interactions on Rheological and Mechanical Properties of HDPE–Wood composites. J. Appl. Polym. Sci. 2008, 111, 2806–2812. [Google Scholar] [CrossRef]

| Sample | Virgin PP | DCP (wt %) | MAH (wt %) | DVB (wt %) |

|---|---|---|---|---|

| MPPD0 | 100 | 0.09 | 0.4 | 0.0 |

| MPPD0.2 | 100 | 0.09 | 0.4 | 0.2 |

| MPPD0.4 | 100 | 0.09 | 0.4 | 0.4 |

| MPPD0.6 | 100 | 0.09 | 0.4 | 0.6 |

| MPPD0.8 | 100 | 0.09 | 0.4 | 0.8 |

| Sample Type | WF Load (wt %) | Virgin PP (wt %) | Grafted PP (wt %) | MAPP (wt %) |

|---|---|---|---|---|

| WF/PP (WP) | 60 | 40 | - | - |

| WF/PP/MAPP (WPMA) | 60 | 36 | - | 4 |

| WF/MPPD0 (WMPD0) | 60 | - | 40 | - |

| WF/MPPD0.2 (WMPD0.2) | 60 | - | 40 | - |

| WF/MPPD0.4 (WMPD0.4) | 60 | - | 40 | - |

| WF/MPPD0.6 (WMPD0.6) | 60 | - | 40 | - |

| WF/MPPD0.8 (WMPD0.8) | 60 | - | 40 | - |

| Sample Type | Tensile Strength (MPa) | Tensile Modulus (GPa) | Flexure Strength (MPa) | Flexure Modulus (GPa) | Impact Strength (KJ/m2) |

|---|---|---|---|---|---|

| WP | 16.0 ± 0.7 | 2.3 ± 0.1 | 26.5 ± 0.7 | 6.3 ± 0.1 | 5.6 ± 0.8 |

| WPMA | 42.5 ± 0.9 | 2.4 ± 0.1 | 73.7 ± 1.1 | 6.7 ± 0.1 | 9.0 ± 0.5 |

| WMPD0 | 51.4 ± 0.6 | 2.1 ± 0.2 | 81.6 ± 0.9 | 5.6 ± 0.2 | 9.8 ± 0.6 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yi, S.; Xu, S.; Fang, Y.; Wang, H.; Wang, Q. Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites. Polymers 2017, 9, 712. https://doi.org/10.3390/polym9120712

Yi S, Xu S, Fang Y, Wang H, Wang Q. Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites. Polymers. 2017; 9(12):712. https://doi.org/10.3390/polym9120712

Chicago/Turabian StyleYi, Shunmin, Shihua Xu, Yiqun Fang, Haigang Wang, and Qingwen Wang. 2017. "Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites" Polymers 9, no. 12: 712. https://doi.org/10.3390/polym9120712

APA StyleYi, S., Xu, S., Fang, Y., Wang, H., & Wang, Q. (2017). Effects of Matrix Modification on the Mechanical Properties of Wood–Polypropylene Composites. Polymers, 9(12), 712. https://doi.org/10.3390/polym9120712