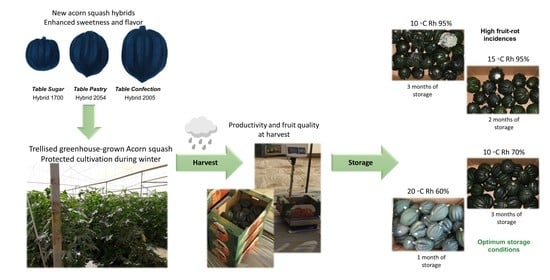

Quality and Storability of Trellised Greenhouse-Grown, Winter-Harvested, New Sweet Acorn Squash Hybrids

Abstract

:1. Introduction

2. Materials and Methods

2.1. Plant Materials

2.2. Growing Conditions

2.3. Experiments and Treatments

2.3.1. Harvesting

2.3.2. Postharvest Handling

2.3.3. Hot Water Rinsing and Brushing Treatment

2.3.4. Storage Conditions

2.4. Fruit Quality Evaluation

2.5. Carotenoid Identification and Quantification

2.6. Statistical Analysis

3. Results

3.1. Productivity and Fruit Quality of the Three Cultivars

3.1.1. Yield and Yield Components

3.1.2. Fruit Quality

3.2. Storability of the Cultivars

3.2.1. Fruit Decay during Storage

3.2.2. Reducing Relative Air Humidity and Fruit Quality

3.2.3. Storage at 20 °C and Rh 60% Compared with 15 °C and 95% Rh

3.2.4. Cold Storage Preservation for 3 Months

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Paris, H.S.; Burger, Y.; Schaffer, A.A. Genetic variability and introgression of horticulturally valuable traits in squash and pumpkins of Cucurbita pepo. Isr. J. Plant Sci. 2006, 54, 223–231. [Google Scholar] [CrossRef]

- Paris, H.S. History of the cultivar-groups of Cucurbita pepo. In Horticultural Reviews; John Wiley & Sons: Hoboken, NJ, USA, 2000; Volume 25, pp. 71–170. [Google Scholar]

- Paris, H.S. A proposed subspecific classification for Cucurbita pepo. Phytologia 1986, 61, 133–138. [Google Scholar]

- Loy, J.B. Interaction of harvest time and storage on attributes of eating quality in acorn squash. HortScience 2006, 41, 496. [Google Scholar] [CrossRef] [Green Version]

- Loy, J.B. Morpho-physiological aspects of productivity and quality in squash and pumpkins (Cucurbita spp.). Crit. Rev. Plant Sci. 2004, 23, 337–363. [Google Scholar] [CrossRef]

- Paris, H.S. Germplasm enhancement of Cucurbita pepo (pumpkin, squash, gourd: Cucurbitaceae): Progress and challenges. Euphytica 2016, 208, 415–438. [Google Scholar] [CrossRef]

- Paris, H.S.; Godinger, D. Sweet acorn squash, a new vegetable on the Israeli market. Acta Hortic. 2016, 451–456. [Google Scholar] [CrossRef]

- Gaba, V.; Zelcer, A.; Gal-On, A. Cucurbit biotechnology-the importance of virus resistance. Vitr. Cell. Dev. Biol. Plant 2004, 40, 346–358. [Google Scholar] [CrossRef]

- Chalupowicz, D.; Alkalai-Tuvia, S.; Zaaroor-Presman, M.; Fallik, E. The potential use of hot water rinsing and brushing technology to extend storability and shelf life of sweet acorn squash (Cucurbita pepo L.). Horticulturae 2018, 4, 19. [Google Scholar] [CrossRef] [Green Version]

- Itle, R.A.; Kabelka, E.A. Correlation between L*a*b* color space values and carotenoid content in pumpkins and squash (Cucurbita spp.). HortScience 2009, 44, 633–637. [Google Scholar] [CrossRef] [Green Version]

- Tadmor, Y.; Paris, H.S.; Meir, A.; Schaffer, A.A.; Lewinsohn, E. Dual role of the pigmentation gene B in affecting carotenoid and vitamin E content in squash (Cucurbita pepo) mesocarp. J. Agric. Food Chem. 2005, 53, 9759–9763. [Google Scholar] [CrossRef]

- Zhang, M.K.; Zhang, M.P.; Mazourek, M.; Tadmor, Y.; Li, L. Regulatory control of carotenoid accumulation in winter squash during storage. Planta 2014, 240, 1063–1074. [Google Scholar] [CrossRef] [PubMed]

- Tadmor, Y.; Larkov, O.; Meir, A.; Minkoff, M.; Lastochkin, E.; Edelstein, M.; Levin, S.; Wong, J.; Rocheford, T.; Lewinsohn, E. Reversed-phase high performance liquid chromatographic determination of vitamin E components in maize kernels. Phytochem. Anal. 2000, 11, 370–374. [Google Scholar] [CrossRef]

- Aliu, S.; Rusinovci, I.; Fetahu, S.; Salihu, S.; Zogaj, R. Nutritive and mineral composition in a collection of Cucurbita pepo L grown in Kosova. Food Nutr. Sci. 2012, 3, 634. [Google Scholar]

- Gharibzahedi, S.M.T.; Jafari, S.M. The importance of minerals in human nutrition: Bioavailability, food fortification, processing effects and nanoencapsulation. Trends Food Sci. Technol. 2017, 62, 119–132. [Google Scholar] [CrossRef]

- Šlosár, M.; Mezeyová, I.; Hegedűsová, A.; Hegedűs, O. Quantitative and qualitative parameters in Acorn squash cultivar in the conditions of the Slovak Republic. Potravin. Slovak J. Food Sci. 2018, 12, 91–98. [Google Scholar] [CrossRef] [Green Version]

- Azevedo-Meleiro, C.H.; Rodriguez-Amaya, D.B. Qualitative and quantitative differences in carotenoid composition among Cucurbita moschata, Cucurbita maxima, and Cucurbita pepo. J. Agric. Food Chem. 2007, 55, 4027–4033. [Google Scholar] [CrossRef]

- Murkovic, M.; Mülleder, U.; Neunteufl, H. Carotenoid content in different varieties of pumpkins. J. Food Compos. Anal. 2002, 15, 633–638. [Google Scholar] [CrossRef]

- Loy, J.B. Harvest period and storage affect biomass partitioning and attributes of eating quality in acorn squash (Cucurbita pepo). In Cucurbitaceae Proceedings; Universal Printing & Publishing: Raleigh, NC, USA, 2006; pp. 568–577. [Google Scholar]

- Schaffer, A.A.; Paris, H.S. Melons, Squashes, and Gourds. In Reference Module in Food Science; Elsevier: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Wyatt, L.E.; Strickler, S.R.; Mueller, L.A.; Mazourek, M. Comparative analysis of Cucurbita pepo metabolism throughout fruit development in acorn squash and oilseed pumpkin. Hortic. Res. 2016, 3, 16045. [Google Scholar] [CrossRef] [Green Version]

- Corrigan, V.K.; Irving, D.E.; Potter, J.F. Sugars and sweetness in buttercup squash. Food Qual. Prefer. 2000, 11, 313–322. [Google Scholar] [CrossRef]

- Jacobo-Valenzuela, N.; de Jesus Zazueta-Morales, J.; Gallegos-Infante, J.A.; Aguilar-Gutierrez, F.; Camacho-Hernandez, I.L.; Rocha-Guzman, N.E.; Gonzalez-Laredo, R.F. Chemical and physicochemical characterization of winter squash (Cucurbita moschata D.). Not. Bot. Horti Agrobot. Cluj Napoca 2011, 39, 34–40. [Google Scholar] [CrossRef] [Green Version]

- Culpepper, C.W.; Moon, H.H. Differences in the composition of the fruits of Cucurbita varieties at different ages in relation to culinary use. J. Agric. Res. 1945, 71, 111–136. [Google Scholar]

- Adeeko, A.; Yudelevich, F.; Regev, R.; Avraham, L.; Alkalai-Tuvia, S.; Paris, H.S.; Fallik, E.; Ziv, C. The effect of postharvest treatments on produce losses during long-term storage of acorn squash. In Proceedings of the 5th International Symposium on Postharvest Pathology. Acta Hortic. (in press).

- Loy, J.B. The nuts and bolts of fruit quality in cucurbits. In Proceedings of the New England Vegetable and Fruit Conference, Manchester, NH, USA, 17–19 December 2013; Volume 17, pp. 201–204. [Google Scholar]

- Bradford, K.J.; Dahal, P.; van Asbrouck, J.; Kunusoth, K.; Bello, P.; Thompson, J.; Wu, F. The dry chain: Reducing postharvest losses and improving food safety in humid climates. Trends Food Sci. Technol. 2018, 71, 84–93. [Google Scholar] [CrossRef]

| Transplanting Date | Introduction of Bumblebees for Pollination | First Harvest | Second Harvest | Third Harvest | |

|---|---|---|---|---|---|

| First Year | 26 September 2017 | 19 October 2017 | 25 December 2017 | 16 January 2018 | 07 February 2018 |

| Days from planting | 90 | 112 | 134 | ||

| Second Year | 17 September 2018 | 07 October 2018 | 10 December 2018 | 15 January 2019 | 20 February 2019 |

| Days from planting | 84 | 120 | 156 | ||

| Third Year | 05 August 2019 | 29 August 2019 | 10 October 2019 | 06 November 2019 | 20 November 2019 |

| Days from planting | 66 | 93 | 107 | ||

| Treatment Name | Temperature (°C) 1 | Humidity (% Rh) 1 | Storage Period (Days) 2 |

|---|---|---|---|

| 20 °C Rh 60% | 19.1 ± 0.6 | 60.1 ± 4.3 | 56 ± 3 |

| 15 °C Rh 95% | 14.6 ± 0.4 | 95.3 ± 3.6 | 85 ± 5 |

| 10 °C Rh 95% | 10.2 ± 0.3 | 94.0 ± 0.6 | 84 ± 6 |

| 10 °C Rh 70% | 9.6 ± 0.3 | 67.0 ± 2.6 | 91 ± 4 |

| Year/Hybrid X | Average Fruit Size (g) | Average Fruit Circumference (cm) | Average Number of Fruits per Plant (No.) | Yield (kg/m2) |

|---|---|---|---|---|

| 2017 | ||||

| 1700 | 370 cd | 27.0 b | 4.5 a | 1.72 c |

| 2054 | 461 bcd | 29.8 b | 4.4 a | 2.04 bc |

| 2005 | 715 a | 35.2 a | 3.7 a | 2.73 ab |

| 2018 | ||||

| 1700 | 348 d | 28.3 b | 5.0 a | 2.16 bc |

| 2054 | 410 bcd | 29.8 b | 5.2 a | 2.86 ab |

| 2005 | 502 b | 33.2 a | 4.9 a | 3.40 a |

| 2019 | ||||

| 1700 | 340 d | n.d. y | 4.8 a | 2.02 bc |

| 2054 | 416 bcd | n.d. | 4.4 a | 2.37 bc |

| 2005 | 498 b | n.d. | 4.9 a | 3.48 a |

| LSD | 43.3 | 1.0 | 0.48 | 0.256 |

| Mean values at each year | ||||

| 2017 | 515.4 a | 30.7 a | 4.2 b | 2.17 b |

| 2018 | 420.0 b | 30.4 a | 5.0 a | 2.80 a |

| 2019 | 417.7 b | n.d. | 4.7 ab | 2.62 a |

| LSD z | 24.5 | 0.55 | 0.28 | 0.148 |

| Mean values of each cultivar | ||||

| 1700 | 352.5 c | 27.6 c | 4.7 a | 1.97 c |

| 2054 | 429.0 b | 29.8 b | 4.7 a | 2.42 b |

| 2005 | 571.7 a | 34.2 a | 4.5 a | 3.20 a |

| LSD | 24.5 | 0.68 | 0.28 | 0.148 |

| Table of Variance (F-value) | ||||

| Year (Yr) | *** | NS | * | *** |

| Cultivar (Cv) | *** | *** | NS | *** |

| Yr x Cv | ** | NS | NS | NS |

| Storage Conditions | Hybrid | Decay (%) | Weight Loss (%) | Rind Color (Hue°) | Flesh Color (a *) | TSS (%) | Dry Weight (%) | Firmness (N) |

|---|---|---|---|---|---|---|---|---|

| 15°C Rh 95% | 1700 | 34.0 a | 6.6 c | 163 ab | 10.4 a | 15.5 a | 26.6 a | 173 ab |

| 2054 | 33.4 a | 7.3 bc | 204 a | 8.2 a | 18.4 a | 25.4 a | 187 a | |

| 2005 | 28.7 ab | 5.1 c | 198 a | 8.0 a | 15.7 a | 20.4 a | 151 c | |

| 20°C Rh 60% | 1700 | 4.8 c | 13.0 a | 131 b | 9.3 a | 16.8 a | 26.4 a | 150 c |

| 2054 | 6.3 bc | 16.3 a | 142 b | 9.8 a | 17.4 a | 19.7 a | 182 a | |

| 2005 | 7.8 c | 11.5 ab | 174 ab | 10.1 a | 15.6 a | 22.7 a | 155 bc | |

| LSD Z | 5.91 | 1.27 | 15.6 | 1.34 | 1.15 | 2.45 | 6.7 | |

| Mean values at each temperature | ||||||||

| 15°C Rh 95% | 32.0 a | 6.3 b | 188 a | 8.9 a | 16.5 a | 24.1 a | 170 a | |

| 20°C Rh 60% | 6.3 b | 13.6 a | 149 b | 9.8 a | 16.6 a | 22.9 a | 162 b | |

| LSD | 3.8 | 0.82 | 9.1 | 0.81 | 0.68 | 1.41 | 3.8 | |

| Mean values of each cultivar | ||||||||

| 1700 | 19.4 a | 9.7 ab | 147 b | 9.9 a | 16.1 ab | 26.5 a | 162 b | |

| 2054 | 19.8 a | 11.8 a | 173 ab | 9.0 a | 17.9 a | 22.6 ab | 185 a | |

| 2005 | 18.2 a | 8.3 b | 186 a | 9.0 a | 15.6 b | 21.5 b | 153 b | |

| LSD | 4.2 | 1.17 | 11.2 | 0.99 | 0.84 | 1.73 | 4.7 | |

| Table of Variance (F-value) | ||||||||

| Temperature (Tr) | *** | *** | *** | NS | NS | NS | * | |

| Cultivar (Cv) | NS | * | ** | NS | * | * | *** | |

| Tr x Cv | NS | NS | NS | NS | NS | NS | * | |

| Storage Conditions | Cultivar | Decay (%) | Weight Loss (%) | Rind Color (Hue°) | Flesh Color (a *) | TSS (%) | Dry Weight (%) | Firmness (N) |

|---|---|---|---|---|---|---|---|---|

| 15°C Rh 95% | 1700 | 34.0 a | 11.9 bcd | 208 b | 10.5 ab | 18.7 ab | 24.2 a | 164 a |

| 2054 | 33.4 a | 11.1 cd | 243 a | 8.5 b | 18.1 ab | 22.9 ab | 169 a | |

| 2005 | 28.7 a | 10.0 d | 245 a | 7.3 b | 15.0 c | 16.9 c | 148 a | |

| 10°C Rh 70% | 1700 | 7.2 b | 14.1 ab | 222 ab | 12.3 a | 19.7 a | 24.2 a | 151 a |

| 2054 | 5.0 b | 14.8 a | 233 ab | 7.7 b | 17.2 abc | 21.0 abc | 146 ab | |

| 2005 | 3.6 b | 12.6 abc | 234 ab | 8.3 b | 16.5 bc | 19.3 bc | 124 b | |

| LSD Z | 6.5 | 0.9 | 9.4 | 1.2 | 0.93 | 1.40 | 8.2 | |

| Mean values at each temperature-Rh | ||||||||

| 15°C Rh 95% | 32.0 a | 11.0 b | 232 a | 8.8 a | 17.8 a | 21.3 a | 160 a | |

| 10°C Rh 70% | 5.3 b | 13.8 a | 229 a | 9.4 a | 17.2 a | 21.5 a | 140 b | |

| LSD | 3.3 | 0.54 | 5.3 | 0.69 | 0.54 | 0.83 | 4.8 | |

| Mean values of each cultivar | ||||||||

| 1700 | 20.6 a | 13.0 a | 215 b | 11.4 a | 19.2 a | 24.2 a | 158 a | |

| 2054 | 19.2 a | 12.9 a | 238 a | 8.1 b | 17.6 a | 21.9 a | 158 a | |

| 2005 | 16.2 a | 11.3 b | 239 a | 7.8 b | 15.8 b | 18.1 b | 136 b | |

| LSD | 4.0 | 0.64 | 6.7 | 0.86 | 0.67 | 1.04 | 5.7 | |

| Table of Variance (F-value) | ||||||||

| Temperature-Rh (Tr) | *** | *** | NS | NS | NS | NS | *** | |

| Cultivar (Cv) | NS | * | *** | *** | *** | *** | *** | |

| Tr x Cv | NS | NS | NS | NS | NS | NS | NS | |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adeeko, A.; Yudelevich, F.; Raphael, G.; Avraham, L.; Alon, H.; Presman, M.Z.; Alkalai-Tuvia, S.; Paris, H.S.; Fallik, E.; Ziv, C. Quality and Storability of Trellised Greenhouse-Grown, Winter-Harvested, New Sweet Acorn Squash Hybrids. Agronomy 2020, 10, 1443. https://doi.org/10.3390/agronomy10091443

Adeeko A, Yudelevich F, Raphael G, Avraham L, Alon H, Presman MZ, Alkalai-Tuvia S, Paris HS, Fallik E, Ziv C. Quality and Storability of Trellised Greenhouse-Grown, Winter-Harvested, New Sweet Acorn Squash Hybrids. Agronomy. 2020; 10(9):1443. https://doi.org/10.3390/agronomy10091443

Chicago/Turabian StyleAdeeko, Ayobami, Fabiola Yudelevich, Ginat Raphael, Lior Avraham, Hana Alon, Merav Zaaroor Presman, Sharon Alkalai-Tuvia, Harry S. Paris, Elazar Fallik, and Carmit Ziv. 2020. "Quality and Storability of Trellised Greenhouse-Grown, Winter-Harvested, New Sweet Acorn Squash Hybrids" Agronomy 10, no. 9: 1443. https://doi.org/10.3390/agronomy10091443

APA StyleAdeeko, A., Yudelevich, F., Raphael, G., Avraham, L., Alon, H., Presman, M. Z., Alkalai-Tuvia, S., Paris, H. S., Fallik, E., & Ziv, C. (2020). Quality and Storability of Trellised Greenhouse-Grown, Winter-Harvested, New Sweet Acorn Squash Hybrids. Agronomy, 10(9), 1443. https://doi.org/10.3390/agronomy10091443