Interactions between Microalgae and Bacteria in the Treatment of Wastewater from Milk Whey Processing

Abstract

:1. Introduction

2. Materials and Methods

2.1. Wastewater

- Reverse osmosis,

- Ultrafiltration,

- Concentration by MVR (mechanical vapor recompression) evaporation.

2.2. Analytical Determinations

2.3. Photosynthetic Efficiency

2.4. Preliminary Screening Test

- Chlorella sp.

- Scenedesmus acuminatus

- Scenedesmus obliquus

- Arthrospira platensis (Spirulina)

- A mixed microalgal population made of Chlorella, Chlamydomonas, and Scenedesmus spp.

2.5. Continuous Test

2.6. Statistical Analyses

3. Results

3.1. Selection of Microalgal Strains and Populations

3.2. Continuous Test

4. Discussion

5. Conclusions

- Scenedesmus acuminatus (SA) and a mixed population of Chlorella, Scenedesmus, and Chlamydomonas spp. (PM) could grow in batch tests on MWPW, unlike other tested pure cultures (Chlorella sp., Scenedesmus obliquus, Arthrospira platensis).

- MWPW was effectively treated in a 70-day continuous test using both SA and PM and effluent pollution level complied with limits set by the Italian law for discharge into surface water.

- Continuously operated PBRs were contaminated by cyanobacteria, whose filamentous nature may have favored biomass aggregation, thus promoting efficient harvesting by gravity settling.

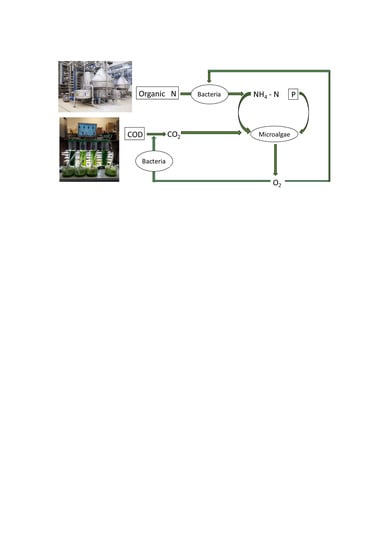

- According to steady state calculations, photo-oxygenation fully compensated for the oxygen request for COD oxidation; on the contrary, CO2 production from COD oxidation by bacteria could cover up to 58% of the algae request, suggesting that the remaining inorganic carbon was taken from other sources (e.g., bubbled CO2, incoming alkalinity, gas exchange with the atmosphere).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Slavov, A.K. General Characteristics and Treatment Possibilities of Dairy Wastewater—A Review. Food Technol. Biotechnol. 2017, 55, 14–28. [Google Scholar] [CrossRef]

- EUROSTAT. Available online: https://ec.europa.eu/eurostat (accessed on 19 January 2020).

- Karadag, D.; Köroğlu, E.O.; Ozkaya, B.; Cakmakci, M. A review on anaerobic biofilm reactors for the treatment of dairy industry wastewater. Process Biochem. 2015, 50, 262–271. [Google Scholar] [CrossRef]

- Nadais, M.H.G.A.G.; Capela, M.I.A.P.F.; Arroja, L.M.G.A.; Hung, Y. Handbook of Environmental Engineering; CRC Press: Boca Raton, FL, USA, 2010; Chapter 17; Volume 11, ISBN 9781603270311. [Google Scholar]

- Ahmad, T.; Aadil, R.M.; Ahmed, H.; Rahman, U.; Soares, B.C.V.; Souza, S.L.Q.; Pimentel, T.C.; Scudino, H.; Guimarães, J.T.; Esmerino, E.A.; et al. Treatment and utilization of dairy industrial waste: A review. Trends Food Sci. Technol. 2019, 88, 361–372. [Google Scholar] [CrossRef]

- Britz, T.J.; Hung, Y. Treatment of Dairy Processing Wastewaters, Waste Treatment on the Food Processing Industry; Wang, L.K., Hung, Y.T., Lo, H.H., Yapijakis, C., Eds.; CRC Press: Boca Raton, FL, USA, 2006; pp. 1–25. [Google Scholar]

- Rosenwinkel, K.H.; Austermann-Haun, U.; Meyer, H. Industrial wastewater sources and treatment strategies. In Environmental Biotechnology: Concepts and Applications; Jördening, H.J., Winter, J., Eds.; Wiley-VCH Verlag: Weinheim, Germany, 2005; pp. 69–70. [Google Scholar]

- Oneţ, C. Characteristics of the untreated wastewater produced by food industry. Analele Universităţii din Oradea Fascicula Protecţia Mediului 2010, 15, 709–714. Available online: http://protmed.uoradea.ro/facultate/anale/protectia_mediului/2010/im/29.%20Onet%20Cristian%201.pdf (accessed on 19 January 2020).

- Yonar, T.; Sivrioğlu, Ö.; Nihan, Ö. Physico-Chemical Treatment of Dairy Industry Wastewaters: A Review. In Technological Approaches for Novel Applications in Dairy Processing; IntechOpen: London, UK, 2018. [Google Scholar] [CrossRef] [Green Version]

- Farizoglu, B.; Keskinler, B.; Yildiz, E.; Nuhoglu, A. Simultaneous removal of C, N, P from cheese whey by jet loop membrane bioreactor (JLMBR). J. Hazard. Mater. 2007, 146, 399–407. [Google Scholar] [CrossRef]

- Carvalho, F.; Prazeres, A.R.; Rivas, J. Cheese whey wastewater: Characterization and treatment. Sci. Total Environ. 2013, 445–446, 385–396. [Google Scholar] [CrossRef]

- Kasmi, M. Biological Processes as Promoting Way for Both Treatment and Valorization of Dairy Industry Effluents. Waste Biomass Valorization 2018, 9, 195–209. [Google Scholar] [CrossRef]

- Panesar, P.S.; Kennedy, J.F.; Gandhi, D.N.; Bunko, K. Bioutilisation of whey for lactic acid production. Food Chem. 2007, 105, 1–14. [Google Scholar] [CrossRef]

- Tawfik, A.; Sobhey, M.; Badawy, M. Treatment of a combined dairy and domestic wastewater in an up-flow anaerobic sludge blanket (UASB) reactor followed by activated sludge (AS system). Desalination 2008, 227, 167–177. [Google Scholar] [CrossRef]

- Marazzi, F.; Ficara, E.; Fornaroli, R.; Mezzanotte, V. Factors Affecting the Growth of Microalgae on Blackwater from Biosolid Dewatering. Water Air Soil Pollut. 2017, 228, 68. [Google Scholar] [CrossRef]

- Marazzi, F.; Bellucci, M.; Rossi, S.; Fornaroli, R.; Ficara, E.; Mezzanotte, V. Outdoor pilot trial integrating a sidestream microalgae process for the treatment of centrate under non optimal climate conditions. Algal Res. 2019, 39, 101430. [Google Scholar] [CrossRef] [Green Version]

- Muñoz, R.; Guieysse, B. Algal-bacterial processes for the treatment of hazardous contaminants: A review. Water Res. 2006, 40, 2799–2815. [Google Scholar] [CrossRef]

- Delgadillo-mirquez, L.; Lopes, F.; Taidi, B.; Pareau, D. Nitrogen and phosphate removal from wastewater with a mixed microalgae and bacteria culture. Biotechnol. Rep. 2016, 11, 18–26. [Google Scholar] [CrossRef]

- Pizzera, A.; Scaglione, D.; Bellucci, M.; Marazzi, F.; Mezzanotte, V.; Parati, K.; Ficara, E. Digestate treatment with algae-bacteria consortia: A field pilot-scale experimentation in a sub-optimal climate area. Bioresour. Technol. 2019, 274, 232–243. [Google Scholar] [CrossRef]

- Ji, M.K.; Yun, H.S.; Park, S.; Lee, H.; Park, Y.T.; Bae, S.; Ham, J.; Choi, J. Effect of food wastewater on biomass production by a green microalga Scenedesmus obliquus for bioenergy generation. Bioresour. Technol. 2015, 179, 624–628. [Google Scholar] [CrossRef]

- Gupta, S.; Pawar, S.B.; Pandey, R.A. Current practices and challenges in using microalgae for treatment of nutrient rich wastewater from agro-based industries. Sci. Total Environ. 2019, 687, 1107–1126. [Google Scholar] [CrossRef]

- Kothari, R.; Prasad, R.; Kumar, V.; Singh, D.P. Production of biodiesel from microalgae Chlamydomonas polypyrenoideum grown on dairy industry wastewater. Bioresour. Technol. 2013, 144, 499–503. [Google Scholar] [CrossRef]

- Ji, M.-K.; Yun, H.-S.; Park, Y.-T.; Kabra, A.N.; Oh, I.-H.; Choi, J. Mixotrophic cultivation of a microalga Scenedesmus obliquus in municipal wastewater supplemented with food wastewater and flue gas CO2 for biomass production. J. Environ. Manag. 2015, 159, 115–120. [Google Scholar] [CrossRef]

- Qin, L.; Shu, Q.; Wang, Z. Cultivation of Chlorella vulgaris in Dairy Wastewater Pretreated by UV Irradiation and Sodium Hypochlorite. Appl. Biochem. Biotechnol. 2014, 172, 1121–1130. [Google Scholar] [CrossRef]

- Redfield, A.C. On the proportions of organic derivatives in sea water and their relation to the composition of plankton. In Liverpool James Johnstone Meml; Liverpool University Press: Liverpool, UK, 1934; pp. 176–192. [Google Scholar]

- Redfield, A.C. The biological control of chemical factors in the environment. Am. Sci. 1958, 46, 205–221. [Google Scholar]

- APHA, AWWA, W. APHA, Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2005. [Google Scholar]

- Kitajima, M.; Butler, W. Quenching of chlorophyll fluorescence and primary photochemistry in chloroplasts by dibromothymoquinone. Biochim. Biophys. Acta 1975, 376, 105–115. [Google Scholar] [CrossRef]

- Bischoff, H.W.; Bold, H.C. Phycological Studies IV. Some Soil Algae from Enchanted Rock and Related Algal Species; No. 6318; The University of Texas Press: Austin, TX, USA, 1963; Volume 95. [Google Scholar]

- Uduman, N.; Qi, Y.; Danquah, M.K.; Forde, G.M.; Hoadley, A. Dewatering of microalgal cultures: A major bottleneck to algae-based fuels. J. Renew. Sustain. Energy 2010, 2, 012701. [Google Scholar] [CrossRef]

- Ranglová, K. Rapid screening test to estimate temperature optima for microalgae growth using photosynthesis activity measurements. Folia Microbiol. (Praha) 2019, 64, 615–625. [Google Scholar] [CrossRef] [PubMed]

- Tchobanoglous. Metcalf & Eddy Inc. Wastewater Engineering: Treatment, Disposal and Reuse, 5th ed.; Mc Graw-Hill: Boston, MA, USA, 2014; ISBN 0-07-041878-0. [Google Scholar]

- Henze, M.; Van Loosdrecht, M.C.M.; Ekama, G.; Brdjanovic, D. Biological Wastewater Treatment: Principles, Modelling and Design; IWA: London, UK, 2008; ISBN 9781843391883. [Google Scholar]

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| pH | 7.8 ± 0.16 | Ca (mg/L) | 177 ± 64 |

| Electric conductivity (µS/cm) | 3312 ± 227 | Si (mg/L) | 4 ± 0.4 |

| Turbidity (FAU) | 87 ± 19 | Fe (mg/L) | 2.3 ± 0.4 |

| Total suspended solids (TSS; mg/L) | 180 ± 40 | Na (mg/L) | 595 ± 66 |

| Volatile suspended solids (VSS; mg/L) | 130 ± 20 | Zn (mg/L) | 0.02 ± 0.01 |

| Total N (mg/L) | 52 ± 7 | Mn (mg/L) | 0.014 ± 0.02 |

| NH4–N (mg/L) | 31 ± 6 | Mo (µg/L) | <0.1 |

| NO3–N/mg/L) | 0.3 ± 0.04 | Al (µg/L) | <0.1 |

| NO2–N (mg/L) | <0.3 | Cr (µg/L) | 1.4 ± 0.7 |

| Total P (mg/L) | 17 ± 1.5 | Ni (µg/L) | 7.8 ± 8.5 |

| PO4–P (mg/L) | 23.0 ± 1.3 | Pb (µg/L) | 29 ± 4 |

| COD (mg/L) | 982 ± 253 | Cu (µg/L) | 21 ± 16 |

| K (mg/L) | 87 ± 9 | Cd (µg/L) | 0.3 ± 0.4 |

| Mg (mg/L) | 15 ± 2 | Cl− (mg/L) | 591 ± 260 |

| SO4—(mg/L) | 33 ± 11 |

| Parameter | Value in Effuents from PBRs | Italian Limits for Discharge in Surface Waters |

|---|---|---|

| pH | 7.5 | 5.5–9.5 |

| COD (mg/L) | 43–102 | 160 |

| NH4–N (mg/L) | 0.14–3.0 | 15 |

| NO3–N (mg/L) | <0.3 | 20 |

| NO2–N (mg/L) | <0.6 | 0.6 |

| Total P (mg/L) | 2.0–7.0 | 10 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Marazzi, F.; Bellucci, M.; Fantasia, T.; Ficara, E.; Mezzanotte, V. Interactions between Microalgae and Bacteria in the Treatment of Wastewater from Milk Whey Processing. Water 2020, 12, 297. https://doi.org/10.3390/w12010297

Marazzi F, Bellucci M, Fantasia T, Ficara E, Mezzanotte V. Interactions between Microalgae and Bacteria in the Treatment of Wastewater from Milk Whey Processing. Water. 2020; 12(1):297. https://doi.org/10.3390/w12010297

Chicago/Turabian StyleMarazzi, Francesca, Micol Bellucci, Tania Fantasia, Elena Ficara, and Valeria Mezzanotte. 2020. "Interactions between Microalgae and Bacteria in the Treatment of Wastewater from Milk Whey Processing" Water 12, no. 1: 297. https://doi.org/10.3390/w12010297

APA StyleMarazzi, F., Bellucci, M., Fantasia, T., Ficara, E., & Mezzanotte, V. (2020). Interactions between Microalgae and Bacteria in the Treatment of Wastewater from Milk Whey Processing. Water, 12(1), 297. https://doi.org/10.3390/w12010297