Trends in Modeling, Design, and Optimization of Multiphase Systems in Minerals Processing

Abstract

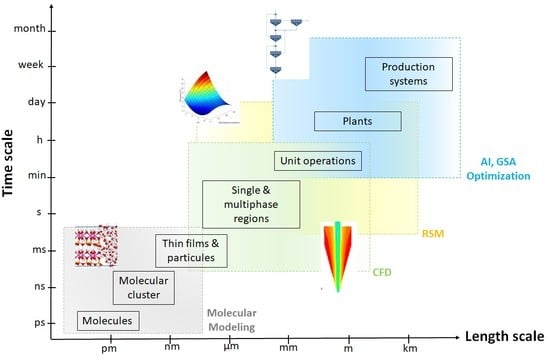

:1. Introduction

2. Molecular Dynamic Modeling

2.1. Collector/Depressor Adsorption on Different Mineral Surfaces in the Flotation Process

2.2. Interaction of Clay Minerals, Water, and Interlayer Structures

3. Computational Fluid Dynamics (CFD) in Multiphase Systems

4. Design and Optimization

5. Artificial Intelligence (AI) Applied to Multiphase Systems

6. Response Surface Methodology (RSM)

7. Uncertainty and Sensitivity Analyses

8. Discussion and Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Grossmann, I.E.; Westerberg, A.W. Research challenges in process systems engineering. AIChE J. 2000, 46, 1700–1703. [Google Scholar] [CrossRef]

- Cygan, R.T. Molecular Modeling in Mineralogy and Geochemistry. Rev. Mineral. Geochem. 2010, 42, 1–35. [Google Scholar] [CrossRef]

- Kirkpatrick, R.J.; Kalinichev, A.G.; Bowers, G.M.; Yazaydin, A.Ö.; Krishnan, M.; Saharay, M.; Morrow, C.P. Review. NMR and computational molecular modeling studies of mineral surfaces and interlayer galleries: A review. Am. Mineral. 2015, 100, 1341–1354. [Google Scholar] [CrossRef]

- De Villiers, J.P.R. Minerals Processing in South Africa: Materials Modelling Opportunities. Mol. Simul. 1999, 22, 81–90. [Google Scholar] [CrossRef]

- Creton, B.; Nieto-Draghi, C.; Pannacci, N. Prediction of Surfactants’ Properties using Multiscale Molecular Modeling Tools: A Review. Oil Gas Sci. Technol. 2012, 67, 969–982. [Google Scholar] [CrossRef] [Green Version]

- Kirkpatrick, R.J.; Kalinichev, A.G.; Wang, J. Molecular dynamics modelling of hydrated mineral interlayers and surfaces: Structure and dynamics. Mineral. Mag. 2005, 69, 289–308. [Google Scholar] [CrossRef]

- Filho, L.S.L.; Seidl, P.R.; Correia, J.C.G.; Cerqueira, L.A.C.K. Molecular modeling of Reagents for flotation process. Miner. Eng. 2000, 13, 1495–1503. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, C.; Yan, K. Adsorption of collectors on model surface of Wiser bituminous coal: A molecular dynamics simulation study. Miner. Eng. 2015, 79, 31–39. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, W.; Xu, H.; Zhuo, Q.; Sun, X. Adsorption Behavior of Methyl Laurate and Dodecane on the Sub-Bituminous Coal Surface: Molecular Dynamics Simulation and Experimental Study. Minerals 2019, 9, 30. [Google Scholar] [CrossRef] [Green Version]

- Nan, N.; Zhu, Y.; Han, Y.; Liu, J. Molecular Modeling of Interactions between N-(Carboxymethyl)-N-tetradecylglycine and Fluorapatite. Minerals 2019, 9, 278. [Google Scholar] [CrossRef] [Green Version]

- Ma, X.; Fan, Y.; Dong, X.; Chen, R.; Li, H.; Sun, D.; Yao, S. Impact of Clay Minerals on the Dewatering of Coal Slurry: An Experimental and Molecular-Simulation Study. Minerals 2018, 8, 400. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Manzano, H.; López-Arbeloa, I.; Shen, X. Water Adsorption on the β-Dicalcium Silicate Surface from DFT Simulations. Minerals 2018, 8, 386. [Google Scholar] [CrossRef] [Green Version]

- Kubicki, J.; Watts, H. Quantum Mechanical Modeling of the Vibrational Spectra of Minerals with a Focus on Clays. Minerals 2019, 9, 141. [Google Scholar] [CrossRef] [Green Version]

- Wang, Q.; Fang, Q.; Li, J.; Tian, Y.; Liu, Y. Subsurface damage and material removal of Al–Si bilayers under high-speed grinding using molecular dynamics (MD) simulation. Appl. Phys. A 2019, 125, 514. [Google Scholar] [CrossRef]

- Ren, J.; Hao, M.; Lv, M.; Wang, S.; Zhu, B. Molecular dynamics research on ultra-high-speed grinding mechanism of monocrystalline nickel. Appl. Surf. Sci. 2018, 455, 629–634. [Google Scholar] [CrossRef]

- Safari, M.; Deglon, D. An attachment-detachment kinetic model for the effect of energy input on flotation. Miner. Eng. 2018, 117, 8–13. [Google Scholar] [CrossRef]

- Gorain, B.K.; Franzidis, J.-P.; Manlapig, E.V. The empirical prediction of bubble surface area flux in mechanical flotation cells from cell design and operating data. Miner. Eng. 1999, 12, 309–322. [Google Scholar] [CrossRef]

- Wang, L.; Runge, K.; Peng, Y.; Vos, C. An empirical model for the degree of entrainment in froth flotation based on particle size and density. Miner. Eng. 2016, 98, 187–193. [Google Scholar] [CrossRef]

- Savassi, O.N.; Alexander, D.J.; Franzidis, J.P.; Manlapig, E.V. An empirical model for entrainment in industrial flotation plants. Miner. Eng. 1998, 11, 243–256. [Google Scholar] [CrossRef]

- Kraipech, W.; Chen, W.; Dyakowski, T.; Nowakowski, A. The performance of the empirical models on industrial hydrocyclone design. Int. J. Miner. Process. 2006, 80, 100–115. [Google Scholar] [CrossRef]

- Gharai, M.; Venugopal, R. Modeling of flotation process—An overview of different approaches. Miner. Process. Extr. Metall. Rev. 2015, 37, 120–133. [Google Scholar] [CrossRef]

- Jovanović, I.; Miljanović, I. Modelling of Flotation Processes by Classical Mathematical Met—A Review. Arch. Min. Sci. 2015, 60, 905–919. [Google Scholar]

- Jovanović, I.; Miljanović, I.; Jovanović, T. Soft computing-based modeling of flotation processes—A review. Miner. Eng. 2015, 84, 34–63. [Google Scholar] [CrossRef]

- Tavares, L.M. A Review of Advanced Ball Mill Modelling. KONA Powder Part. J. 2017, 34, 106–124. [Google Scholar] [CrossRef] [Green Version]

- Narasimha, M.; Brennan, M.; Holtham, P.N. A Review of CFD Modelling for Performance Predictions of Hydrocyclone. Eng. Appl. Comput. Fluid Mech. 2007, 1, 109–125. [Google Scholar] [CrossRef] [Green Version]

- Wang, G.; Nguyen, A.V.; Mitra, S.; Joshi, J.B.; Jameson, G.J.; Evans, G.M. A review of the mechanisms and models of bubble-particle detachment in froth flotation. Sep. Purif. Technol. 2016, 170, 155–172. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Peng, Y.; Runge, K.; Bradshaw, D. A review of entrainment: Mechanisms, contributing factors and modelling in flotation. Miner. Eng. 2015, 70, 77–91. [Google Scholar] [CrossRef]

- Zheng, X.; Franzidis, J.P.; Johnson, N.W. An evaluation of different models of water recovery in flotation. Miner. Eng. 2006, 19, 871–882. [Google Scholar] [CrossRef]

- Andersson, B.; Andersson, R.; Hakansson, L.; Mortensen, M.; Sudiyo, R.; Van Wachem, B. Computational Fluid Dynamics for Engineers; Cambridge University Press: Cambridge, UK, 2012; ISBN 978-1-107-01895-2. [Google Scholar]

- Jayanti, S. Computational Fluid Dynamics for Engineers and Scientists; Cambridge University Press: Cambridge, UK, 2018; ISBN 9789402412178. [Google Scholar]

- Koh, P.T.L.; Schwarz, M.P. CFD modelling of bubble—Particle attachments in flotation cells. Miner. Eng. 2006, 19, 619–626. [Google Scholar] [CrossRef]

- Chen, X.; Zhou, J.; Chen, Q.; Shi, X.; Gou, Y. CFD Simulation of Pipeline Transport Properties of Mine Tailings Three-Phase Foam Slurry Backfill. Minerals 2017, 7, 149. [Google Scholar] [CrossRef] [Green Version]

- Narasimha, M.; Brennan, M.S.; Holtham, P.N. CFD modeling of hydrocyclones: Prediction of particle size segregation. Miner. Eng. 2012, 39, 173–183. [Google Scholar] [CrossRef]

- Johansson, R.; Evertsson, M. CFD simulation of a centrifugal air classifier used in the aggregate industry. Miner. Eng. 2014, 63, 149–156. [Google Scholar] [CrossRef]

- Mohanty, S.; Das, B.; Mishra, B.K. A preliminary investigation into magnetic separation process using CFD. Miner. Eng. 2011, 24, 1651–1657. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Powell, M.S. Performance characterisation of AG/SAG mill pulp lifters using CFD techniques. Miner. Eng. 2014, 63, 118–124. [Google Scholar] [CrossRef]

- Wang, G.; Ge, L.; Mitra, S.; Evans, G.M.; Joshi, J.B.; Chen, S. A review of CFD modelling studies on the flotation process. Miner. Eng. 2018, 127, 153–177. [Google Scholar] [CrossRef]

- Farzanegan, A.; Khorasanizadeh, N.; Sheikhzadeh, G.A.; Khorasanizadeh, H. Laboratory and CFD investigations of the two-phase flow behavior in flotation columns equipped with vertical baffle. Int. J. Miner. Process. 2017, 166, 79–88. [Google Scholar] [CrossRef]

- Sarhan, A.R.; Naser, J.; Brooks, G. CFD simulation on influence of suspended solid particles on bubbles’ coalescence rate in flotation cell. Int. J. Miner. Process. 2016, 146, 54–64. [Google Scholar] [CrossRef]

- Lakghomi, B.; Lawryshyn, Y.; Hofmann, R. A model of particle removal in a dissolved air flotation tank: Importance of stratified flow and bubble size. Water Res. 2015, 68, 262–272. [Google Scholar] [CrossRef]

- Xia, Y.K.; Peng, F.F.; Wolfe, E. CFD simulation of alleviation of fluid back mixing by baffles in bubble column. Miner. Eng. 2006, 19, 925–937. [Google Scholar] [CrossRef]

- Bondelind, M.; Sasic, S.; Kostoglou, M.; Bergdahl, L.; Pettersson, T.J.R. Single- and two-phase numerical models of Dissolved Air Flotation: Comparison of 2D and 3D simulations. Colloids Surf. A Physicochem. Eng. Asp. 2010, 365, 137–144. [Google Scholar] [CrossRef]

- Schwarz, M.P.; Koh, P.T.L.; Verrelli, D.I.; Feng, Y. Sequential multi-scale modelling of mineral processing operations, with application to flotation cells. Miner. Eng. 2016, 90, 2–16. [Google Scholar] [CrossRef]

- Liu, T.Y.; Schwarz, M.P. CFD-based modelling of bubble-particle collision efficiency with mobile bubble surface in a turbulent environment. Int. J. Miner. Process. 2009, 90, 45–55. [Google Scholar] [CrossRef] [Green Version]

- Liu, T.Y.; Schwarz, M.P. CFD-based multiscale modelling of bubble–particle collision efficiency in a turbulent flotation cell. Chem. Eng. Sci. 2009, 64, 5287–5301. [Google Scholar] [CrossRef]

- Lichter, J.; Potapov, A.; Peaker, R. The use of computational fluid dynamics and discrete element modeling to understand the effect of cell size and inflow rate on flotation bank retention time distribution and mechanism performance. In Proceedings of the 39th Annual Canadian Mineral Processors Operators Conference, Ottawa, ON, Canada, 23–25 January 2007. [Google Scholar]

- Ji, L.; Chu, K.; Kuang, S.; Chen, J.; Yu, A. Modeling the Multiphase Flow in Hydrocyclones Using the Coarse-Grained Volume of Fluid—Discrete Element Method and Mixture-Discrete Element Method Approaches. Ind. Eng. Chem. Res. 2018, 57, 9641–9655. [Google Scholar] [CrossRef]

- Chu, K.W.; Wang, B.; Yu, A.B.; Vince, A.; Barnett, G.D.; Barnett, P.J. CFD–DEM study of the effect of particle density distribution on the multiphase flow and performance of dense medium cyclone. Miner. Eng. 2009, 22, 893–909. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Powell, M.S.; Cleary, P.W.; Tavares, L.M.; Evertsson, M.; Morrison, R.D.; Quist, J.; Carvalho, R.M. The contribution of DEM to the science of comminution. Powder Technol. 2013, 248, 3–24. [Google Scholar] [CrossRef]

- Cleary, P.W. Prediction of coupled particle and fluid flows using DEM and SPH. Miner. Eng. 2015, 73, 85–99. [Google Scholar] [CrossRef]

- Ye, T.; Li, Y.A. Comparative Review of Smoothed Particle Hydrodynamics, Dissipative Particle Dynamics and Smoothed Dissipative Particle Dynamics. Int. J. Comput. Methods 2018, 15, 1850083. [Google Scholar] [CrossRef]

- Cleary, P.W.; Sinnott, M.; Morrison, R. Prediction of slurry transport in SAG mills using SPH fluid flow in a dynamic DEM based porous media. Miner. Eng. 2006, 19, 1517–1527. [Google Scholar] [CrossRef]

- Cleary, P.W.; Delaney, G.W.; Sinnott, M.D.; Morrison, R.D. Inclusion of incremental damage breakage of particles and slurry rheology into a particle scale multiphase model of a SAG mill. Miner. Eng. 2018, 128, 92–105. [Google Scholar] [CrossRef]

- Beinert, S.; Fragnière, G.; Schilde, C.; Kwade, A. Analysis and modelling of bead contacts in wet-operating stirred media and planetary ball mills with CFD–DEM simulations. Chem. Eng. Sci. 2015, 134, 648–662. [Google Scholar] [CrossRef]

- Li, J.; Ge, W.; Wang, W.; Yang, N. Focusing on the meso-scales of multi-scale phenomena—In search for a new paradigm in chemical engineering. Particuology 2010, 8, 634–639. [Google Scholar] [CrossRef]

- Li, J.; Kwauk, M. Particle-Fluid Two-Phase Flow—The Energy-Minimization Multi-Scale Method; Metallurgical Industry Press: Beijing, China, 1994. [Google Scholar]

- Jávor, Z.; Schreithofer, N.; Heiskanen, K. Multi-scale analysis of the effect of surfactants on bubble properties. Miner. Eng. 2016, 99, 170–178. [Google Scholar] [CrossRef]

- Cisternas, L.A. On the synthesis of inorganic chemical and metallurgical processes, review and extension. Miner. Eng. 1999, 12, 15–41. [Google Scholar] [CrossRef]

- Loveday, B.K.; Brouckaert, C.J. An analysis of flotation circuit design principles. Chem. Eng. J. Biochem. Eng. J. 1995, 59, 15–21. [Google Scholar] [CrossRef]

- Chan, W.K.; Prince, R.G.H. Heuristic evolutionary synthesis with non-sharp separators. Comput. Chem. Eng. 1989, 13, 1207–1219. [Google Scholar] [CrossRef]

- Noble, A.; Luttrell, G.H.; Amini, S.H. Linear Circuit Analysis: A Tool for Addressing Challenges and Identifying Opportunities in Process Circuit Design. Min. Metall. Explor. 2019, 36, 159–171. [Google Scholar] [CrossRef]

- Meloy, T.P. Analysis and optimization of mineral processing and coal-cleaning circuits—Circuit analysis. Int. J. Miner. Process. 1983, 10, 61–80. [Google Scholar] [CrossRef]

- Williams, M.C.; Meloy, T.P. Dynamic model of flotation cell banks—Circuit analysis. Int. J. Miner. Process. 1983, 10, 141–160. [Google Scholar] [CrossRef]

- Williams, M.C.; Fuerstenau, D.W.; Meloy, T.P. Circuit analysis—General product equations for multifeed, multistage circuits containing variable selectivity functions. Int. J. Miner. Process. 1986, 17, 99–111. [Google Scholar] [CrossRef]

- Williams, M.C.; Meloy, T.P. Feasible designs for separation networks: A selection technique. Int. J. Miner. Process. 1991, 32, 161–174. [Google Scholar] [CrossRef]

- Williams, M.C.; Fuerstenau, D.W.; Meloy, T.P. A graph-theoretic approach to process plant design. Int. J. Miner. Process. 1992, 36, 1–8. [Google Scholar] [CrossRef]

- Luttrell, G.H.; Kohmuench, J.; Mankosa, M. Optimization of magnetic separator circuit configurations. In Proceedings of the SME Annual Conference and Expo, Englewood, CO, USA, 23–25 February 2004. [Google Scholar]

- Luttrell, G.H.; Kohmuench, J.N.; Stanley, F.A.L.; Trump, G.D. Improving spiral performance using circuit analysis. Miner. Metall. Process. 1998, 15, 16–21. [Google Scholar] [CrossRef]

- Mckeon, T.; Luttrel, G.H. Optimization of multistage circuits for gravity concentration of heavy mineral sands. Miner. Metall. Process. 2012, 29, 1–5. [Google Scholar] [CrossRef]

- Noble, A.; Luttrell, G.H. Micro-pricing optimization: Value based partition curve analysis with applications to coal separation. In Proceedings of the 2015 SME Annual Conference and Expo and CMA 117th National Western Mining Conference—Mining: Navigating the Global Waters, Denver, CO, USA, 15–18 February 2015. [Google Scholar]

- Amini, S.H.; Noble, A. Application of linear circuit analysis in the evaluation of mineral processing circuit design under uncertainty. Miner. Eng. 2017, 102, 18–29. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Acosta-Flores, R.; Gálvez, E.D. Some Limitations and Disadvantages of Linear Circuit Analysis. In Proceedings of the 7th International Computational Modelling Symposium (Computational Modelling ’19, Falmouth, UK, 11–12 June 2019. [Google Scholar]

- Radmehr, V.; Shafaei, S.; Noaparast, M.; Abdollahi, H. Optimizing Flotation Circuit Recovery by Effective Stage Arrangements: A Case Study. Minerals 2018, 8, 417. [Google Scholar] [CrossRef] [Green Version]

- Cruz, R.; Cisternas, L.A.; Gálvez, E.D. Optimal Design of a Solid-Liquid Separation System. Comput. Aided Chem. Eng. 2013, 32, 907–912. [Google Scholar]

- Mehrotra, S.P. Design of optimal flotation circuits—A review. Miner. Metall. Process. 1988, 5, 142–152. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Lucay, F.A.; Acosta-Flores, R.; Gálvez, E.D. A quasi-review of conceptual flotation design methods based on computational optimization. Miner. Eng. 2018, 117. [Google Scholar] [CrossRef]

- Mendez, D.A.; Gálvez, E.D.; Cisternas, L.A. State of the art in the conceptual design of flotation circuits. Int. J. Miner. Process. 2009, 90, 1–15. [Google Scholar] [CrossRef]

- Saito, F.; Baron, M.; Dodds, J.; Muramatsu, A. Morphology Control of Materials and Nanoparticles: Chapiter I and II; Waseda, Y., Muramatsu, A., Eds.; Springer: Berlin/Heidelberg, Germany, 2004; ISBN 978-3-642-05671-0 (Print) 978-3-662-08863-0 (Online). [Google Scholar]

- Yingling, J.C. Parameter and configuration optimization of flotation circuits, part I. A review of prior work. Int. J. Miner. Process. 1993, 38, 21–40. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Jamett, N.; Gálvez, E.D. Approximate recovery values for each stage are sufficient to select the concentration circuit structures. Miner. Eng. 2015, 83, 175–184. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Méndez, D.A.; Gálvez, E.D.; Jorquera, R.E. A MILP model for design of flotation circuits with bank/column and regrind/no regrind selection. Int. J. Miner. Process. 2006, 79, 253–263. [Google Scholar] [CrossRef]

- Méndez, D.A.; Gálvez, E.D.; Cisternas, L.A. Modeling of grinding and classification circuits as applied to the design of flotation processes. Comput. Chem. Eng. 2009, 33, 97–111. [Google Scholar] [CrossRef]

- Schena, G.D.; Zanin, M.; Chiarandini, A. Procedures for the automatic design of flotation networks. Int. J. Miner. Process. 1997, 52, 137–160. [Google Scholar] [CrossRef]

- Acosta-Flores, R.; Lucay, F.A.; Cisternas, L.A.; Gálvez, E.D. Two phases optimization methodology for the design of mineral flotation plants including multi-species, bank or cell models. Miner. Met. Process. J. 2018, 35, 24–34. [Google Scholar]

- Mehrotra, S.P.; Kapur, P.C. Optimal-Suboptimal Synthesis and Design of Flotation Circuits. Sep. Sci. 1974, 9, 167–184. [Google Scholar] [CrossRef]

- Reuter, M.A.; van Deventer, J.S.J.; Green, J.C.A.; Sinclair, M. Optimal design of mineral separation circuits by use of linear programming. Chem. Eng. Sci. 1988, 43, 1039–1049. [Google Scholar] [CrossRef]

- Reuter, M.A.; Van Deventer, J.S.J. The use of linear programming in the optimal design of flotation circuits incorporating regrind mills. Int. J. Miner. Process. 1990, 28, 15–43. [Google Scholar] [CrossRef]

- Schena, G.; Villeneuve, J.; Noël, Y. A method for a financially efficient design of cell-based flotation circuits. Int. J. Miner. Process. 1996, 46, 1–20. [Google Scholar] [CrossRef]

- Guria, C.; Verma, M.; Mehrotra, S.P.; Gupta, S.K. Multi-objective optimal synthesis and design of froth flotation circuits for mineral processing, using the jumping gene adaptation of genetic algorithm. Ind. Eng. Chem. Res. 2005, 44, 2621–2633. [Google Scholar] [CrossRef]

- Guria, C.; Verma, M.; Gupta, S.K.; Mehrotra, S.P. Simultaneous optimization of the performance of flotation circuits and their simplification using the jumping gene adaptations of genetic algorithm. Int. J. Miner. Process. 2005, 77, 165–185. [Google Scholar] [CrossRef]

- Ghobadi, P.; Yahyaei, M.; Banisi, S. Optimization of the performance of flotation circuits using a genetic algorithm oriented by process-based rules. Int. J. Miner. Process. 2011. [Google Scholar] [CrossRef]

- Maldonado, M.; Araya, R.; Finch, J. Optimizing flotation bank performance by recovery profiling. Miner. Eng. 2011, 24, 939–943. [Google Scholar] [CrossRef]

- Hu, W.; Hadler, K.; Neethling, S.J.; Cilliers, J.J. Determining flotation circuit layout using genetic algorithms with pulp and froth models. Chem. Eng. Sci. 2013, 102, 32–41. [Google Scholar] [CrossRef]

- Cisternas, L.A.; Lucay, F.; Gálvez, E.D. Effect of the objective function in the design of concentration plants. Miner. Eng. 2014, 63, 16–24. [Google Scholar] [CrossRef]

- Pirouzan, D.; Yahyaei, M.; Banisi, S. Pareto based optimization of flotation cells configuration using an oriented genetic algorithm. Int. J. Miner. Process. 2014, 126, 107–116. [Google Scholar] [CrossRef]

- Calisaya, D.A.; López-Valdivieso, A.; de la Cruz, M.H.; Gálvez, E.E.; Cisternas, L.A. A strategy for the identification of optimal flotation circuits. Miner. Eng. 2016, 96–97, 157–167. [Google Scholar] [CrossRef]

- Lucay, F.; Gálvez, E.; Cisternas, L. Design of Flotation Circuits Using Tabu-Search Algorithms: Multispecies, Equipment Design, and Profitability Parameters. Minerals 2019, 9, 181. [Google Scholar] [CrossRef] [Green Version]

- McCarthy, J.; Minsky, M.; Rochester, N.; Shannon, C. A proposal for the Dartmouth summer research project on artificial intelligence. AI Mag. 2012, 27, 12–14. [Google Scholar]

- McCoy, J.T.; Auret, L. Machine learning applications in minerals processing: A review. Miner. Eng. 2019, 132, 95–109. [Google Scholar] [CrossRef]

- Bergh, L. Artificial Intelligence in Mineral Processing Plants: An Overview. In Proceedings of the 2016 International Conference on Artificial Intelligence: Technologies and Applications, Bangkok, Thailand, 24–25 January 2016. [Google Scholar]

- Hoseinian, F.S.; Rezai, B.; Kowsari, E.; Safari, M. A hybrid neural network/genetic algorithm to predict Zn(II) removal by ion flotation. Sep. Sci. Technol. 2019, 2019, 1–10. [Google Scholar] [CrossRef]

- Zadeh, L.A. Soft Computing and Fuzzy Logic. IEEE Softw. 1994, 11, 48–56. [Google Scholar] [CrossRef]

- Thyagharajan, K.K.; Vignesh, T. Soft Computing Techniques for Land Use and Land Cover Monitoring with Multispectral Remote Sensing Images: A Review. Arch. Comput. Methods Eng. 2019, 26, 275–301. [Google Scholar] [CrossRef]

- Das, S.K.; Kumar, A.; Das, B.; Burnwal, B. On Soft Computing Techniques in Various Areas. Int. J. Inform. Technol. Comput. Sci. 2013, 3, 59–68. [Google Scholar] [CrossRef]

- Sharma, D.; Chandra, P. A comparative analysis of soft computing techniques in software fault prediction model development. Int. J. Inf. Technol. 2018, 11, 1–10. [Google Scholar] [CrossRef]

- Jeffers, J.; Reinders, J.; Sodani, A. Machine learning. In Intel Xeon Phi Processor High Performance Programming; Elsevier: Amsterdam, The Netherlands, 2016; pp. 527–548. ISBN 9780128091944. [Google Scholar]

- Qin, S.J. Statistical process monitoring: Basics and beyond. J. Chemom. 2003, 17, 480–502. [Google Scholar] [CrossRef]

- Umucu, Y.; Çaǧlar, M.F.; Gündüz, L.; Bozkurt, V.; Deniz, V. Modeling of grinding process by artificial neural network for calcite mineral. In Proceedings of the INISTA 2011 International Symposium on INnovations in Intelligent SysTems and Applications, Istanbul, Turkey, 15–18 June 2011. [Google Scholar]

- Umucu, Y.; Deniz, V.; Bozkurt, V.; Çağlard, M.F. The evaluation of grinding process using artificial neural network. Int. J. Miner. Process. 2016, 146, 46–53. [Google Scholar] [CrossRef]

- Warren Liao, T.; Chen, L.J. A neural network approach for grinding processes: Modelling and optimization. Int. J. Mach. Tools Manuf. 1994, 34, 919–937. [Google Scholar] [CrossRef]

- Makokha, A.B.; Moys, M.H. Multivariate approach to on-line prediction of in-mill slurry density and ball load volume based on direct ball and slurry sensor data. Miner. Eng. 2012. [Google Scholar] [CrossRef]

- Mitra, K.; Ghivari, M. Modeling of an industrial wet grinding operation using data-driven techniques. Comput. Chem. Eng. 2006, 30, 508–520. [Google Scholar] [CrossRef]

- Curilem, M.; Acuña, G.; Cubillos, F.; Vyhmeister, E. Neural Networks and Support Vector Machine models applied to energy consumption optimization in semiautogeneous grinding. Chem. Eng. Trans. 2011, 25, 761–766. [Google Scholar]

- Núñez, F.; Silva, D.; Cipriano, A. Characterization and modeling of semi-autogenous mill performance under ore size distribution disturbances. IFAC Proc. Vol. 2011, 44, 9941–9946. [Google Scholar] [CrossRef]

- Vini, M.H. Using Artificial Neural Networks to predict rolling force and real exit thickness of steel strips. J. Mod. Process. Manuf. Prod. 2014, 3, 53–60. [Google Scholar]

- Nakhaei, F.; Irannajad, M. Comparison between neural networks and multiple regression methods in metallurgical performance modeling of flotation column. Physicochem. Probl. Miner. Process. 2013, 49, 255–266. [Google Scholar] [CrossRef]

- Hosseini, M.R.; Shirazi, H.H.A.; Massinaei, M.; Mehrshad, N. Modeling the Relationship between Froth Bubble Size and Flotation Performance Using Image Analysis and Neural Networks. Chem. Eng. Commun. 2015, 202, 911–919. [Google Scholar] [CrossRef]

- Estrada-Ruiz, R.H.; Peérez-Garibay, R. Neural networks to estimate bubble diameter and bubble size distribution of Dotation froth surfaces. J. S. Afr. Inst. Min. Metall. 2009, 109, 441–446. [Google Scholar]

- Chelgani, S.C.; Shahbazi, B.; Rezai, B. Estimation of froth flotation recovery and collision probability based on operational parameters using an artificial neural network. Int. J. Miner. Metall. Mater. 2010, 17, 526–534. [Google Scholar] [CrossRef]

- Jahedsaravani, A.; Marhaban, M.H.; Massinaei, M. Prediction of the metallurgical performances of a batch flotation system by image analysis and neural networks. Miner. Eng. 2014, 69, 137–145. [Google Scholar] [CrossRef]

- Saravani, A.J.; Mehrshad, N.; Massinaei, M. Fuzzy-Based Modeling and Control of an Industrial Flotation Column. Chem. Eng. Commun. 2014, 201, 896–908. [Google Scholar] [CrossRef]

- Karimi, M.; Dehghani, A.; Nezamalhosseini, A.; Talebi, S.H. Prediction of hydrocyclone performance using artificial neural networks. J. S. Afr. Inst. Min. Metall. 2010, 110, 207–212. [Google Scholar]

- Razavi, S.; Tolson, B.A.; Burn, D.H. Review of surrogate modeling in water resources. Water Resour. Res. 2012, 48. [Google Scholar] [CrossRef]

- Aldrich, C.; Jemwa, G.T.; Krishnannair, S. Multiscale process monitoring with singular spectrum analysis. IFAC Proc. Vol. 2007, 12, 167–172. [Google Scholar] [CrossRef] [Green Version]

- Bergh, L.G.; Yianatos, J.B.; León, A. Multivariate projection methods applied to flotation columns. Miner. Eng. 2005, 18, 721–723. [Google Scholar] [CrossRef]

- Groenewald, J.W.D.V.; Coetzer, L.P.; Aldrich, C. Statistical monitoring of a grinding circuit: An industrial case study. Miner. Eng. 2006, 19, 1138–1148. [Google Scholar] [CrossRef]

- Wakefield, B.J.; Lindner, B.S.; McCoy, J.T.; Auret, L. Monitoring of a simulated milling circuit: Fault diagnosis and economic impact. Miner. Eng. 2018, 120, 132–151. [Google Scholar] [CrossRef]

- Groenewald, J.W.D.; Aldrich, C. Root cause analysis of process fault conditions on an industrial concentrator circuit by use of causality maps and extreme learning machines. Miner. Eng. 2015, 74, 30–40. [Google Scholar] [CrossRef]

- Lindner, B.; Auret, L. Application of data-based process topology and feature extraction for fault diagnosis of an industrial platinum group metals concentrator plant. IFAC-PapersOnLine 2015, 48, 102–107. [Google Scholar] [CrossRef]

- Cao, B.; Xie, Y.; Gui, W.; Wei, L.; Yang, C. Integrated prediction model of bauxite concentrate grade based on distributed machine vision. Miner. Eng. 2013, 53, 31–38. [Google Scholar] [CrossRef]

- Rughooputh, H.C.S.; Rughooputh, S.D.D.V. Neural network process vision systems for flotation process. Kybernetes 2002, 31, 529–535. [Google Scholar] [CrossRef]

- Zhu, J.; Yu, K.W. Application of image recognition system in flotation process. In Proceedings of the World Congress on Intelligent Control and Automation (WCICA), Chongqing, China, 25–27 June 2008. [Google Scholar]

- Sharad, M.; Augustine, C.; Panagopoulos, G.; Roy, K. Ultra low energy analog image processing using spin based neurons. In Proceedings of the 2012 IEEE/ACM International Symposium on Nanoscale Architectures (NANOARCH), Amsterdam, The Netherlands, 4–6 July 2012. [Google Scholar]

- Zhao, L.; Peng, T.; Xie, Y.; Yang, C.; Gui, W. Recognition of flooding and sinking conditions in flotation process using soft measurement of froth surface level and QTA. Chemom. Intell. Lab. Syst. 2017, 169, 45–52. [Google Scholar] [CrossRef]

- Çinar, A. A Method for Local Tuning of Fuzzy Membership Functions. In Proceedings of the ICCS 2010: “Celebrating 10 years of Advancing Computational Thinking”, Amsterdam, The Netherlands, 31 May–2 June 2010. [Google Scholar]

- Tandon, V.; El-Mounayri, H.; Kishawy, H. NC end milling optimization using evolutionary computation. Int. J. Mach. Tools Manuf. 2002, 42, 595–605. [Google Scholar] [CrossRef]

- Massinaei, M.; Falaghi, H.; Izadi, H. Optimisation of metallurgical performance of industrial flotation column using neural network and gravitational search algorithm. Can. Metall. Q. 2013, 52, 115–122. [Google Scholar] [CrossRef]

- Shunmugam, M.S.; Bhaskara Reddy, S.V.; Narendran, T.T. Selection of optimal conditions in multi-pass face-milling using a genetic algorithm. Int. J. Mach. Tools Manuf. 2000, 40, 401–414. [Google Scholar] [CrossRef]

- Moscato, P. On evolution, search, optimization, genetic algorithms and martial arts: Towards memetic algorithms. In Caltech Concurrent Computation. Program, C3P Report; California Institute of Technology, (Caltech): Pasadena, CA, USA, 1989. [Google Scholar]

- Ojha, V.K.; Abraham, A.; Snásel, V. Metaheuristic Design of Feedforward Neural Networks: A Review of Two Decades of Research. Eng. Appl. Artif. Intell. 2017, 60, 97–116. [Google Scholar] [CrossRef] [Green Version]

- Tang, Q.; Lau, Y.B.; Hu, S.; Yan, W.; Yang, Y.; Chen, T. Response surface methodology using Gaussian processes: Towards optimizing the trans-stilbene epoxidation over Co2+—NaX catalysts. Chem. Eng. J. 2010, 156, 423–431. [Google Scholar] [CrossRef] [Green Version]

- Garud, S.S.; Karimi, I.A.; Kraft, M. Design of computer experiments: A review. Comput. Chem. Eng. 2017, 106, 71–95. [Google Scholar] [CrossRef]

- Bezerra, M.A.; Santelli, R.E.; Oliveira, E.P.; Villar, L.S.; Escaleira, L.A. Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 2008, 76, 965–977. [Google Scholar] [CrossRef]

- Gutmann, H.M. A Radial Basis Function Method for Global Optimization. J. Glob. Optim. 2001, 19, 201–227. [Google Scholar] [CrossRef]

- Montgomery, D.C. Design and Analysis of Experiments, 8th ed.; Wiley: Hoboken, NJ, USA, 2012. [Google Scholar]

- Gan, Y.; Duan, Q.; Gong, W.; Tong, C.; Sun, Y.; Chu, W.; Ye, A.; Miao, C.; Di, Z. A comprehensive evaluation of various sensitivity analysis methods: A case study with a hydrological model. Environ. Model. Softw. 2014, 51, 269–285. [Google Scholar] [CrossRef] [Green Version]

- Ye, K.Q.; Li, W.; Sudjianto, A. Algorithmic construction of optimal symmetric Latin hypercube designs. J. Stat. Plan. Inference 2000, 90, 145–159. [Google Scholar] [CrossRef]

- Shahreza, S.; Shafaei, S.; Noaparast, M.; Sarvi, M. Optimization of Galena Flotation Process of Irankouh Complex Ore Using A Statistical Design of Experiments. Curr. World Environ. 2015, 10, 626–636. [Google Scholar] [CrossRef] [Green Version]

- Vieceli, N.; Durão, F.O.; Guimarães, C.; Nogueira, C.A.; Pereira, M.F.C.; Margarido, F. Grade-recovery modelling and optimization of the froth flotation process of a lepidolite ore. Int. J. Miner. Process. 2016, 157, 184–194. [Google Scholar] [CrossRef]

- Ebadnejad, A.; Karimi, G.R.; Dehghani, H. Application of response surface methodology for modeling of ball mills in copper sulphide ore grinding. Powder Technol. 2013, 245, 292–296. [Google Scholar] [CrossRef]

- Krajnik, P.; Kopac, J.; Sluga, A. Design of grinding factors based on response surface methodology. J. Mater. Process. Technol. 2005, 162, 629–636. [Google Scholar] [CrossRef]

- Chen, G.; Peng, J.H.; Chen, J. Optimizing conditions for wet grinding of synthetic rutile using response surface methodology. Miner. Metall. Process. 2011, 28, 44–48. [Google Scholar] [CrossRef]

- Alireza, A.S.; Ataallah, S.G.; Majid, E.G.; Amir, S.; Mohammad, R.; Hadi, A. Application of response surface methodology and central composite rotatable design for modeling the influence of some operating variables of the lab scale thickener performance. Int. J. Min. Sci. Technol. 2013, 23, 717–724. [Google Scholar] [CrossRef]

- Costa, N.R.; Lourenço, J. Gaussian Process Model—An Exploratory Study in the Response Surface Methodology. Qual. Reliab. Eng. Int. 2016, 32. [Google Scholar] [CrossRef]

- Charte, F.; Romero, I.; Pérez-Godoy, M.D.; Rivera, A.J.; Castro, E. Comparative analysis of data mining and response surface methodology predictive models for enzymatic hydrolysis of pretreated olive tree biomass. Comput. Chem. Eng. 2017, 101, 23–30. [Google Scholar] [CrossRef]

- Gutiérrez, A.; Olivera, C.A.C.; Hacha, R.R.; Torem, M.L.; Santos, B.F. dos Optimization of hematite and quartz BIOFLOTATION by AN artificial neural network (ANN). J. Mater. Res. Technol. 2019, 8, 3076–3087. [Google Scholar]

- Asher, M.J.; Croke, B.F.W.; Jakeman, A.J.; Peeters, L.J.M. A review of surrogate models and their application to groundwater modeling. Water Resour. Res. 2015, 51, 5957–5973. [Google Scholar] [CrossRef]

- Rabhi, A.; Chkifa, A.; Benjelloun, S.; Latifi, A. Surrogate-based modeling in flotation processes. Comput. Aided Chem. Eng. 2018, 43, 229–234. [Google Scholar]

- Stephens, D.W.; Gorissen, D.; Crombecq, K.; Dhaene, T. Surrogate based sensitivity analysis of process equipment. Appl. Math. Model. 2011, 35, 1676–1687. [Google Scholar] [CrossRef] [Green Version]

- Stephens, D.; Fawell, P. Optimization of Process Equipment Using Global Surrogate Models. In Proceedings of the Conference on CFD in the Minerals and Process Industries CSIRO, Melbourne, Australia, 10–12 December 2012. [Google Scholar]

- Metta, N.; Ramachandran, R.; Ierapetritou, M. A Computationally Efficient Surrogate-Based Reduction of a Multiscale Comill Process Model. J. Pharm. Innov. 2019, 2019, 1–21. [Google Scholar] [CrossRef]

- Lucay, F.A.; Gálvez, E.D.; Salez-Cruz, M.; Cisternas, L.A. Improving milling operation using uncertainty and global sensitivity analyses. Miner. Eng. 2019, 131, 249–261. [Google Scholar] [CrossRef]

- Saltelli, A.; Tarantola, S.; Campolongo, F. Sensitivity analysis as an ingredient of modeling. Stat. Sci. 2000, 15, 377–395. [Google Scholar]

- Lane, W.A.; Ryan, E.M. Verification, validation, and uncertainty quantification of a sub-grid model for heat transfer in gas-particle flows with immersed horizontal cylinders. Chem. Eng. Sci. 2018, 176, 409–420. [Google Scholar] [CrossRef]

- Mellado, M.E.; Cisternas, L.A.; Gálvez, E.D. An analytical model approach to heap leaching. Hydrometallurgy 2009, 95, 33–38. [Google Scholar] [CrossRef]

- Mellado, M.; Lucay, F.; Cisternas, L.; Gálvez, E.; Sepúlveda, F. A Posteriori Analysis of Analytical Models for Heap Leaching Using Uncertainty and Global Sensitivity Analyses. Minerals 2018, 8, 44. [Google Scholar] [CrossRef] [Green Version]

- Mellado, M.E.; Casanova, M.P.; Cisternas, L.A.; Gálvez, E.D. On scalable analytical models for heap leaching. Comput. Chem. Eng. 2011, 35, 220–225. [Google Scholar] [CrossRef]

- Mellado, M.E.; Gálvez, E.D.; Cisternas, L.A. Stochastic analysis of heap leaching process via analytical models. Miner. Eng. 2012, 33, 93–98. [Google Scholar] [CrossRef]

- Sepúlveda, F.D.; Lucay, F.; González, J.F.; Cisternas, L.A.; Gálvez, E.D. A methodology for the conceptual design of flotation circuits by combining group contribution, local/global sensitivity analysis, and reverse simulation. Int. J. Miner. Process. 2017, 164, 56–66. [Google Scholar] [CrossRef]

- Lucay, F.; Cisternas, L.A.; Gálvez, E.D. Global sensitivity analysis for identifying critical process design decisions. Chem. Eng. Res. Des. 2015, 103, 74–83. [Google Scholar] [CrossRef]

- Lucay, F.; Cisternas, L.A.; Gálvez, E.D. Retrofitting of Concentration Plants Using Global Sensitivity Analysis. Comput. Aided Chem. Eng. 2015, 37, 311–316. [Google Scholar]

- Sepúlveda, F.D.; Cisternas, L.A.; Gálvez, E.D. The use of global sensitivity analysis for improving processes: Applications to mineral processing. Comput. Chem. Eng. 2014, 66, 221–232. [Google Scholar] [CrossRef]

- Saltelli, A.; Annoni, P.; Azzini, I.; Campolongo, F.; Ratto, M.; Tarantola, S. Variance based sensitivity analysis of model output. Design and estimator for the total sensitivity index. Comput. Phys. Commun. 2010, 181, 259–270. [Google Scholar] [CrossRef]

- Li, S.; Yang, B.; Qi, F. Accelerate global sensitivity analysis using artificial neural network algorithm: Case studies for combustion kinetic model. Combust. Flame 2016, 168, 53–64. [Google Scholar] [CrossRef]

- Sakizlis, V.; Perkins, J.D.; Pistikopoulos, E.N. Recent advances in optimization-based simultaneous process and control design. Comput. Chem. Eng. 2004, 28, 2069–2086. [Google Scholar] [CrossRef]

- Eljack, F.T.; Solvason, C.C.; Chemmangattuvalappil, N.; Eden, M.R. A Property Based Approach for Simultaneous Process and Molecular Design. Chin. J. Chem. Eng. 2008, 16, 424–434. [Google Scholar] [CrossRef]

- Kazantzi, V.; Qin, X.; El-Halwagi, M.; Eljack, F.; Eden, M. Simultaneous Process and Molecular Design through Property Clustering Techniques: A Visualization Tool. Ind. Eng. Chem. Res. 2007, 46, 3400–3409. [Google Scholar] [CrossRef]

- Eljack, F.T.; Eden, M.R.; Kazantzi, V.; Qin, X.; El-Halwagi, M.M. Simultaneous process and molecular design—A property based approach. AIChE J. 2007, 53, 1232–1239. [Google Scholar] [CrossRef]

| Reference | Model Type | Cell or Bank Model | Entrainment Model | Froth Recovery Model | Algorithm Used | Maximum Number of Species | Maximum Number of Cell or Bank |

|---|---|---|---|---|---|---|---|

| Mehrotra and Kapur [85] | NLP | Bank | no | no | Mathematical programming | 3 | 4 |

| Reuter et al. [86] | LP | Bank | no | no | Mathematical programming | 3 | 4 |

| Reuter and Van Deventer [87] | LP | Bank | no | no | Mathematical programming | 3 | 5 |

| Schena et al. [88] | MINLP | Bank | no | no | Mathematical programming | 2 | 4 |

| Schena et al. [83] | MINLP | Bank | no | no | Mathematical programming | 2 | 6 |

| Guria et al. [89] | NLP | Cell | no | no | Genetic Algorithm | 3 | 4 |

| Guria et al. [90] | NLP | Cell | no | no | Genetic Algorithm | 2 | 2 |

| Cisternas et al. [81] | MINLP | Bank | no | no | Mathematical programming | 3 | 4 |

| Méndez et al. [82] | MINLP | Bank | no | no | Mathematical programming | 3 | 3 |

| Ghobadi et al. [91] | MINLP | Bank | yes | no | Genetic Algorithm | 3 | 2 |

| Maldonado et al. [92] | NLP | Bank | no | no | Mathematical programming | 2 | 6 |

| Hu et al. [93] | MINLP | Cell | yes | yes | Genetic Algorithm | 2 | 8 |

| Cisternas et al. [94] | MINLP | Bank | no | no | Mathematical programming | 3 | 5 |

| Pirouzan et al. [95] | NLP | Bank | no | no | Genetic Algorithm | 2 | 4 |

| Calisaya et al. [96] | MILP MINLP | Bank | no | no | Mathematical programming | 5 | 7 |

| Acosta-Flores et al. [84] | MILP MINLP | Bank Cell | no | yes | Mathematical programming | 15 | 3 8 |

| Lucay et al. [97] | MINLP | Bank | no | no | Tabu-search | 7 | 5 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cisternas, L.A.; Lucay, F.A.; Botero, Y.L. Trends in Modeling, Design, and Optimization of Multiphase Systems in Minerals Processing. Minerals 2020, 10, 22. https://doi.org/10.3390/min10010022

Cisternas LA, Lucay FA, Botero YL. Trends in Modeling, Design, and Optimization of Multiphase Systems in Minerals Processing. Minerals. 2020; 10(1):22. https://doi.org/10.3390/min10010022

Chicago/Turabian StyleCisternas, Luis A., Freddy A. Lucay, and Yesica L. Botero. 2020. "Trends in Modeling, Design, and Optimization of Multiphase Systems in Minerals Processing" Minerals 10, no. 1: 22. https://doi.org/10.3390/min10010022

APA StyleCisternas, L. A., Lucay, F. A., & Botero, Y. L. (2020). Trends in Modeling, Design, and Optimization of Multiphase Systems in Minerals Processing. Minerals, 10(1), 22. https://doi.org/10.3390/min10010022