A New Belt Ore Image Segmentation Method Based on the Convolutional Neural Network and the Image-Processing Technology

Abstract

:1. Introduction

2. Details of the Method

2.1. The Convolutional Neural Network Classifier

2.1.1. The Dataset Preparation

2.1.2. Model Training

2.2. CIS and FIS Algorithms

2.2.1. CIS Algorithm

2.2.2. FIS Algorithm

3. Experimental Details

3.1. Image Acquisition and Classification

3.2. Estimation of Segmentation Accuracy

4. Experimental Results and Discussions

4.1. The Segmentation Result Analysis of Different Algorithms

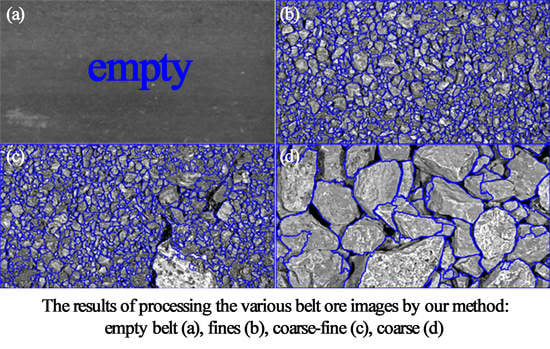

4.2. The Processing Result Analysis of Our Method

5. Conclusions

- This study used a convolutional neural network to identify empty belts.

- The new method adopted the strategy which is to classify the belt ore images first and then use different algorithms for processing different kinds of images.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Tessier, J.; Duchesne, C.; Bartolacci, G. A machine vision approach to on-line estimation of run-of-mine ore composition on conveyor belts. Miner. Eng. 2007, 20, 1129–1144. [Google Scholar] [CrossRef]

- Lange, T.B. Real-time measurement of the size distribution of rocks on a conveyor belt. IFAC Proc. Vol. 1988, 21, 25–34. [Google Scholar] [CrossRef]

- Ko, Y.D.; Shang, H. A neural network-based soft sensor for particle size distribution using image analysis. Powder Technol. 2011, 212, 359–366. [Google Scholar] [CrossRef]

- Hamzeloo, E.; Massinaei, M.; Mehrshad, N. Estimation of particle size distribution on an industrial conveyor belt using image analysis and neural networks. Powder Technol. 2014, 261, 185–190. [Google Scholar] [CrossRef]

- Lin, C.L.; Miller, J.D. Development of a pc, image-based, on-line particle-size analyzer. Min. Metall. Explor. 1993, 10, 29–35. [Google Scholar] [CrossRef]

- Liao, C.W.; Tarng, Y.S. On-line automatic optical inspection system for coarse particle size distribution. Powder Technol. 2009, 189, 508–513. [Google Scholar] [CrossRef]

- Yen, Y.K.; Lin, C.L.; Miller, J.D. Particle overlap and segregation problems in on-line coarse particle size measurement. Powder Technol. 1998, 98, 1–12. [Google Scholar] [CrossRef]

- Singh, V.; Rao, S.M. Application of image processing and radial basis neural network techniques for ore sorting and ore classification. Miner. Eng. 2005, 18, 1412–1420. [Google Scholar] [CrossRef]

- Al-Thyabat, S.; Miles, N.J.; Koh, T.S. Estimation of the size distribution of particles moving on a conveyor belt. Minerals Eng. 2007, 20, 72–83. [Google Scholar] [CrossRef]

- Ilya, L.; Hong, Z. Classification-driven watershed segmentation. IEEE Trans. Image Process. 2007, 16, 1437–1445. [Google Scholar]

- Outal, S.; Schleifer, J.; Pirard, E. In Evaluating a calibration method for the estimation of fragmented rock 3d-size-distribution out of 2d images. In Proceedings of the FRAGBLAST 9—9th International Symposium on Rock Fragmentation by Blasting, Granada, Spain, 13–17 September 2009; pp. 221–228. [Google Scholar]

- Andersson, T.; Thurley, M.J. Minimizing profile error when estimating the sieve-size distribution of iron ore pellets using ordinal logistic regression. Powder Technol. 2011, 206, 218–226. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.O.; Columbus, E.P.; Batchelor, W.D.; Methuku, S.R. Shape identification and particles size distribution from basic shape parameters using imagej. Comput. Electron. Agric. 2008, 63, 168–182. [Google Scholar] [CrossRef]

- Gawenda, T.; Krawczykowski, D.; Krawczykowska, A.; Saramak, A.; Nad, A. Application of dynamic analysis methods into assessment of geometric properties of chalcedonite aggregates obtained by means of gravitational upgrading operations. Minerals 2020, 10, 180. [Google Scholar] [CrossRef] [Green Version]

- Krawczykowski, D. Application of a vision systems for assessment of particle size and shape for mineral crushing products. IOP Conf. Ser. Mater. Sci. Eng. 2018, 427, 1–5. [Google Scholar] [CrossRef] [Green Version]

- Fannin, R.J.; Shuttle, D.A.; Rousé, P.C. Influence of roundness on the void ratio and strength of uniform sand. Géotechnique 2008, 58, 227–231. [Google Scholar]

- Split Engineering Products. Split-Online Software and Systems. 2020. Available online: https://www.spliteng.com/products/split-online-systems/ (accessed on 12 January 2020).

- Outotec Products and Services. Outotec® Act Grinding Optimization System. 2020. Available online: http://www.outotec.cn/products-and-services/technologies/grinding/act-grinding-optimization-system/ (accessed on 3 February 2020).

- WipWare Products and Services. Wipware Conveyor Analysis System. 2020. Available online: http://wipware.com/products/momentum/ (accessed on 7 January 2020).

- Zhang, Z.; Yang, J.; Ding, L.; Zhao, Y. Estimation of coal particle size distribution by image segmentation. Int. J. Mining Sci. Technol. 2012, 22, 739–744. [Google Scholar]

- Chauhan, R.; Ghanshala, K.K.; Joshi, R.C. Convolutional neural network (cnn) for image detection and recognition. In Proceedings of the 2018 First International Conference on Secure Cyber Computing and Communication (ICSCCC), Jalandhar, India, 15–17 December 2018. [Google Scholar]

- Sultana, F.; Sufian, A.; Dutta, P. Advancements in image classification using convolutional neural network. In Proceedings of the 2018 Fourth International Conference on Research in Computational Intelligence and Communication Networks (ICRCICN), Kolkata, India, 22–23 November 2018; IEEE: Piscataway, NJ, USA; pp. 122–129. [Google Scholar]

- Krizhevsky, A.; Sutskever, I.; Hinton, G.E. Imagenet classification with deep convolutional neural networks. Adv. Neural Inf. Process. Syst. 2012, 25. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Szegedy, C.; Liu, W.; Jia, Y.; Sermanet, P.; Reed, S.; Anguelov, D.; Erhan, D.; Vanhoucke, V.; Rabinovich, A. Going deeper with convolutions. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Columbus, OH, USA, 23–28 June 2014. [Google Scholar]

- Simonyan, K.; Zisserman, A. Very deep convolutional networks for large-scale image recognition. arXiv 2014, arXiv:1409.1556. [Google Scholar]

- Ye, L.; Chao, G.; Cheng, G. Rock classification based on images color spaces and artificial neural network. In Proceedings of the Fifth International Conference on Intelligent Systems Design & Engineering Applications, Hunan, China, 15–16 June 2014. [Google Scholar]

- Cheng, G.; Guo, W. Rock images classification by using deep convolution neural network. J. Physics Conf. Ser. 2017, 887, 012089. [Google Scholar] [CrossRef] [Green Version]

- Liu, C.; Li, M.; Zhang, Y.; Han, S.; Zhu, Y. An enhanced rock mineral recognition method integrating a deep learning model and clustering algorithm. Minerals 2019, 9, 516. [Google Scholar] [CrossRef] [Green Version]

- Guarnieri, G.; Marsi, S.; Ramponi, G. Fast bilateral filter for edge-preserving smoothing. Electron. Lett. 2006, 42, 396–397. [Google Scholar] [CrossRef]

- Tomasi, C.; Manduchi, R. Bilateral filtering for gray and color images. In Proceedings of the International Conference on Computer Vision, Copenhagen, Denmark, 28–31 May 2002. [Google Scholar]

- Zhang, X.; Wang, X. Novel survey on the color-image graying algorithm. In Proceedings of the IEEE International Conference on Computer & Information Technology, Helsinki, Finland, 21–23 August 2017. [Google Scholar]

- Bradley, D.; Roth, G. Adaptive thresholding using the integral image. J. Graph. GPU Game Tools 2007, 12, 13–21. [Google Scholar] [CrossRef]

- Tang, J.; Wang, Y.; Cao, W.; Yang, J. Improved adaptive median filtering for structured light image denoising. In Proceedings of the International Conference on Information, Communication and Networks, Macau, China, 24–26 April 2019. [Google Scholar]

- Ataman, E.; Aatre, V.K.; Wong, K.M. A fast method for real-time median filtering. IEEE Trans. Acoust. Speech Signal. Process. 1980, 28, 415–421. [Google Scholar] [CrossRef]

- Lien, B.K. Efficient implementation of binary morphological image processing. Opt. Eng. 1994, 33, 3733–3738. [Google Scholar] [CrossRef]

- Sha, H.; Wah, C.C. Morphological image processing and its parallel implementation. In Proceedings of the 3rd International Conference on Signal Processing, Beijing, China, 18 October 1996. [Google Scholar]

- Gonzalez, R.C.; Woods, R.E.; Eddins, S.L. Digital Image Processing Using Matlab; Pearson Education India: Noida, India, 2004. [Google Scholar]

- Amankwah, A.; Aldrich, C. Rock image segmentation using watershed with shape markers. In Proceedings of the IEEE 39th Applied Imagery Pattern Recognition Workshop (AIPR), Washington, DC, USA, 13–15 October 2010. [Google Scholar]

- Smet, P.D. Implementation and analysis of an optimized rainfalling watershed algorithm. In Proceedings of the International Society for Optics and Photonics, San Jose, CA, USA, 19 April 2000. [Google Scholar]

| Classification | Segmentation Contour Count | |||

|---|---|---|---|---|

| Manual | PCS | CIS | FIS | |

| Empty belt | 0 | 371 | 51 | 92 |

| Mixed materials | 885 | 942 | 123 | 955 |

| Coarse materials | 101 | 408 | 91 | 280 |

| Groups | Status |

|---|---|

| 2 | Alarm |

| 3 | Alarm |

| 4 | Alarm |

| Groups | Methods | Cumulative Area Distribution (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 2000 | 4000 | 6000 | 8000 | 10,000 | 20,000 | 30,000 | 40,000 | ||

| 2 (F) | Our method | 55.59 | 85.64 | 96.82 | 100 | 100 | 100 | 100 | 100 |

| Manual | 58.06 | 87.6 | 94.11 | 98.61 | 100 | 100 | 100 | 100 | |

| 3 (M) | Our method | 16.44 | 36.67 | 50.89 | 62.29 | 69.54 | 89.07 | 92.08 | 92.08 |

| Manual | 18 | 38.09 | 55.54 | 66.82 | 73.67 | 89.49 | 92.8 | 92.8 | |

| 4 (M) | Our method | 26.4 | 50.64 | 67.1 | 77.11 | 90.78 | 95.17 | 100 | 100 |

| Manual | 28.09 | 55.66 | 71.1 | 80.66 | 94.77 | 100 | 100 | 100 | |

| Groups | Methods | Cumulative Area Distribution (%) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| 5000 | 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | ||

| 2 | Our method | 8.86 | 26 | 41.58 | 56.73 | 63.02 | 72.61 | 79.91 | 85.05 |

| Manual | 10.43 | 29.51 | 41.94 | 57.48 | 64.07 | 74.07 | 80.65 | 85.99 | |

| 3 | Our method | 6 | 15.38 | 25.81 | 40.83 | 57.06 | 64.08 | 79.86 | 84.57 |

| Manual | 7.34 | 18.55 | 31.42 | 43.26 | 61.66 | 67.26 | 85.26 | 85.26 | |

| 4 | Our method | 8.49 | 22.74 | 33.68 | 43.76 | 51.15 | 66.5 | 71 | 74.34 |

| Manual | 6.92 | 25.5 | 37.02 | 46.46 | 53.02 | 63.73 | 72.86 | 78.17 | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, X.; Zhang, P.; Man, X.; Ou, L. A New Belt Ore Image Segmentation Method Based on the Convolutional Neural Network and the Image-Processing Technology. Minerals 2020, 10, 1115. https://doi.org/10.3390/min10121115

Ma X, Zhang P, Man X, Ou L. A New Belt Ore Image Segmentation Method Based on the Convolutional Neural Network and the Image-Processing Technology. Minerals. 2020; 10(12):1115. https://doi.org/10.3390/min10121115

Chicago/Turabian StyleMa, Xiqi, Pengyu Zhang, Xiaofei Man, and Leming Ou. 2020. "A New Belt Ore Image Segmentation Method Based on the Convolutional Neural Network and the Image-Processing Technology" Minerals 10, no. 12: 1115. https://doi.org/10.3390/min10121115

APA StyleMa, X., Zhang, P., Man, X., & Ou, L. (2020). A New Belt Ore Image Segmentation Method Based on the Convolutional Neural Network and the Image-Processing Technology. Minerals, 10(12), 1115. https://doi.org/10.3390/min10121115