Adaptive Robust Vehicle Motion Control for Future Over-Actuated Vehicles †

Abstract

:1. Introduction

2. Vehicle Modelling

2.1. Multi-Body Approach

- Σ: the overall vehicle of a mass M and a Center of Gravity (CoG) G,

- : the sprung mass of a mass and a CoG ,

- : the front unsprung mass of a mass and a CoG ,

- : the rear unsprung mass of a mass and a CoG .

2.2. Linear Equations of Motion

- : longitudinal tire force (Where “i” is front or rear, and “j” is right or left.),

- : lateral tire force,

- : vertical load on the tire,

- : the vehicle’s weight.

- : vertical travel of tires,

- : vertical travel of suspensions,

- : suspension’s stiffness,

- : suspension’s damping,

- : the front and rear anti-roll bars stiffness respectively,

- : the front and rear track of the vehicle respectively,

- : control forces of the active suspensions.

2.3. Angular Equations of Motion

2.4. Model Simplification and Validation

- z: vertical travel of the sprung mass,

- : vertical velocity of the sprung mass,

- : equivalent overall antiroll bar stiffness,

- : equivalent overall roll suspension damping,

- : equivalent overall pitch suspension stiffness,

- : equivalent overall pitch suspension damping,

- : yaw inertia moment of the overall vehicle with respect to its CoG,

- : combination of tire forces projected at the axis “i”,

- : combination of moments generated by tire forces with respect to the axis “i”.

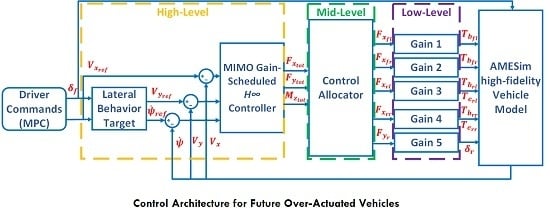

3. Vehicle Motion Control Synthesis

3.1. High-Level Control

3.1.1. The RGA

3.1.2. Bode Diagrams

3.1.3. Controller Design

3.2. Mid-Level Control

- ,

- ,

- ,

- ,

- .

- : preferred control vector,

- : non-singular weighting matrix affecting control distribution among the actuators,

- : non-singular weighting matrix affecting the prioritization among the virtual control components when cannot be attained due to the actuator constraints.

3.3. Low-Level Control

| Algorithm 1: Torques calculation |

| Let be starting values if then else end if |

4. Co-Simulation Results

4.1. Controller Only

4.2. Gain-Scheduled Controller

4.3. Relevance of Lateral Velocity Control

5. Open Challenges

5.1. Friction Estimation

5.2. Motion Feelings

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| 2WS | 2-Wheel Steering |

| 4WS | four-Wheel Steering |

| AFS | Active Front Steering |

| ARS | Active Rear Steering |

| ASA | Active Set Algorithm |

| CA | Control Allocation |

| CoG | Center of Gravity |

| DoF | Degrees of Freedom |

| ESP | Electronic Stability Program |

| GCC | Global Chassis Control |

| LPV | Linear with Varying Parameters |

| MIMO | Multi-Inputs Multi-Outputs |

| q-LPV | quasi-Linear with Varying Parameters |

| RGA | Relative Gain Array |

| SMC | Sliding Mode Control |

| VDC | Vehicle Dynamics Control |

| WLS | Weighted Least Squares |

References

- Pacejka, H.B. Tyre Characteristics and Vehicle Handling and Stability. In Tyre and Vehicle Dynamics, 2nd ed.; Elsevier: Amsterdam, The Netherlands; Butterworth-Heinemann: Oxford, UK, 2006; pp. 1–60. [Google Scholar]

- Zhao, S.; Li, Y.; Qu, X. Vehicle Chassis Integrated Control Based on Multimodel and Multilevel Hierarchical Control. Math. Probl. Eng. 2014, 2014, 248676. [Google Scholar]

- Kritayakirana, K. Autonomous Vehicle Control at the Limits Of Handling; Stanford University: Stanford, CA, USA, 2012. [Google Scholar]

- Reinold, P.; Traechtler, A. Closed-loop control with optimal tire-force distribution for the horizontal dynamics of an electric vehicle with single-wheel chassis actuators. In Proceedings of the 2013 American Control Conference, Washington, DC, USA, 17–19 June 2013; pp. 2159–2164. [Google Scholar]

- Chebly, A.; Talj, R.; Charara, A. Coupled Longitudinal and Lateral Control for an Autonomous Vehicle Dynamics Modeled Using a Robotics Formalism. IFAC-PapersOnLine 2017, 50, 12526–12532. [Google Scholar] [CrossRef]

- Soltani, A.M. High-Level Control System Development. In Low Cost Integration of Electric Power-Assisted Steering (EPAS) with Enhanced Stability Program (ESP); Cranfield University: Cranfield, UK, 2014; pp. 95–140. [Google Scholar]

- Yim, S. Coordinated control with electronic stability control and active steering devices. J. Mech. Sci. Technol. 2015, 12, 5409–5416. [Google Scholar] [CrossRef]

- Feng, C.; Ding, N.; He, Y.; Xu, G.; Gao, F. Control allocation algorithm for over-actuated electric vehicles. J. Cent. South Univ. 2014, 21, 3705–3712. [Google Scholar] [CrossRef]

- Doumiati, M.; Sename, O. Integrated vehicle dynamics control via coordination of active front steering and rear braking. Eur. J. Control 2013, 19, 121–143. [Google Scholar] [CrossRef]

- Kissai, M.; Monsuez, B.; Tapus, A.; Mouton, X.; Martinez, D. Gain-Scheduled for Vehicle High-Level Motion Control. In Proceedings of the 6th International Conference on Control, Mechatronics and Automation, Tokyo, Japan, 12–14 October 2018; pp. 97–104. [Google Scholar]

- Noxon, N.J.; Yu, H.; Ujiie, B.; Miller, J. Development of Dynamic Vehicle Model. In A Model Predictive Control Approach to Roll Stability of a Scaled Crash Avoidance Vehicle; The Faculty of California Polytechnic State University: San Luis Obispo, CA, USA, 2012; pp. 11–40. [Google Scholar]

- Pommier, S.; Berthaud, Y. Principe Fondamental de la Dynamique. In Mécanique Générale; DUNOD: Paris, France, 2010; pp. 167–173. ISBN 978-2-10-054820-0. [Google Scholar]

- Kissai, M.; Monsuez, B.; Tapus, A. Review of integrated vehicle dynamics control architectures. In Proceedings of the 2017 European Conference on Mobile Robots (ECMR), Paris, France, 6–8 September 2017; pp. 1–8. [Google Scholar]

- Selby, M.A. Brake-Based Sub-System Controller Design. In Intelligent Vehicle Motion Control; University of Leeds: Leeds, UK, 2003; pp. 127–145. [Google Scholar]

- Kissai, M.; Mouton, X.; Monsuez, B.; Martinez, D.; Tapus, A. Optimizing Vehicle Motion Control for Generating Multiple Sensations. In Proceedings of the 2018 IEEE Intelligent Vehicles Symposium (IV), Changshu, China, 26–30 June 2018; pp. 928–935. [Google Scholar]

- Bristol, E. On a new measure of interaction for multivariable process control. IEEE Trans. Autom. Control 1966, 11, 133–134. [Google Scholar] [CrossRef]

- Skogestad, S.; Postlethwaite, I. Robust Stability and Performance Analysis. In Multivariable Feedback Control: Analysis and Design; John Wiley & Sons: Hoboken, NJ, USA, 2005; pp. 293–354. [Google Scholar]

- Scorletti, G.; Fromion, V. Synthèse de correcteurs par la méthode . In Automatique Fréquentielle Avancée; Ecole Centrale de Lyon: Ecully, France, 2009; pp. 91–118. [Google Scholar]

- Kissai, M.; Monsuez, B.; Tapus, A.; Martinez, D. A new linear tire model with varying parameters. In Proceedings of the 2017 2nd IEEE International Conference on Intelligent Transportation Engineering (ICITE), Singapore, 1–3 September 2017; pp. 108–115. [Google Scholar]

- Apkarian, P.; Noll, D. Nonsmooth Synthesis. IEEE Trans. Autom. Control 2006, 51, 71–86. [Google Scholar] [CrossRef]

- Rugh, W.J.; Shamma, J.S. Research on gain scheduling. Automatica 2000, 36, 1401–1425. [Google Scholar] [CrossRef]

- Biannic, J.M. Linear Parameter Varying Control Strategies for Aerospace Applications. In Robust Control and Linear Parameter Varying Approaches; Springer: Berlin/Heidelberg, Germany, 2013; pp. 347–373. [Google Scholar]

- Biannic, J.M.; Roos, C.; Knauf, A. Design and Robustness Analysis of Fighter Aircraft Flight Control Laws. Eur. J. Control 2006, 12, 71–85. [Google Scholar] [CrossRef]

- Oppenheimer, M.W.; Doman, D.B.; Bolender, M.A. Control Allocation for Over-actuated Systems. In Proceedings of the 2006 14th Mediterranean Conference on Control and Automation, Ancona, Italy, 28–30 June 2006; pp. 1–6. [Google Scholar]

- Bodson, M. Evaluation of Optimization Methods for Control Allocation. J. Guid. Control Dyn. 2002, 25, 703–711. [Google Scholar] [CrossRef]

- Sill, J.; Ayalew, B. Vehicle Stability Control Through Predictive and Optimal Tire Saturation Management. In Proceedings of the 14th International Conference on Advanced Vehicle Technologies, Chicago, IL, USA, 12–15 August 2012; Volume 6, pp. 407–416. [Google Scholar]

- Harkegard, O.; Ayalew, B. Efficient active set algorithms for solving constrained least squares problems in aircraft control allocation. In Proceedings of the 41st IEEE Conference on Decision and Control, Las Vegas, NV, USA, 10–13 December 2002; Volume 2, pp. 1295–1300. [Google Scholar]

- Petersen, J.A.M.; Bodson, M. Constrained quadratic programming techniques for control allocation. IEEE Trans. Control Syst. Technol. 2006, 14, 91–98. [Google Scholar] [CrossRef]

- Bordignon, K.A. Cascading Generalized Inverse Solutions. In Constrained Control Allocation For Systems with Redundant Control Effectors; Virginia Tech Faculty: Blacksburg, VA, USA, 1996; pp. 29–63. [Google Scholar]

- Burken, J.J.; Lu, P.; Wu, Z.; Bahm, C. Two Reconfigurable Flight-Control Design Methods: Robust Servomechanism and Control Allocation. J. Guid. Control. Dyn. 2001, 24, 482–493. [Google Scholar] [CrossRef]

- Kissai, M.; Mouton, X.; Monsuez, B.; Martinez, D.; Tapus, A. Complementary Chassis Systems for Ground Vehicles Safety. In Proceedings of the 2018 IEEE Conference on Control Technology and Applications (CCTA), Copenhagen, Denmark, 21–24 August 2018; pp. 179–186. [Google Scholar]

- Burckhardt, M. Fahrwerktechnik: Radschlupf-Regelsysteme; Vogel-Verlag: Munchen, Germany, 1993. [Google Scholar]

- Maakaroun, S. Description du véhicule et de son environnement. In Robotics Modelling and Tilting Control of An Innovative Urban Vehicle; Ecole des Mines de Nantes: Nantes, France, 2011; pp. 11–27. [Google Scholar]

- Patra, N.; Datta, K. Observer Based Road-Tire Friction Estimation for Slip Control of Braking System. Procedia Eng. 2012, 38, 1566–1574. [Google Scholar] [CrossRef]

- Dugoff, H.; Fancher, P.; Segel, L. Tire Performance Characteristics Affecting Vehicle Response to Steering and Braking Control Inputs; Technical Report, CST 460; Highway Safety Research Institute of Science and Technology, The University of Michigan: Ann Arbor, MI, USA, 1969. [Google Scholar]

- Villagra, J.; d’Andréa-Novel, B.; Fliess, M.; Mounier, H. A diagnosis-based approach for tire-road forces and maximum friction estimation. Control Eng. Pract. 2011, 19, 174–184. [Google Scholar] [CrossRef]

- Liu, Y.-H.; Li, T.; Yang, Y.-Y.; Ji, X.-W.; Wu, J. Estimation of tire-road friction coefficient based on combined APF-IEKF and iteration algorithm. Mech. Syst. Signal Process. 2017, 88, 25–35. [Google Scholar] [CrossRef]

- Stormont, D.P. Analyzing Human Trust of Autonomous Systems in Hazardous Environments. In Proceedings of the Twenty-Third AAAI Conference on Artificial Intelligence, Chicago, IL, USA, 13–17 July 2008; pp. 27–32. [Google Scholar]

- Raimondi, F.M.; Melluso, M. Fuzzy motion control strategy for cooperation of multiple automated vehicles with passengers comfort. Automatica 2008, 44, 2804–2816. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kissai, M.; Monsuez, B.; Mouton, X.; Martinez, D.; Tapus, A. Adaptive Robust Vehicle Motion Control for Future Over-Actuated Vehicles. Machines 2019, 7, 26. https://doi.org/10.3390/machines7020026

Kissai M, Monsuez B, Mouton X, Martinez D, Tapus A. Adaptive Robust Vehicle Motion Control for Future Over-Actuated Vehicles. Machines. 2019; 7(2):26. https://doi.org/10.3390/machines7020026

Chicago/Turabian StyleKissai, Moad, Bruno Monsuez, Xavier Mouton, Didier Martinez, and Adriana Tapus. 2019. "Adaptive Robust Vehicle Motion Control for Future Over-Actuated Vehicles" Machines 7, no. 2: 26. https://doi.org/10.3390/machines7020026

APA StyleKissai, M., Monsuez, B., Mouton, X., Martinez, D., & Tapus, A. (2019). Adaptive Robust Vehicle Motion Control for Future Over-Actuated Vehicles. Machines, 7(2), 26. https://doi.org/10.3390/machines7020026